length SSANGYONG RODIUS 2007 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2007, Model line: RODIUS, Model: SSANGYONG RODIUS 2007Pages: 465, PDF Size: 56.32 MB

Page 243 of 465

0-7

RAIN SENSOR

RODIUS 2006.09

8610-11

4. FUNCTIONS OF RAIN SENSOR

1) Windshield Glass and Coupler Attachment

Check the outer windshield surface of sensing area for wear, damage and scratch. The sensor

is able to compensate the wear up to a specific level. Check the coupler attached surface of

windshield for porosity. If the porosity exists, the sensor cannot function properly.

2) Recognition of AUTO Mode

3) Instant Wipe Function

When the variable resistance knob on the multifunction wiper switch is turned by each 1 stage

from low sensitivity (Smark) to high sensitivity (F mark), the wiper operates one cycle.

And, the wiper also operates during raining up to 5 minutes after rain stops.When the engine is started with the wiper switch “AUTO” position, the wiper operates

one cycle to remind a driver that the wiper switch is in “AUTO” position.

When the wiper switch is turned to “AUTO” from OFF, the wiper operates one cycle. It

always operates one cycle for the initial operation, however, the wiper does not operate

afterwards to prevent the wiper blade wear if not raining when turning the wiper switch to

“AUTO” from “OFF”. However, the wiper operates up to 5 minutes after rain stops.

If this function does not occur, check No. 2 terminal on the rain sensor. If any defective

cannot be found, check the wiper relay (LOW) for defective. 1)

2)

3)If the installed wiper brushes are out of specification (size and length), the rain sensing

area cannot be fully wiped. In this case, the rain sensor’s sensitivity could be

decreased and the wipers are not properly operated -

As described, the STICS recognizes the wiper switch “AUTO” position. If there are not

any problem, go to diagnosis mode in STICS and check the terminal that receives signal

from wiper and communication lines between rain sensor unit and STICS. -

Page 292 of 465

0-4

RODIUS 2006.09

3010-01

CLUTCH

1. OVERVIEW

1) Driving Elements

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch cover pressure

plate. The clutch pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

2) Driven Elements

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along

the splines of the input shaft. The driving and driven elements are held in contact by spring

pressure. This pressure is exerted by a diaphragm spring in the clutch cover pressure plate

assembly.

3) Operating Elements

The clutch control system consists of the clutch pedal, clutch master cylinder, concentric slave

cylinder. This system directly releases the clutch by using hydraulic pressure while the

conventional clutch system releases the clutch by using release lever and release fork. This

system provides higher efficiency than conventional clutch system, and its durability is superior.

Adaptor (mounted on transmission case) Concentric slave cylinder pipe (mounted inside o

f

transmission) Concentric slave cylinder (mounted inside of transmission)

Page 309 of 465

0-3

PROPELLER SHAFT

RODIUS 2006.09

3310-01

3310-01PROPELLER SHAFT

1. PROPELLER SHAFT GENERAL INFORMATION

The propeller shaft transfers the power through

the transmission and transfer case to the

front/rear axle differential carrier (final reduction

gear). It is manufactured by a thin rounded steel

pipe to have the strong resisting force against

the torsion and bending. Both ends of propelle

r

shaft are connected to the spider and the cente

r

of propeller shaft is connected to the spline to

accommodate the changes of the height and

length. The rubber bushing that covers the

intermediate bearing keeps the balance of rea

r

propeller shaft and absorbs its vibration.

2. SPECIFICATION

Page 315 of 465

0-7

SUSPENSION SYSTEM

RODIUS 2006.09

4111-01

Marking Point

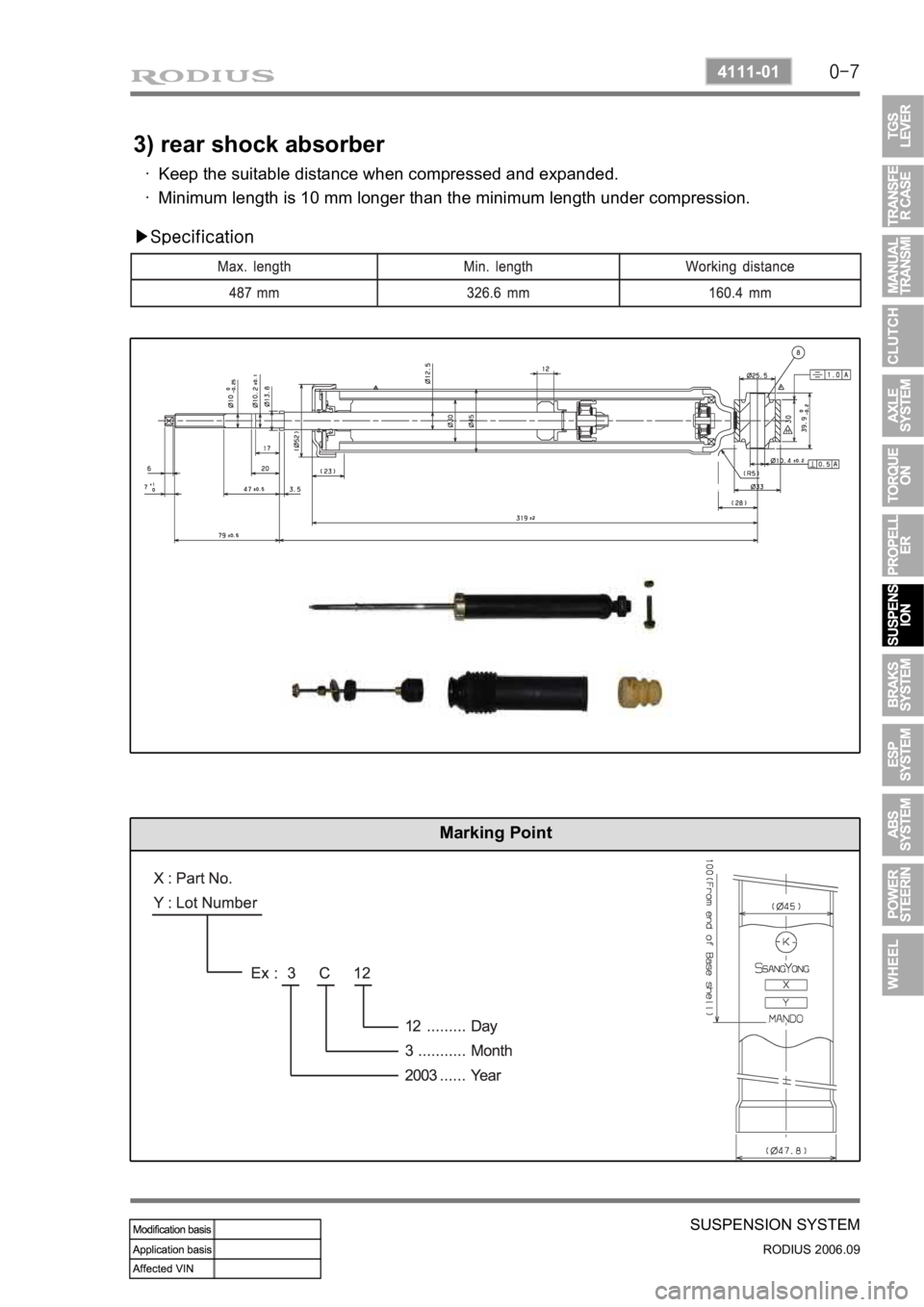

3) rear shock absorber

Keep the suitable distance when compressed and expanded.

Minimum length is 10 mm longer than the minimum length under compression. ·

·

▶Specification