air filter SSANGYONG RODIUS 2007 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2007, Model line: RODIUS, Model: SSANGYONG RODIUS 2007Pages: 465, PDF Size: 56.32 MB

Page 122 of 465

0-26

RODIUS 2006.09

0000-00

ENGINE GENERAL

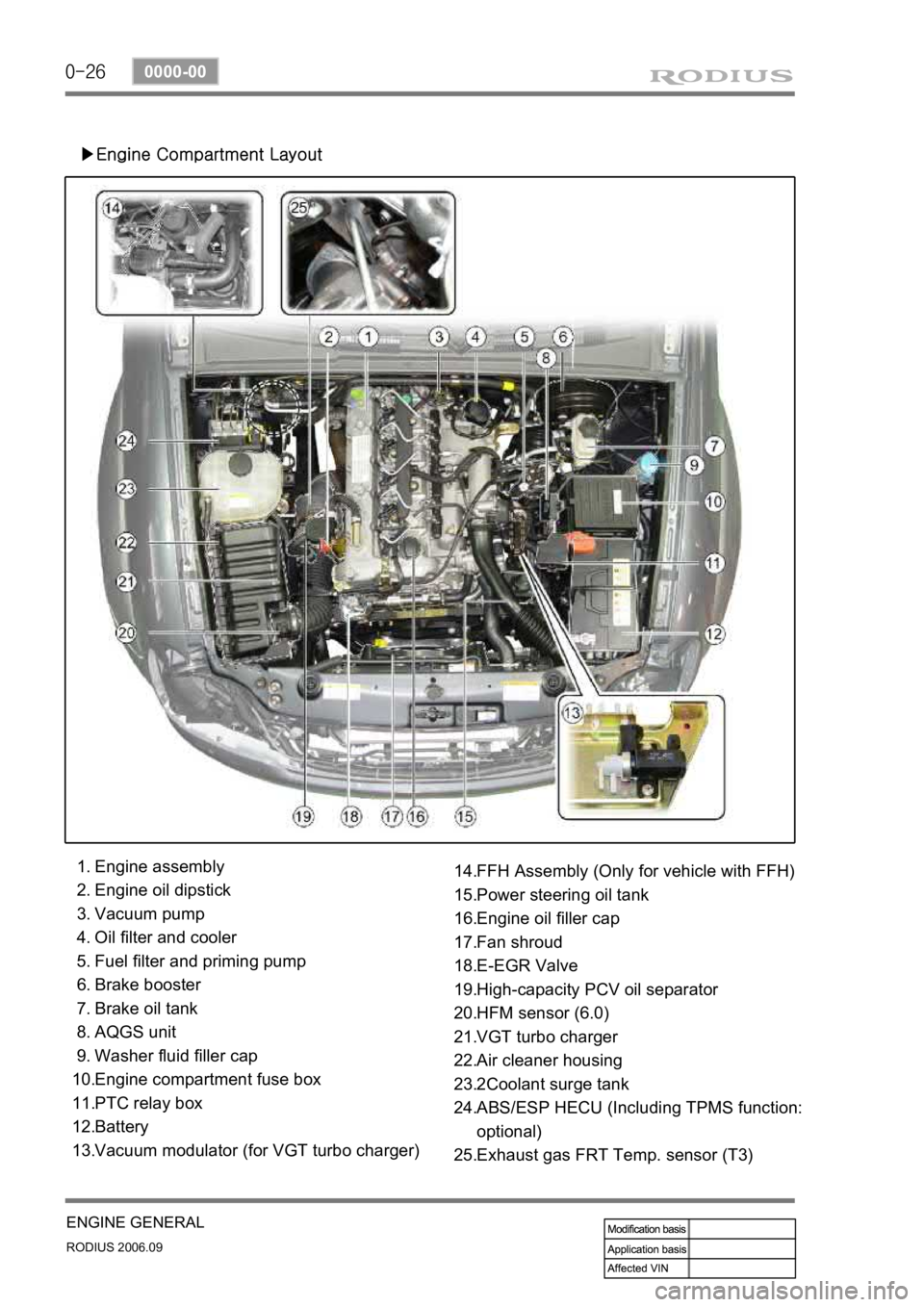

▶Engine Compartment Layout

Engine assembly

Engine oil dipstick

Vacuum pump

Oil filter and cooler

Fuel filter and priming pump

Brake booster

Brake oil tank

AQGS unit

Washer fluid filler cap

Engine compartment fuse box

PTC relay box

Battery

Vacuum modulator (for VGT turbo charger) 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.FFH Assembly (Only for vehicle with FFH)

Power steering oil tank

Engine oil filler cap

Fan shroud

E-EGR Valve

High-capacity PCV oil separator

HFM sensor (6.0)

VGT turbo charger

Air cleaner housing

2Coolant surge tank

ABS/ESP HECU (Including TPMS function:

optional)

Exhaust gas FRT Temp. sensor (T3) 14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

Page 146 of 465

0-9

CDEF(Catalytic Disel Particulate Filter)

RODIUS 2006.09

0000-00

2) Sytem Composition for Soot Combustion

When the engine is running in low load range, the temperature of exhaust gas is decreased as

the amount of fuel supplied is decreased. To burnt the soot filtered in the CDPF, the control

system should be installed to check the operating range and increase the temperature o

f

exhaust gas by controlling the amount of fuel supplied and and intake air.

Two temperature sensors and one differential pressure sensor monitor the CDPF's operating

range. According to theses sensors' information, the throttle flap decreases the intake ai

r

entered to the throttle body. Also, the fuel injection pattern is added to increase the temperature

of exhaust gas for soot combustion.

There are two fuel injection patterns (pilot injection and main injection). As the CDPF is

installed, the post injection pattern is added.

3) Post Injection and Air Mass Control

When the differential pressure sensor detects the pressure difference between the front and the

rear side of CDPF, the sensor sends signal indicating the soot is acumulated and the post

injection is performed to raise the temperature of exhaust gas. The amount of fuel injected is

determined according to the temperature of exhaust gas detected by the rear temperature

<009a008c0095009a00960099005500470070008d0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c00470090009a00470089008c00930096009e0047005d0057005700b6006a00530047009b008f008c004700880094009600

9c0095009b00470096008d0047008d009c008c009300470090>njected is increased to

<009900880090009a008c0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c005500470070008d0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c00470090009a00470096009d008c0099004700

5d0057005700b6006a00530047009b008f008c004700880094>ount of fuel injected is

decreased or not controlled.

When the engine is running in low load range, the amount of post injection and the amount of

intake air are controlled.

It is to raise the temperature by increasing the amount of fuel while decreasing the amount of

intake air.

Page 321 of 465

0-7

BRAKS SYSTEM

RODIUS 2006.09

4830-01

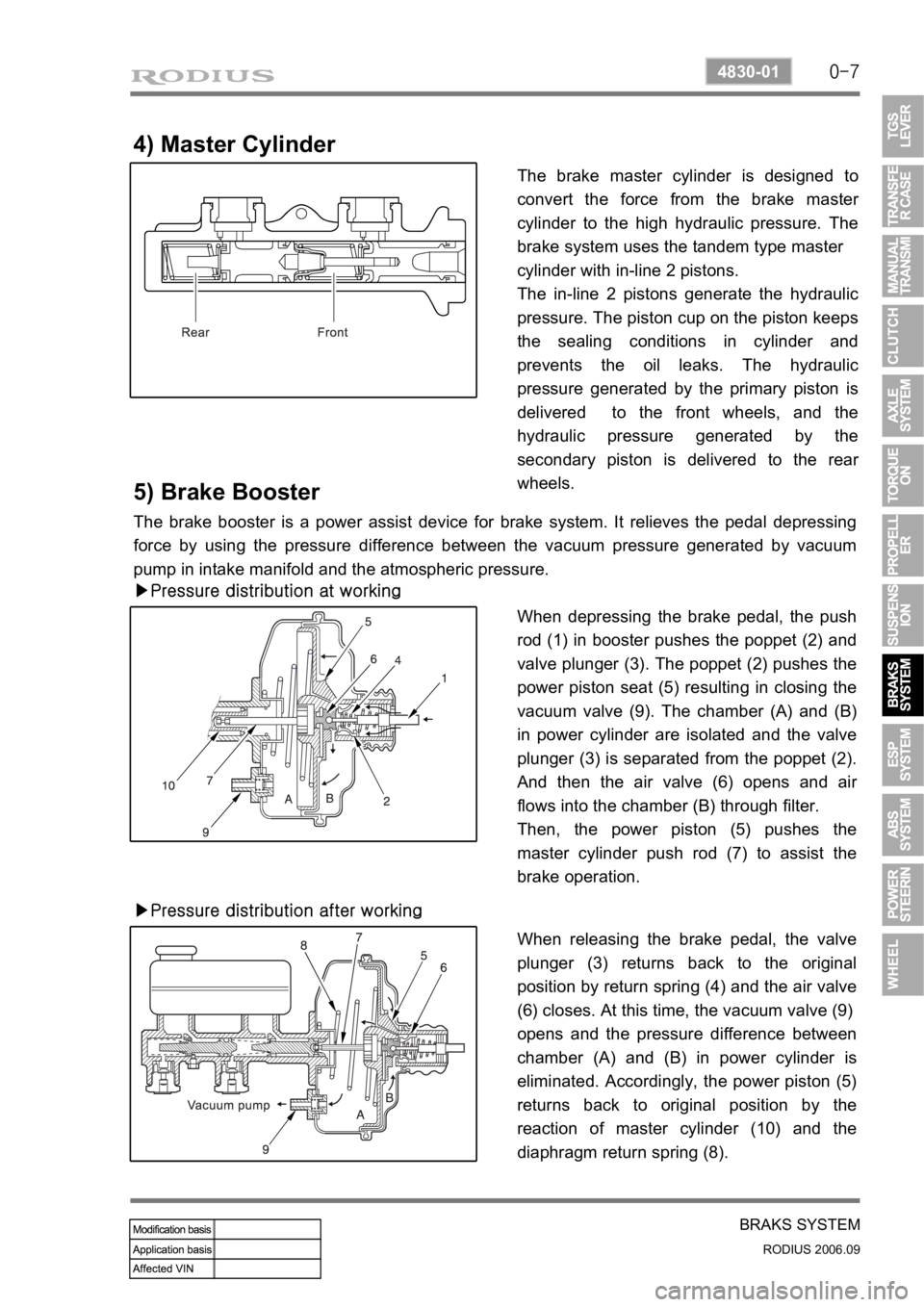

4) Master Cylinder

The brake master cylinder is designed to

convert the force from the brake maste

r

cylinder to the high hydraulic pressure. The

brake system uses the tandem type master

cylinder with in-line 2 pistons.

The in-line 2 pistons generate the hydraulic

pressure. The piston cup on the piston keeps

the sealing conditions in cylinder and

prevents the oil leaks. The hydraulic

pressure generated by the primary piston is

delivered to the front wheels, and the

hydraulic pressure generated by the

secondary piston is delivered to the rea

r

wheels.

5) Brake Booster

The brake booster is a power assist device for brake system. It relieves the pedal depressing

force by using the pressure difference between the vacuum pressure generated by vacuum

pump in intake manifold and the atmospheric pressure.

▶Pressure distribution at working

When depressing the brake pedal, the push

rod (1) in booster pushes the poppet (2) and

valve plunger (3). The poppet (2) pushes the

power piston seat (5) resulting in closing the

vacuum valve (9). The chamber (A) and (B)

in power cylinder are isolated and the valve

plunger (3) is separated from the poppet (2).

And then the air valve (6) opens and ai

r

flows into the chamber (B) through filter.

Then, the power piston (5) pushes the

master cylinder push rod (7) to assist the

brake operation.

▶Pressure distribution after working

When releasing the brake pedal, the valve

plunger (3) returns back to the original

position by return spring (4) and the air valve

(6) closes. At this time, the vacuum valve (9)

opens and the pressure difference between

chamber (A) and (B) in power cylinder is

eliminated. Accordingly, the power piston (5)

returns back to original position by the

reaction of master cylinder (10) and the

diaphragm return spring (8).

Page 382 of 465

0-10

RODIUS 2006.09

6810-20

AIR CONDITIONING SYSTEM

2. AIR CONDITIONER MODULE WIRING AND LAYOUT

1) Front Air Conditioner Module

Wiring layout

Components

Air source selection

door actuatorAir conditioner filterEvaporator

Blower

motor

Blower high

speed relay

Heater core