transmission SSANGYONG RODIUS 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 554 of 715

02-16

2) Sectional Diagram

3) Gear Ratio

Transmission housing

Extension housing

Main shaft Counter shaft Main drive gearIntermediate plate

GearTeeth

Final gear ratio

Input Output

1st 13 38 4.489

2nd 23 35 2.337

3rd 33 29 1.350

4th 28 43 1.000

5th 47 24 0.784

6th 52 23 0.679

R 13 36 4.253

IDLE : 25

Page 566 of 715

03-93010-00

2) Overview

Driving elements ▶

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch pressure plate. The

clutch pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

Driven elements ▶

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along the

splines of the input shaft.

The driving and driven elements are held in contact by spring pressure. This pressure is exerted

by a diaphragm spring in the clutch cover pressure plate assembly.

Operating Elements ▶

The clutch "release" system consists of the clutch pedal and clutch release cylinder.

This system directly releases the clutch by using hydraulic pressure while the conventional clutch

system releases the clutch by using release lever and release fork. This system provides higher

efficiency than conventional clutch system, and its durability is superior.

Clutch master cylinder (mounted on clutch pedal)

Concentric slave cylinder pipe (mounted inside of transmission) -

-

Page 568 of 715

03-113010-00

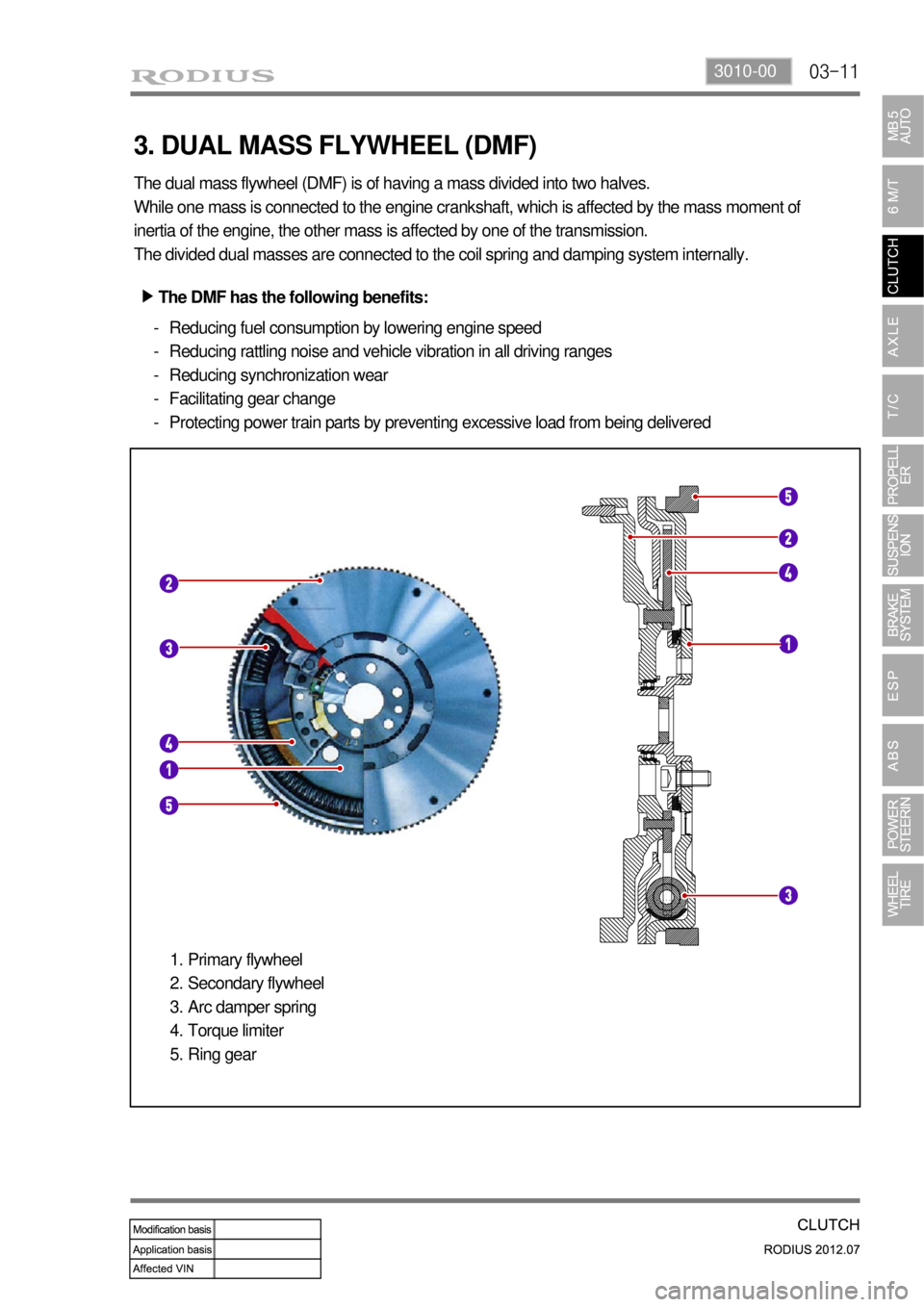

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of

inertia of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits: ▶

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered -

-

-

-

-

Primary flywheel

Secondary flywheel

Arc damper spring

Torque limiter

Ring gear 1.

2.

3.

4.

5.

Page 573 of 715

05-6

Operation ▶

Description Mode Conditions

Driving mode 2H 2 Wheel drive

(rear wheel)Rear-wheel drive mode. This is used under

normal or high-speed driving conditions on public

roads or highways.

4H 4 Wheel drive

(high speed)This is used under sandy, muddy or snow-

covered road conditions

4L 4 Wheel drive

(low speed)This is used for maximum traction.

When cornering with low speed in 4WD condition,

there could be tire dragging, some

mechanical shocks and resistances in vehicle’s

drive train. These are normal conditions due to

internal resistance in the drive train when the

4WD system is properly working

Mode change2H ↔

4H 2 Wheel drive

↔4 Wheel driveShifting is possible while driving at the speed of

70 km/h or less

2H, 4H

↔ 4L 2 Wheel drive,

4 Wheel drive

(high speed)

↔4 Wheel drive

(low speed)

To make the mode change easily, stop the

vehicle on level ground and turn the mode

switch to the desired position and move the

shift lever to "N"-"R"-"N" while depressing

the brake pedal. For Automatic Transmission:

Stop the vehicle on level ground and move

the gear selector lever into the “N” position.

Turn the switch to the desired position. -

For Manual Transmission:

Stop the vehicle on level ground and move

the gear selector lever into the “N” position.

Then turn the switch to the desired position

while depressing the clutch pedal. -

Page 579 of 715

05-12

1) 2H Mode (2 Wheel Drive)

Power Flow ▶

Output shaft of

transmission

Rear propeller shaftRear wheel

Rear axle

Rear wheel

The driving force is directly engaged (1:1) to rear axle and is transferred only to the rear

wheels.

Input shaft of transfer

case

↓

Output shaft of transfer

case

Page 584 of 715

06-53310-01

1. OVERVIEW

The propeller shaft transfers the power through the transmission and transfer case to the

front/rear axle differential carrier (final reduction gear). It is manufactured by a thin rounded steel

pipe to have the strong resisting force against the torsion and bending. Both ends of propeller

shaft are connected to the spider and the center of propeller shaft is connected to the spline to

accommodate the changes of the height and length. The rubber bushing that covers the

intermediate bearing keeps the balance of rear propeller shaft and absorbs its vibration.

Function of propeller shaft ▶

Transmits driving torque.

Compensates the angle change (universal joint / CV joint).

Compensates the axial length change (splines for the slip joint). -

-

-

4WD AT 2WD MT