engine SSANGYONG TURISMO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 159 of 796

01-150000-00

7. CODING AND INITIALIZATION

1) Engine Variant Coding

Unit Selection Description

PTC auxiliary heater NO For PTC auxiliary heaterequipped vehicle,

select"YES".

YES

Glow plug Relay (K-line) Select "AQGS".

AQGS (CAN)

Transmission MT 5-speed Select the appropriate system.

MT 6-speed

AT 5-speed (DC 5AT)

AT 6-speed (DSI 6AT)

AT 7-speed (DC 7AT)

Pressure sensor

forA/C refrigerantNOSelect “Refrigerant pressure sensor”.

Refrigerant Pressure Sensor

Immobilizer NO Select "YES" if the vehicle has

immobilizer.

YES

Vehicle speed input

typeCAN Select "CAN" if the vehicle has ABS or

ESP

WIRE

Cooling fan Relay Select "PWM".

PWM

Auto cruise NO Select "YES" if the vehicle hascruise

control.

YES

Engine level control NO Select "NO".

YES

G-sensor NOABS: Select “NO”.

4WD ABS or ESP: Select “YES”.

YES

SMART key NO Select "NO".

YES

Page 161 of 796

01-170000-00

Unit Selection Description

Sedan/Limousine Sedan (RV) Select "Sedan (RV)".

Limousine

Vehicle code

(Platform)Rodius Select "Rodius".

Rexton

Korando C

Kyron

Korando Sport

Vehicle code (Engine) D32DTSelect “D20DTR”.

D27DT

D27DTP

D20DTR

ECU coding status ECU not codedSelect “ECU coded”.

ECU coded

Signal not valid

Not defind

Page 162 of 796

02-30000-00

Cylinder block Piston protrusion 0.475 to 0.745mm -

Piston ring TOP ring end gap 0.20 to 0.40 mm -

2nd ring end gap 0.35 to 0.50 mm -

3rd ring end gap 0.2 to 0.40 mm -

Offset 0.3mm -

Head gasket Piston protrusion 0.475 to 0.540 1.2t -

0.541 to 0.649 1.3t -

0.650 to 0.745 1.4t -

Valve Clearance between

valve and pistonIntake 1.12 mm -

Exhaust 1.09 mm -

Valve recess Intake 0.6 to 1.0 mm -

Exhaust 0.6 to 1.0 mm -

1. ENGINE ASSEMBLY

Unit Description Specification Remark

Cylinder head Height 131.9 to 132.1 mm -

Flatness below 0.1 mm -

Valve protrusion Intake valve 0.6 to 1.0 mm -

Exhaust valve 0.6 to 1.0 mm -

Flatness on manifold

sideIntake manifold 0.08 mm -

Exhaust manifold 0.08 mm -

Connecting rod End play 0.5 to 0.31 mm -

Camshaft

Axial end playIntake 0.1 to 0.35 mm -

Exhaust 0.1 to 0.35 mm -

Camshaft position

sensorDistance between Camshaft position

sensor and sprocket0.20 to 1.80 mm -

Page 163 of 796

02-4

2. MAJOR CHANGES

Rear Engine Mounting Insulator (for 4WD)

Design changed for reducing abnormal noise during driving

Page 167 of 796

02-8

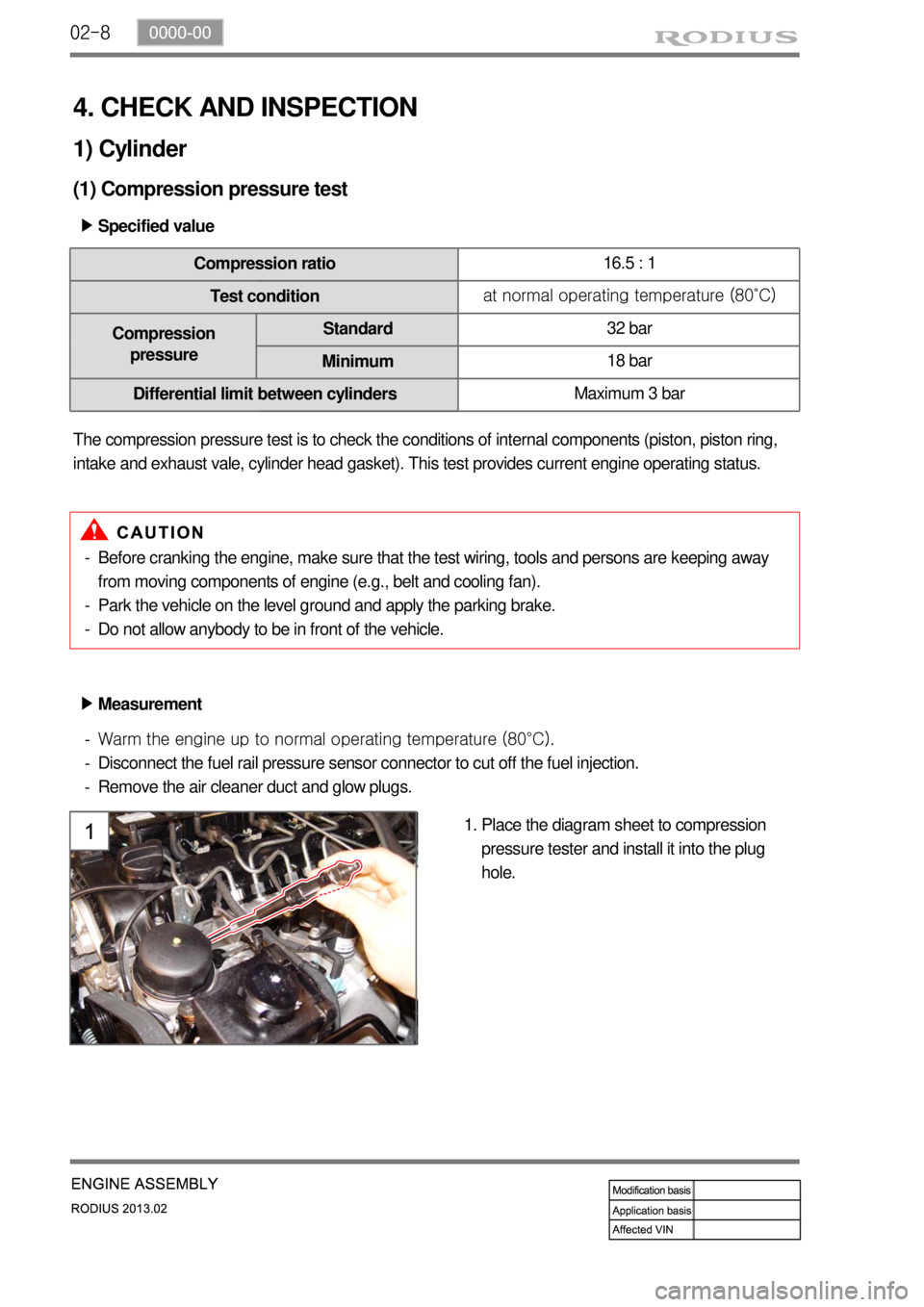

4. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value ▶

Compression ratio16.5 : 1

Test conditionat normal operating temperature (80˚C)

Compression

pressureStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston ring,

intake and exhaust vale, cylinder head gasket). This test provides current engine operating status.

Measurement ▶

Warm the engine up to normal operating temperature (80°C).

Disconnect the fuel rail pressure sensor connector to cut off the fuel injection.

Remove the air cleaner duct and glow plugs. -

-

-

Place the diagram sheet to compression

pressure tester and install it into the plug

hole. 1. Before cranking the engine, make sure that the test wiring, tools and persons are keeping away

from moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

Page 168 of 796

02-90000-00

(2) Cylinder pressure leakage test

If the measured value of the compression pressure test is not within the specifications, perform the

cylinder pressure leakage test.Specified value ▶

Perform this test in the sequence of firing order.

Do not test the cylinder pressure leakage with wet type test procedure. (do not inject the engine oil

into the combustion chamber) -

-

Test condition: normal engine operating

temperature (80˚C)Specified value

Whole engine below 25%

at valve and cylinder head gasket below 10%

at piston ring below 20%

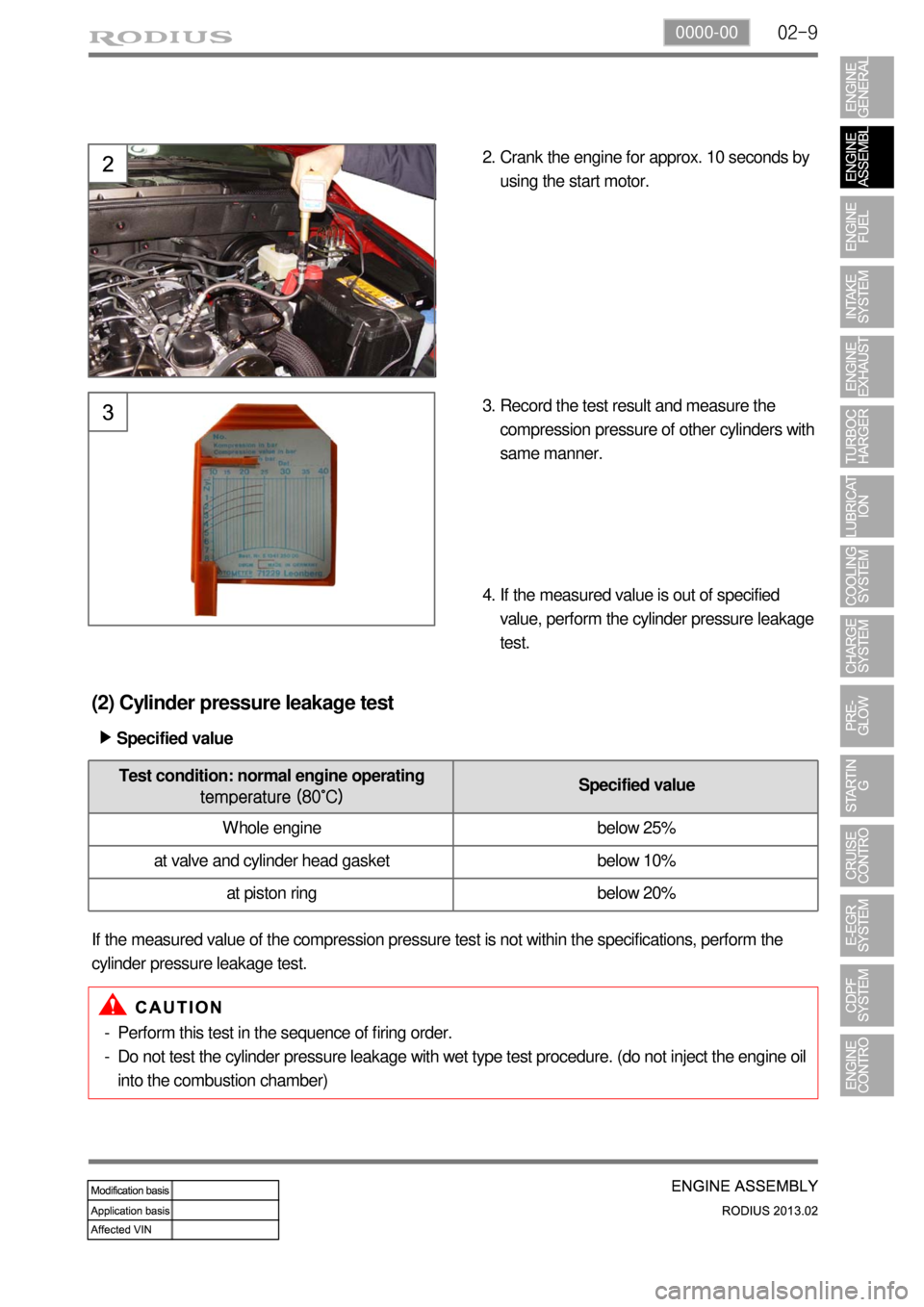

Crank the engine for approx. 10 seconds by

using the start motor. 2.

Record the test result and measure the

compression pressure of other cylinders with

same manner. 3.

If the measured value is out of specified

value, perform the cylinder pressure leakage

test. 4.

Page 171 of 796

02-12

5. GUIDELINES ON ENGINE SERVICE

To prevent personal injuries and vehicle damages that can be caused by mistakes during engine and

unit inspection/repair and to secure optimum engine performance and safety after service works, basic

cautions and service work guidelines that can be easily forgotten during engine service works are

described in.

Cautions before service works

For safe and correct works, you must observe the working procedures and instructions in this

manual. And, use the designated tools as follow:

Engine stand / Heavy duty engine jack

To prevent the engine from starting abruptly, do not allow anybody to get in the vehicle while

servicing in engine compartment.

Before work on engine and each electrical equipment, be sure to disconnect battery negative (-)

terminal.

Before service works, be sure to prepare the works by cleaning and aligning work areas.

Do not allow the foreign material get into the fuel injection system.

When removing the engine, use only the safety hook on engine and engine hanger. Do not

support the bottom of oil pan with a jack.

Engine and accessories

Completely drain the engine oil, coolant and fuel from engine before removal.

Before disassembling/assembling the engine components, carefully read the working procedures

in this manual.

Make sure to keep the specified tightening torques during installation.

Clean and properly lubricate the parts before reassembly.

Carefully check that there are not any interference while servicing. ▶

-

-

-

-

-

-

▶

-

-

-

-

-

Page 172 of 796

02-130000-00

Electrical equipment ▶

Electric devices should be handled more carefully.

Currently, the engine has a lot of electric devices. there could be poor engine performance, incomplete

combustion and other abnormal symptoms due to short circuit or poor contact.

Before work on engine and each electrical equipment, be sure to disconnect battery negative (-)

terminal.

When replacing the electric device, use only genuine part and check the conditions of connections

and grounds. Loosened connection or ground make cause a fire and personal injury. -

-Fuel and lubrication system ▶

Do not allow the fluid and engine oil to make contact with the body paintwork and hoses.

If work on the fluid system such as fuel and oil, working area should be well ventilated and smoking

should be prohibited.

Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and nuts

should be tightened as specified.

After removal/installation works, be sure to check whether there is leak on the connecting section. -

-

-

-

If fine dust or foreign material enters into DI engine's fuel system, there can be serious damages in HP

pump and injectors. Thus, be sure to plug the inlets of removed fuel line components with cap and

protect removed parts not to be contaminated with dirt. (Refer to cleanness in this manual while

working on DI engine fuel system)

Page 173 of 796

02-14

D20DTR Engine

1. BELT LAYOUT

It is single drive type and uses FEAD (Front End Accessories Drive) design to make a compact layout.

Components ▶

HPS

(Hydraulic Power Steering)

1 Crankshaft pulley (DDU)

2 Auto tensioner

3 Tensioner pulley

4 Vacuum pump

5 A/C compressor pulley

6 Alternator pulley

7 Water pump pulley

8 Idle pulley #1

9 Idle pulley #2

10 Power steering pump pulley

Page 176 of 796

02-170000-00

2) Belt Tensioner

(1) Overview

The torque deviation from crankshaft affects the components in belt drive system and the belt

movement. The auto tensioner system is to adjust this deviation automatically.

In D20DTR engine, one of the mechanical tensioner, pivot damped tensioner is used to keep the

damping force, system reliability and durability. The single belt drive system needs to use the automati

c

belt tensioning device to transfer the power to pulleys effectively. To get this, the tensioner uses the

spring and damping unit.

(2) Location

Belt tensioner