oil temperature SSANGYONG NEW REXTON 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 200 of 600

0000-00

Oil Temperature/Pressure and Boost Pressure

Page 233 of 600

0000-00

1. SPECIFICATIONS

Frequent stop-and-go traffic, extended idling, short driving distance below 6 km, driving distance

below 16 km when the outside temperature remains below freezing

Driving in a hilly or mountainous terrain, sandy, or dusty area

High load driving such as trailer towing

Taxi, patrol service or delivery service (extended idling and excessive driving with low speed) *

-

-

-

-

Engine Oil Quality classSsangyong genuine engine oil (Approved by MB

Sheet 229.1 or 229.3 or 229.31 for DSL/GSL ENG

without CDPF)

(Approved by MB Sheet 229.31 for DSL ENG with

CDPF)

Viscosity: MB sheet No. 224.1

Capacity

Service

intervalEUInitial check: 5,000 km, and replenish if necessary,

change every 20,000 km or 12 months (But,

shorten the service interval under severe condition)

GeneralInitial change: 5,000 km, change every 15,000 km

or 12 months (But, shorten the service interval

under severe conditions)

Engine oil filterSame interval with the engine oil

Oil filter relief valve opening pressure

Page 243 of 600

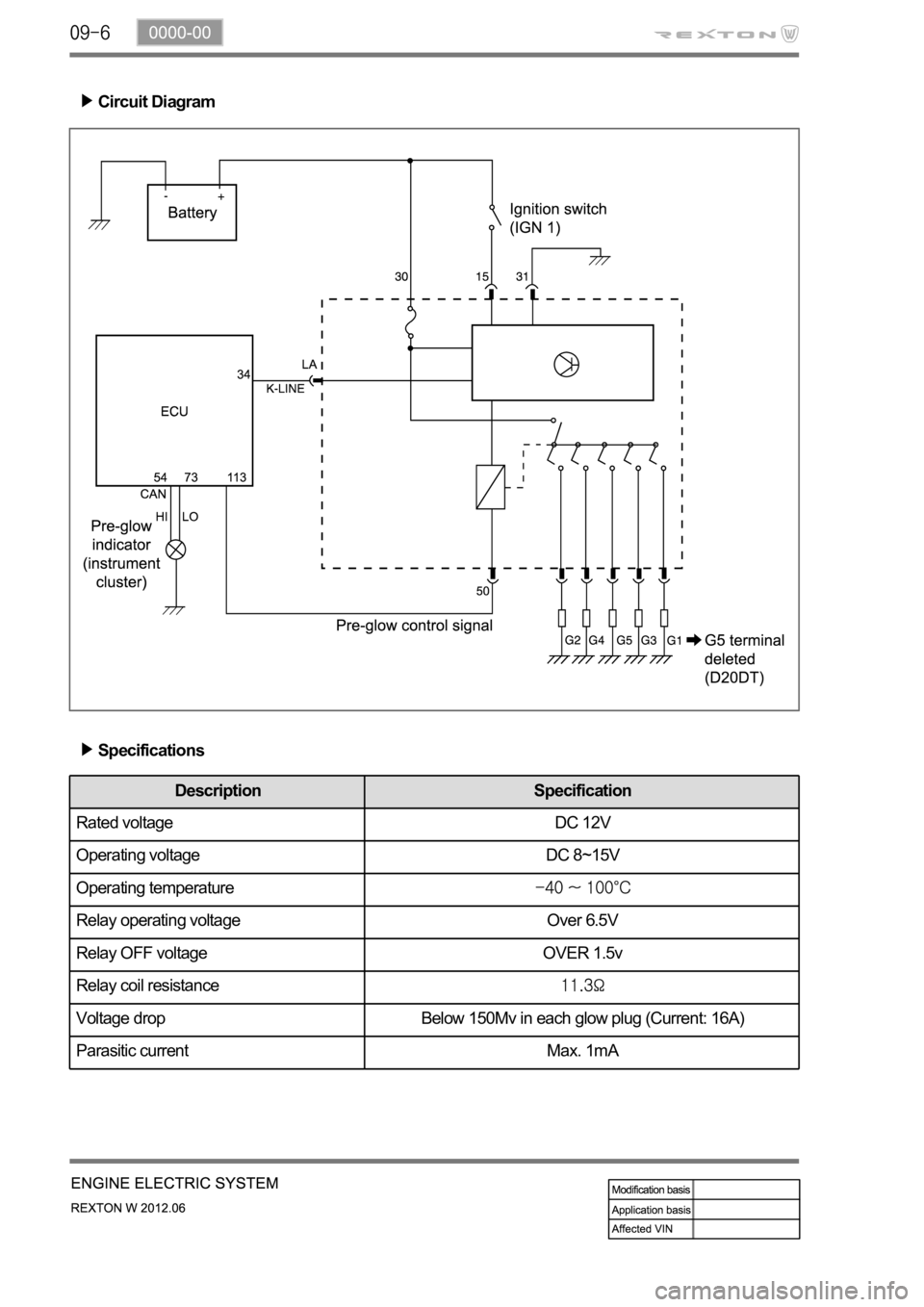

Circuit Diagram

Specifications

Description Specification

Rated voltage DC 12V

Operating voltage DC 8~15V

Operating temperature

Relay operating voltage Over 6.5V

Relay OFF voltage OVER 1.5v

Relay coil resistance

Voltage drop Below 150Mv in each glow plug (Current: 16A)

Parasitic current Max. 1mA

Page 258 of 600

2. MAJOR COMPONENTS

Front view

Vacuum pump

Camshaft position sensor

Oil filter assembly

Power steering pump pulley

Oil pressure switch

Idler pulley No. 2

Water pump pulley

Alternator pulley

Auto tensioner

Idler pulley No. 1

A/C compressor pulley

Rear view

E-EGR valve

Fuel temperature sensor

Fuel HP pump assembly

Coolant temperature sensor

IMV valve Crankshaft position sensor

Isolation damper

Page 259 of 600

0000-00

Right view

Front exhaust gas temperature

sensor

Oil dipstick tube &

gauge assembly

E-VGT actuator

E-VGT turbocharger

Coolant screw plug

Oil drain plug

Left view

Thermostat assembly

Variable swirl valve assembly

E-EGR valve

E-EGR solenoid valve

EGR cooler

Electronic throttle body

Oil cooler assembly

Page 262 of 600

2) Specification and Capacity

Engine oilSpecification Quality class: Ssangyong genuine engine oil (Total Quartz INEO

ECS 5W 30, SK ZIC SY 5W 30) or oil Approved by MB Sheet

229.51

Capacity approx. 6.0 litter

Engine

coolantSpecification Ssangyong genuine coolant Anti-Freeze SYC-1025

Capacity approx. 8.5 litter

Severe condition

Frequent stop-and-go traffic, extended idling, short driving distance below 6 km, driving distance

below 16 km when the outside temperature remains below freezing

Driving in a hilly or mountainous terrain, sandy, or dusty area

High load driving such as trailer towing

Taxi, patrol service or delivery service (extended idling and excessive driving with low speed) -

-

-

-

Page 266 of 600

6. TIGHTENING TORQUE

Name SizeNumbers of

fastenerTightening

torque (Nm)Note (total

tightening

torque)

Main bearing cap

10 Not-reusable

Connecting rod cap

8 50 ~80Nm

Crankshaft rear seal

6 -

Oil pump

3 -

Drive plate

8 Not-reusable

Isolation damper center

bolt

1 660~720 Nm

Not-reusable

Oil pan

18 -

2 -

2 -

2 -

2 -

Mounting nut for high

pressure pump

1 -

Mounting bolt for high

pressure pump

3 -

Cylinder head

12 85Nm-

Camshaft cap

16 -

4 -

Exhaust stud bolt 10

-

Exhaust sprocket

1 -

Chain tensioner screw

plug

1 -

Coolant temperature

sensor1

-

Belt auto tensioner

1 -

1 -

Water pump

7 -

Page 271 of 600

2. TIGHTENING TORQUE

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Main bearing cap

10 Not re-usable

Connecting rod cap

850 to 80 Nm

Rear cover

6-

Oil pump

3-

Flywheel

860 to 100 Nm

Crankshaft center bolt

1660 to 720 Nm

Not re-usable

Oil pan

18-

2-

2-

2-

2-

HP pump main nut

1-

HP pump bolt

3-

Cylinder head

12 85Nm-

Camshaft cap

16-

4-

Exhaust stud bolt 10

-

Exhaust sprocket bolt

1-

Chain tensioner screw

bolt

1-

Coolant temperature

sensor1

-

Auto tensioner

1-

1-

Coolant pump

1-

Page 285 of 600

Brake booster and naster

cylinderVacuum pump

Pump capacity: 210 cc/rev

Camshaft speed: 375 to 3,000 rpm

Lubrication temperature: -40 to

Oil: 5W30

Drive type: Driven by exhaust

Camshaft sprocket

2. VACUUM PUMP

Vacuum pump generates the vacuum pressure and supplies it to EGR cooler bypass solenoid. This

pump is single vane type and displacement is 210 cc/rev. The lubrication oil is supplied through the hole

in hollow shaft.

Components

EGR cooler bypass valve

This valve is controlled by ECU.

When the engine is cooled, the

exhaust gas goes to combustion

chamber without passing through

EGR cooler because the valve is

closed by vacuum pressure.

Page 334 of 600

(2) Di engine and its expected problems and remedies can be caused by

water in fuel

System supplement against paraffin separation

In case of Diesel fuel, paraffin, one of the elements, can be separated from fuel during winter and then

can stick on the fuel filter blocking fuel flow and causing difficult starting finally. Oil companies supply

summer fuel and winter fuel by differentiating mixing ratio of kerosene and other elements by region and

season. However, above phenomenon can be happened if stations have poor facilities or sell improper

fuel for the season. In case of DI engine, purity of fuel is very important factor to keep internal

preciseness of HP pump and injector.

Accordingly, more dense mesh than conventional fuel filter is used. To prevent fuel filter internal clogging

due to paraffin separation, SYMC is using fuel line that high pressure and temperature fuel injected by

injector returns through fuel filter to have an effect of built-in heater (see fuel system).

System supplement and remedy against water in fuel

As mentioned above, some gas stations supply fuel with excessive than specified water. In the

conventional IDI engine, excessive water in the fuel only causes dropping engine power or engine

hunting. However, fuel system in the DI engine consists of precise components so water in the fuel can

cause malfunctions of HP pump due to poor lubrication of pump caused by poor coating film during high

speed pumping and bacterization (under long period parking). To prevent problems can be caused by

excessive water in fuel, water separator is installed inside of fuel filter. When fuel is passing filter, water

that has relatively bigger specific gravity is accumulated on the bottom of the filter.

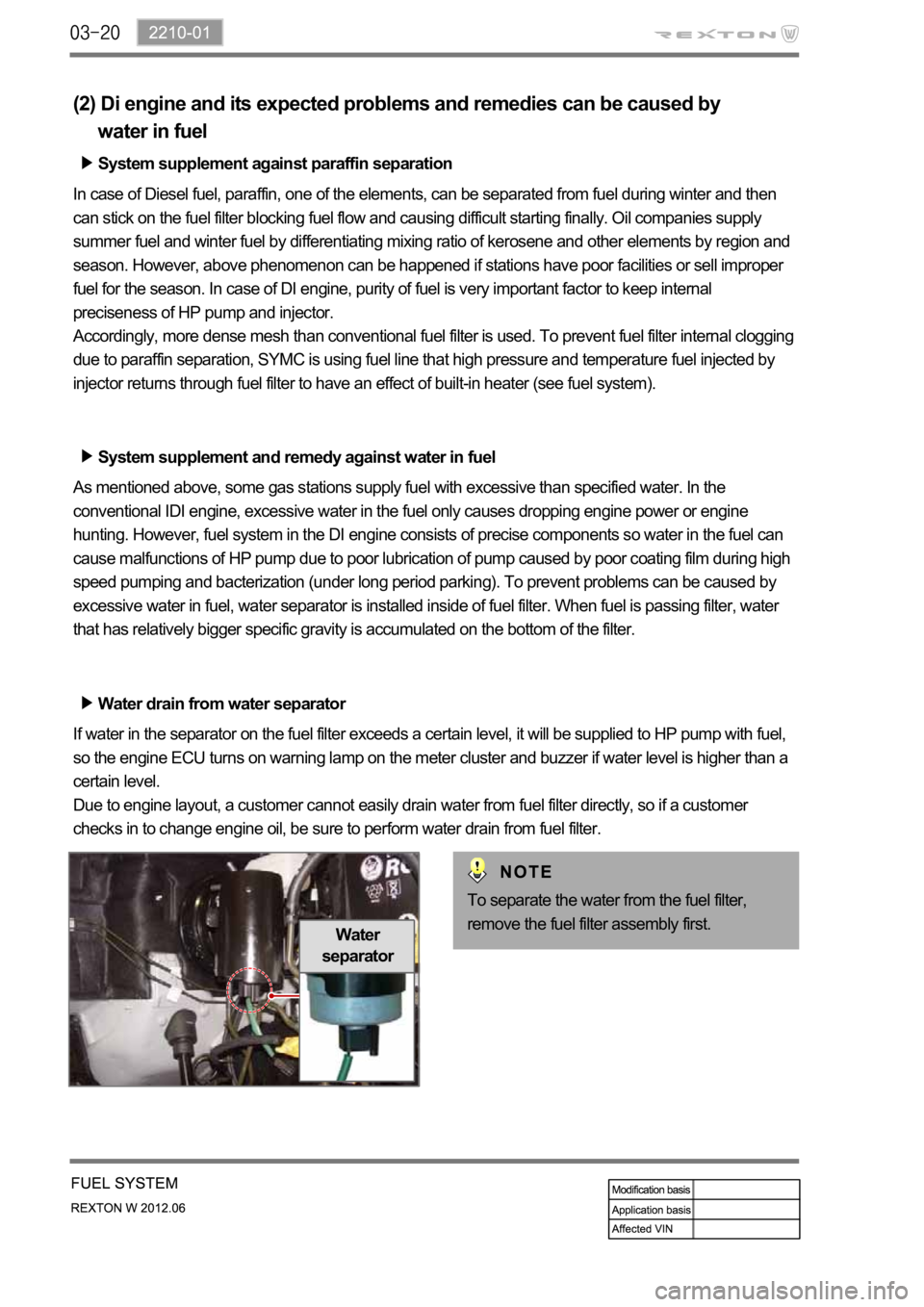

Water drain from water separator

If water in the separator on the fuel filter exceeds a certain level, it will be supplied to HP pump with fuel,

so the engine ECU turns on warning lamp on the meter cluster and buzzer if water level is higher than a

certain level.

Due to engine layout, a customer cannot easily drain water from fuel filter directly, so if a customer

checks in to change engine oil, be sure to perform water drain from fuel filter.

Water

separator

To separate the water from the fuel filter,

remove the fuel filter assembly first.