fuel SSANGYONG NEW REXTON 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 278 of 600

0000-00

4. GUIDELINES ON ENGINE SERVICE

To prevent personal injuries and vehicle damages that can be caused by mistakes during engine and

unit inspection/repair and to secure optimum engine performance and safety after service works, basic

cautions and service work guidelines that can be easily forgotten during engine service works are

described in.

Cautions before service works

For safe and correct works, you must observe the working procedures and instructions in this

manual. And, use the designated tools as follow:

Engine stand / Heavy duty engine jack

To prevent the engine from starting abruptly, do not allow anybody to get in the vehicle while

servicing in engine compartment.

Before work on engine and each electrical equipment, be sure to disconnect battery negative (-)

terminal.

Before service works, be sure to prepare the works by cleaning and aligning work areas.

Do not allow the foreign material get into the fuel injection system.

When removing the engine, use only the safety hook on engine and engine hanger. Do not support

the bottom of oil pan with a jack.

Engine and accessories

-

-

-

-

-

-

Completely drain the engine oil, coolant and fuel from engine before removal.

Before disassembling/assembling the engine components, carefully read the working procedures in

this manual.

Make sure to keep the specified tightening torques during installation.

Clean and properly lubricate the parts before reassembly.

Carefully check that there are not any interference while servicing. -

-

-

-

-

Page 279 of 600

Electrical equipment

Electric devices should be handled more carefully.

Currently, the engine has a lot of electric devices. there could be poor engine performance, incomplete

combustion and other abnormal symptoms due to short circuit or poor contact.

Before work on engine and each electrical equipment, be sure to disconnect battery negative (-)

terminal.

When replacing the electric device, use only genuine part and check the conditions of connections

and grounds. Loosened connection or ground make cause a fire and personal injury. -

-Fuel and lubrication system

Do not allow the fluid and engine oil to make contact with the body paintwork and hoses.

If work on the fluid system such as fuel and oil, working area should be well ventilated and smoking

should be prohibited.

Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and nuts

should be tightened as specified.

After removal/installation works, be sure to check whether there is leak on the connecting section. -

-

-

-

If fine dust or foreign material enters into DI engine's fuel system, there can be serious damages in HP

pump and injectors. Thus, be sure to plug the inlets of removed fuel line components with cap and

protect removed parts not to be contaminated with dirt. (Refer to cleanness in this manual while working

on DI engine fuel system)

Page 295 of 600

3) Valve Assembly (Installed in Cylinder Head)

(1) Features

Automatic valve clearance adjuster by hydraulic pressure (Maintenance Free) - Hydraulic lash

Optimized adjustment of valve clearance reduces the valve noise.

Roller type finger follower reduces the friction loss.

Vertical installation.

Simple and compact design reduces the moving operation (improving valve following and fuel

consumption at high speed) 1.

2.

3.

4.

5.

(2) Arrangement

Hydraulic lash adjuster

Upper valve spring retainer

Lower valve spring retainer

Valve spring

Exhaust valveIntake valve

Finger follower

Page 317 of 600

2210-01

1. SPECIFICATION

Description Specification

Fuel Diesel

Fuel filterType Fuel heater + priming pump + water

separator integrated type

Filter type Changeable filter element type

Water accumulating capacity 200 cc

Heater capacity 250W 13.5V

Injector System pressure 1800 bar

High pressure fuel

pumpType Eccentric cam/Plunger type

Operating type Gear driven type

Normal operating temperature

Operating pressure 1800 bar

Operating temperature

Low pressure fuel

pumpType Vane type

Gear ratio (pump/engine) 0.5 : 1

Pressure 6 bar

Fuel tankCapacity 75 L

Material Steel

Fuel sender Single sender type

Change interval EU every 40,000 km

GEN every 45,000 km

Water separation

intervalEU every 20,000 km

GEN every 15,000 km

Page 318 of 600

2. MAINTENANCE AND INSPECTION

1) Maintenance Procedures for DI Engine Fuel System

Always keep the workshop and lift clean (especially, from dust).

Always keep the tools clean (from oil or foreign materials).

Wear a clean vinyl apron to prevent the fuzz, dust and foreign materials from getting into fuel system.

Wash your hands and do not wear working gloves. 1.

2.

3.

Follow the below procedures before starting service works for fuel system.

If the problem is from HP pump, fuel supply line or injector, prepare the clean special tools and sealing

caps to perform the diagnosis for DI engine fuel system in this manual. At this point, thoroughly clean

the related area in engine compartment. 4.

Clean the engine compartment before starting service works.

Tool kit for high pressure lineTook kit for low pressure line

Page 319 of 600

2210-01

Priming pump cap

Follow the job procedures. If you find a defective component, replace it with new one. 5.

Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail and each

injector should be replaced with new ones. The pipes should be tightened tospecified tightening torques

during installation. Over or under torques out of specified range may cause damages and leaks at

connections. Once installed, the pipes have been deformed according to the force during installation,

therefore they are not reusable. The copper washer on injector should be replaced with new one. The

injector holder bolt should be tightened to specified tightening torque as well. If not, the injection point

may be deviated from correct position, and it may cause engine disorder.

Plug the removed components with clean and undamaged sealing caps and store it into the box to

keep the conditions when it was installed. 6.

To supply the fuel to transfer line of HP pump

press the priming pump until it becomes

hard. 7.

Priming pump

Fuel filter assembly

Check the installed components again and connect the negative battery cable. Start the engine and

check the operating status.

With Scan Tool, check if there are current faults and erase the history faults. 8.

9.

Page 320 of 600

2) Diagnostic Test for Engine Fuel System

(1) Overview

If a DTC is displayed on the diagnostic device, check the low pressure- and high pressure fuel systems

before removing the components.

To run the system properly, the electric system must be intact but for the DI engine, the fuel pressure

should be measured also when there is a malfunction even after the diagnostic test with a diagnostic

device.

(2) Hydraulic system

Page 322 of 600

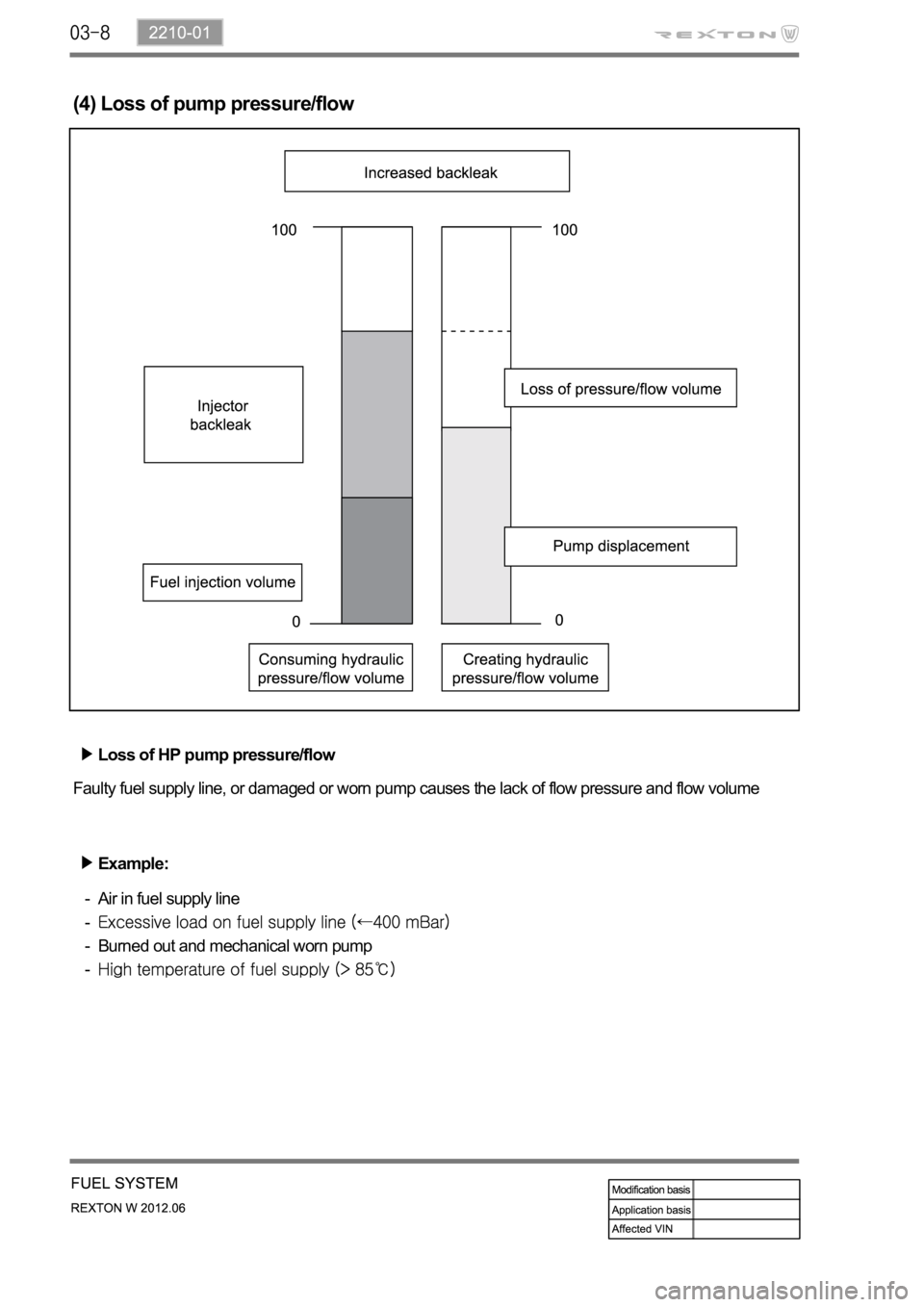

(4) Loss of pump pressure/flow

Loss of HP pump pressure/flow

Faulty fuel supply line, or damaged or worn pump causes the lack of flow pressure and flow volume

Example:

Air in fuel supply line

Burned out and mechanical worn pump

-

-

-

-

Page 323 of 600

2210-01

3) DI Engine Fuel System Pressure Test

(1) Test device (Tool kit)

Device for high pressure

Device for low pressure

(2) Pre-check

Check-tighten fuel supply line

Check fuel level in fuel tank

Check air in fuel supply line (bubble in fuel supply line or fuel)

Check fuel supply line for leaks (low pressure and high pressure)

Check that specified fuel is used

Check fuel filter for contamination -

-

-

-

-

-

Page 324 of 600

(3) DI Engine Fuel System Check Procedure

If several DTCs are output simultaneously, check the electric wiring for open or short circuit.

Check the low pressure fuel system and fuel filter and confirm that there are no abnormalities. Carry

out the high pressure fuel system check.