check engine SSANGYONG RODIUS 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 246 of 715

06-51914-01

2) Inspection of Turbocharger

When problem occurs with the turbocharger, it could cause engine power decline, excessive

discharge of exhaust gas, outbreak of abnormal noise and excessive consumption of oil.

On-board Inspection 1.

Check the bolts and nuts foe looseness or missing

Check the intake and exhaust manifold for looseness or damage

Check the oil supply pipe and drain pipe for damages

Check the housing for crack and deterioration -

-

-

-

Inspection of turbine 2.

Remove the exhaust pipe at the opening of the turbine and check, with a lamp, the existence of

interference of housing and wheel, oil leakage and contamination (at blade edge) of foreign

materials.

Interference: In case where the oil leak sign exists, even the small traces of interferences on

the turbine wheel mean, most of times, that abrasion has occurred on the journal bearing.

Must inspect after overhauling the turbocharger.

Oil Leakage: Followings are the reasons for oil leakage condition -

-

Problems in engine: In case where the oil is smeared on inner wall section of the exhaust

gas opening.

Problems in turbocharger: In case where the oil is smeared on only at the exhaust gas

outlet section. *

*

Idling for long period of time can cause oil leakage to the turbine side due to low pressure of

exhaust gas and the rotation speed of turbine wheel. Please note this is not a turbocharger

problem.

Oil Drain Pipe Defect

In case where oil flow from the turbocharger sensor housing to the crank case is not smooth

would become the reason for leakage as oil builds up within the center housing. Also, oil

thickens (sludge) at high temperature and becomes the indirect reason of wheel hub section.

In such case, clogging and damage of the oil drain pipe and the pressure of blow-by gas

within the crank case must be inspected.

Damages due to Foreign Materials.

When the foreign materials get into the system, it could induce inner damage as rotating

balance of the turbocharger gets out of alignment. -

-

-

Page 247 of 715

06-6

3) Inspection of Turbine

Thoroughly check the followings.

Must absolutely not operate the turbocharger with the compressor outlet and inlet opened as it

could damage the turbocharger or be hazardous during inspection.

Interference: In case where is trace of interference or smallest damage on the compressor

wheel means, most of times, that abrasion has occurred on the journal bearing. Must inspect

after the overhaul.

Oil Leakage: The reason for oil leakage at the compressor section is the air cleaner, clogged

by substances such as dust, causes the compressor inlet negative pressure. -

-

Rotating in high speed at no-load for extended period of time can cause oil leakage to the

compressor section as oil pressure within the center housing gets higher than pressure

within the compressor housing.

Overuse of engine break (especially in low gear) in down hill makes significantly low

exhaust gas energy compared to the time where great amount of air is required during

idling conditions of the engine. Therefore, amount of air in the compressor inlet increases

but the turbocharge pressure is not high, which makes negative a.

b.

No problem will occur with the turbocharger if above conditions are found in early stage but oil

leaked over long period of time will solidify at each section causing to breakout secondary

defects.

Damages by foreign materials: In case where the compressor wheel is damaged by foreign

materials requires having an overhaul. At this time, it's necessary to check whether the foreign

materials have contaminated intake/exhaust manifold or inside of engine.

Page 252 of 715

06-111914-01

3. TROUBLESHOOTING

The followings are cautions to take in handling defects of turbocharger, which must be fully aware

of.

1) Cautions

After stopping the engine, check whether the bolts on pipe connecting section are loose as

well as the connecting condition of vacuum port and modulator, which is connected to the

actuator.

During idling of the engine, check for leakage in the connecting section of pipe (hoses and

pipes, duct connections, after the turbocharger) by applying soap water. The leakage condition

in the engine block and turbine housing opening can be determined by the occurrence of

abnormal noise of exhaust.

By running the engine at idle speed, abnormal vibration and noise can be checked.

Immediately stop the engine when abnormal vibration and noise is detected and make

thorough inspection whether the turbocharger shaft wheel has any damages as well as

checking the condition of connections between pipes.

In case where the noise of engine is louder than usual, there is possibility of dampness in the

areas related with air cleaner and engine or engine block and turbocharger. And it could affect

the smooth supply of engine oil and discharge.

Check for damp condition in exhaust gas when there is sign of thermal discoloration or

discharge of carbon in connecting area of the duct.

When the engine rotates or in case where there is change in noise level, check for clogging of

air cleaner or air cleaner duct or if there is any significant amount of dust in the compressor

housing.

During the inspection of center housing, inspect inside of the housing by removing the oil drain

pipe to check for sludge generation and its attachment condition at shaft area or turbine side.

Inspect or replace the air cleaner when the compressor wheel is damaged by inflow of foreign

materials.

Inspect both side of the turbocharger wheel after removing inlet and outlet pipe of the

turbocharger. 1.

2.

3.

4.

5.

6.

7.

8.

9.

Page 264 of 715

07-31543-00

1. SPECIFICATION

The engine oil filter element should be changed at the same time with the engine oil.

Regularly check the engine oil level and add the engine oil if necessary.

Remember to check the engine oil level and shorten the cycle to replace the engine oil

under severe driving conditions. -

-

Severe Driving Condition

Frequent stop-and-go traffic, extended idling, short driving distance below 6 km, driving

distance below 16 km when the outside temperature remains below freezing

Driving in a hilly or mountainous terrain, sandy, or dusty area

High load driving such as trailer towing

Taxi, patrol service or delivery service (extended idling and excessive driving with low speed) -

-

-

-

Unit Specification

Oil pump Lubrication system Gear pump, forced circulation

Type Inscribed gear

Capacity 63 L at 4,000 rpm

Relief pressure5.8 bar ± 0.3 bar

Oil filter Type Full flow/Paper element

Engine oil Specified oil SAE 5W30 (approved by MB SHEET 229.51)

Capacity (L) Min.: 4.5 L

Max.: 6.0 L

Service

intervalEU Change every 20,000 km or 12 months

(The service interval should be shortened under

severe conditions)

General Change every 15,000 km or 12 months

(The service interval should be shortened under

severe conditions)

Oil injection nozzle Type Piston

Operating pressure 1.5bar

Closing pressure 1.0bar

Oil flow 4 L/min

Oil pressure switch Permissible pressure 10bar

Page 265 of 715

07-4

2. MAINTENANCE

1) Level Check

Park the vehicle on a level ground and apply the parking brake. Stop the engine and wait more than 5

minutes.

Pull out the dipstick and wipe it with a clean cloth. Reinsert it all the way.

Pull out it again and check the oil level.

The oil level should be between the maximum (Max) mark and minimum (Min) mark on the oil

dipstick. Oil should be replenished before the level goes below the minimum mark. -

-

-

Operating vehicle with insufficient amount of oil can damage the engine. Make sure the

engine oil level is correct and add oil if necessary.

2) Replenishment

If the level gets to the lower point, open the filler cap on top of the cylinder block and add the

genuine oil without exceeding the level of the upper mark.

Recheck the oil level after 5 minutes.

Regularly check the engine oil level and add Ssangyong genuine engine oil if necessary.

Clean the dipstick with clean cloth so that any foreign materials cannot get into the engine.

The oil should not go above the upper mark on the dipstick.

The engine oil may be consumed more if the engine is new. -

-

-

-

Engine oil dipstick

Engine oil filler

Page 270 of 715

08-51520-00

1) Coolant Level Check

Park the vehicle on level ground and apply the parking brake. Stop the engine and wait until it is

cooled down.

The coolant level should be between the MAX and MIN mark on the coolant reservoir.

Check the coolant level. If the level is below the “MIN” mark, immediately add coolant. 1.

2.

Scalding hot coolant and steam could be blown out under pressure, which could cause

serious injury. Never remove the coolant reservoir cap when the engine and radiator are hot.

Avoid any direct contact of the coolant to the painted body of the vehicle. -

-

Page 276 of 715

09-4

2. INSPECTION

1) Alternator Output Test

Item How to check DTC set value / Action

Output

current

B terminal

current

Rotor

coil

resistance

D terminal

voltage

Disconnect the cable connected to the

B terminal on the alternator. Connect

one end of the ammeter to the B

terminal and the other end to the cable

connected to the B terminal.

Measure the maximum output value.

(Maintain the engine speed between

2,500 and 3,000 rpm.)

(Turn the headlamp and all the electrical

switches on.) 1.

2.Pass: If the measured current is

45 A or higher.

Fail: If the measured current is

less than 45 A.

Check the current of the B

terminal. -

-

-

Move the gear selector lever to the

neutral position.

Maintain the engine speed at 2,500 rpm

with the vehicle unloaded.

(Turn all the electrical switches off.) 1.

2.Open circuit: If the measured

current is 5 A or higher. -

Disconnect the negative cable from the

battery.

Remove the B terminal and turn off the

ignition switch.

Measure the resistance between the L

and F terminals with an ohmmeter. 1.

2.

3.Pass: If the measured resistance

is between 3 and 6 Ω.

Faulty rotor coil or slip ring: If the

measured resistance is less than

3 Ω or greater than 6 Ω. -

-

Connect the B terminal wiring.

Measure the voltage with the engine

running. 1.

2.Specification: 12.5 V to 14.5 V

Faulty IC regulator or field coil: If

the measured voltage is 14.5 V

or higher. -

-

Disconnect the negative battery cable.

Connect the negative cable again after connecting the ammeter. -

-

Page 290 of 715

10-71413-00

4) Operation

Glow plug is installed in the cylinder head. It enhances the cold starting performance and reduces

the exhaust gas during cold starting.

ECU receives the data (engine rpm, coolant temperature, vehicle speed) through CAN lines.

Based on the data, GCU controls the pre-glow, cranking and post-glow. It also checks the glow

plugs, and sends the result to ECU.

(1) Temperature/Current Properties of GCU

GCU increases the temperature of glow plug very rapidly (approx. 2 seconds up to

1000°C)

FETs (similar to transistor) for each cylinder are integrated in GCU. During the pre-

glow period, battery voltage is supplied to the glow plugs directly to heat them rapidly.

After getting the desired temperature by pre-glowing, the temperature is controlled by

duty ratio. Step 1:

Step 2 & 3:

Step 4:

This shows the supplying voltage and time by GCU in each step. The step 4 is the period to

keep the temperature. -Step 1: I1

Step 2: I2

Step 3: I3

Step 4: I4

Page 313 of 715

14-32412-02

1. CAUTIONS

Standard pattern of soot accumulation ▶

(1) Abnormal Soot Accumulation (2) Normal Soot Combustion

Cautions to protect the catalyst filter ▶

Use the designated fuel only.

Observe the recommended service intervals of engine oil.

Check the engine oil level frequently and add if necessary.

Do not idle the vehicle unnecessarily.

Do not turn off the engine while the vehicle is running.

Do not shift the gear selector lever to neutral when going downhill.

Do not use improper engine oil or fuel additives.

Do not drive for a long time when the warning lamp is illuminated.

Make sure no flammable material, such as dry grass or tissue paper, contacts with the catalyst

filter while the vehicle is parked.

For the vehicles used in urban traffic, driving on the expressways for more than 1 hour at least

once per week is needed so that the PM inside CDPF isn't collected to one side only. -

-

-

-

-

-

-

-

-

-

Page 314 of 715

14-4

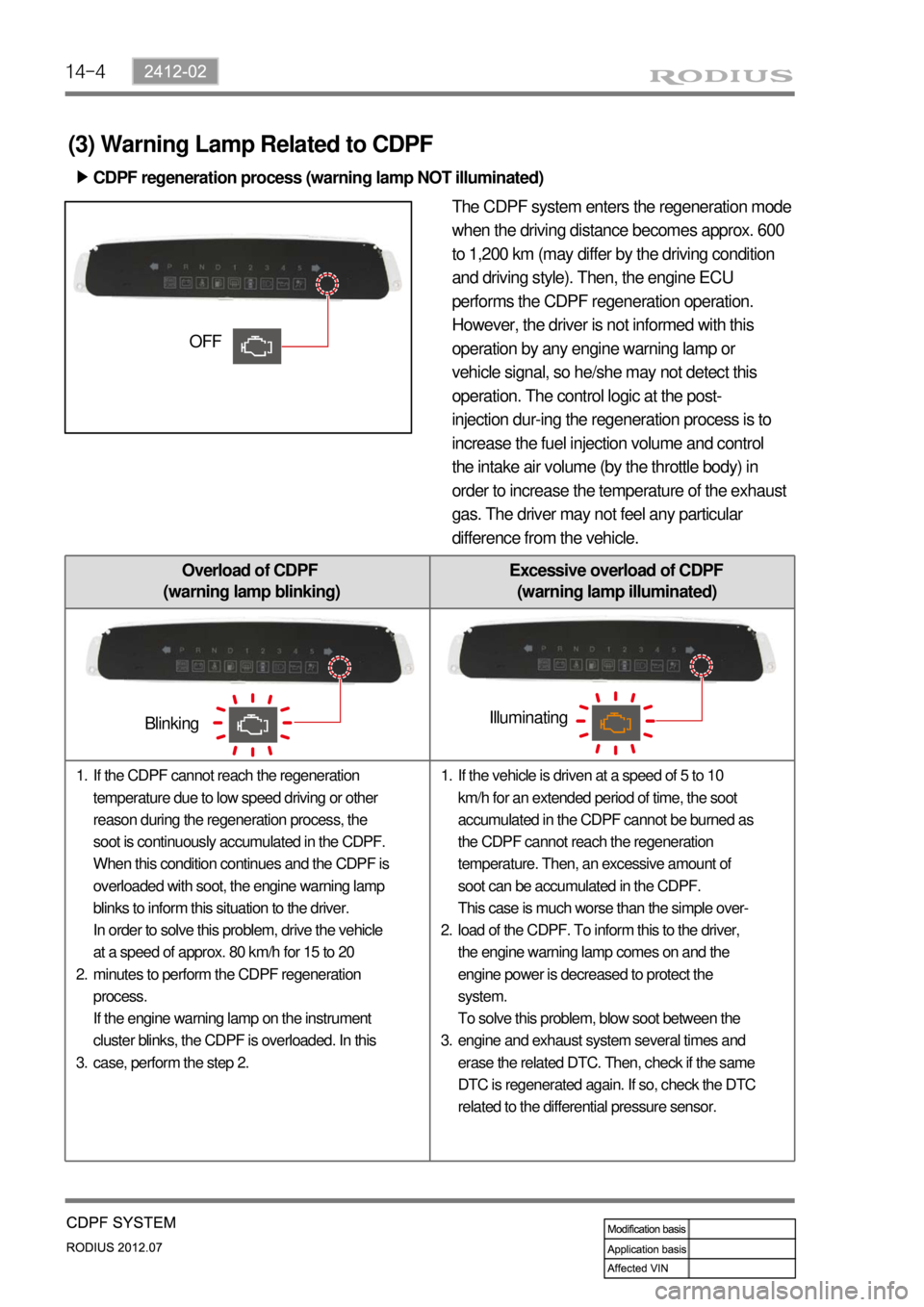

Overload of CDPF

(warning lamp blinking)Excessive overload of CDPF

(warning lamp illuminated)

(3) Warning Lamp Related to CDPF

CDPF regeneration process (warning lamp NOT illuminated) ▶

The CDPF system enters the regeneration mode

when the driving distance becomes approx. 600

to 1,200 km (may differ by the driving condition

and driving style). Then, the engine ECU

performs the CDPF regeneration operation.

However, the driver is not informed with this

operation by any engine warning lamp or

vehicle signal, so he/she may not detect this

operation. The control logic at the post-

injection dur-ing the regeneration process is to

increase the fuel injection volume and control

the intake air volume (by the throttle body) in

order to increase the temperature of the exhaust

gas. The driver may not feel any particular

difference from the vehicle.

If the CDPF cannot reach the regeneration

temperature due to low speed driving or other

reason during the regeneration process, the

soot is continuously accumulated in the CDPF.

When this condition continues and the CDPF is

overloaded with soot, the engine warning lamp

blinks to inform this situation to the driver.

In order to solve this problem, drive the vehicle

at a speed of approx. 80 km/h for 15 to 20

minutes to perform the CDPF regeneration

process.

If the engine warning lamp on the instrument

cluster blinks, the CDPF is overloaded. In this

case, perform the step 2. 1.

2.

3.If the vehicle is driven at a speed of 5 to 10

km/h for an extended period of time, the soot

accumulated in the CDPF cannot be burned as

the CDPF cannot reach the regeneration

temperature. Then, an excessive amount of

soot can be accumulated in the CDPF.

This case is much worse than the simple over-

load of the CDPF. To inform this to the driver,

the engine warning lamp comes on and the

engine power is decreased to protect the

system.

To solve this problem, blow soot between the

engine and exhaust system several times and

erase the related DTC. Then, check if the same

DTC is regenerated again. If so, check the DTC

related to the differential pressure sensor. 1.

2.

3.

OFF

BlinkingIlluminating