service SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1544 of 2870

ME(H4DOTC)-84

MECHANICAL

Cylinder Block

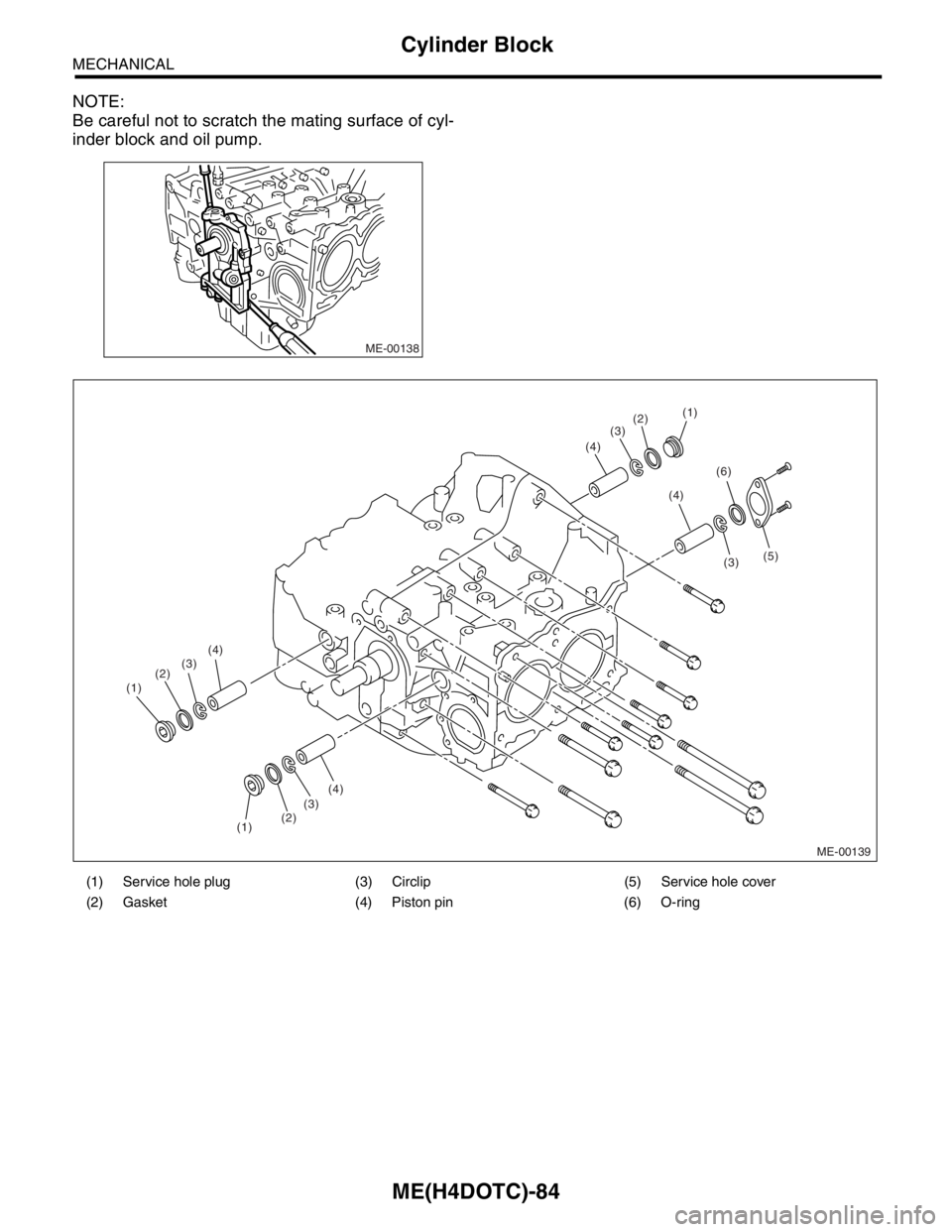

NOTE:

Be careful not to scratch the mating surface of cyl-

inder block and oil pump.

ME-00138

(1) Service hole plug (3) Circlip (5) Service hole cover

(2) Gasket (4) Piston pin (6) O-ring

ME-00139

(3)

(4) (2)(1)

(3)

(4)

(5)

(6)

(2)(3)

(2)

(1)(3)(4)

(4)

(1)

Page 1545 of 2870

![SUBARU FORESTER 2004 Service Repair Manual ME(H4DOTC)-85

MECHANICAL

Cylinder Block

24) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].

25) Rotate the crankshaft to bring #1 and #2 pis-

tons to botto SUBARU FORESTER 2004 Service Repair Manual ME(H4DOTC)-85

MECHANICAL

Cylinder Block

24) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].

25) Rotate the crankshaft to bring #1 and #2 pis-

tons to botto](/img/17/57426/w960_57426-1544.png)

ME(H4DOTC)-85

MECHANICAL

Cylinder Block

24) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].

25) Rotate the crankshaft to bring #1 and #2 pis-

tons to bottom dead center position, and then re-

move the piston circlip through service hole of #1

and #2 cylinders.

26) Draw out the piston pin from #1 and #2 pistons

using ST.

ST 499097600 PISTON PIN REMOVER (2.0

L model)

ST 499097700 PISTON PIN REMOVER (2.5

L model)

NOTE:

Be careful not to confuse the original combination

of piston, piston pin and cylinder.

27) Similarly remove the piston pins from #3 and #4

pistons.

28) Remove the bolts which connect the cylinder

block on the side of #2 and #4 cylinders.29) Back off the bolts which connect the cylinder

block on the side of #1 and #3 cylinders two or

three turns.

30) Set up the cylinder block so that #1 and #3 cyl-

inders are on the upper side, then remove the cyl-

inder block connecting bolts.

31) Separate the cylinder blocks (LH) and (RH).

ME-00140

ME-00141

ME-00142

ST

Page 1549 of 2870

ME(H4DOTC)-89

MECHANICAL

Cylinder Block

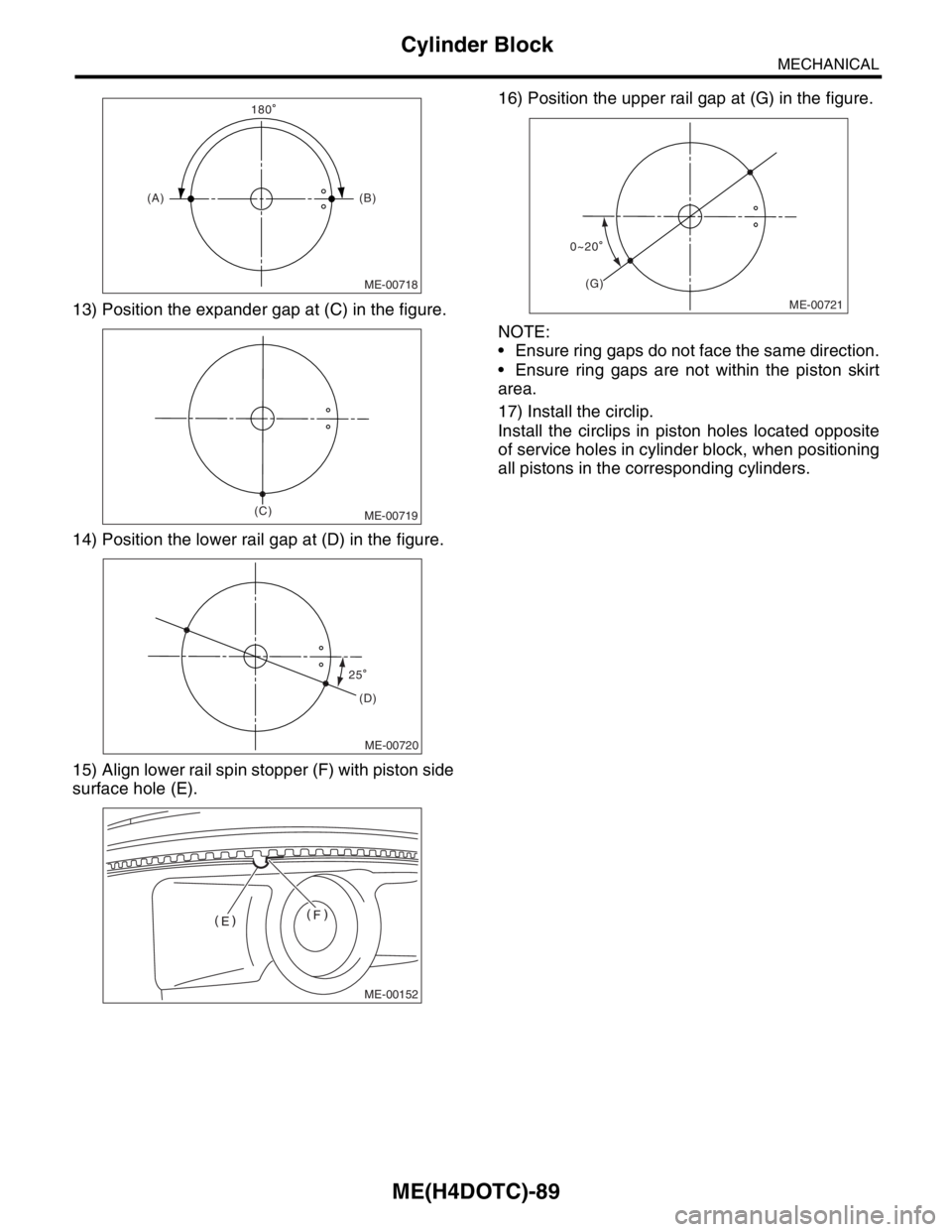

13) Position the expander gap at (C) in the figure.

14) Position the lower rail gap at (D) in the figure.

15) Align lower rail spin stopper (F) with piston side

surface hole (E).16) Position the upper rail gap at (G) in the figure.

NOTE:

Ensure ring gaps do not face the same direction.

Ensure ring gaps are not within the piston skirt

area.

17) Install the circlip.

Install the circlips in piston holes located opposite

of service holes in cylinder block, when positioning

all pistons in the corresponding cylinders.

ME-00718

(A)(B)

180

ME-00719

(C)

ME-00720

(D)

25

ME-00152

ME-00721

(G)

0 20

Page 1550 of 2870

ME(H4DOTC)-90

MECHANICAL

Cylinder Block

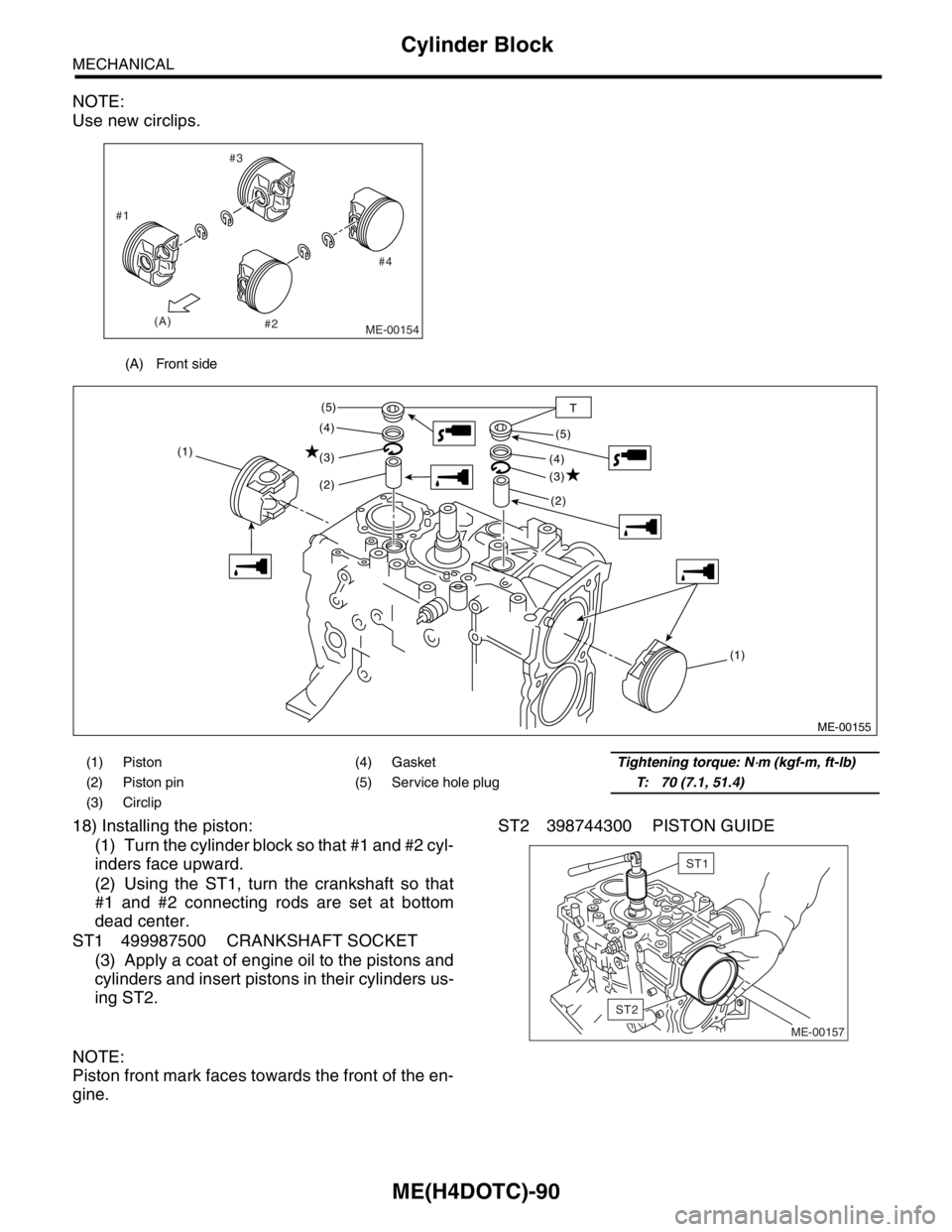

NOTE:

Use new circlips.

18) Installing the piston:

(1) Turn the cylinder block so that #1 and #2 cyl-

inders face upward.

(2) Using the ST1, turn the crankshaft so that

#1 and #2 connecting rods are set at bottom

dead center.

ST1 499987500 CRANKSHAFT SOCKET

(3) Apply a coat of engine oil to the pistons and

cylinders and insert pistons in their cylinders us-

ing ST2.ST2 398744300 PISTON GUIDE

NOTE:

Piston front mark faces towards the front of the en-

gine.

(A) Front side

ME-00154

#4 #3

#2 #1

(A)

(1) Piston (4) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (5) Service hole plugT: 70 (7.1, 51.4)

(3) Circlip

ME-00155

(1) (1)

(2)

(2) (3)

(3) (4)

(4) (5)

(5)

T

ME-00157

ST2

ST1

Page 1551 of 2870

ME(H4DOTC)-91

MECHANICAL

Cylinder Block

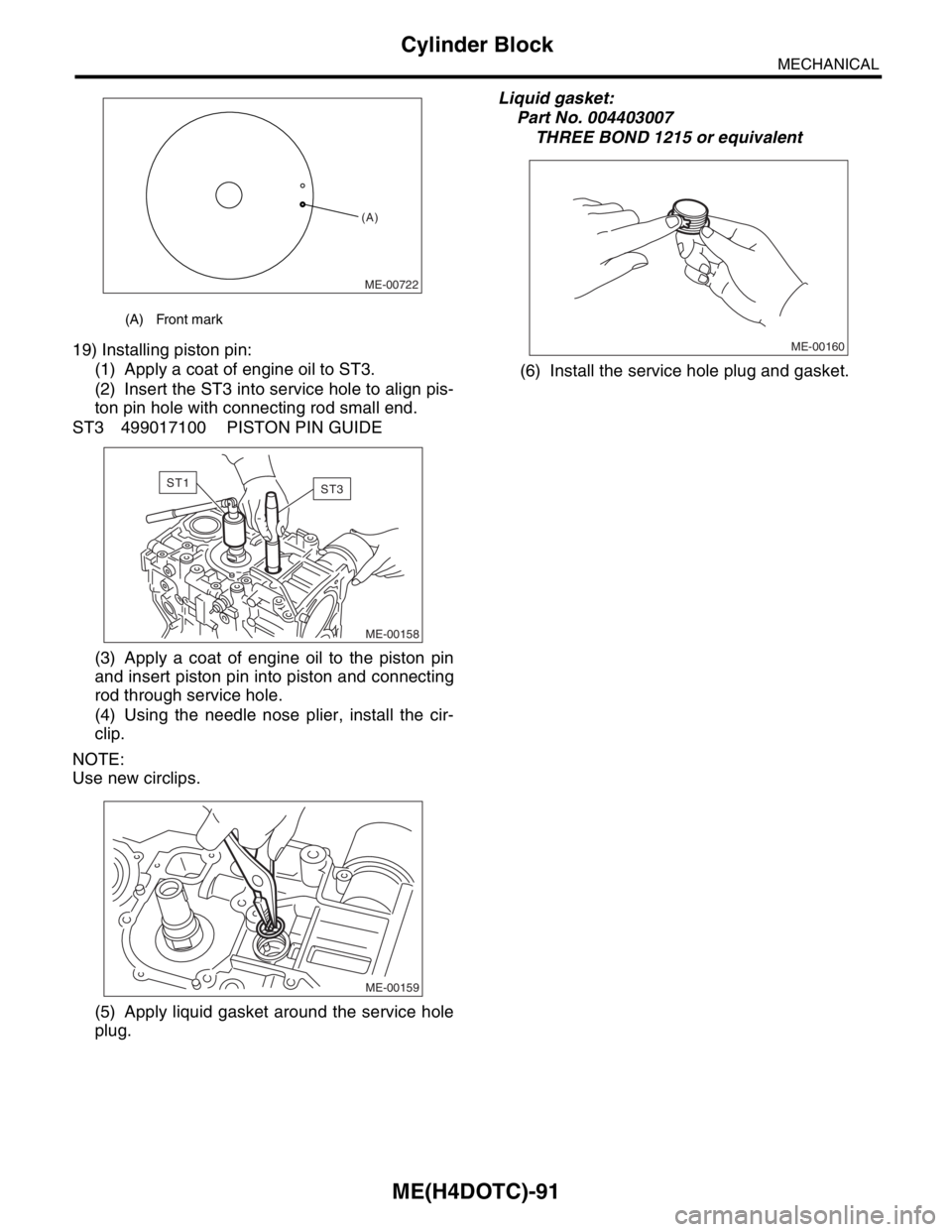

19) Installing piston pin:

(1) Apply a coat of engine oil to ST3.

(2) Insert the ST3 into service hole to align pis-

ton pin hole with connecting rod small end.

ST3 499017100 PISTON PIN GUIDE

(3) Apply a coat of engine oil to the piston pin

and insert piston pin into piston and connecting

rod through service hole.

(4) Using the needle nose plier, install the cir-

clip.

NOTE:

Use new circlips.

(5) Apply liquid gasket around the service hole

plug.Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

(6) Install the service hole plug and gasket.

(A) Front mark

ME-00722

(A)

ME-00158

ST1ST3

ME-00159

ME-00160

Page 1552 of 2870

ME(H4DOTC)-92

MECHANICAL

Cylinder Block

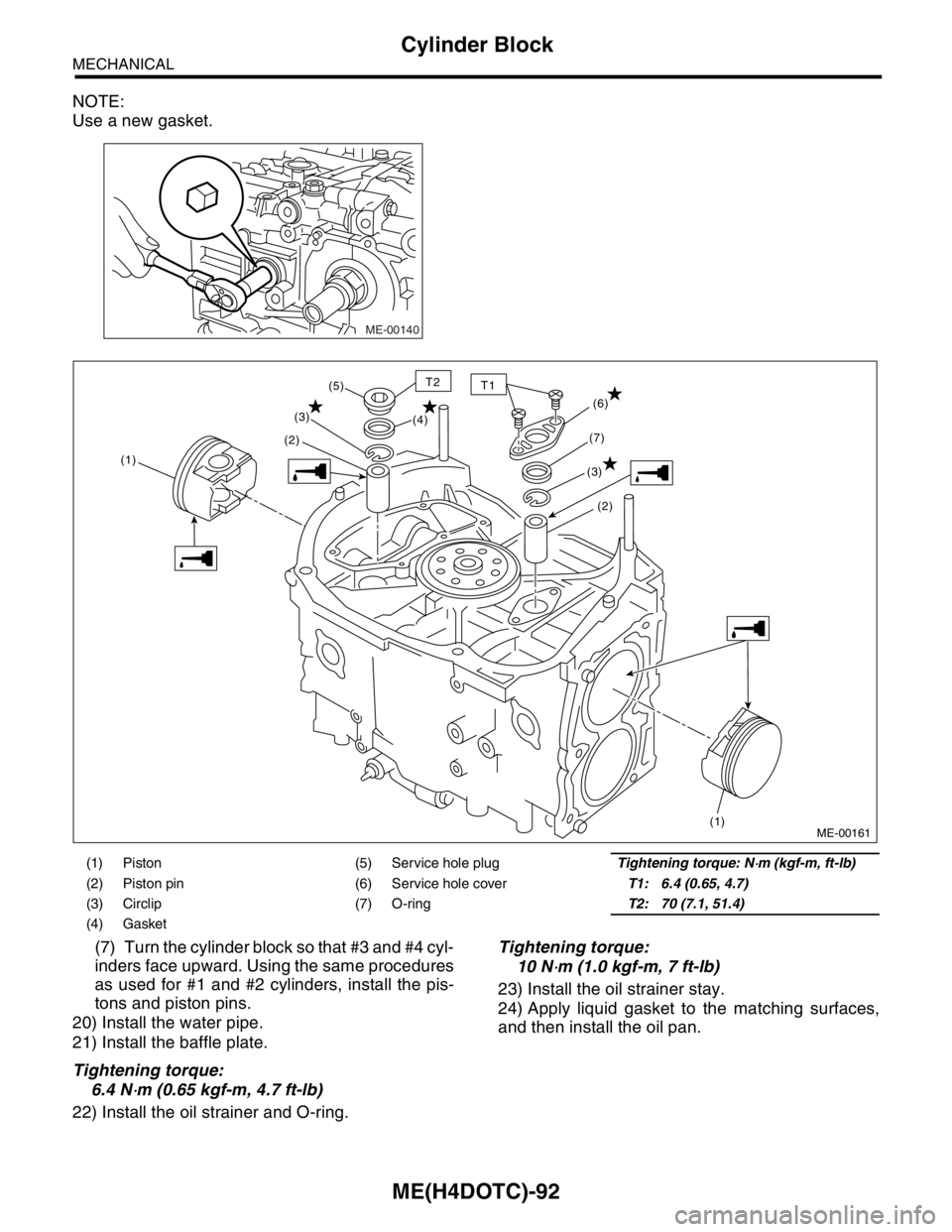

NOTE:

Use a new gasket.

(7) Turn the cylinder block so that #3 and #4 cyl-

inders face upward. Using the same procedures

as used for #1 and #2 cylinders, install the pis-

tons and piston pins.

20) Install the water pipe.

21) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

22) Install the oil strainer and O-ring.Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

23) Install the oil strainer stay.

24) Apply liquid gasket to the matching surfaces,

and then install the oil pan.

ME-00140

(1) Piston (5) Service hole plugTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (6) Service hole coverT1: 6.4 (0.65, 4.7)

(3) Circlip (7) O-ringT2: 70 (7.1, 51.4)

(4) Gasket

(1)(2)(3)

(1)

(2) (6)

(3)(7) (4) (5)

ME-00161

T2T1

Page 1559 of 2870

ME(H4DOTC)-99

MECHANICAL

Cylinder Block

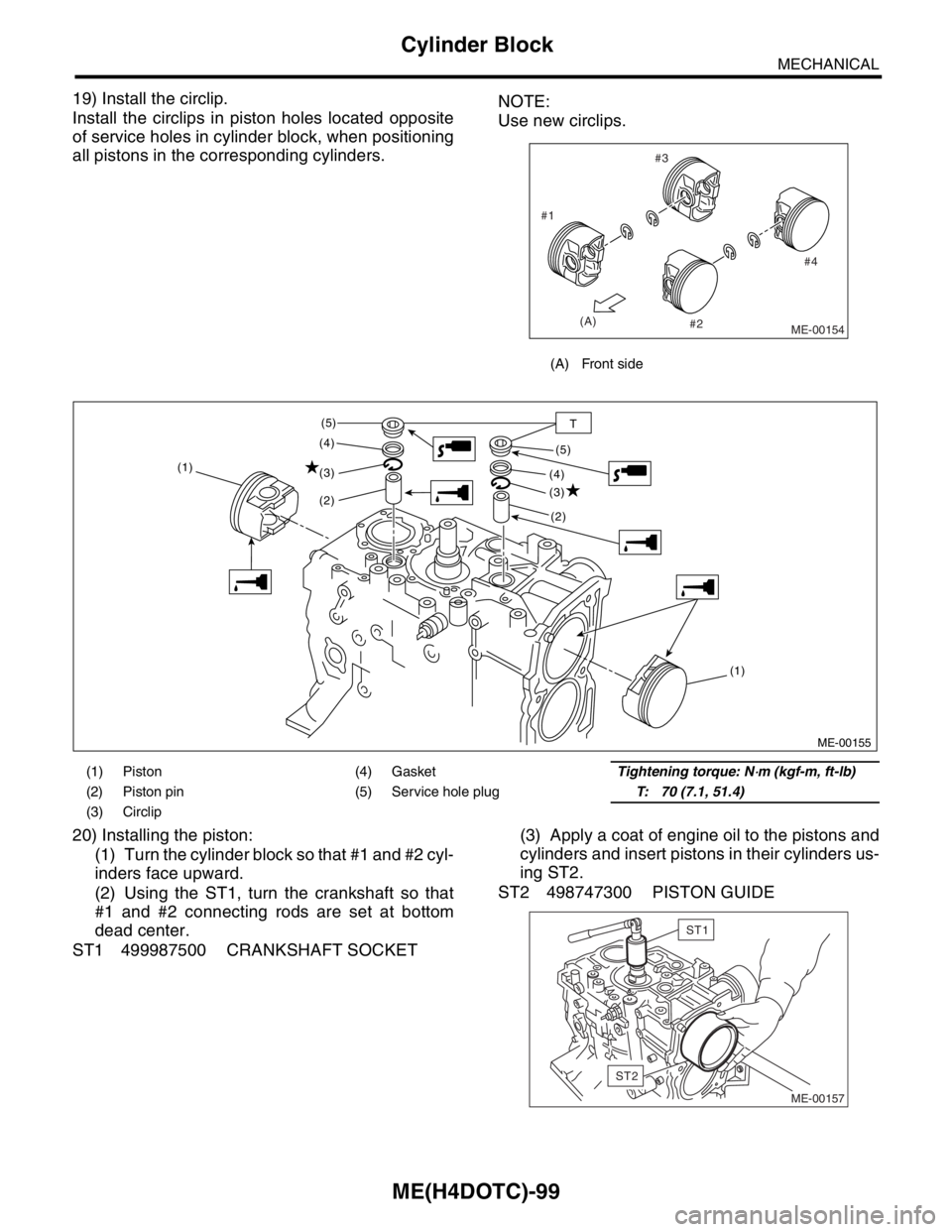

19) Install the circlip.

Install the circlips in piston holes located opposite

of service holes in cylinder block, when positioning

all pistons in the corresponding cylinders.NOTE:

Use new circlips.

20) Installing the piston:

(1) Turn the cylinder block so that #1 and #2 cyl-

inders face upward.

(2) Using the ST1, turn the crankshaft so that

#1 and #2 connecting rods are set at bottom

dead center.

ST1 499987500 CRANKSHAFT SOCKET(3) Apply a coat of engine oil to the pistons and

cylinders and insert pistons in their cylinders us-

ing ST2.

ST2 498747300 PISTON GUIDE

(A) Front side

ME-00154

#4 #3

#2 #1

(A)

(1) Piston (4) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (5) Service hole plugT: 70 (7.1, 51.4)

(3) Circlip

ME-00155

(1) (1)

(2)

(2) (3)

(3) (4)

(4) (5)

(5)

T

ME-00157

ST2

ST1

Page 1560 of 2870

ME(H4DOTC)-100

MECHANICAL

Cylinder Block

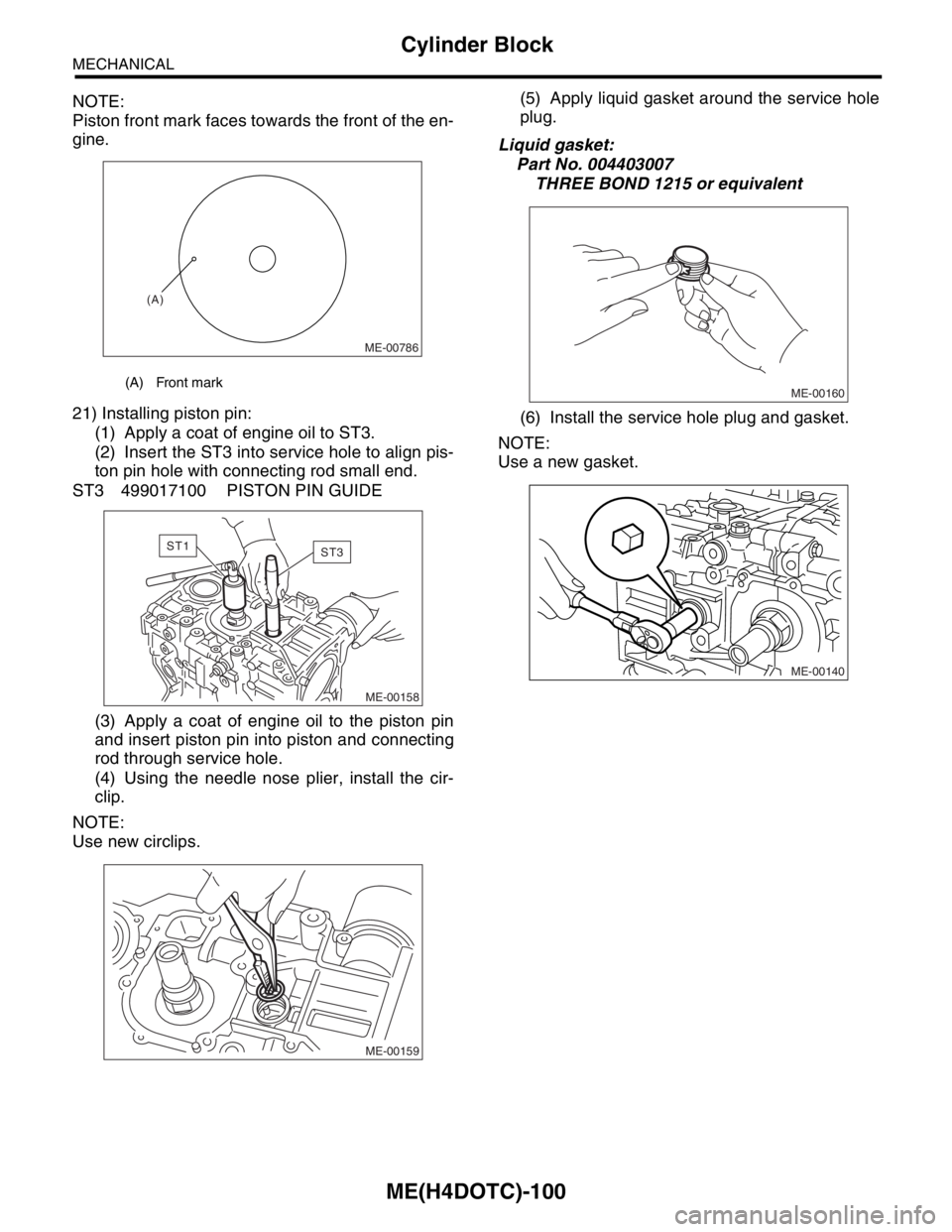

NOTE:

Piston front mark faces towards the front of the en-

gine.

21) Installing piston pin:

(1) Apply a coat of engine oil to ST3.

(2) Insert the ST3 into service hole to align pis-

ton pin hole with connecting rod small end.

ST3 499017100 PISTON PIN GUIDE

(3) Apply a coat of engine oil to the piston pin

and insert piston pin into piston and connecting

rod through service hole.

(4) Using the needle nose plier, install the cir-

clip.

NOTE:

Use new circlips.(5) Apply liquid gasket around the service hole

plug.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

(6) Install the service hole plug and gasket.

NOTE:

Use a new gasket.

(A) Front mark

ME-00786

(A)

ME-00158

ST1ST3

ME-00159

ME-00160

ME-00140

Page 1561 of 2870

ME(H4DOTC)-101

MECHANICAL

Cylinder Block

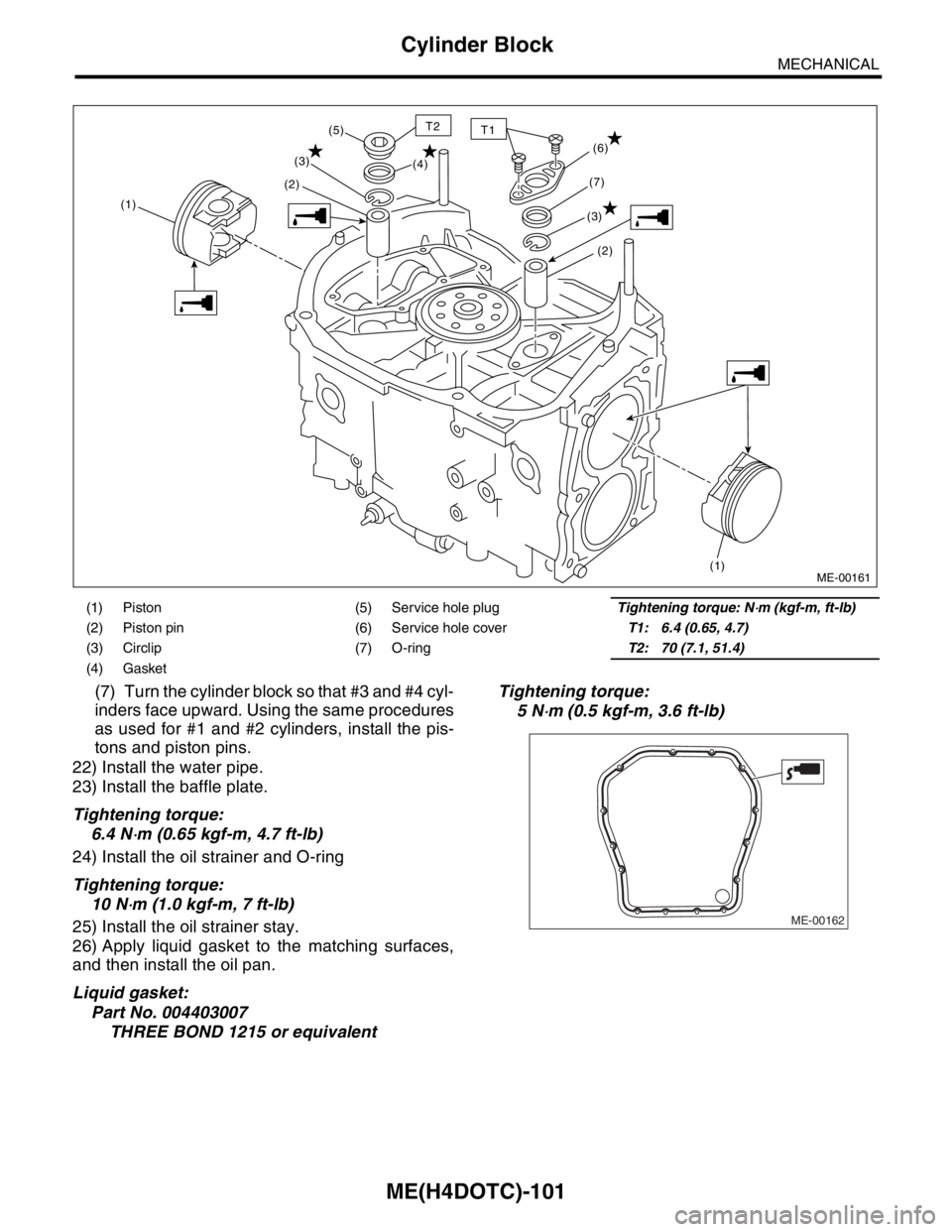

(7) Turn the cylinder block so that #3 and #4 cyl-

inders face upward. Using the same procedures

as used for #1 and #2 cylinders, install the pis-

tons and piston pins.

22) Install the water pipe.

23) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

24) Install the oil strainer and O-ring

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

25) Install the oil strainer stay.

26) Apply liquid gasket to the matching surfaces,

and then install the oil pan.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalentTightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

(1) Piston (5) Service hole plugTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (6) Service hole coverT1: 6.4 (0.65, 4.7)

(3) Circlip (7) O-ringT2: 70 (7.1, 51.4)

(4) Gasket

(1)(2)(3)

(1)

(2) (6)

(3)(7) (4) (5)

ME-00161

T2T1

ME-00162

Page 1585 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE3

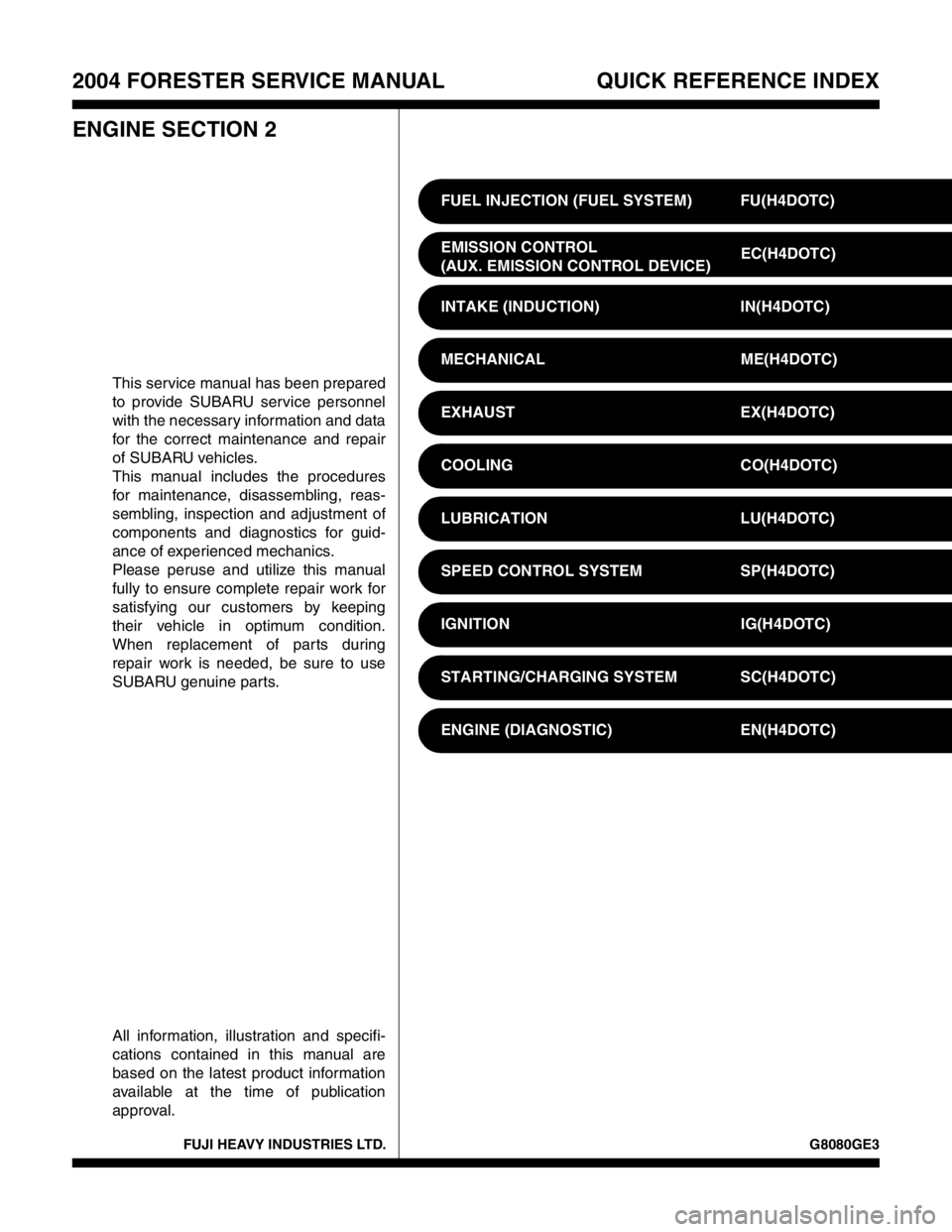

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

ENGINE SECTION 2

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.FUEL INJECTION (FUEL SYSTEM) FU(H4DOTC)

EMISSION CONTROL

(AUX. EMISSION CONTROL DEVICE)EC(H4DOTC)

INTAKE (INDUCTION) IN(H4DOTC)

MECHANICAL ME(H4DOTC)

EXHAUST EX(H4DOTC)

COOLING CO(H4DOTC)

LUBRICATION LU(H4DOTC)

SPEED CONTROL SYSTEM SP(H4DOTC)

IGNITION IG(H4DOTC)

STARTING/CHARGING SYSTEM SC(H4DOTC)

ENGINE (DIAGNOSTIC) EN(H4DOTC)