engine SSANGYONG RODIUS 2007 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2007, Model line: RODIUS, Model: SSANGYONG RODIUS 2007Pages: 465, PDF Size: 56.32 MB

Page 68 of 465

03-4

RODIUS 2006.09

0000-00

ENGINE FUEL SYSTEM

temperature vs resistance ▶

Page 70 of 465

05-3

ENGINE EXHAUST SYSTEM

RODIUS 2006.09

0000-00

2420-01ENGINE EXHAUST SYSTEM

1. OVERVIEW OF EXHAUST SYSTEM

When you are inspecting or replacing exhaust system components, make sure there is

adequate clearance from all points on the underbody to avoid possible overheating of the

floor panel and possible damage to the passenger compartment insulation and trim

materials.

Check the complete exhaust system and the nearby body areas and trunk lid for broken,

damaged, missing or mispositioned parts, open seams, holes, loose connections, or othe

r

deterioration which could permit exhaust fumes to seep into the trunk may be an indication

of a problem in one of these areas. Any defects should be corrected immediately. -

2. OVERVIEW OF MUFFLER

Aside from the exhaust manifold connection, the exhaust system uses a flange and seal joint

design rather than a slip joint coupling design with clamp and U-bolts.

If hole, open seams, or any deterioration is discovered upon inspection of the front muffler and

pipe assembly, the complete assembly should be replace, the complete assembly should be

replaced.

The same procedure is applicable to the rear muffler assembly. Heat shields for the front and

rear muffler assembly and catalytic converter protect the vehicle and the environment from the

high temperatures that the exhaust system develops.

3. OVERVIEW OF CATALYTIC CONVERTER

When jacking or lifting the vehicle from the body side rails, be certain that the lift pads do

not contact the catalytic converter, as this could damage the catalytic converter. -

Use of anything other than unleaded fuel will damage the catalyst in the catalytic

converter. -

The catalytic converter are emission-control devices added to the exhaust system to

reduce pollutants from the exhaust pipes.

The oxidation catalyst is coated with a catalytic material containing platinum and

palladium, which reduces levels of hydrocarbon (HC) and carbon monoxide (CO) from

the exhaust gas. The three-way catalyst has coatings which contain platinum and

rhodium, which additionally lower the levels of oxides of nitrogen (NOx). ·

·

Page 71 of 465

05-4

RODIUS 2006.09

0000-00

ENGINE EXHAUST SYSTEM

4. FASTENER TIGHTENING

SPECIFICATIONS

Page 72 of 465

06-3

LUBRICATION SYSTEM

RODIUS 2006.09

0000-00

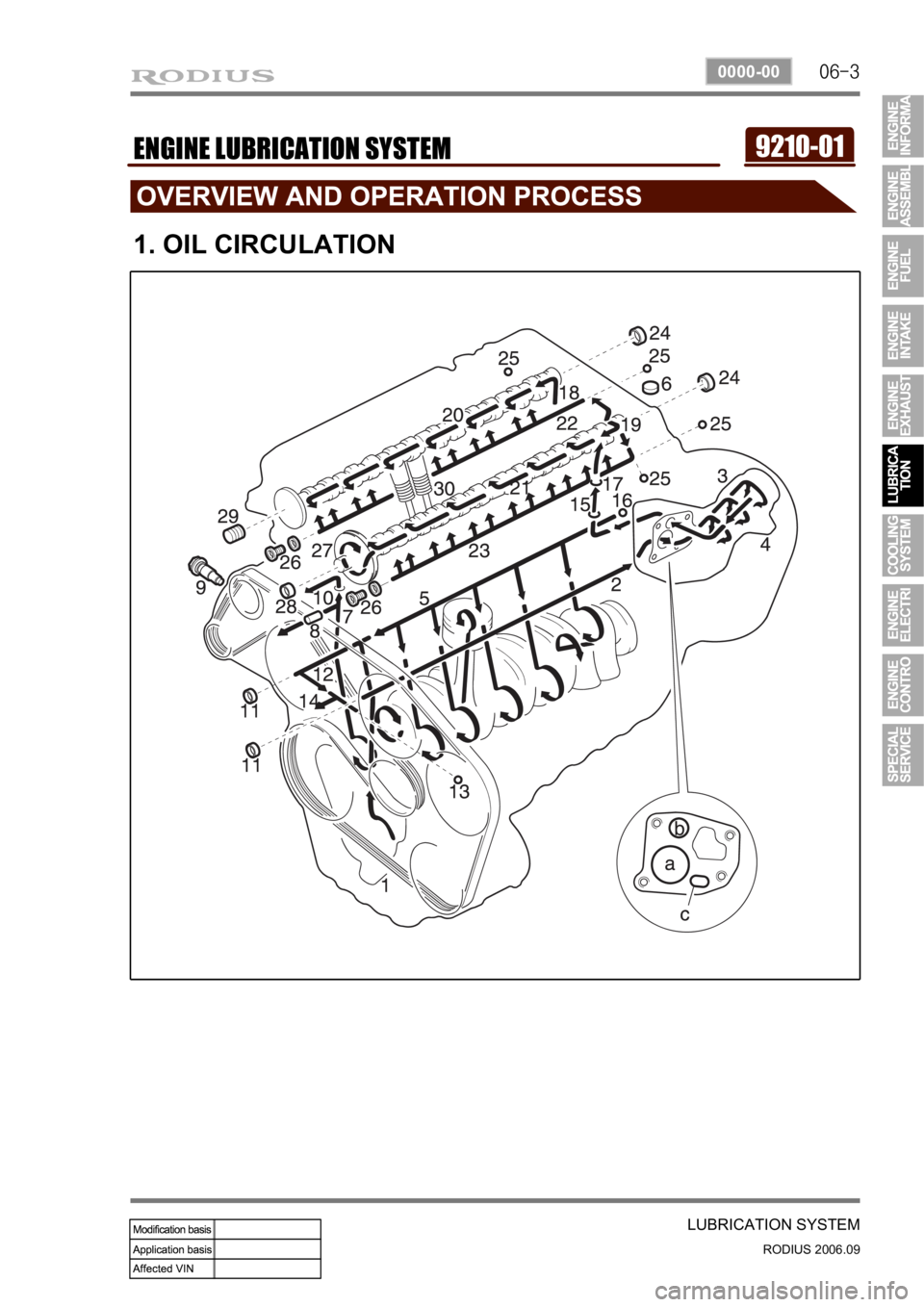

9210-01ENGINE LUBRICATION SYSTEM

1. OIL CIRCULATION

Page 74 of 465

07-3

COOLING SYSTEM

RODIUS 2006.09

0000-00

2110-01ENGINE COOLING SYSTEM

1. GENERAL SPECIFICATIONS

Page 77 of 465

07-6

RODIUS 2006.09

0000-00

COOLING SYSTEM

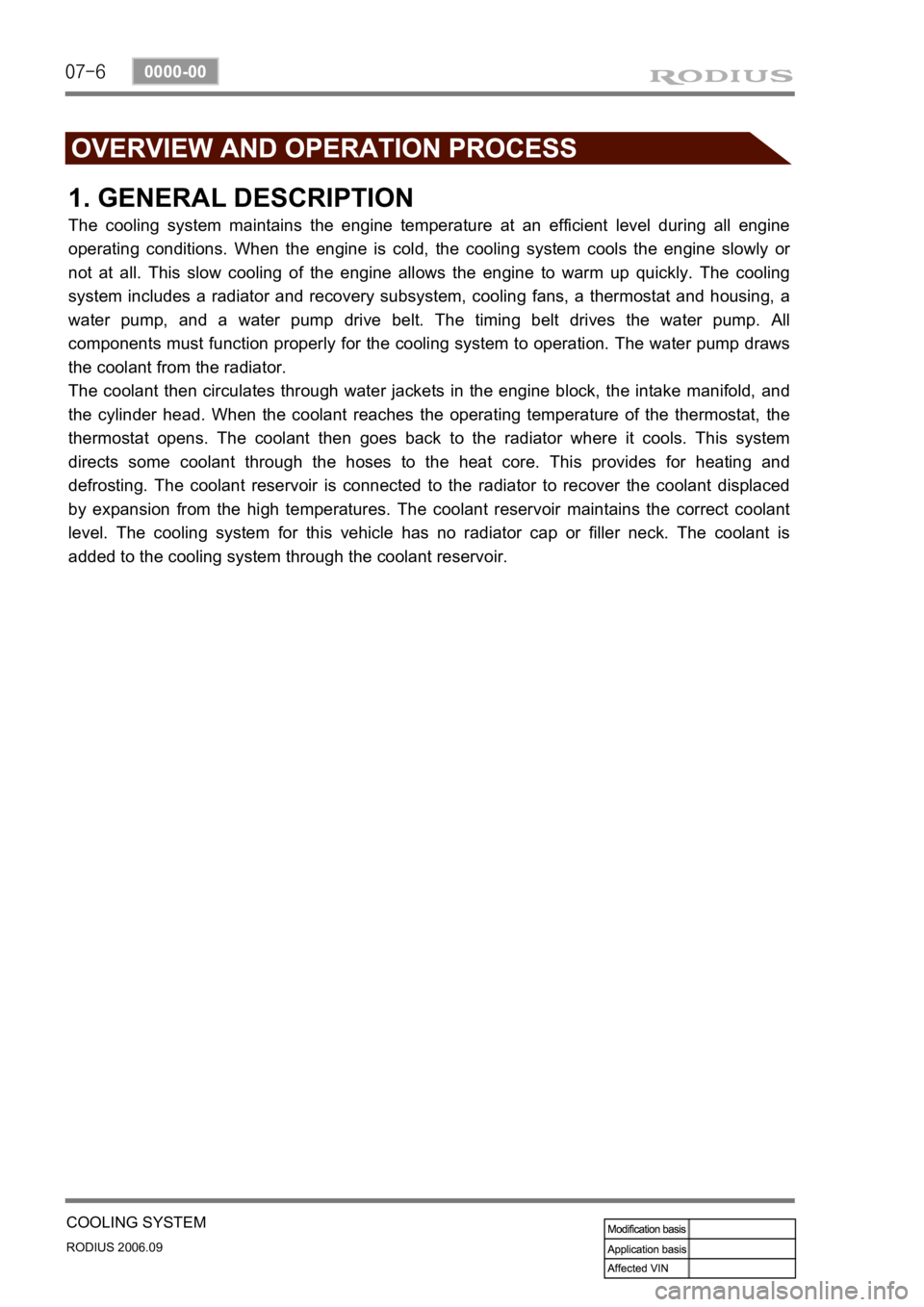

1. GENERAL DESCRIPTION

The cooling system maintains the engine temperature at an efficient level during all engine

operating conditions. When the engine is cold, the cooling system cools the engine slowly o

r

not at all. This slow cooling of the engine allows the engine to warm up quickly. The cooling

system includes a radiator and recovery subsystem, cooling fans, a thermostat and housing, a

water pump, and a water pump drive belt. The timing belt drives the water pump.

All

components must function properly for the cooling system to operation. The water pump draws

the coolant from the radiator.

The coolant then circulates through water jackets in the engine block, the intake manifold, and

the cylinder head. When the coolant reaches the operating temperature of the thermostat, the

thermostat opens. The coolant then goes back to the radiator where it cools. This system

directs some coolant through the hoses to the heat core. This provides for heating and

defrosting. The coolant reservoir is connected to the radiator to recover the coolant displaced

by expansion from the high temperatures. The coolant reservoir maintains the correct coolant

level. The cooling system for this vehicle has no radiator cap or filler neck. The coolant is

added to the cooling system through the coolant reservoir.

Page 80 of 465

08-3

ENGINE ELECTRIC DEVICES

RODIUS 2006.09

0000-00

1452-01ENGINE ELECTRIC DEVICES

1. GENERAL SPECIFICATIONS

Page 81 of 465

08-4

RODIUS 2006.09

0000-00

ENGINE ELECTRIC DEVICES

2. FASTENER TIGHTENING SPECIFICATIONS

Page 82 of 465

08-5

ENGINE ELECTRIC DEVICES

RODIUS 2006.09

0000-00

1. CHARGING SYSTEM OPERATION

Alternators use a new type of regulator that incorpo-rates a diode trio. A Delta stator, a rectifier

bridge, and a rotor with slip rings and brushes are electrically similar to earlier alternators.

A conventional pulley and fan are used. There is no test hole.

1) CHARGING TIME REQUIRED

The time required to charge a battery will vary depending upon the following factors:

▶ Size of Battery

A Completely discharged large heavy-duty battery required more than twice the

recharging time as a completely discharged small passenger car battery. -

▶ Temperature

A longer time will be needed to charge any battery at -18°C (0°F) than at 27°C

(80°F). When a fast charger is connected to a cold battery, the current accepted

by the battery will be very low at first. The battery will accept a higher current rate as the

battery warms. -

▶ Charger Capacity

A charger which can supply only 5 amperes will require a much longer charging period

than a charger that can supply 30 amperes or more. -

▶ State-of-Charge

A completely discharged battery requires more than twice as much charge as a onehal

f

charged battery. Because the electrolyte is nearly pure water and a poor conductor in a

completely discharged battery, the current accepted by the battery is very low at first.

Later, as the charging current causes the electrolyte acid content to increase, the

charging current will likewise increase. -

2. STARTING SYSTEM OPERATION

The engine electrical system includes the battery, the ignition, the starter, the alternator, and all

the related wiring. Diagnostic tables will aid in troubleshooting system faults. When a fault is

traced to a particular component, refer to that component section of the service manual. The

starting system circuit consists of the battery, the starter motor, the ignition switch, and all the

related electrical wiring. All of these components are connected electrically.

Page 83 of 465

08-6

RODIUS 2006.09

0000-00

ENGINE ELECTRIC DEVICES

3. IGNITION SYSTEM OPERATION

This ignition system does not use a conventional distributor and coil. It uses a crankshaft

position sensor input to the Engine Control Module (ECM).

The ECM then determines Electronic Spark Timing (EST) and triggers the electronic ignition

system ignition coil.

This type of distributorless ignition system uses a “waste spark” method of spark

distribution. Each cylinder is paired with the cylinder that is opposite it (2.3L DOHC: 2 - 3 or 1 -

4, 3.2L DOHC: 1 - 6 or 2 - 5 or 3 - 4).

The spark occurs simultaneously in the cylinder coming up on the compression stroke and in

the cylinder coming up on the exhaust stroke.

The cylinder on the exhaust stroke requires very little of the available energy to fire the spark

plug.

The remaining energy is available to the spark plug in the cylinder on the compression stroke.

These systems use the EST signal from the ECM to control the EST.

The ECM uses the following information: Engine load (mass air flow sensor, manifold ai

r

pressure sensor).

Engine coolant temperature.

Intake air temperature.

Crankshaft position.

Engine speed (rpm).

1) Electronic Ignition System Ignition Coil

The Electronic Ignition (EI) system ignition coil is located on the cylinder head cover.

The double ended coils re ceive the signal for the ECM which controls the spark advance.

Each EI system ignition coil provides the high voltage to two spark plugs simultaneously;

3.2L DOHC

T1/1: cylinder 2 and 5

T1/2: cylinder 3 and 4

T1/3: cylinder 1 and 6

The EI system ignition coil is not serviceable and must be replaced as an assembly.