air filter SSANGYONG RODIUS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 149 of 715

01-70000-00

1) Service Interval

DescriptionDaily

inspectionWeekly

inspectionService interval

Engine oil & oil

filterInspection - EU Change every 20,000 km or 12

months (The service interval should

be shortened under severe

conditions)

General Change every 15,000 km or 12

months (The service interval should

be shortened under severe

conditions)

Coolant Inspection - Change every 200,000 km or 5 years

Air cleaner

element- Inspection Diesel EU Change every 20,000 km

(The service interval should

be shortened under severe

conditions)

General Change every 15,000 km

(The service interval should

be shortened under severe

conditions)

Gasoline Clean every 15,000 km, replace every

60,000 km (The service interval should

be shortened under severe

conditions)

Fuel filter - - EU Change every 40,000 km (Draining

water from fuel filter: whenever

replacing the engine oil)

General Change every 45,000 km (Draining

water from fuel filter: whenever

replacing the engine oil)

Page 155 of 715

01-130000-00

T/C oil supply pipe M6(to block) 1 10±1.0Nm -

M6

(to turbocharger)1 17±2.0Nm-

T/C oil return pipeM6×16(to block)2 10±1Nm -

M6×16

(to turbocharger)210±1Nm -

EGR valveM8×223 25±2.5Nm -

EGR pipe bolt

(to exhaust manifold)M8×16 2 10±1Nm -

EGR pipe bolt

(to EGR cooler)M8×16 2 25±2.5Nm -

Name SizeNumbers of

fastenerTightening torque

(Nm)Note (total

tightening

torque)

Hot water inlet pipeM6×12210±1Nm-

AlternatorM10×901(LO) 25±2.5Nm -

M10×1161(HI) 46±4.6Nm -

Air conditioner

compressorM8×854 25~2.5Nm -

Air conditioner bracketM6×25410±1Nm-

Intake manifoldM8×35225±2.5Nm-

M8×110625±2.5Nm-

Oil filter moduleM8×40625±2.5Nm-

M8×20125±2.5Nm-

M8×140225±2.5Nm-

Knock sensorM8×28220±5Nm-

Camshaft position

sensorM8×141 10~14Nm -

T-T-MAP pressure

sensorM6×20110±1Nm-

Exhaust manifold M8 1040±4Nm-

Turbocharger M8 325±2.5Nm-

T/C support bolt M8 125±2.5Nm-

Page 213 of 715

03-92210-01

Device for high pressure

Device for low pressure

3) DI Engine Fuel System Pressure Test

(1) Test device (Tool kit)

(2) Pre-check

Check-tighten fuel supply line

Check fuel level in fuel tank

Check air in fuel supply line (bubble in fuel supply line or fuel)

Check fuel supply line for leaks (low pressure and high pressure)

Check that specified fuel is used

Check fuel filter for contamination -

-

-

-

-

-

Page 218 of 715

03-14

(6) Low Pressure System Pressure Test

Inspection procedure ▶

All wirings/connectors and fuel lines should

be connected and the engine should work

properly.

Prepare a special tool for low pressure test

and clean it thoroughly to prevent foreign

materials from entering. 1.

2.

Disconnect the key connector for fuel filter connection, and connect both connectors to the

fuel filter and hose. 3.

Start the engine and check visually for clogged low pressure fuel system, excessive air or air

entry.

If the fuel flow is not sufficient or air is in the fuel, repair the leak area. 4.

5.

Page 231 of 715

04-31719-00

1. SPECIFICATIONS

Shorten the service interval under severe conditions such as driving on a dusty road or off-

road. *

Unit Description Specification

Air cleaner elementFilter type Dry, filter element

Initial resistance Max. 300 mmAq

Service interval EU: Change every 20,000 km

GEN: Change every 15,000 km

Air cleaner assemblyWeight 2.36kg

Operating temperature-30 ~ 100℃

IntercoolerRadiation over 13,000 Kcal

Pressure loss at turbocharger below 90 mmHg

Cooling type Air cooled type

Core size 450W*130H*70T

Core type C/FIN

Page 250 of 715

06-91914-01

Turbine Side: Inflow of foreign materials from engine

Compressor Side: such as air filter, muffler and nut 3.

Page 323 of 715

14-132412-02

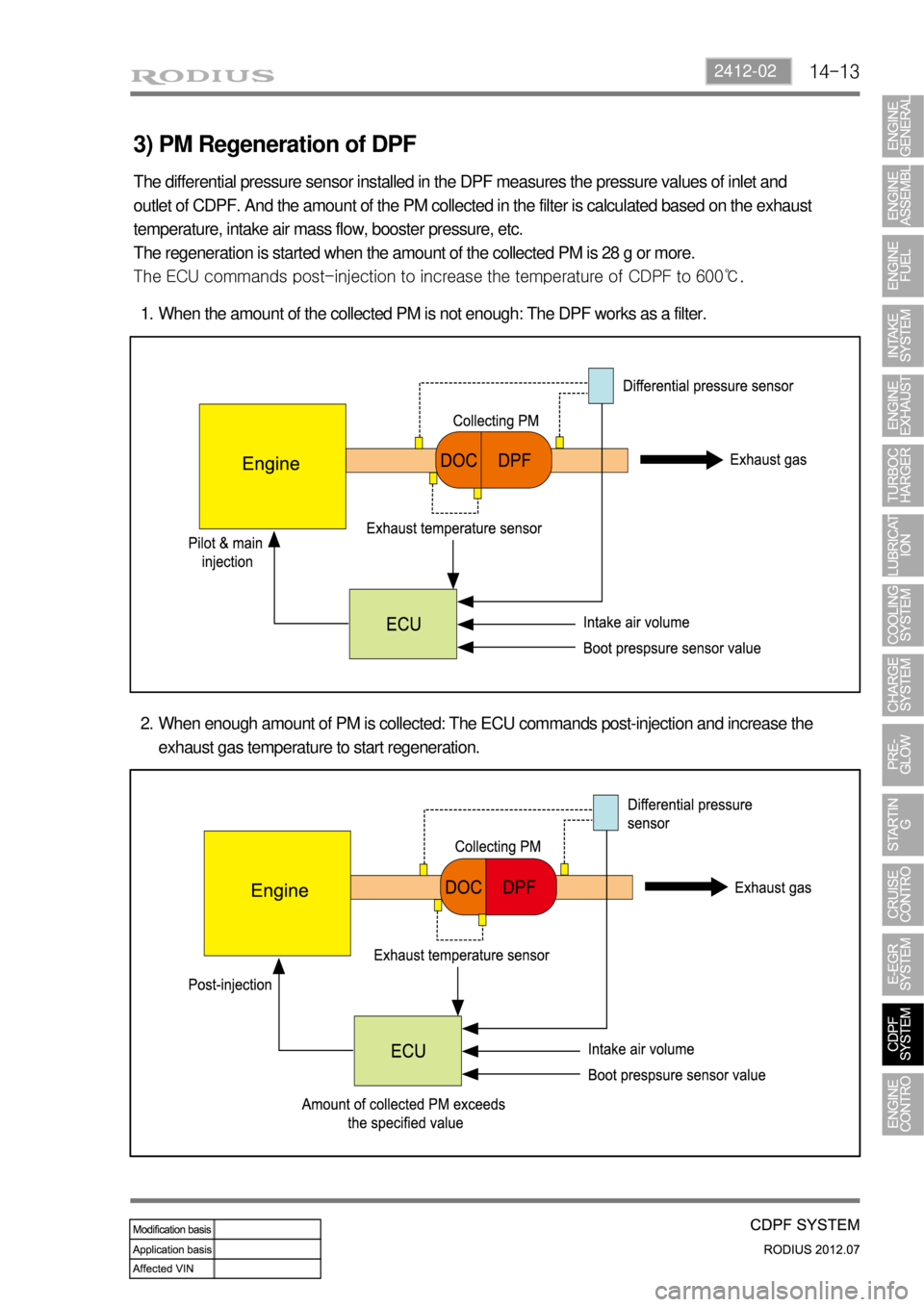

3) PM Regeneration of DPF

The differential pressure sensor installed in the DPF measures the pressure values of inlet and

outlet of CDPF. And the amount of the PM collected in the filter is calculated based on the exhaust

temperature, intake air mass flow, booster pressure, etc.

The regeneration is started when the amount of the collected PM is 28 g or more.

<007b008f008c0047006c006a007c0047008a00960094009400880095008b009a004700970096009a009b0054009000950091008c008a009b0090009600950047009b0096004700900095008a0099008c0088009a008c0047009b008f008c0047009b008c00

940097008c00990088009b009c0099008c00470096008d0047>CDPF to 600℃.

When the amount of the collected PM is not enough: The DPF works as a filter. 1.

When enough amount of PM is collected: The ECU commands post-injection and increase the

exhaust gas temperature to start regeneration. 2.

Page 326 of 715

14-16

7. CAUTIONS

1) Designated Engine Oil for CDPF (Low Ash Oil)

Need to use the designated engine oil for CDPF 1.

The smoke from the vehicle may generate the particle material in the ambient air. CDPF is

the device to reduce the smoke by collecting and recycling it. To ensure the performance

of CDPF, the designated engine oil should be used.

The smoke including combusted sulfur in fuel cannot be recycled in CDPF. This smoke

generates the ash, resulting in clogging the filter. -

-

Advantages when using the designated engine oil for CDPF 2.

Reduces the amount of ash

Improves the fuel economy and reduces the CO2

Increases the life span of engine oil

Available for all engines (diesel and gasoline) -

-

-

-

Problems when using non-designated engine oil for CDPF 3.

Decreases the life span of engine oil due to accumulated ash in DPF (around 30%)

Decreases the fuel economy due to friction resistance, exhaust gas resistance and

frequent recycling process of DPF -

-

The fuel containing high sulfur may cause the same problems.

Page 657 of 715

01-2

Front air conditioner module assembly - inside instrument panel

Compressor - engine rightAQS/Air source selection

switch

Sun load sensor - instrument

panel upper left

1. SYSTEM LAYOUT AND COMPONENTS

Type Air cindotioner controller

FATC

Manual air

conditioner

It change sun load coming through

front windshield into current to input to

FATC controller. *

Air mix door

actuator

PTC (If equipped)

Duct temperature

sensor

Mode door

actuator

Air conditioner wiring

Thermo AMP

Air source door

actuator

Air conditioner

filter

Bloewr motor

Blower high speed relayPower transistor

Page 661 of 715

01-6

2) AIR CONDITIONER MODULE WIRING AND LAYOUT

(1) Front Air Conditioner Module

Air source selection

door actuator

Air conditioner

filterEvaporator

Blower motor

Blower high

speed relay

Heater core

Wiring layout

Components