fuel filter SSANGYONG TURISMO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 148 of 796

01-4

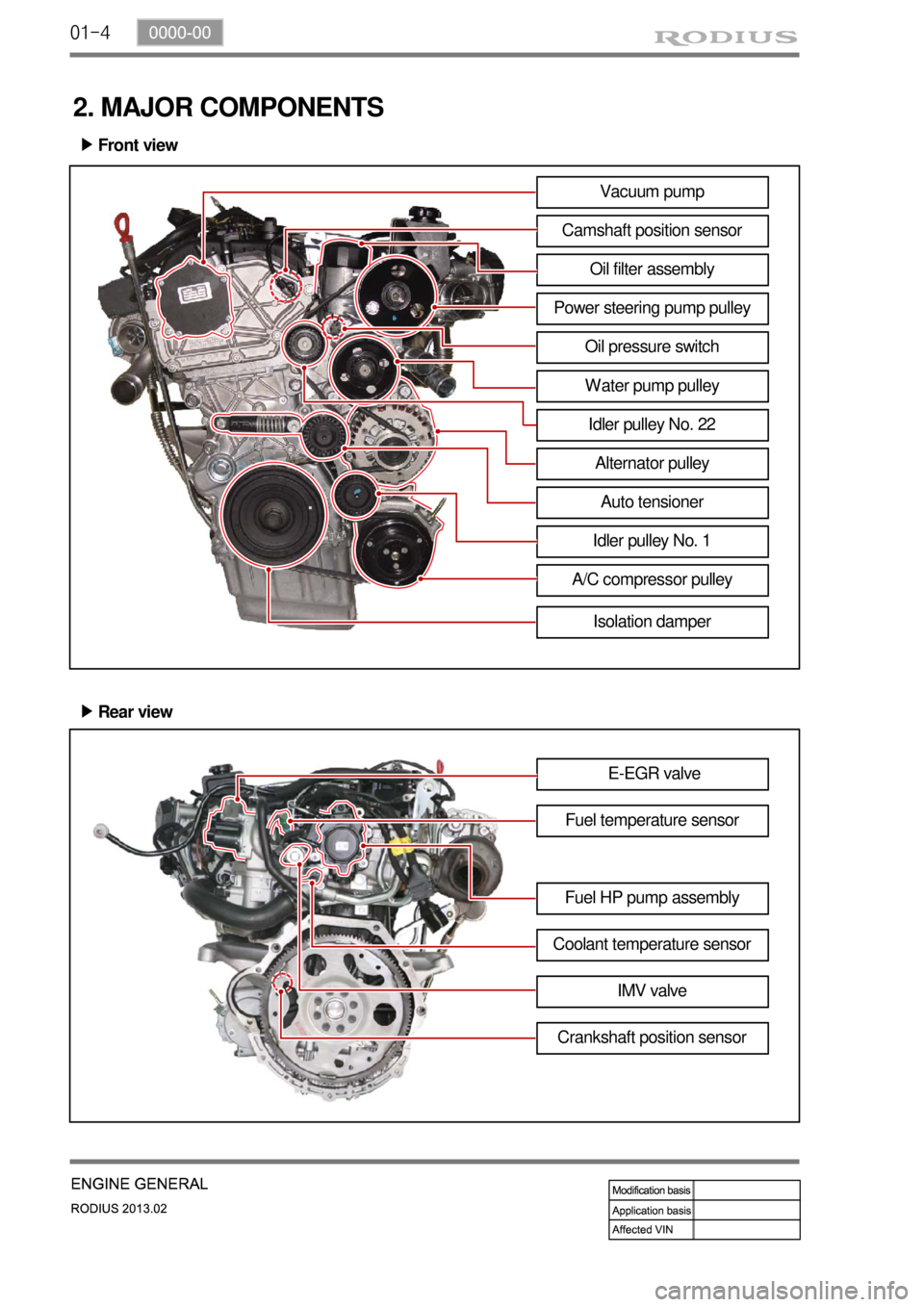

2. MAJOR COMPONENTS

Front view ▶

Vacuum pump

Camshaft position sensor

Oil filter assembly

Power steering pump pulley

Oil pressure switch

Water pump pulley

Idler pulley No. 22

Alternator pulley

Auto tensioner

Idler pulley No. 1

A/C compressor pulley

Rear view ▶

E-EGR valve

Fuel temperature sensor

Fuel HP pump assembly

Coolant temperature sensor

Crankshaft position sensorIMV valve

Isolation damper

Page 151 of 796

01-70000-00

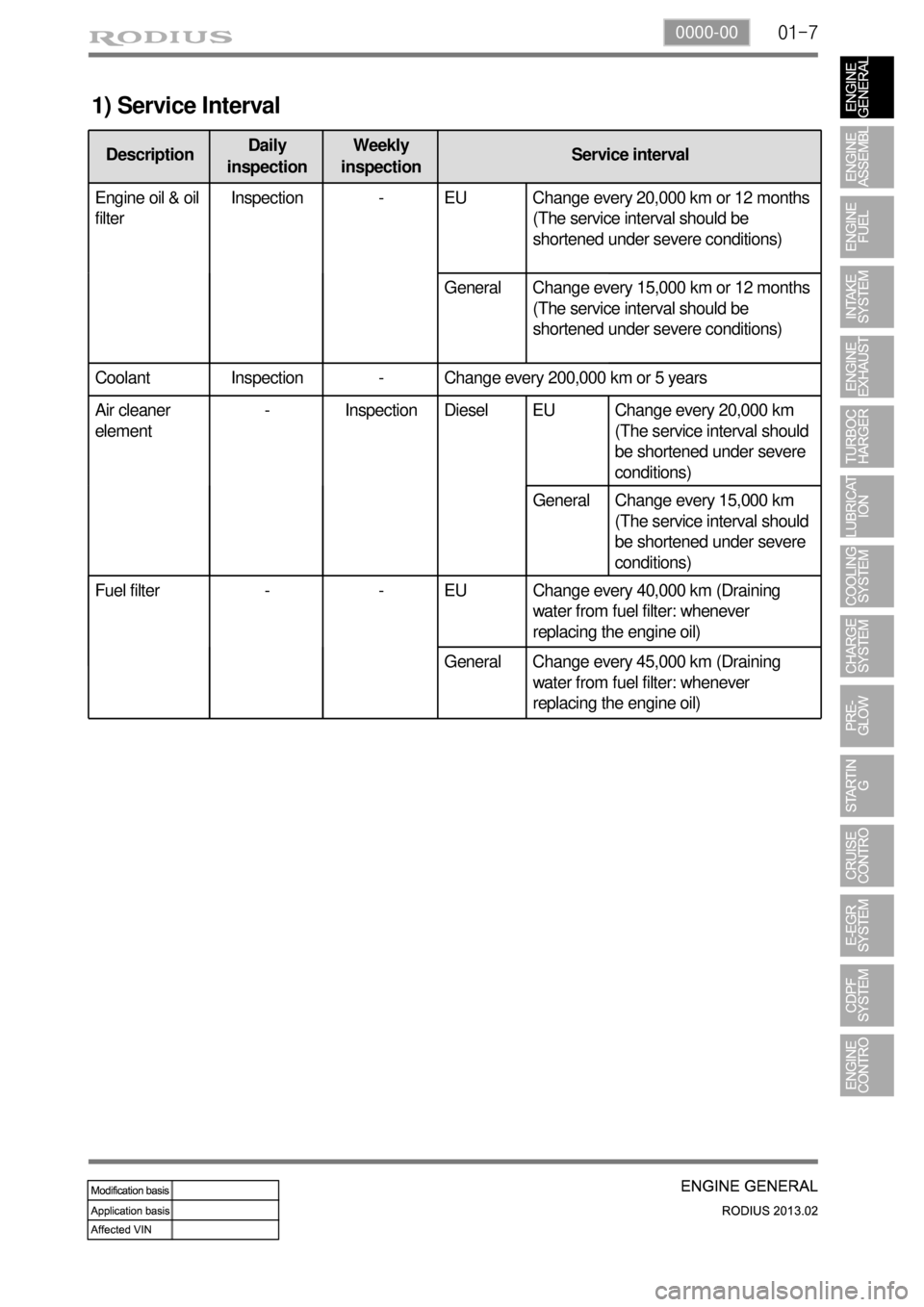

1) Service Interval

DescriptionDaily

inspectionWeekly

inspectionService interval

Engine oil & oil

filterInspection - EU Change every 20,000 km or 12 months

(The service interval should be

shortened under severe conditions)

General Change every 15,000 km or 12 months

(The service interval should be

shortened under severe conditions)

Coolant Inspection - Change every 200,000 km or 5 years

Air cleaner

element- Inspection Diesel EU Change every 20,000 km

(The service interval should

be shortened under severe

conditions)

General Change every 15,000 km

(The service interval should

be shortened under severe

conditions)

Fuel filter - - EU Change every 40,000 km (Draining

water from fuel filter: whenever

replacing the engine oil)

General Change every 45,000 km (Draining

water from fuel filter: whenever

replacing the engine oil)

Page 158 of 796

01-14

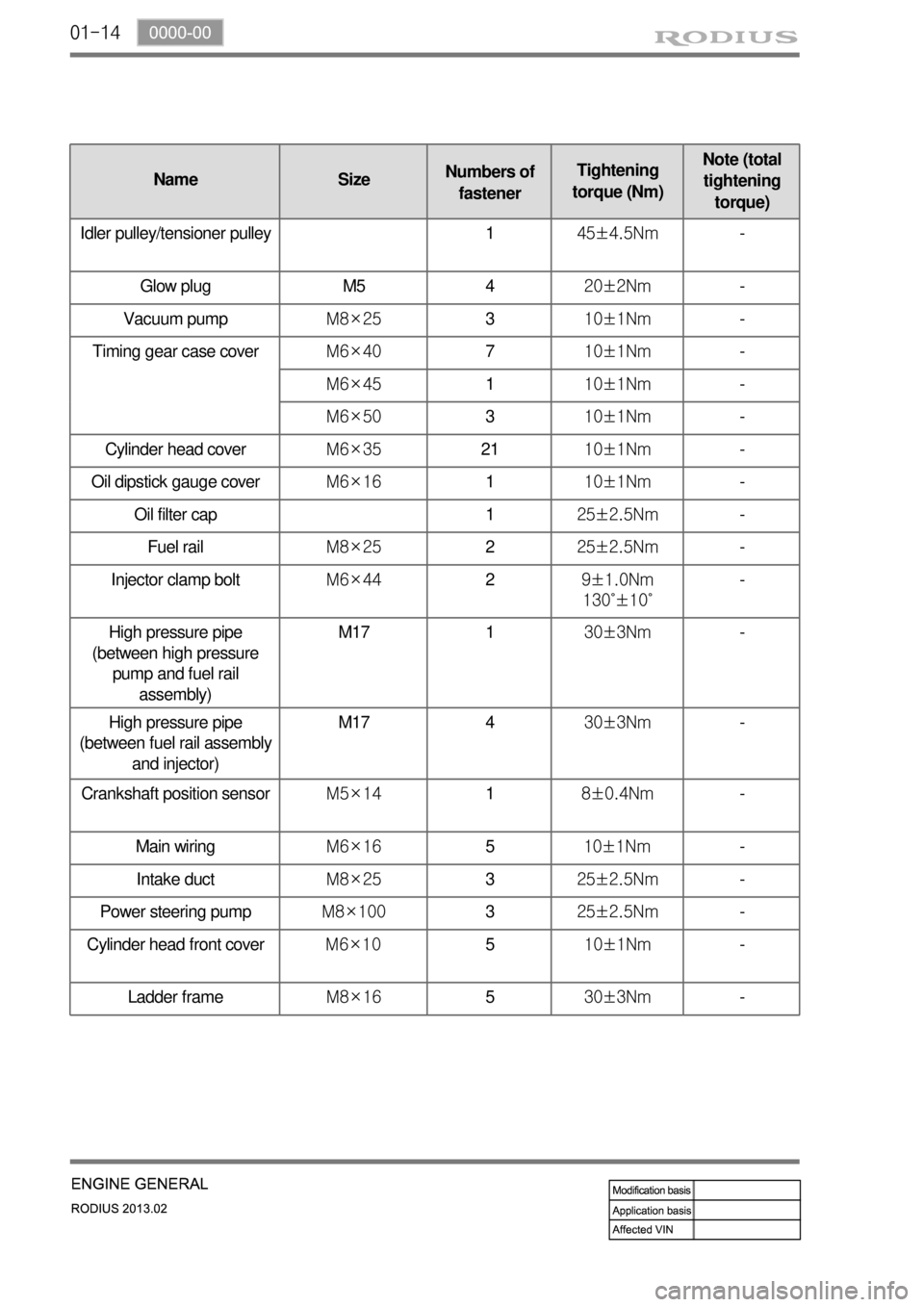

Name SizeNumbers of

fastenerTightening

torque (Nm)Note (total

tightening

torque)

Idler pulley/tensioner pulley 1 45±4.5Nm -

Glow plug M5 4 20±2Nm -

Vacuum pumpM8×25 3 10±1Nm -

Timing gear case coverM6×40 7 10±1Nm -

M6×45 1 10±1Nm -

M6×50 3 10±1Nm -

Cylinder head coverM6×35 21 10±1Nm -

Oil dipstick gauge coverM6×16 1 10±1Nm -

Oil filter cap 1 25±2.5Nm -

Fuel railM8×25 2 25±2.5Nm -

Injector clamp boltM6×44 2 9±1.0Nm

130˚±10˚ -

High pressure pipe

(between high pressure

pump and fuel rail

assembly)M17 1 30±3Nm -

High pressure pipe

(between fuel rail assembly

and injector)M17 4 30±3Nm -

Crankshaft position sensorM5×14 1 8±0.4Nm -

Main wiringM6×16 5 10±1Nm -

Intake ductM8×25 3 25±2.5Nm -

Power steering pumpM8×100 3 25±2.5Nm -

Cylinder head front coverM6×10 5 10±1Nm -

Ladder frameM8×16 5 30±3Nm -

Page 166 of 796

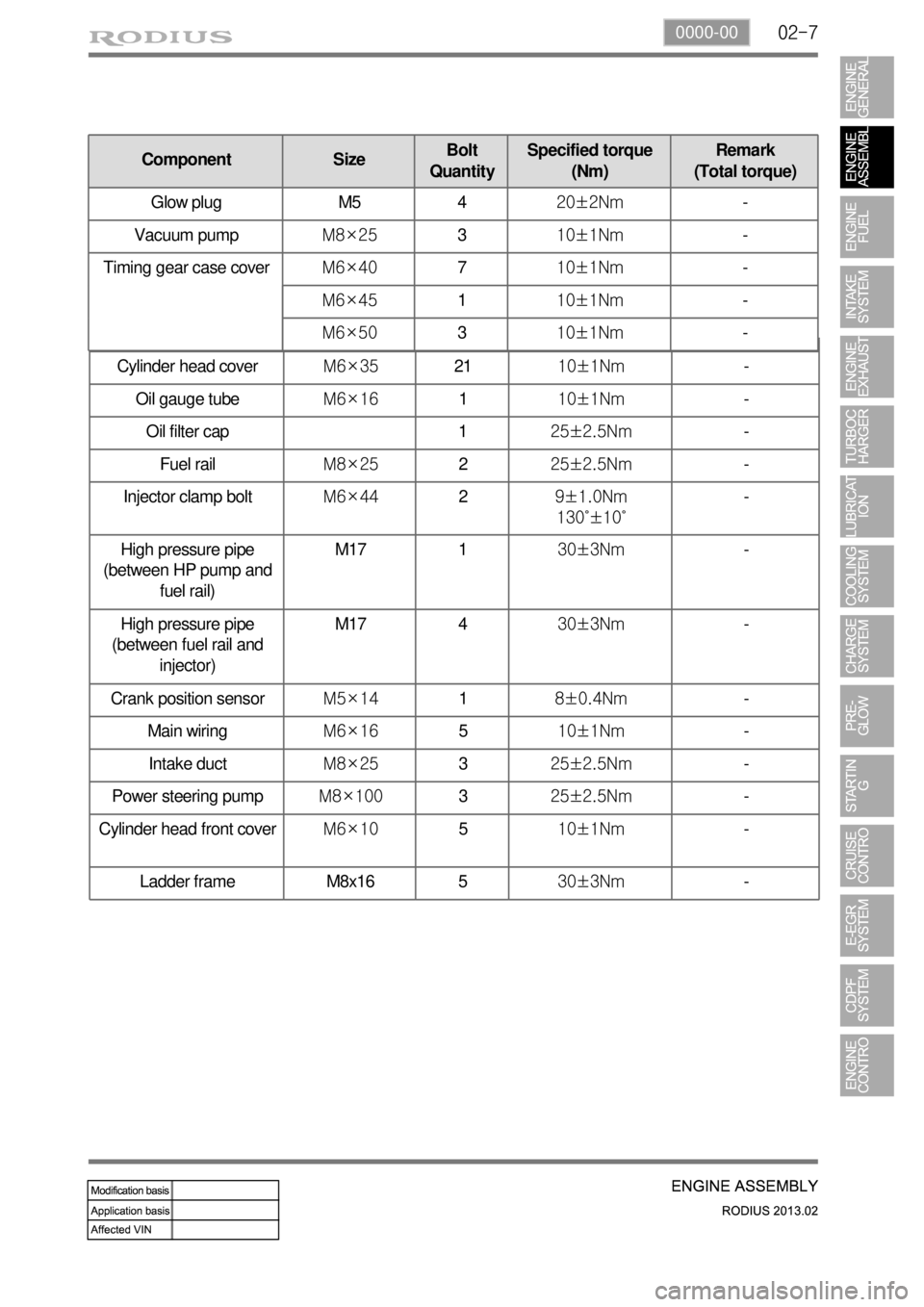

02-70000-00

Cylinder head coverM6×352110±1Nm-

Oil gauge tubeM6×16110±1Nm-

Oil filter cap 125±2.5Nm-

Fuel railM8×25225±2.5Nm-

Injector clamp boltM6×4429±1.0Nm

130˚±10˚-

High pressure pipe

(between HP pump and

fuel rail)M17 130±3Nm-

High pressure pipe

(between fuel rail and

injector)M17 430±3Nm-

Crank position sensorM5×1418±0.4Nm-

Main wiringM6×16510±1Nm-

Intake ductM8×25325±2.5Nm-

Power steering pumpM8×100325±2.5Nm-

Cylinder head front coverM6×10510±1Nm-

Ladder frame M8x16 530±3Nm-

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Glow plug M5 420±2Nm-

Vacuum pumpM8×25310±1Nm-

Timing gear case coverM6×40710±1Nm-

M6×45110±1Nm-

M6×50310±1Nm-

Page 210 of 796

03-32210-01

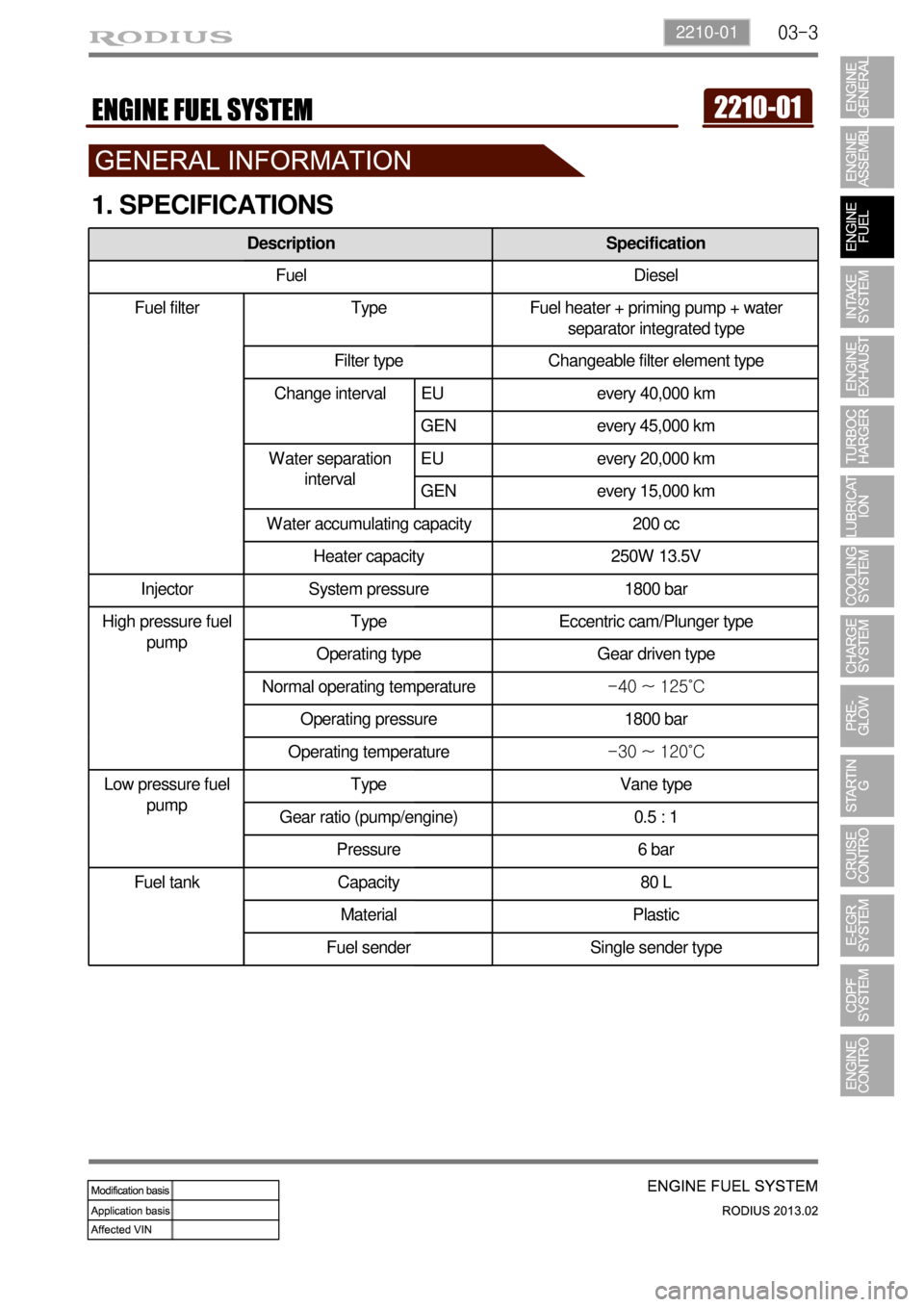

1. SPECIFICATIONS

Description Specification

Fuel Diesel

Fuel filter Type Fuel heater + priming pump + water

separator integrated type

Filter type Changeable filter element type

Change interval EU every 40,000 km

GEN every 45,000 km

Water separation

intervalEU every 20,000 km

GEN every 15,000 km

Water accumulating capacity 200 cc

Heater capacity 250W 13.5V

Injector System pressure 1800 bar

High pressure fuel

pumpType Eccentric cam/Plunger type

Operating type Gear driven type

Normal operating temperature-40 ~ 125˚C

Operating pressure 1800 bar

Operating temperature-30 ~ 120˚C

Low pressure fuel

pumpType Vane type

Gear ratio (pump/engine) 0.5 : 1

Pressure 6 bar

Fuel tank Capacity 80 L

Material Plastic

Fuel sender Single sender type

Page 212 of 796

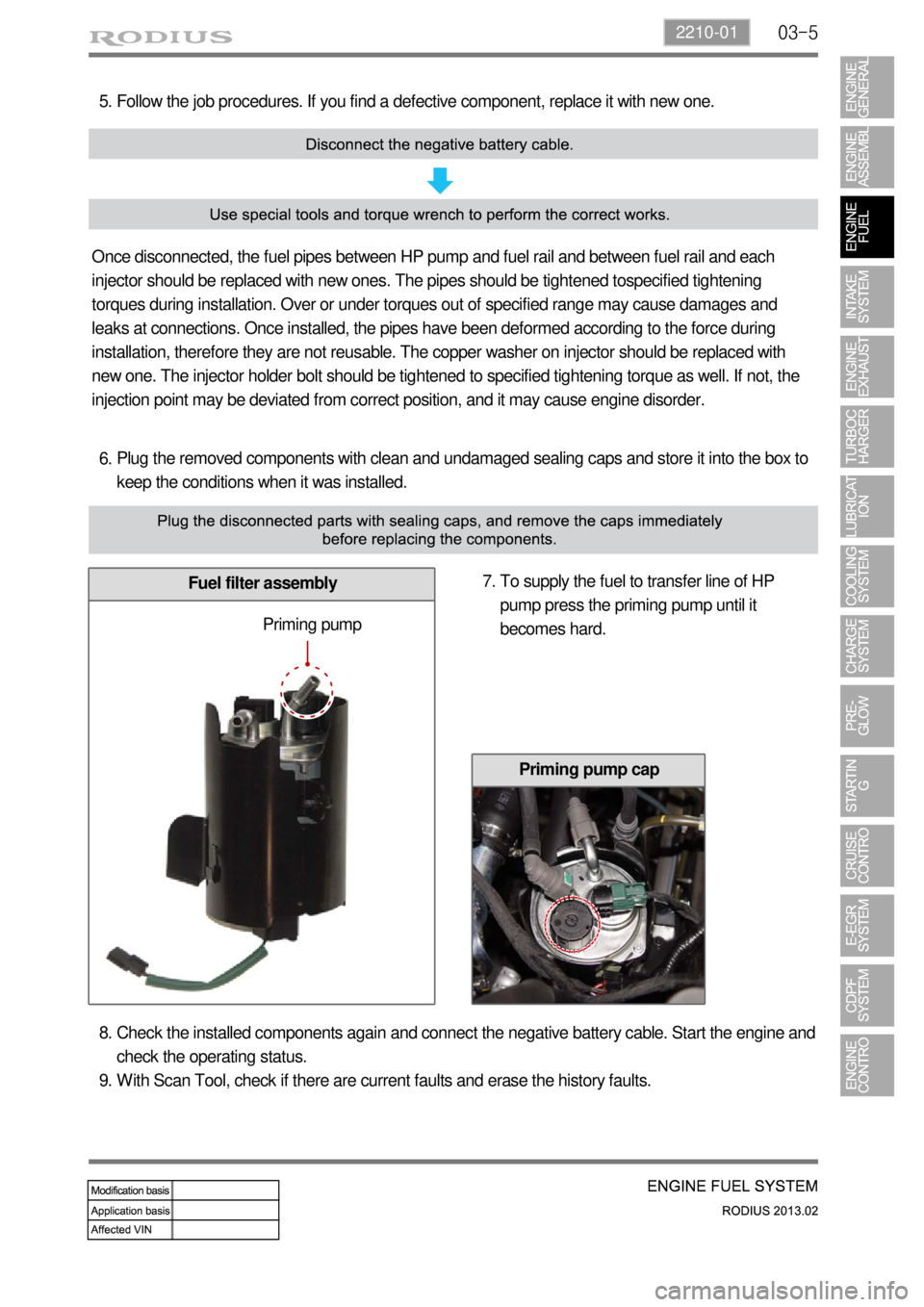

03-52210-01

Plug the removed components with clean and undamaged sealing caps and store it into the box to

keep the conditions when it was installed. 6.

Fuel filter assembly

Follow the job procedures. If you find a defective component, replace it with new one. 5.

Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail and each

injector should be replaced with new ones. The pipes should be tightened tospecified tightening

torques during installation. Over or under torques out of specified range may cause damages and

leaks at connections. Once installed, the pipes have been deformed according to the force during

installation, therefore they are not reusable. The copper washer on injector should be replaced with

new one. The injector holder bolt should be tightened to specified tightening torque as well. If not, the

injection point may be deviated from correct position, and it may cause engine disorder.

To supply the fuel to transfer line of HP

pump press the priming pump until it

becomes hard. 7.

Priming pump

Check the installed components again and connect the negative battery cable. Start the engine and

check the operating status.

With Scan Tool, check if there are current faults and erase the history faults. 8.

9.

Priming pump cap

Page 216 of 796

03-92210-01

Device for high pressure

Device for low pressure

3) DI Engine Fuel System Pressure Test

(1) Test device (Tool kit)

(2) Pre-check

Check-tighten fuel supply line

Check fuel level in fuel tank

Check air in fuel supply line (bubble in fuel supply line or fuel)

Check fuel supply line for leaks (low pressure and high pressure)

Check that specified fuel is used

Check fuel filter for contamination -

-

-

-

-

-

Page 217 of 796

03-10

(3) DI Engine Fuel System Check Procedure

If several DTCs are output simultaneously, check the electric wiring for open or short circuit.

Check the low pressure fuel system and fuel filter and confirm that there are no abnormalities.

Carry out the high pressure fuel system check.

Page 221 of 796

03-14

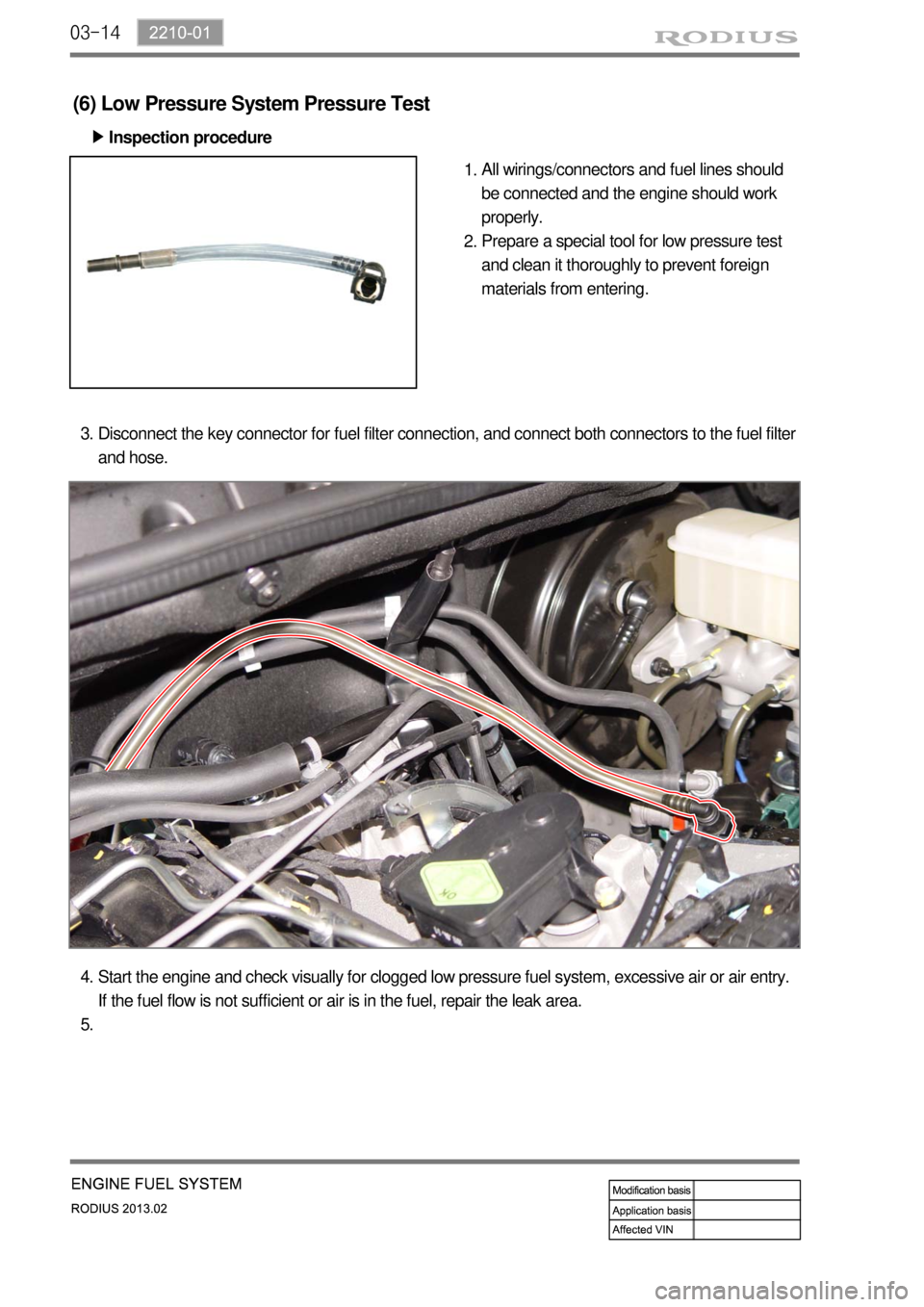

(6) Low Pressure System Pressure Test

Inspection procedure ▶

All wirings/connectors and fuel lines should

be connected and the engine should work

properly.

Prepare a special tool for low pressure test

and clean it thoroughly to prevent foreign

materials from entering. 1.

2.

Disconnect the key connector for fuel filter connection, and connect both connectors to the fuel filter

and hose. 3.

Start the engine and check visually for clogged low pressure fuel system, excessive air or air entry.

If the fuel flow is not sufficient or air is in the fuel, repair the leak area. 4.

5.

Page 225 of 796

03-18

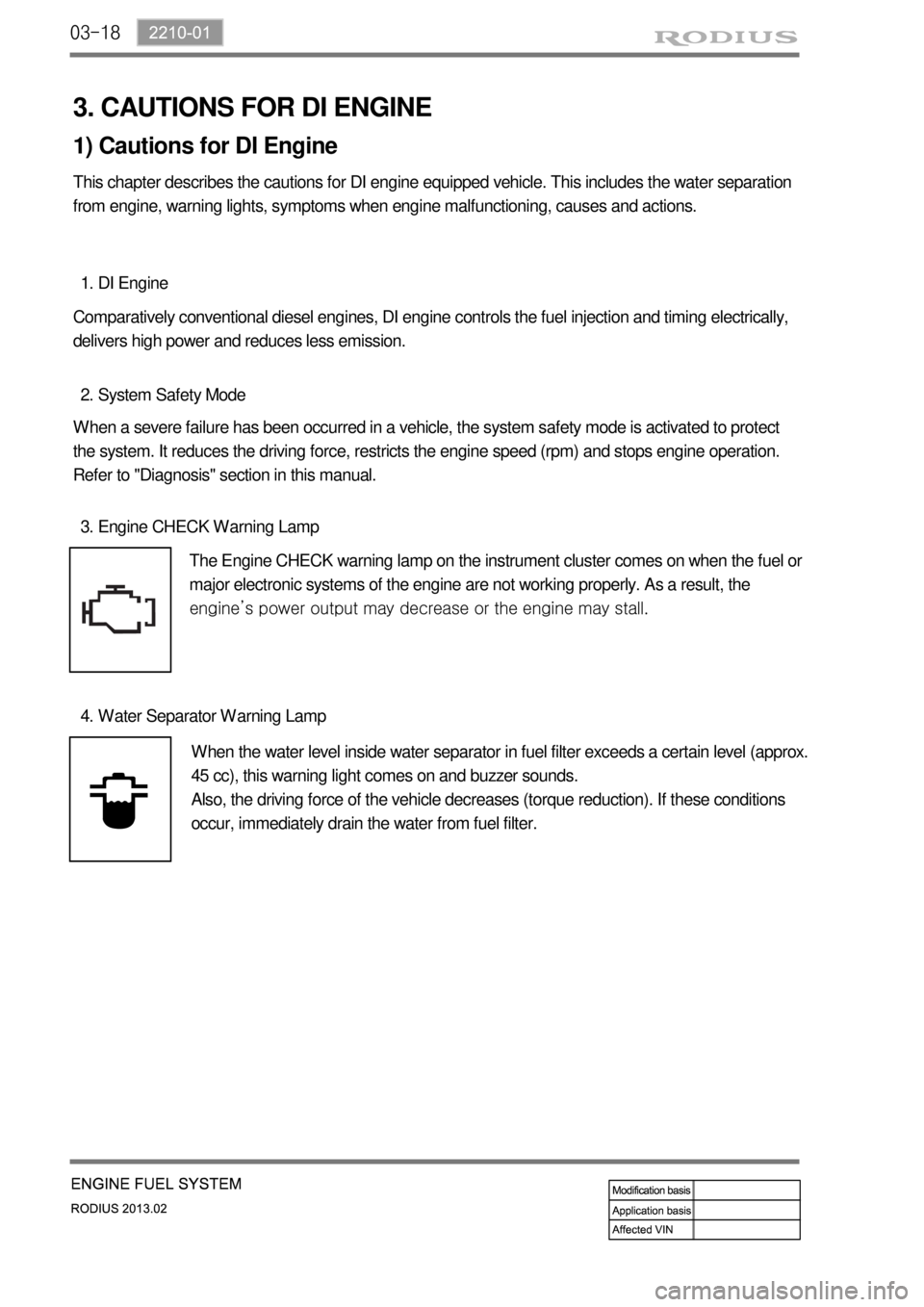

3. CAUTIONS FOR DI ENGINE

1) Cautions for DI Engine

This chapter describes the cautions for DI engine equipped vehicle. This includes the water separation

from engine, warning lights, symptoms when engine malfunctioning, causes and actions.

DI Engine 1.

Comparatively conventional diesel engines, DI engine controls the fuel injection and timing electrically,

delivers high power and reduces less emission.

System Safety Mode 2.

When a severe failure has been occurred in a vehicle, the system safety mode is activated to protect

the system. It reduces the driving force, restricts the engine speed (rpm) and stops engine operation.

Refer to "Diagnosis" section in this manual.

Engine CHECK Warning Lamp 3.

The Engine CHECK warning lamp on the instrument cluster comes on when the fuel or

major electronic systems of the engine are not working properly. As a result, the

engine’s power output may decrease or the engine may stall.

Water Separator Warning Lamp

4.

When the water level inside water separator in fuel filter exceeds a certain level (approx.

45 cc), this warning light comes on and buzzer sounds.

Also, the driving force of the vehicle decreases (torque reduction). If these conditions

occur, immediately drain the water from fuel filter.