differential SSANGYONG RODIUS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 164 of 715

02-70000-00

3. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value ▶

Compression ratio16.5 : 1

Test conditionat normal operating temperature (80˚C)

Compression pressur

eStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston

ring, intake and exhaust vale, cylinder head gasket). This test provides current engine operating

status.

Measurement ▶

<007e0088009900940047009b008f008c0047008c0095008e00900095008c0047009c00970047009b00960047009500960099009400880093004700960097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c00

47004f005f005700b6006a00500055>

Disconnect the fuel rail pressure sensor connector to cut off the fuel injection.

Remove the air cleaner duct and glow plugs. -

-

-

Place the diagram sheet to compression

pressure tester and install it into the plug

hole. 1. Before cranking the engine, make sure that the test wiring, tools and persons are keeping

away from moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

Page 314 of 715

14-4

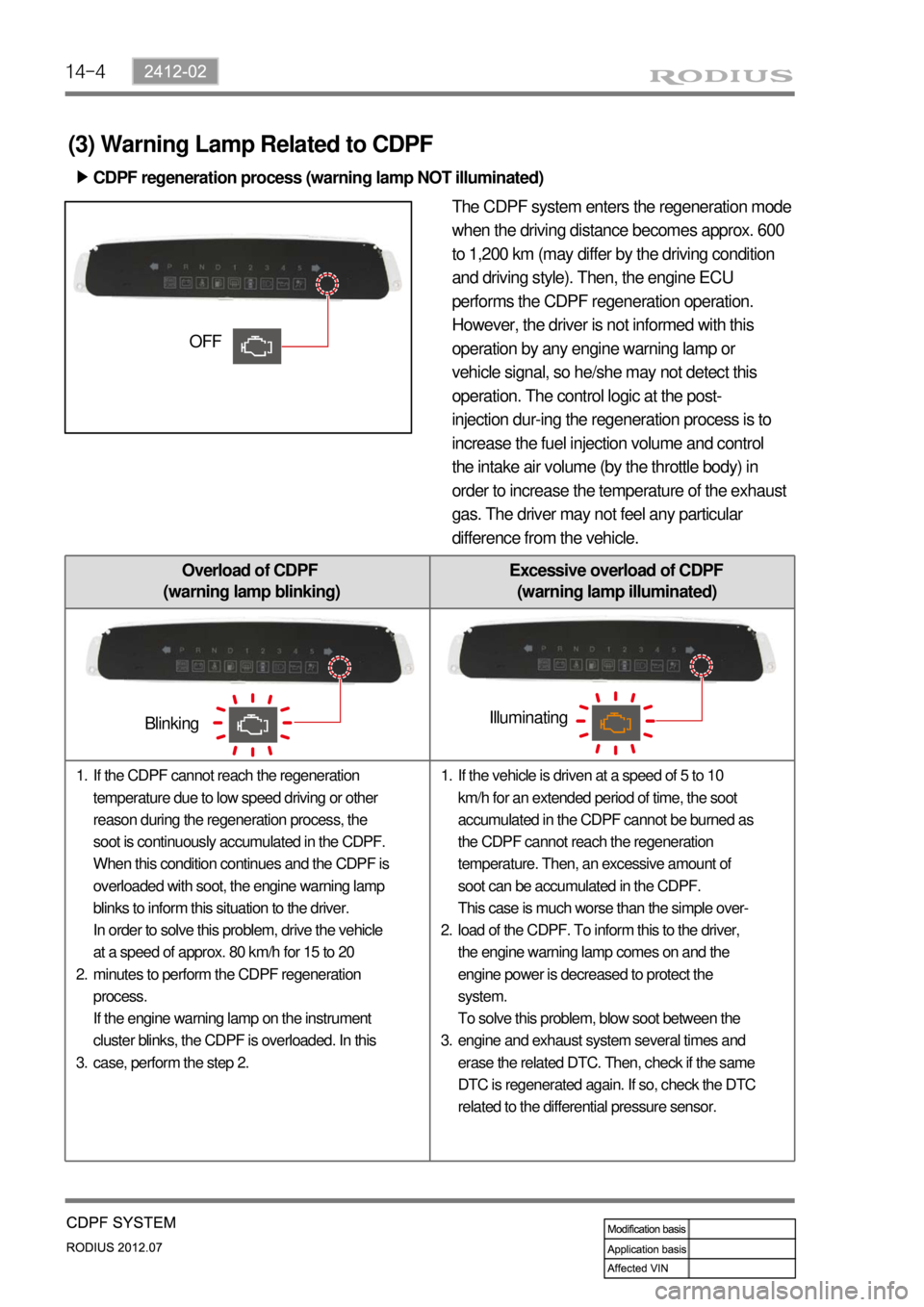

Overload of CDPF

(warning lamp blinking)Excessive overload of CDPF

(warning lamp illuminated)

(3) Warning Lamp Related to CDPF

CDPF regeneration process (warning lamp NOT illuminated) ▶

The CDPF system enters the regeneration mode

when the driving distance becomes approx. 600

to 1,200 km (may differ by the driving condition

and driving style). Then, the engine ECU

performs the CDPF regeneration operation.

However, the driver is not informed with this

operation by any engine warning lamp or

vehicle signal, so he/she may not detect this

operation. The control logic at the post-

injection dur-ing the regeneration process is to

increase the fuel injection volume and control

the intake air volume (by the throttle body) in

order to increase the temperature of the exhaust

gas. The driver may not feel any particular

difference from the vehicle.

If the CDPF cannot reach the regeneration

temperature due to low speed driving or other

reason during the regeneration process, the

soot is continuously accumulated in the CDPF.

When this condition continues and the CDPF is

overloaded with soot, the engine warning lamp

blinks to inform this situation to the driver.

In order to solve this problem, drive the vehicle

at a speed of approx. 80 km/h for 15 to 20

minutes to perform the CDPF regeneration

process.

If the engine warning lamp on the instrument

cluster blinks, the CDPF is overloaded. In this

case, perform the step 2. 1.

2.

3.If the vehicle is driven at a speed of 5 to 10

km/h for an extended period of time, the soot

accumulated in the CDPF cannot be burned as

the CDPF cannot reach the regeneration

temperature. Then, an excessive amount of

soot can be accumulated in the CDPF.

This case is much worse than the simple over-

load of the CDPF. To inform this to the driver,

the engine warning lamp comes on and the

engine power is decreased to protect the

system.

To solve this problem, blow soot between the

engine and exhaust system several times and

erase the related DTC. Then, check if the same

DTC is regenerated again. If so, check the DTC

related to the differential pressure sensor. 1.

2.

3.

OFF

BlinkingIlluminating

Page 316 of 715

14-6

Differential Pressure Sensor

Calculates the amount of PM

collected by reading the pressure

difference between pre-CDPF and

post-CDPF.Engine ECU (D20DTR)

Post injection

Electric Throttle Body

Regulates the air intake

rate.CDPF

(DOC+DPF)Front EGT Sensor

Measures the combustion

temperature.

Rear EGT Sensor

Measures the CDPF

temperature.

2. COMPONENTS

For details, refer to section "Engine Control". *

Page 317 of 715

14-72412-02

3. INPUT/OUTPUT DEVICES

Front temperature sensor: This sensor is installed at the inlet of DOC and detects whether the

DOC can burn (oxidize) the post-injected fuel or not.

Rear temperature sensor: This sensor is installed at the inlet of DPF and monitors that the

temperature of the exhaust gas is kept at 600℃. 1.

2.

<0070008d0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c0047008c009f008a008c008c008b009a0047005d005700570b4500530047009b008f008c004700930090008d008c00470096008d0047006a006b0077006d004700

8a0088009500470089008c00470099008c008b009c008a008c>d. So the amount of fuel

post-injection is decreased.

<0070008d0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c0047008b009900960097009a0047009c0095008b008c00990047005d005700570b4500530047009b008f008c004700990088009b008c00470096008d0047009900

8c008e008c0095008c00990088009b0090009600950047008a>an be decreased. So the

amount of fuel post-injection is increased. -

-

Differential pressure sensor: This sensor checks the amount of PM collected by calculating the

pressure difference between before and after the CDPF.

Electric throttle valve: This valve reduces the intake air flow to raise the temperature of the

exhaust gas when the CDPF is operating during idling. 3.

4.

Page 318 of 715

14-8

4. POST-INJECTION AND AIR MASS CONTROL

A DPS (Differential Pressure Sensor) measures the pressure difference between before and after

the CDPF and detects whether the soot is collected in the CDPF or not. If PM is collected in the

CDPF (In this case the pressure difference between before and after the CDPF exceeds the

specified value. Normally, the system sends the signal when the driving distance becomes approx.

600 to 1,200 km), the temperature of exhaust gas is increased and the post-injection is started for

regeneration. The amount of fuel post-injection is controlled by the exhaust gas temperature

<0094008c0088009a009c0099008c008b0047008900a00047009b008f008c00470099008c008800990047009b008c00940097008c00990088009b009c0099008c0047009a008c0095009a00960099005500470070008d0047009b008f008c0047009b008c00

940097008c00990088009b009c0099008c00470090009a0047>less than 600℃, the amount of

post-injection is increased to increase the regeneration temperature. Otherwise, the fuel injection

amount is decreased or the fuel is not injected.

When the engine is running with low load, the intake air amount is also controlled as well as fuel

injection amount. This function is used to increaser the combustion temperature by increasing the

amount of fuel post-injection with the lowest air amount within the specified control logic.

Page 319 of 715

14-92412-02

Rear temperature sensor

Measure the outlet

temperature of DOC.

This sensor is located at

the rear side of DOC and

monitors the overheating of

CDPF and post injection

volume.

Differential pressure sensor

Measures the difference between

inlet and outlet pressures of

CDPF.

If the difference is higher than the

specified value when collecting

the PM, this makes the post

injection for forced recycling of

PM.

Front temperature sensor

Measures the temperature of

exhaust gas.

This sensor is located at the rear

side of exhaust manifold and

monitors the temperature of

combusted gas to prevent the

exhaust system from overheating.

When the temperature gets

higher, this sensor cuts off the

fuel delivery and controls the EGR

to lower the temperature.

Engine ECU (D20DTR)

T-MAP sensorIntake air

mass

Measures

the

excessive

amount of

PM.

Injector (C31)

Controls the post injection.

Electric throttle body

Controls the intake air

mass.

HFM sensor

Wide band

oxygen

sensor

Boost

pressure/

temperature

Page 320 of 715

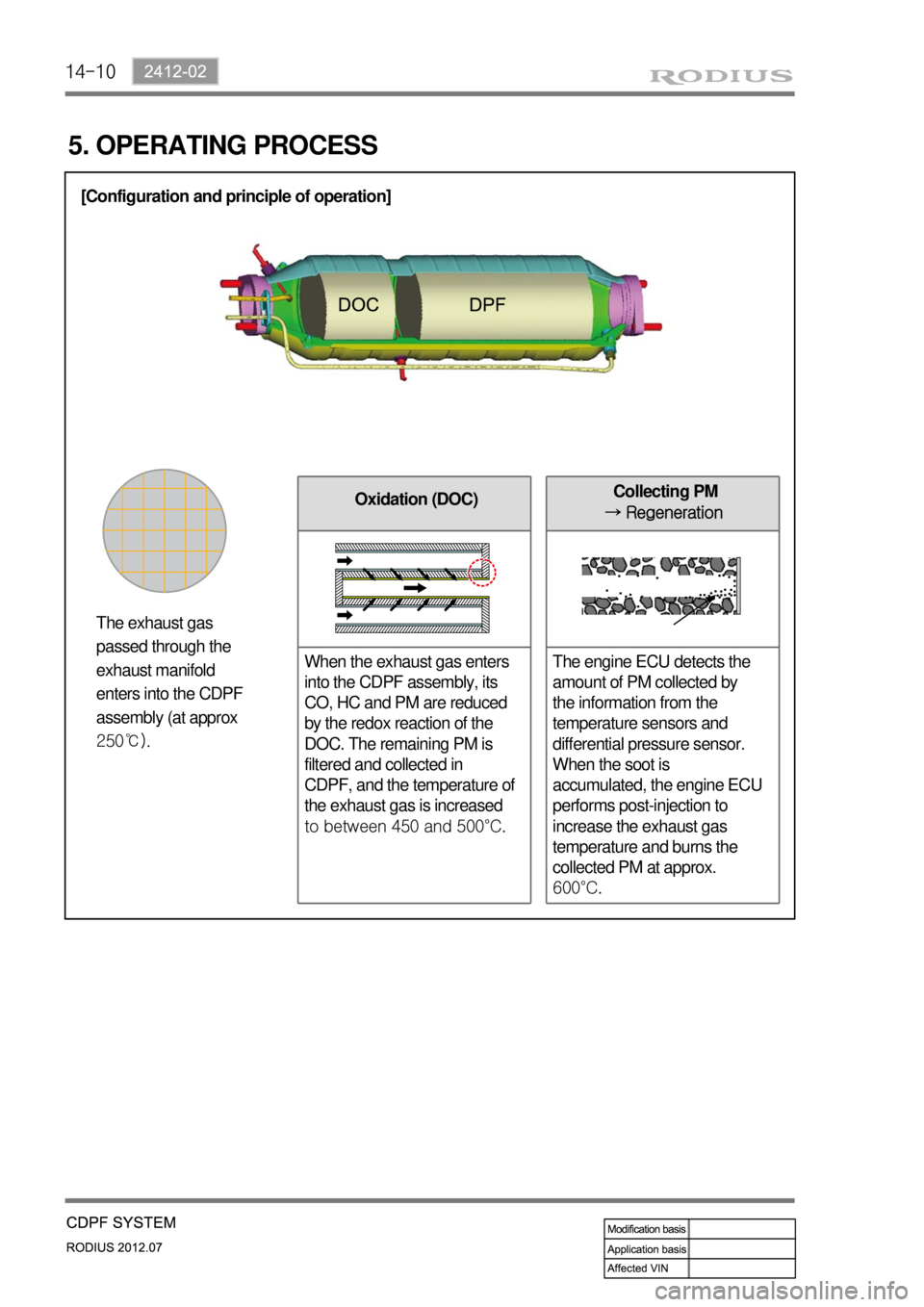

14-10

Collecting PM

→ Regeneration

The engine ECU detects the

amount of PM collected by

the information from the

temperature sensors and

differential pressure sensor.

When the soot is

accumulated, the engine ECU

performs post-injection to

increase the exhaust gas

temperature and burns the

collected PM at approx.

600°C.Oxidation (DOC)

When the exhaust gas enters

into the CDPF assembly, its

CO, HC and PM are reduced

by the redox reaction of the

DOC. The remaining PM is

filtered and collected in

CDPF, and the temperature of

the exhaust gas is increased

to between 450 and 500°C.

5. OPERATING PROCESS

[Configuration and principle of operation]

The exhaust gas

passed through the

exhaust manifold

enters into the CDPF

assembly (at approx

250℃).

Page 323 of 715

14-132412-02

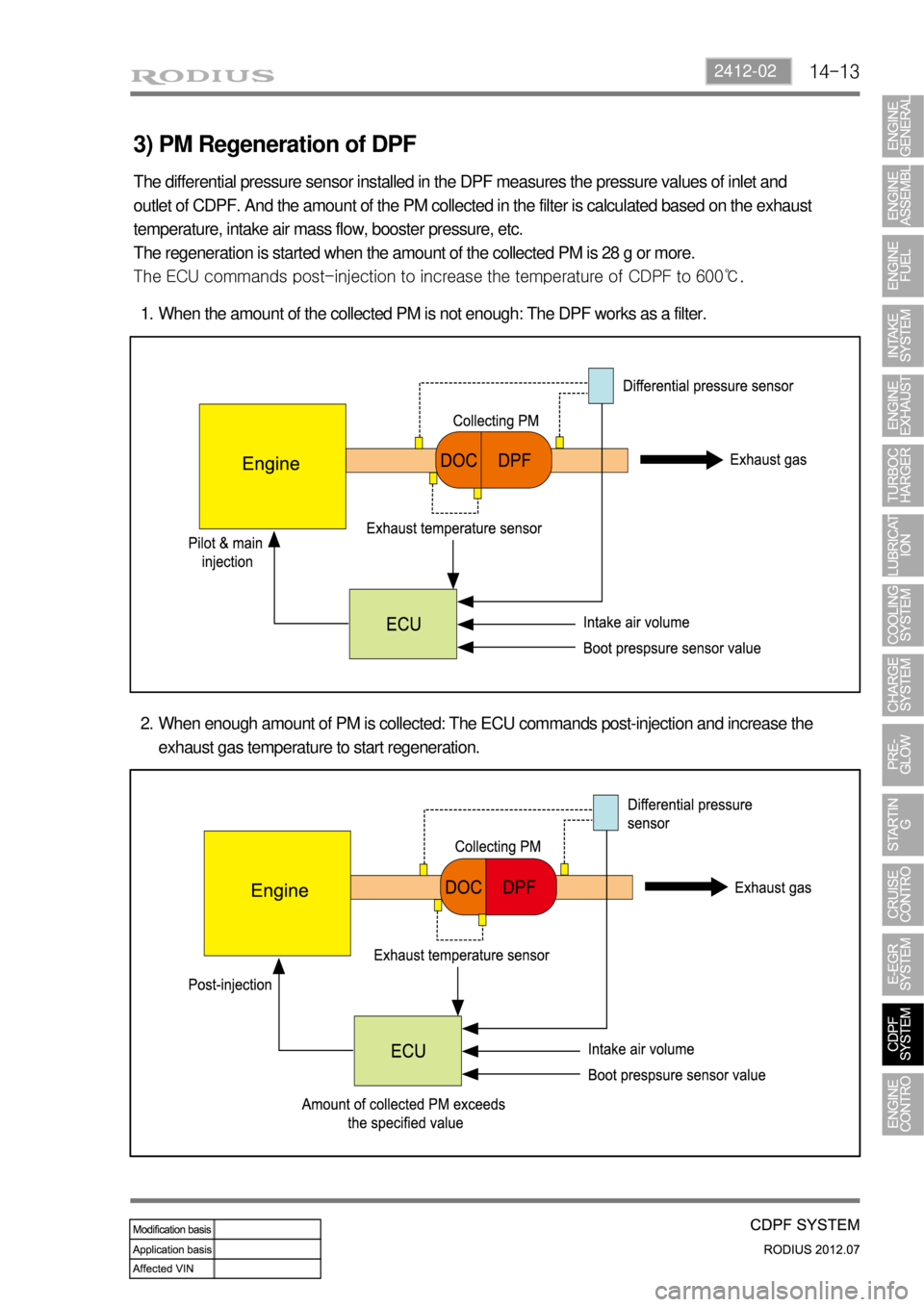

3) PM Regeneration of DPF

The differential pressure sensor installed in the DPF measures the pressure values of inlet and

outlet of CDPF. And the amount of the PM collected in the filter is calculated based on the exhaust

temperature, intake air mass flow, booster pressure, etc.

The regeneration is started when the amount of the collected PM is 28 g or more.

<007b008f008c0047006c006a007c0047008a00960094009400880095008b009a004700970096009a009b0054009000950091008c008a009b0090009600950047009b0096004700900095008a0099008c0088009a008c0047009b008f008c0047009b008c00

940097008c00990088009b009c0099008c00470096008d0047>CDPF to 600℃.

When the amount of the collected PM is not enough: The DPF works as a filter. 1.

When enough amount of PM is collected: The ECU commands post-injection and increase the

exhaust gas temperature to start regeneration. 2.

Page 331 of 715

15-6

Fuel Rail Pressure SensorFront EGT Sensor

Differential Pressure SensorCamshaft Position SensorRear EGT Sensor

Page 334 of 715

15-90000-00

Fuel rail pressure Water sensor

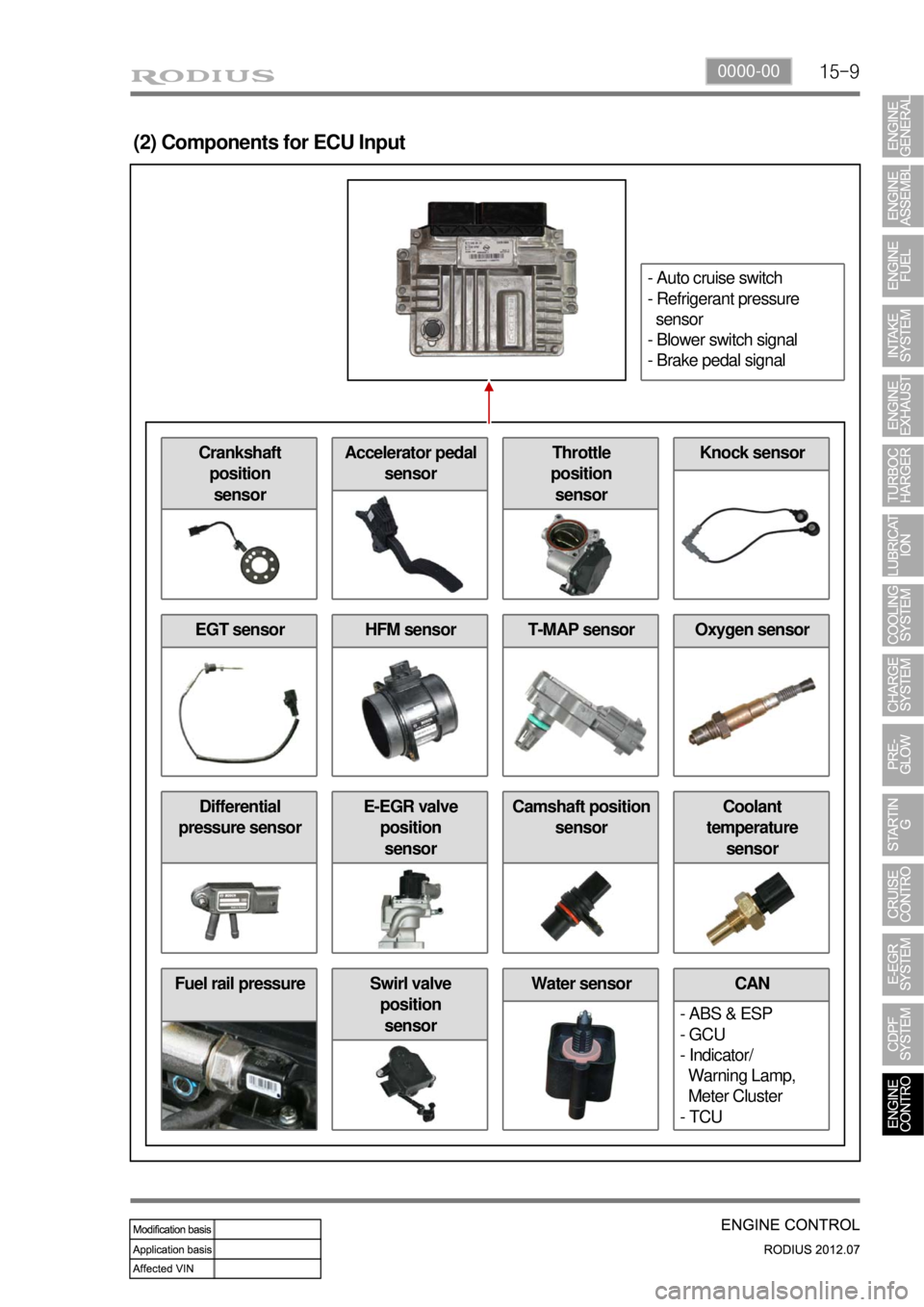

(2) Components for ECU Input

CAN

- ABS & ESP

- GCU

- Indicator/

Warning Lamp,

Meter Cluster

- TCUSwirl valve

position

sensor

Differential

pressure sensorE-EGR valve

position

sensorCamshaft position

sensorCoolant

temperature

sensor

EGT sensorHFM sensorOxygen sensorT-MAP sensor

Crankshaft

position

sensorAccelerator pedal

sensorThrottle

position

sensorKnock sensor

- Auto cruise switch

- Refrigerant pressure

sensor

- Blower switch signal

- Brake pedal signal