heating SSANGYONG NEW REXTON 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 240 of 600

0000-00

1. SPECIFICATIONS

Description Unit Specification

Starter Type - WP220

Output power KW 2.2

No load test (12 volts) A 160

Drive pinion speed at no load rpm 4500

Drive pinion speed at load rpm/A 1700/430

Brush length mm 18

Armature diameter mm 55

Armature run-out mm 0.1

Segment groove depth mm 21.7

Alternator Type - CSI128D

Output voltage/current V/A PTC equipped vehicle: 12V-140A

FFH equipped vehicle: 12V-115A

Regulator type -

Regulating voltage V 14.6

Brush Length mm 12.5

Quantity - 2

Wear limit mm 7

Battery Type - M F

Capacity AH 12V - 90AH

Glow plug Reserved capacity RC 160

Type - Seized type

Rated voltage - 11.5

Circuit connection - Parallel

Preheating time sec

Page 244 of 600

0000-00

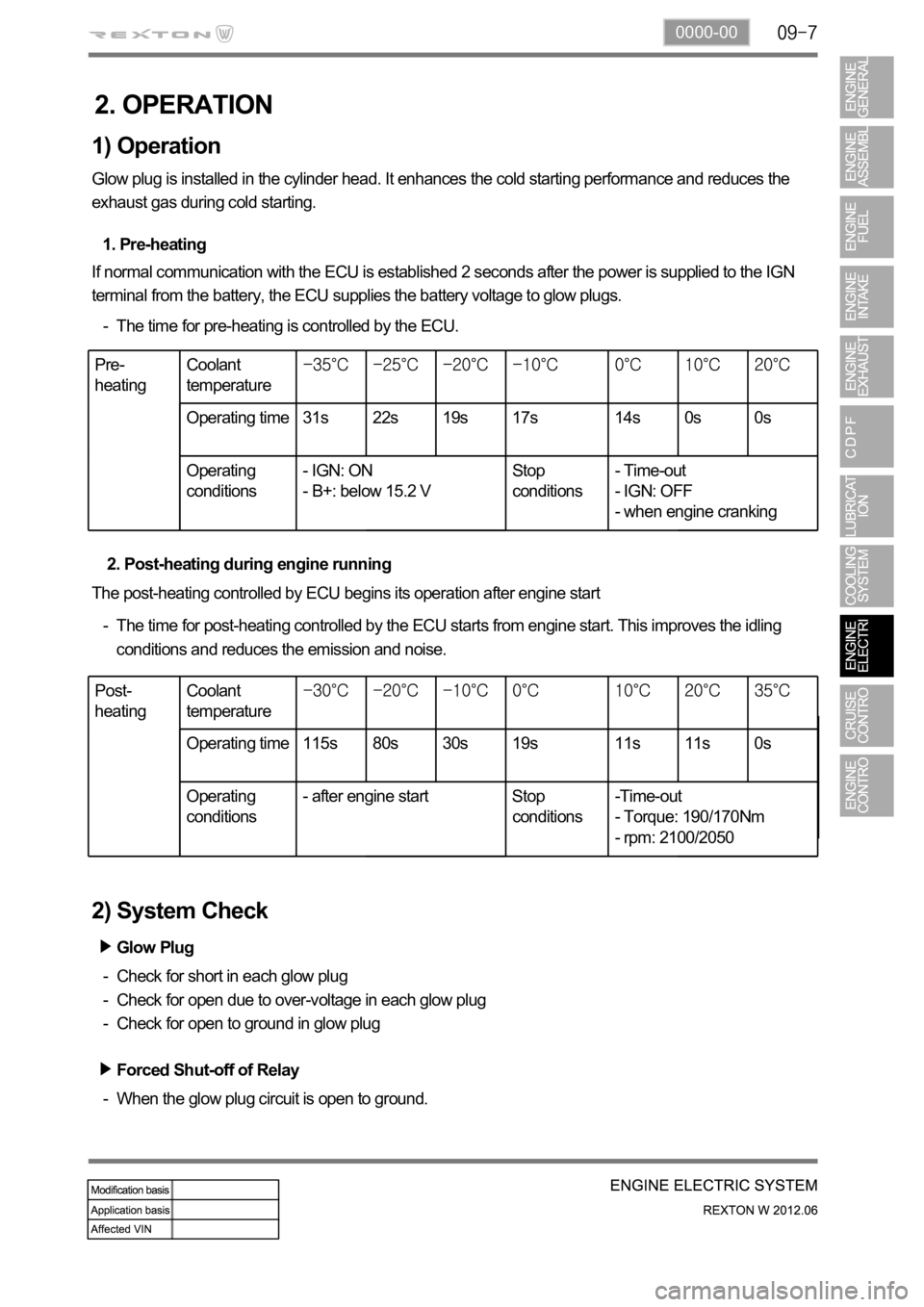

2. OPERATION

Glow plug is installed in the cylinder head. It enhances the cold starting performance and reduces the

exhaust gas during cold starting.

1. Pre-heating

2. Post-heating during engine running If normal communication with the ECU is established 2 seconds after the power is supplied to the IGN

terminal from the battery, the ECU supplies the battery voltage to glow plugs.

The post-heating controlled by ECU begins its operation after engine start The time for pre-heating is controlled by the ECU. -

The time for post-heating controlled by the ECU starts from engine start. This improves the idling

conditions and reduces the emission and noise. -

2) System Check

Glow Plug

Forced Shut-off of Relay

Check for short in each glow plug

Check for open due to over-voltage in each glow plug

Check for open to ground in glow plug -

-

-

When the glow plug circuit is open to ground. -

1) Operation

Pre-

heatingCoolant

temperature

Operating time 31s 22s 19s 17s 14s 0s 0s

Operating

conditions- IGN: ON

- B+: below 15.2 VStop

conditions- Time-out

- IGN: OFF

- when engine cranking

Post-

heatingCoolant

temperature

Operating time 115s 80s 30s 19s 11s 11s 0s

Operating

conditions- after engine start Stop

conditions-Time-out

- Torque: 190/170Nm

- rpm: 2100/2050

Page 337 of 600

2210-01

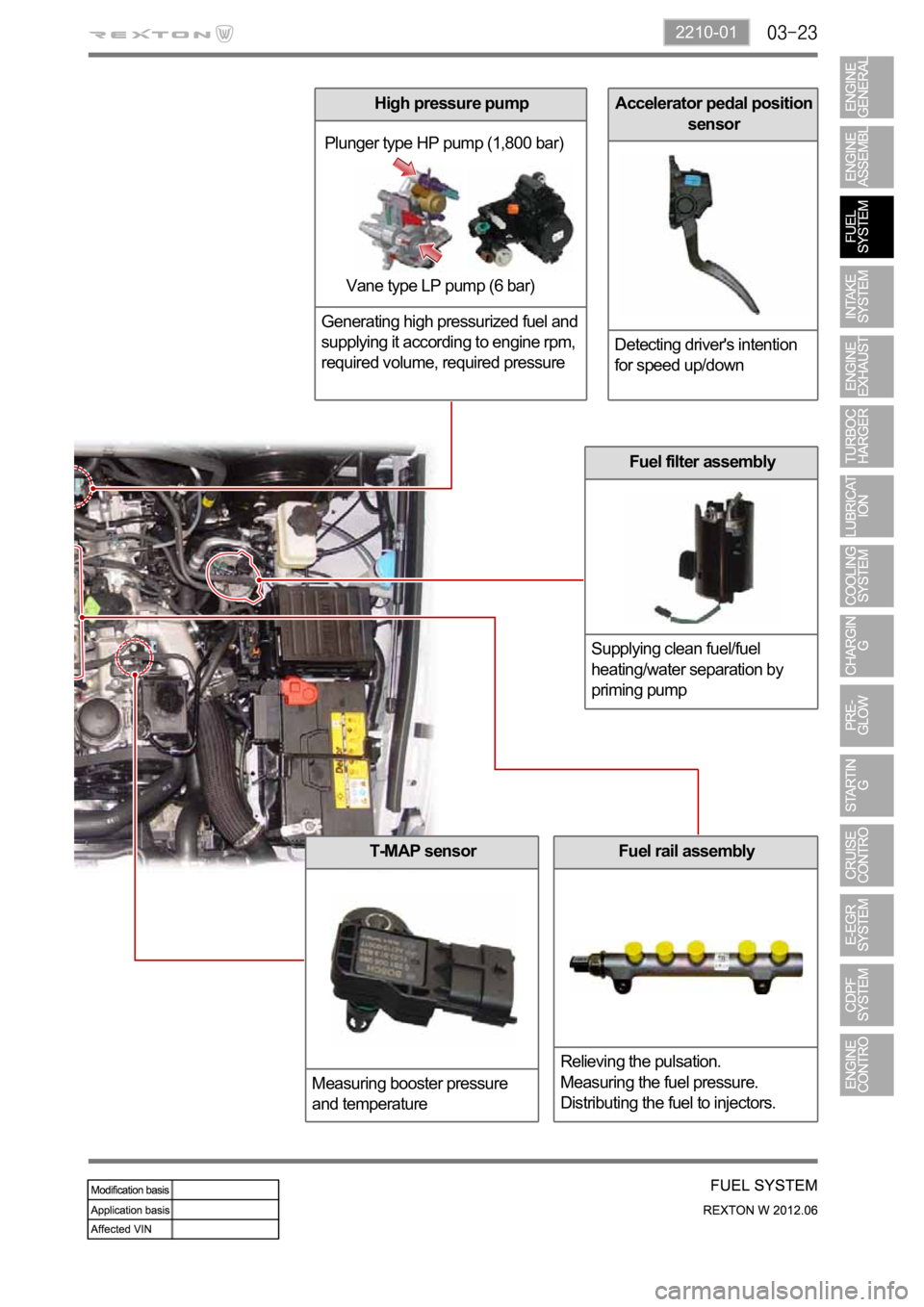

Accelerator pedal position

sensor

Detecting driver's intention

for speed up/down

Fuel rail assembly

Relieving the pulsation.

Measuring the fuel pressure.

Distributing the fuel to injectors.

Fuel filter assembly

Supplying clean fuel/fuel

heating/water separation by

priming pump

Plunger type HP pump (1,800 bar)

Vane type LP pump (6 bar)

T-MAP sensor

Measuring booster pressure

and temperature

High pressure pump

Generating high pressurized fuel and

supplying it according to engine rpm,

required volume, required pressure

Page 377 of 600

2. FUNCTIONS OF LUBRICATION

1) Lubrication

It creates a viscous barrier between moving parts that reduces friction, which means less heat and

longer life for those parts. As a lubricant, oil must maintain a protective film to prevent metal-to-metal

contact. It must be fluid enough to allow easy starting and to circulate quickly through the engine, yet

remain thick enough at higher operating temperatures and speeds to provide adequate lubrication.

2) Cooling

Combustion heat and friction energy must be removed from the engine in order to prevent its

overheating. Most of heat energy is taken by the engine oil.

Clean oil passages, proper viscosity and low contamination provide sufficient flow rate of the engine oil

and effective cooling.

3) Sealing

It helps to seal the space between the pistons and the cylinder walls so that compression is more

effective and power is not lost during combustion.

4) Anti-corrosion

As a corrosion inhibitor, oil coats internal engine parts to prevent surface rust on the inside of the engine

which can be caused by blow-by products and water formed in combustion. It must also be capable of

neutralizing the acids that are formed by combustion blow-by and oil oxidation at high temperatures.

5) Cleaning

The small particles of dirt or other contaminants are suspended in oil and carried away to be filtered out.

As a detergent, engine oil must be able to gather and suspend dirt and other contaminants until the oil

can leave them as it passes through the filter and returns to the internal engine environment.

Page 382 of 600

1520-00

3. CAUTIONS

If 100% of anti-freeze is added, the water pump vane can be damaged and thermal conductivity

can be decreased resulting in poor circulation in the cooling system which leads to overheated

engine.

Use of non-recommended coolant could cause damage to the cooling system and overheating of

the engine.

Opening the coolant reservoir cap while the engine is running or hot can cause burns by hot steam

or water.

To open the coolant reservoir cap, wrap the cap with a wet towel or thick cloth after the engine is

cooled down sufficiently.

If cool water is added to the heated engine, the engine or radiator can be deformed.

The anti-freeze in the coolant can damage the painted surface, so avoid the contact of the coolant

to the painted body.

The anti-freeze and water should be mixed in proper mixture ratio. Never add only water when

adding coolant.

If the anti-freeze content is too low, the coolant can be frozen while the engine can be overheated if

anti-freeze content is too high. -

-

-

-

-

-

-

-

Page 397 of 600

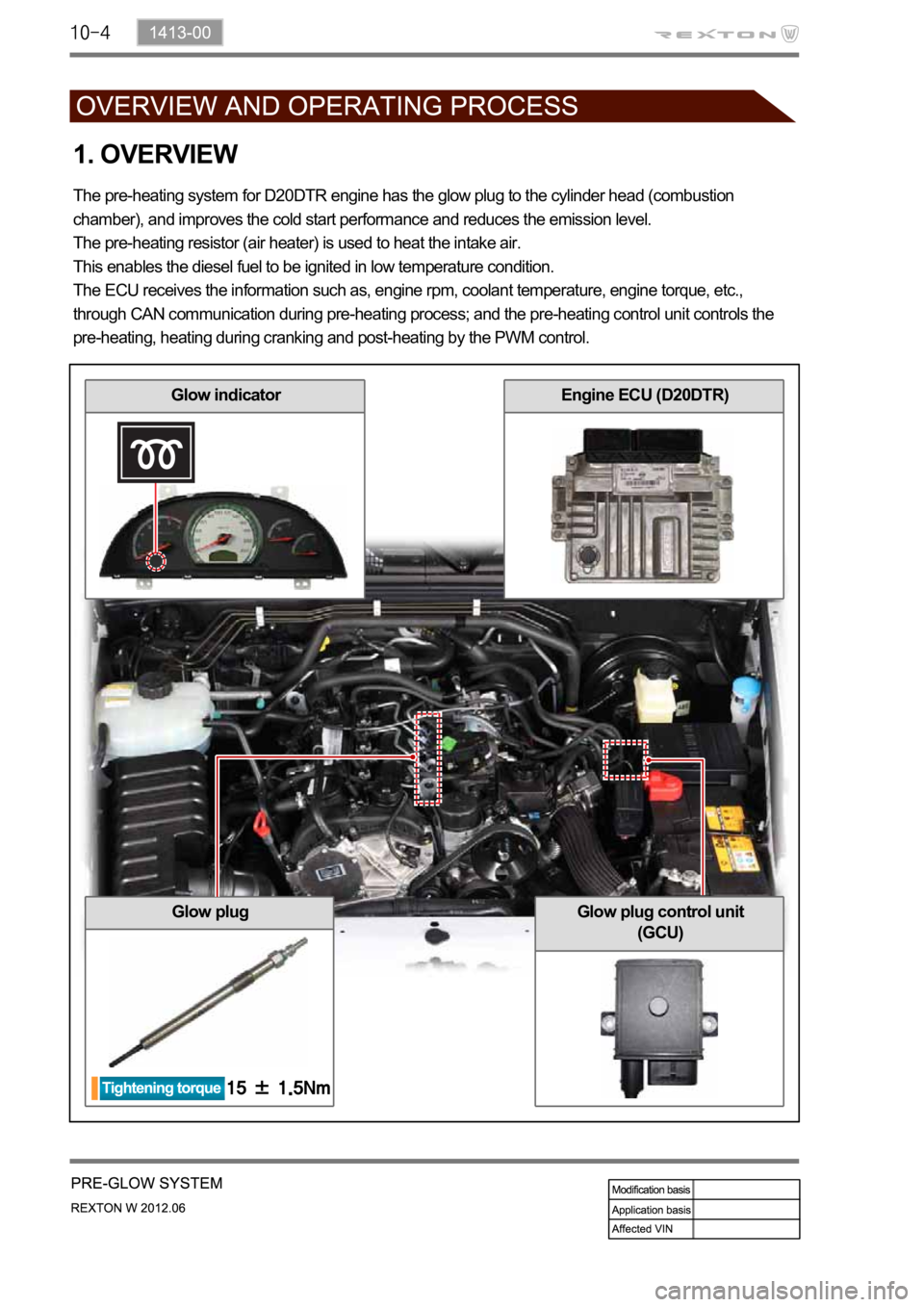

1. OVERVIEW

The pre-heating system for D20DTR engine has the glow plug to the cylinder head (combustion

chamber), and improves the cold start performance and reduces the emission level.

The pre-heating resistor (air heater) is used to heat the intake air.

This enables the diesel fuel to be ignited in low temperature condition.

The ECU receives the information such as, engine rpm, coolant temperature, engine torque, etc.,

through CAN communication during pre-heating process; and the pre-heating control unit controls the

pre-heating, heating during cranking and post-heating by the PWM control.

Glow plug

Glow indicatorEngine ECU (D20DTR)

Glow plug control unit

(GCU)

Page 401 of 600

(3) Operation

Pre-Glow: Step 1

If normal communication with the ECU is established 2 seconds after the power is supplied to the IGN

terminal from the battery, the GCU supplies the battery power to raise the temperature of the glow plug

- The time for pre-heating is controlled by the ECU.

Input power VB(V) Arrival time T1(s)

68.27

75.8

84.1

93.15

10 2.4

11 1.95

1.9

If the input power (VB) is 11.5 V or less, the GCU supplies the battery power for arrival time (T1).

If the input power (VB) is greater than 11.5 V, the GCU supplies the voltage of 11.5 V for arrival time

(T1). -

-

The time for pre-heating by coolant temperature can vary slightly depending on e.g. other vehicle

operation elements.

Page 402 of 600

1413-00

During cranking: Step 2 and step 3

Step 2: If the ECU receives the cranking signal after pre-heating (step 1), the GCU supplies the 1.

2.

Under fixed temperature: The AQGS unit supplies power for 30 seconds (Step 1 + Step 3)

if no cranking signal is received after the step 1.

At cranking: The step 3 is started after the step 2. *

*

Post-glow: Step 4:

The post-heating is for reducing HC/CO after the engine is started. If the time for post-heating exceeds

180 sec., the GCU unit cuts off the power to each glow plug even if there is pre-heating request from the

engine ECU.

Emergency glow

If no CAN signal is received for 4 seconds from the engine ECU after the IGN ON signal is input, the

GCU performs emergency preheat (Step 3) for 30 seconds.

Post-heatingOperating time

(approx.)

Operating time

(approx.)100 s 50 s 25 s 10 s 10 s

Page 433 of 600

2412-02

Front temperature sensor

Measures the temperature of

exhaust gas.

This sensor is located at the rear

side of exhaust manifold and

monitors the temperature of

combusted gas to prevent the

exhaust system from overheating.

When the temperature gets higher,

this sensor cuts off the fuel delivery

and controls the EGR to lower the

temperature.Rear temperature sensor

Measure the outlet

temperature of DOC.

This sensor is located at the

rear side of DOC and

monitors the overheating of

CDPF and post injection

volume.

Engine ECU (D20DTR)

Differential pressure sensor

Measures the difference between

inlet and outlet pressures of CDPF.

If the difference is higher than the

specified value when collecting the

PM, this makes the post injection for

forced recycling of PM.

T-MAP sensorIntake air

mass

Measures

the

excessive

amount of

PM.

Boos

t

pressure

/

temperature

Injector (C31)

Controls the post injection.

Electric throttle body

Controls the intake air mass.

HFM sensor

Wide band

oxygen senso

r

Page 479 of 600

0000-00

(13) PTC heater control

A. Overview

The supplementary electrical heater is installed in DI engine equipped vehicle as a basic equipment. The

PTC system is operated according to two temperature values measured at the coolant temperature

sensor and HFM sensor. This device is mounted in the heater air outlet and increase the temperature of

air to the passenger compartment. Because PTC system is heated by electrical power, high capacity

alternator is required. PTC does not operate during engine cranking, while the battery voltage is lower

than 11 V or during preheating process of glow plugs.

B. Components

HFM (intake air

temperature)

Coolant temperature

sensorPTC heaterD20DTR ECU

PTC 1 relay

PTC 2 relay

PTC 3 relay

PTC Fuse 3 (40A)PTC Fuse 2 (40A)PTC Fuse 1(40A)

Relay box in engine compartment