engine oil SSANGYONG RODIUS 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 180 of 715

02-230000-00

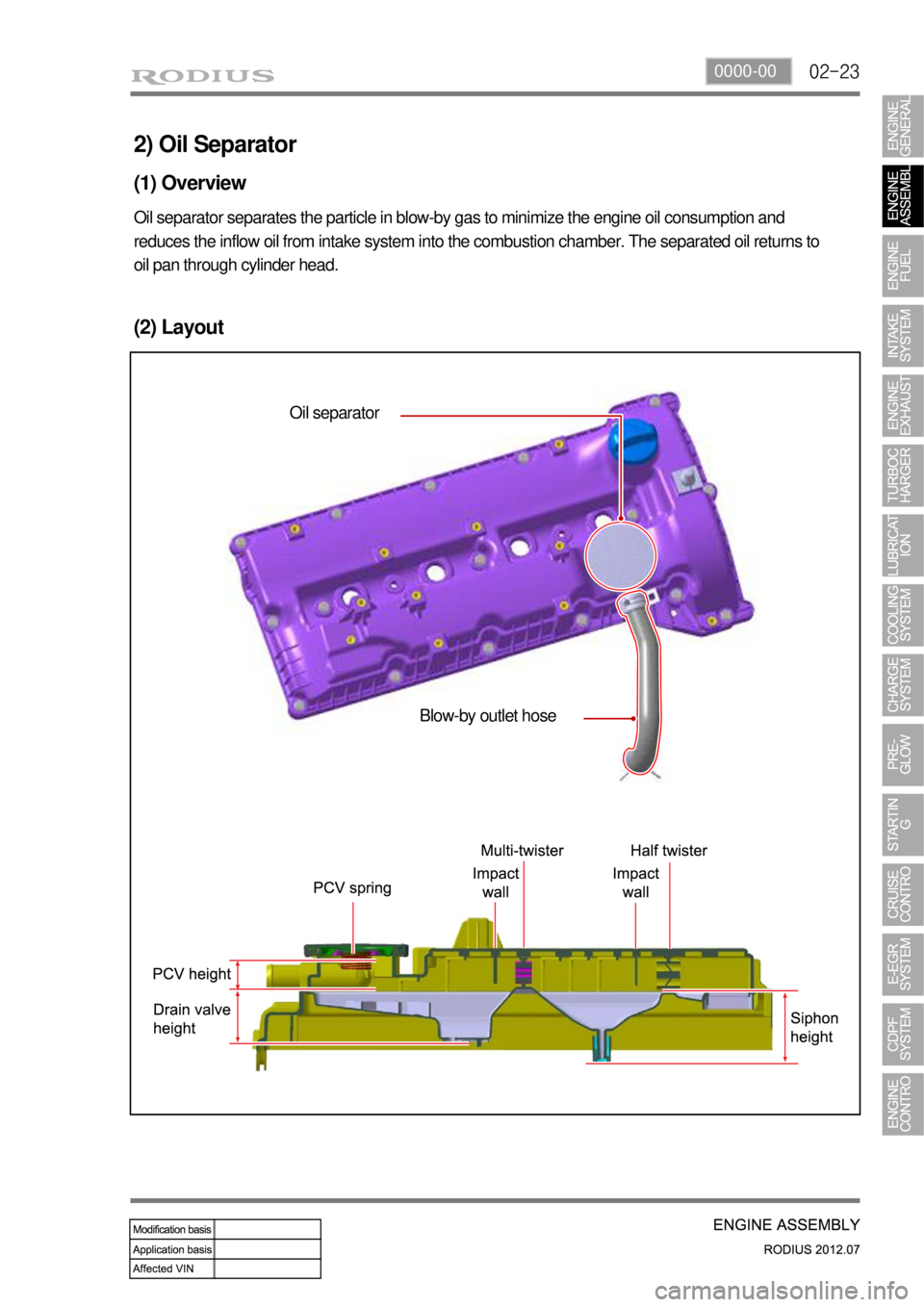

2) Oil Separator

Oil separator separates the particle in blow-by gas to minimize the engine oil consumption and

reduces the inflow oil from intake system into the combustion chamber. The separated oil returns to

oil pan through cylinder head.

Oil separator

Blow-by outlet hose

(1) Overview

(2) Layout

Page 183 of 715

02-26

Intake/Exhaust Camshafts

2) Camshaft

(1) Overview

Hollow type camshaft contains cam, octagon cam, HP pump gear and intake/exhaust gears.

Camshaft operates the intake/exhaust valves, vacuum pump and HP pump, and transfers the

engine oil to vacuum pump through the internal oil passage.

(2) Location

Exhaust CamshaftExhaust Camshaft

Thrust journalIntake Camshaft

Closed flow type water jacket (improving cooling performance) ▶

Octagon cam

(for tooling)

Connected to

vacuum pump

Page 186 of 715

02-290000-00

1) Chain Drive

(1) Overview

The drive chain is single chain drive system with simple design and variable performance, and it

utilizes the hydraulic tensioner to reduce the wave impact generated by the chain. This chain is light

weight and has high durability through single bush chain. Shoulder bolts are used for better NHV.

7. CHAIN AND GEAR DRIVE SYSTEM

D20DTR engine uses single stage chain drive system. Timing chain drives the exhaust side and

gear drive the intake side. Timing chain is single bush type. Upper chain drives HP pump

connected to intake Camshaft by driving exhaust cam shift sprocke, and lower chain drives oil

pump to lubricate the engine.

Page 192 of 715

02-350000-00

Oil pan sassembly

8. OIL PAN

The oil pan in D20DTR engine improves the NVH. Especially, the oil draining is much easier than

before.

Components ▶

Page 197 of 715

02-40

1) Piston

(1) Overview

Piston assembly contains piston, #1 ring, #2

ring, oil ring, piston pin and snap ring. The

expansion energy from engine is transferred

to the crankshaft through connecting rod to

convert the linear movement to rotating

energy.

(2) Layout

#1 ring

Oil ring

Snap ring

#2 ring

Material:

B2+

Skirt coating:

MoS2

Piston cooling gallery

for connecting rod

Wide bawl type (CR 16.5)

Cooling jet

Page 198 of 715

02-410000-00

(3) Functions

Piston transfers the combustion energy from engine to connecting rod. Especially in the direct

injection engine such as D20DTF, it provides the combustion space and largely effects to the

engine performance and exhaust gas.

Piston ring

#1 ring (Top ring) : Prevents the high pressurized combustion gas from leaking into crank

chamber, and prevents the engine oil getting into combustion chamber.

#2 ring: Scrapes the engine oil on the cylinder bore, and prevents the leaked combustion gas

from #1 ring from leaking into the crank chamber.

Oil ring: Scrapes the engine oil on the cylinder bore.

Piston pin

Connects the piston the connecting rod, and transfers the linear movement of piston to

connecting rod to convert it to rotating energy

Snap pin

Locks the piston pin. ▶

-

-

-

▶

-

▶

-

(4) Assembling the piston

Install the piston rings with the "Y" mark on

the ring facing upwards.

Position the end gap of #1 ring at 180˚

away from the end gap of #1 ring.

Position the end gap of oil ring at 180˚

away from the end gap of coil spring, and

position the end gap of oil ring at 90˚ away

from the end gap of #2 ring. 1.

2.

3.

Page 206 of 715

02-490000-00

The bottom side of water jacket is desgined as sine wave to strengthen the structure of crankcase.

The main flow of coolant starts from outlet port of water pump and goes along the longitudinal

direction of engine. The coolant passage from cylinder head to inlet port of water pump is

integrated in cylinder head.

The engine oil from oil pump is supplied to the main oil gallery through oil channel, oil filter

module and cross bore in cylinder block without using external pipes. This oil is supplied to main

bearing, cylinder head and MBU. And, it is sprayed to the chain through the chain tensioner

connected to cross bore.

Crankcase cross bore for oil supply

Water jacket core

Page 208 of 715

03-4

Took kit for low pressure lineTool kit for high pressure line

2. MAINTENANCE AND INSPECTION

1) Maintenance Procedures for DI Engine Fuel System

Always keep the workshop and lift clean (especially, from dust).

Always keep the tools clean (from oil or foreign materials).

Wear a clean vinyl apron to prevent the fuzz, dust and foreign materials from getting into fuel

system. Wash your hands and do not wear working gloves. 1.

2.

3.

Follow the below procedures before starting service works for fuel system.

If the problem is from HP pump, fuel supply line or injector, prepare the clean special tools and

sealing caps to perform the diagnosis for DI engine fuel system in this manual. At this point,

thoroughly clean the related area in engine compartment. 4.

Clean the engine compartment before starting service works.

Page 224 of 715

03-20

Water

separator

(2) Di engine and its expected problems and remedies can be caused by

water in fuel

System supplement against paraffin separation ▶

In case of Diesel fuel, paraffin, one of the elements, can be separated from fuel during winter and

then can stick on the fuel filter blocking fuel flow and causing difficult starting finally. Oil

companies supply summer fuel and winter fuel by differentiating mixing ratio of kerosene and

other elements by region and season. However, above phenomenon can be happened if stations

have poor facilities or sell improper fuel for the season. In case of DI engine, purity of fuel is very

important factor to keep internal preciseness of HP pump and injector.

Accordingly, more dense mesh than conventional fuel filter is used. To prevent fuel filter internal

clogging due to paraffin separation, SYMC is using fuel line that high pressure and temperature

fuel injected by injector returns through fuel filter to have an effect of built-in heater (see fuel

system).

System supplement and remedy against water in fuel ▶

As mentioned above, some gas stations supply fuel with excessive than specified water. In the

conventional IDI engine, excessive water in the fuel only causes dropping engine power or engine

hunting. However, fuel system in the DI engine consists of precise components so water in the

fuel can cause malfunctions of HP pump due to poor lubrication of pump caused by poor coating

film during high speed pumping and bacterization (under long period parking). To prevent

problems can be caused by excessive water in fuel, water separator is installed inside of fuel

filter. When fuel is passing filter, water that has relatively bigger specific gravity is accumulated on

the bottom of the filter.

Water drain from water separator ▶

If water in the separator on the fuel filter exceeds a certain level, it will be supplied to HP pump

with fuel, so the engine ECU turns on warning lamp on the meter cluster and buzzer if water level

is higher than a certain level.

Due to engine layout, a customer cannot easily drain water from fuel filter directly, so if a

customer checks in to change engine oil, be sure to perform water drain from fuel filter.

To separate the water from the fuel filter,

remove the fuel filter assembly first.

Page 232 of 715

04-4

2. INSPECTION

1) Troubleshooting

When Abnormal Noises are Heard from the Engine Room ▶

For the vehicle equipped with DI engine, if a learning noise occurs in each range or other

noises occur, the major cause of it is a faulty turbocharger assembly. But an interference

issue, poor tightness or loose in the intake and exhaust system also can cause those noises.

This is mainly because the operator didn't follow the instruction exactly when reconnecting

the intake hoses and pipes which were disconnected to check the system or replace the air

cleaner. If the intake system is free of any faults, check the EGR and PCV oil separator

connected to the intake system.

The figure may be different from the actual engine. Therefore, read thoroughly below before

replacing the parts.

2) Abnormal Noise Caused by Poor Tightness of Intake System

When the DI engine is running, the air entered into the engine flows in the sequence as shown

above. If high intake pressure is applied to the loose or damaged part, a whistling noise may

occur, the intake air volume is measured incorrectly or the engine power is derated.