Head light SUBARU FORESTER 2004 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 271 of 2870

LI-17

LIGHTING SYSTEM

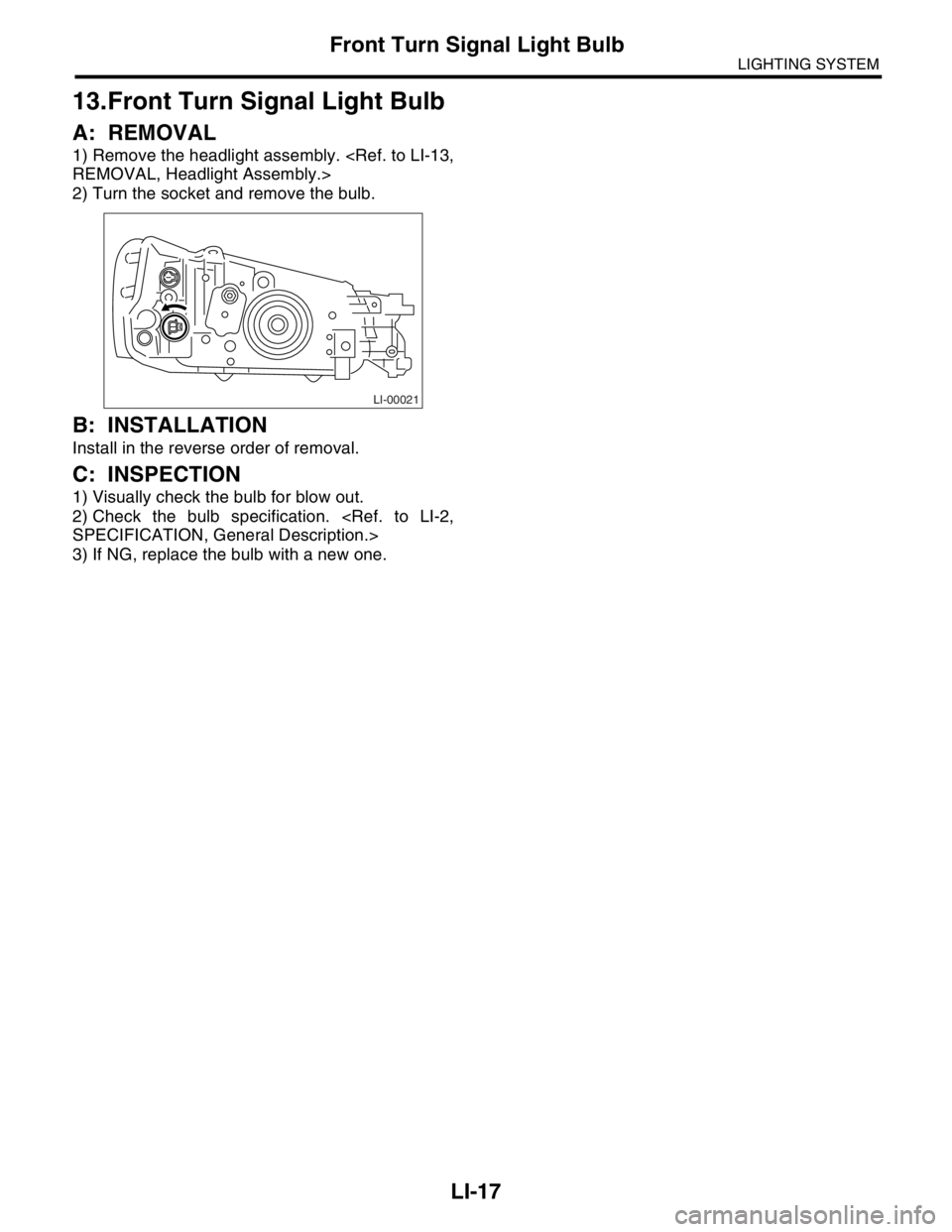

Front Turn Signal Light Bulb

13.Front Turn Signal Light Bulb

A: REMOVAL

1) Remove the headlight assembly.

2) Turn the socket and remove the bulb.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

1) Visually check the bulb for blow out.

2) Check the bulb specification.

3) If NG, replace the bulb with a new one.

LI-00021

Page 272 of 2870

LI-18

LIGHTING SYSTEM

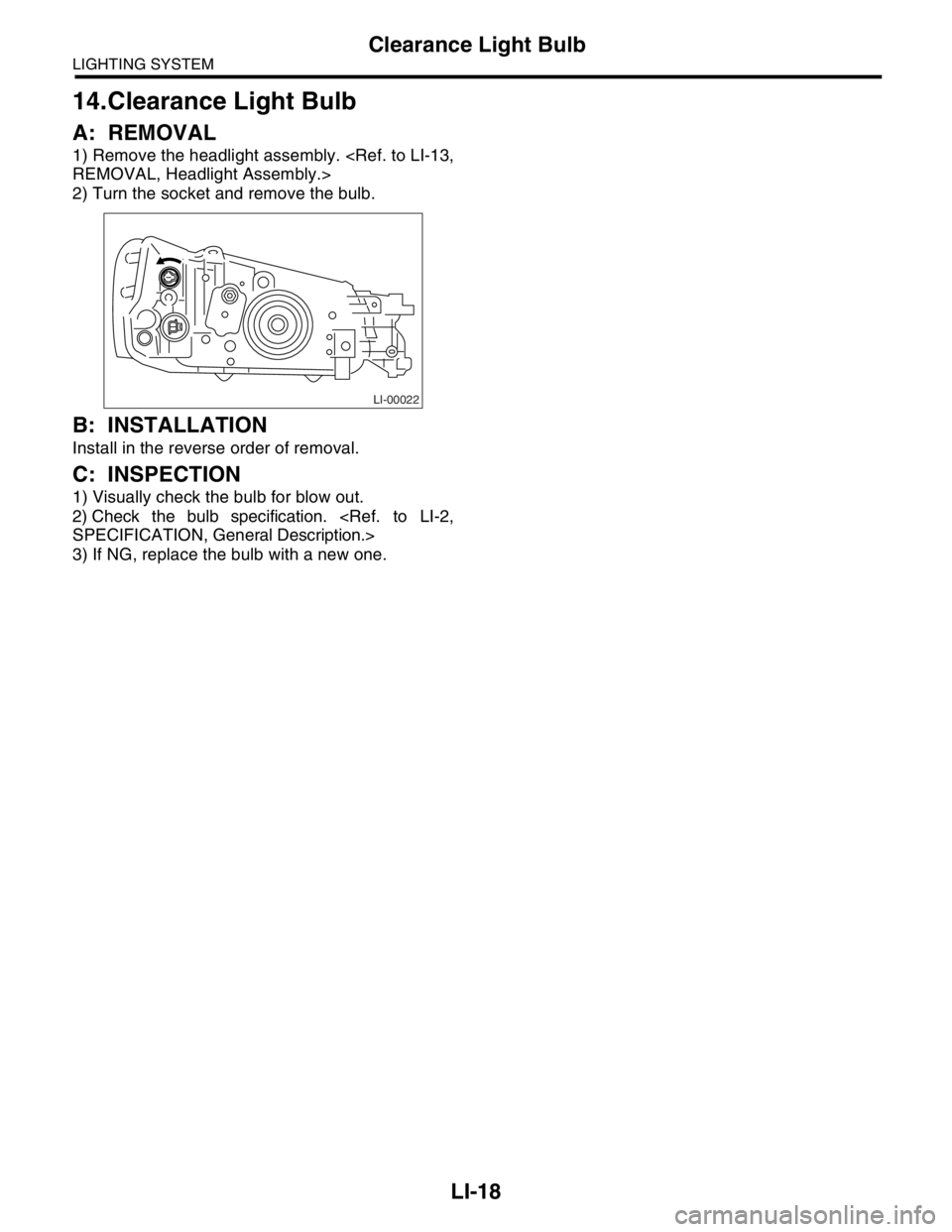

Clearance Light Bulb

14.Clearance Light Bulb

A: REMOVAL

1) Remove the headlight assembly.

2) Turn the socket and remove the bulb.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

1) Visually check the bulb for blow out.

2) Check the bulb specification.

3) If NG, replace the bulb with a new one.

LI-00022

Page 289 of 2870

WIPER AND WASHER SYSTEM

WW

Page

1. General Description ....................................................................................2

2. Wiper and Washer System .........................................................................6

3. Combination Switch (Wiper)........................................................................7

4. Wiper Blade.................................................................................................9

5. Washer Tank and Motor............................................................................11

6. Front Wiper Arm ........................................................................................12

7. Front Wiper Motor and Link.......................................................................13

8. Front Washer Nozzle ................................................................................15

9. Rear Wiper Arm ........................................................................................16

10. Rear Wiper Motor ......................................................................................17

11. Rear Washer .............................................................................................18

12. Wiper Control Relay ..................................................................................19

13. Headlight Washer......................................................................................20

Page 292 of 2870

WW-4

WIPER AND WASHER SYSTEM

General Description

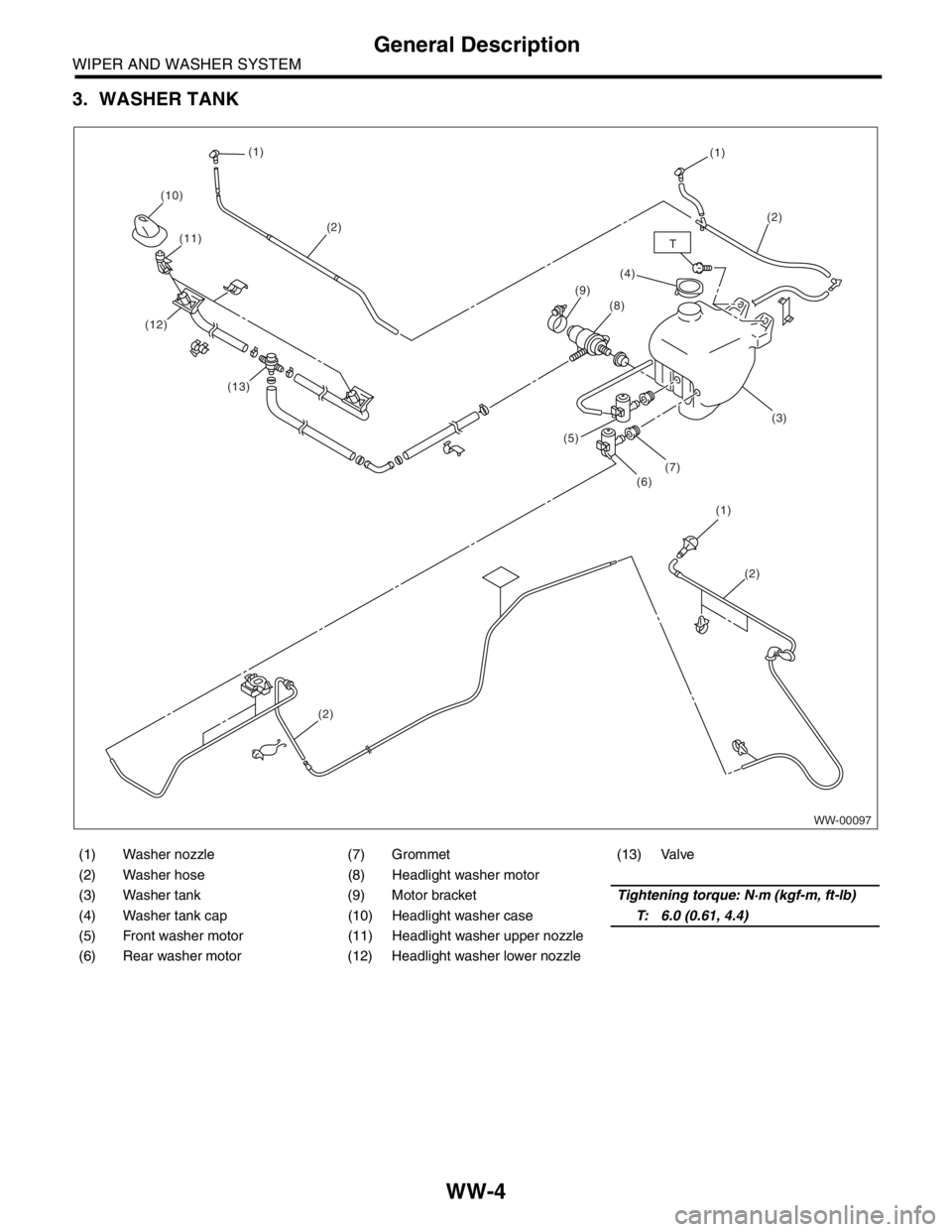

3. WASHER TANK

(1) Washer nozzle (7) Grommet (13) Valve

(2) Washer hose (8) Headlight washer motor

(3) Washer tank (9) Motor bracketTightening torque: N·m (kgf-m, ft-lb)

(4) Washer tank cap (10) Headlight washer caseT: 6.0 (0.61, 4.4)

(5) Front washer motor (11) Headlight washer upper nozzle

(6) Rear washer motor (12) Headlight washer lower nozzle

WW-00097

(1) (1)

(1)(2)

(2) (10)

(11)

(12)

(13)

(2)

(2)(8)

(7)

(6) (5)(9)

T

(3)

(4)

Page 299 of 2870

WW-11

WIPER AND WASHER SYSTEM

Washer Tank and Motor

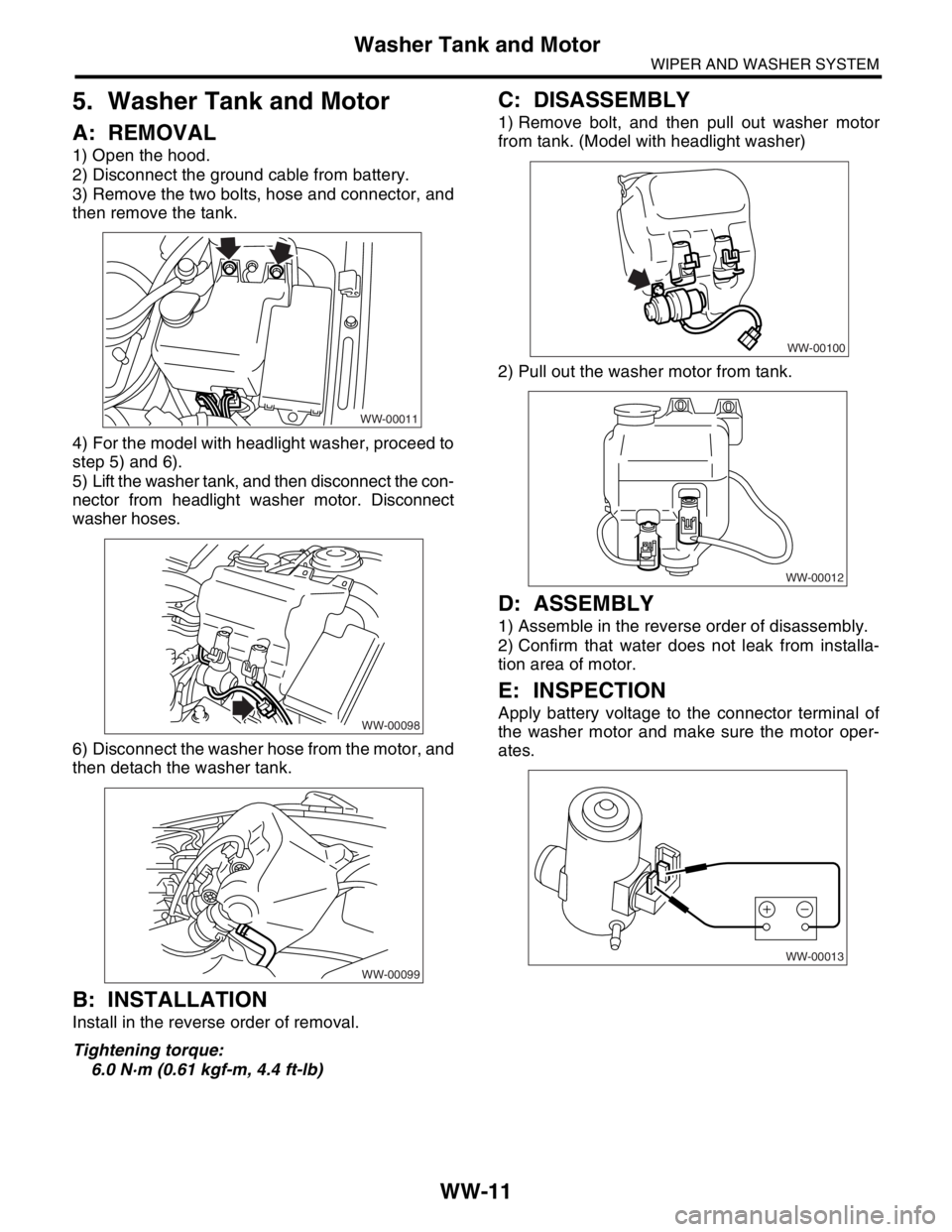

5. Washer Tank and Motor

A: REMOVAL

1) Open the hood.

2) Disconnect the ground cable from battery.

3) Remove the two bolts, hose and connector, and

then remove the tank.

4) For the model with headlight washer, proceed to

step 5) and 6).

5) Lift the washer tank, and then disconnect the con-

nector from headlight washer motor. Disconnect

washer hoses.

6) Disconnect the washer hose from the motor, and

then detach the washer tank.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

6.0 N·m (0.61 kgf-m, 4.4 ft-lb)

C: DISASSEMBLY

1) Remove bolt, and then pull out washer motor

from tank. (Model with headlight washer)

2) Pull out the washer motor from tank.

D: ASSEMBLY

1) Assemble in the reverse order of disassembly.

2) Confirm that water does not leak from installa-

tion area of motor.

E: INSPECTION

Apply battery voltage to the connector terminal of

the washer motor and make sure the motor oper-

ates.

WW-00011

WW-00098

WW-00099

WW-00100

WW-00012

WW-00013

Page 308 of 2870

WW-20

WIPER AND WASHER SYSTEM

Headlight Washer

13.Headlight Washer

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Remove the front grille.

3) Remove the headlight.

4) Draw out headlight washer hose.

5) Disconnect hose (A) from valve (B).

NOTE:

Washer fluid may drain from valve. Put a pan under

the valve, then disconnect valve from hose while

pinching the hose edge.

6) Remove nozzle cover (A).

7) Push the three pawls to remove outer nozzle (A).

Then pull out inner nozzle (B).

NOTE:

Before pushing the outer nozzle pawls, cover the

bumper to avoid scratches.

B: INSTALLATION

Install in the reverse order of removal.

WW-00102

(B) (A)

(A)

WW-00109

(A)

WW-00110

(A)

(B)

Page 370 of 2870

BS-4

BODY STRUCTURE

Datum Points

(1) Radiator panel gauge hole 6 mm

(0.24 in) dia. (Vehicle center)(14) Fender attaching hole 10 mm

(0.39 in) dia. (Symmetrical)(31) Harness attaching hole 7 mm

(0.28 in) dia. (Symmetrical)

(2) Radiator attaching hole 12 mm

(0.47 in) dia.(15) Fender attaching hole 10 mm

(0.39 in) dia. (Symmetrical)(32) Trim attaching hole 8.5 mm (0.33

in) dia. (Symmetrical)

(3) Headlight attaching hole 7 mm

(0.28 in) dia. (Symmetrical)(16) Front door hinge attaching hole 12

mm (0.47 in) dia. (Symmetrical)(33) Trim attaching hole 7 mm (0.28 in)

dia. (Symmetrical)

(4) Frame plate gauge hole 8 mm

(0.31 in) dia. (Symmetrical)(17) Front door hinge attaching hole 12

mm (0.47 in) dia. (Symmetrical)(34) Harness attaching hole 7×7 mm

(0.28×0.28 in) (Symmetrical)

(5) Bumper beam attaching hole 11

mm (0.43 in) dia. (Symmetrical)(20) Front door switch attaching hole

4.1 mm (0.16 in) dia. (Symmetri-

cal)(35) Tonneau cover bracket attaching

hole 5.5 mm (0.22 in) dia. (Sym-

metrical)

(6) Fender attaching hole 7 mm (0.28

in) dia. (Symmetrical)

(21) Rear door hinge attaching hole 12

mm (0.47 in) dia. (Symmetrical)(36) Rear strut attaching hole 10 mm

(0.39 in) (Symmetrical)

(7) Fender attaching hole 9 mm (0.35

in) dia. (Symmetrical)

(22) Rear door hinge attaching hole 12

mm (0.47 in) dia. (Symmetrical)(37) Floor mat attaching hole 8 mm

(0.31 in) dia.

(8) Power steering tank attaching hole

RH ATF cooler pipe attaching hole

LH 9 mm (0.35 in) dia.(23) Front weather strip attaching hole

5.2 mm (0.20 in) dia. (Symmetri-

cal)(38) Trim attaching hole 9×9 mm

(0.35×0.35 in) (Symmetrical)

(9) Fender attaching hole 10 mm

(0.39 in) dia. (Symmetrical)(39) Trim attaching hole 8 mm (0.31 in)

dia. (Symmetrical)

(25) Rear weather strip attaching hole

5.2 mm (0.20 in) dia. (Symmetri-

cal) (10) Fender attaching hole 7 mm (0.28

in) dia. (Symmetrical)(40) Trim attaching hole 8 mm (0.31 in)

dia. (Symmetrical)

(11) Modular bracket gauge hole 8 mm

(0.31 in) dia. (Vehicle center)(26) Rear door switch attaching hole

4.1 mm (0.16 in) dia. (Symmetri-

cal)

(12) Front strut attaching hole 9.5 mm

(0.37 in) dia. (Symmetrical)

(29) Trim attaching hole 8.5 mm (0.33

in) dia. (Symmetrical)

(13) Front glass attaching hole LH

6.5×10.5 mm (0.26×0.41 in) RH

6.5×7 mm (0.26×0.28 in)(30) Pad attaching hole 5 mm (0.20 in)

dia. (Symmetrical)

Page 410 of 2870

SE-6

SEAT

Front Seat

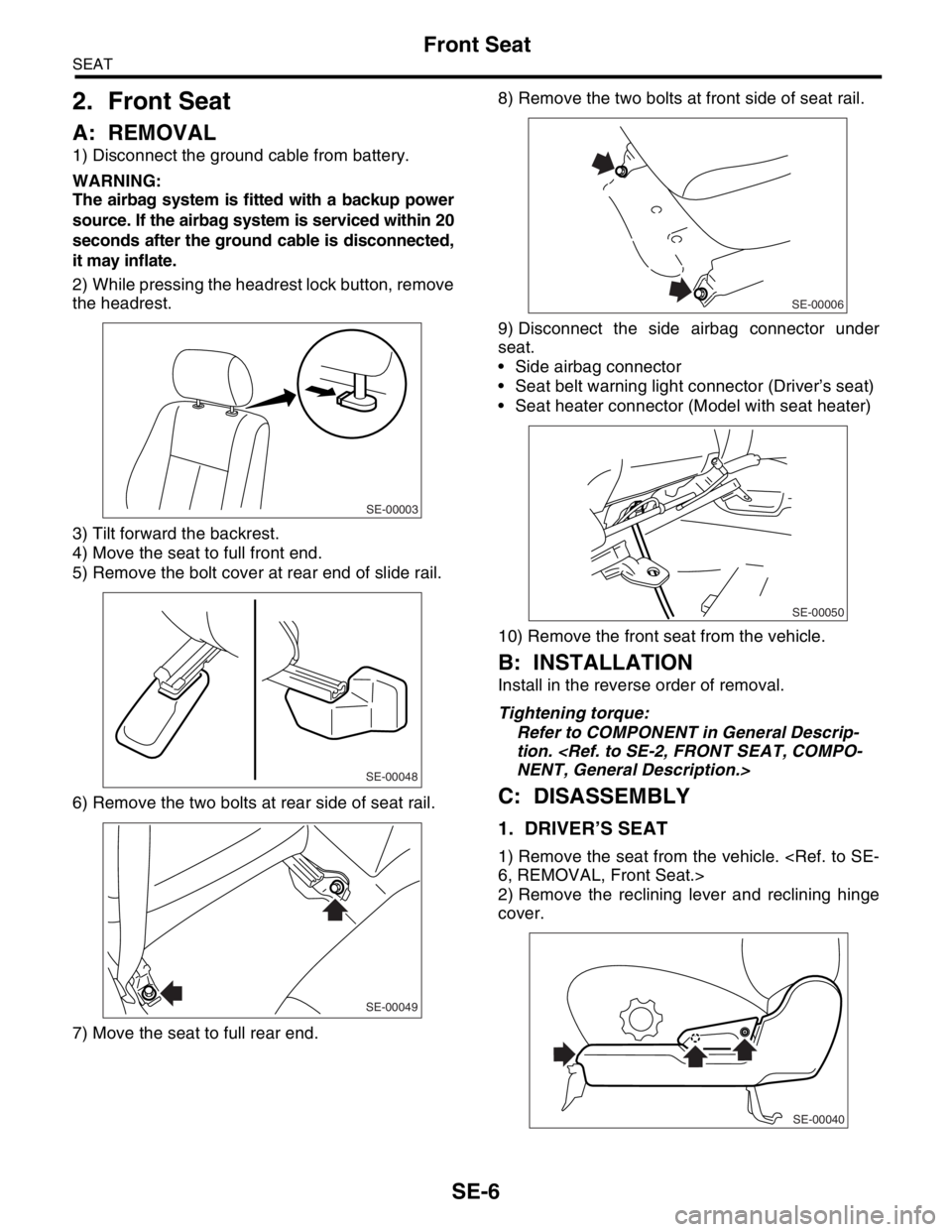

2. Front Seat

A: REMOVAL

1) Disconnect the ground cable from battery.

WARNING:

The airbag system is fitted with a backup power

source. If the airbag system is serviced within 20

seconds after the ground cable is disconnected,

it may inflate.

2) While pressing the headrest lock button, remove

the headrest.

3) Tilt forward the backrest.

4) Move the seat to full front end.

5) Remove the bolt cover at rear end of slide rail.

6) Remove the two bolts at rear side of seat rail.

7) Move the seat to full rear end.8) Remove the two bolts at front side of seat rail.

9) Disconnect the side airbag connector under

seat.

Side airbag connector

Seat belt warning light connector (Driver’s seat)

Seat heater connector (Model with seat heater)

10) Remove the front seat from the vehicle.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

C: DISASSEMBLY

1. DRIVER’S SEAT

1) Remove the seat from the vehicle.

2) Remove the reclining lever and reclining hinge

cover.

SE-00003

SE-00048

SE-00049

SE-00006

SE-00050

SE-00040

Page 523 of 2870

EI-47

EXTERIOR/INTERIOR TRIM

Roof Trim

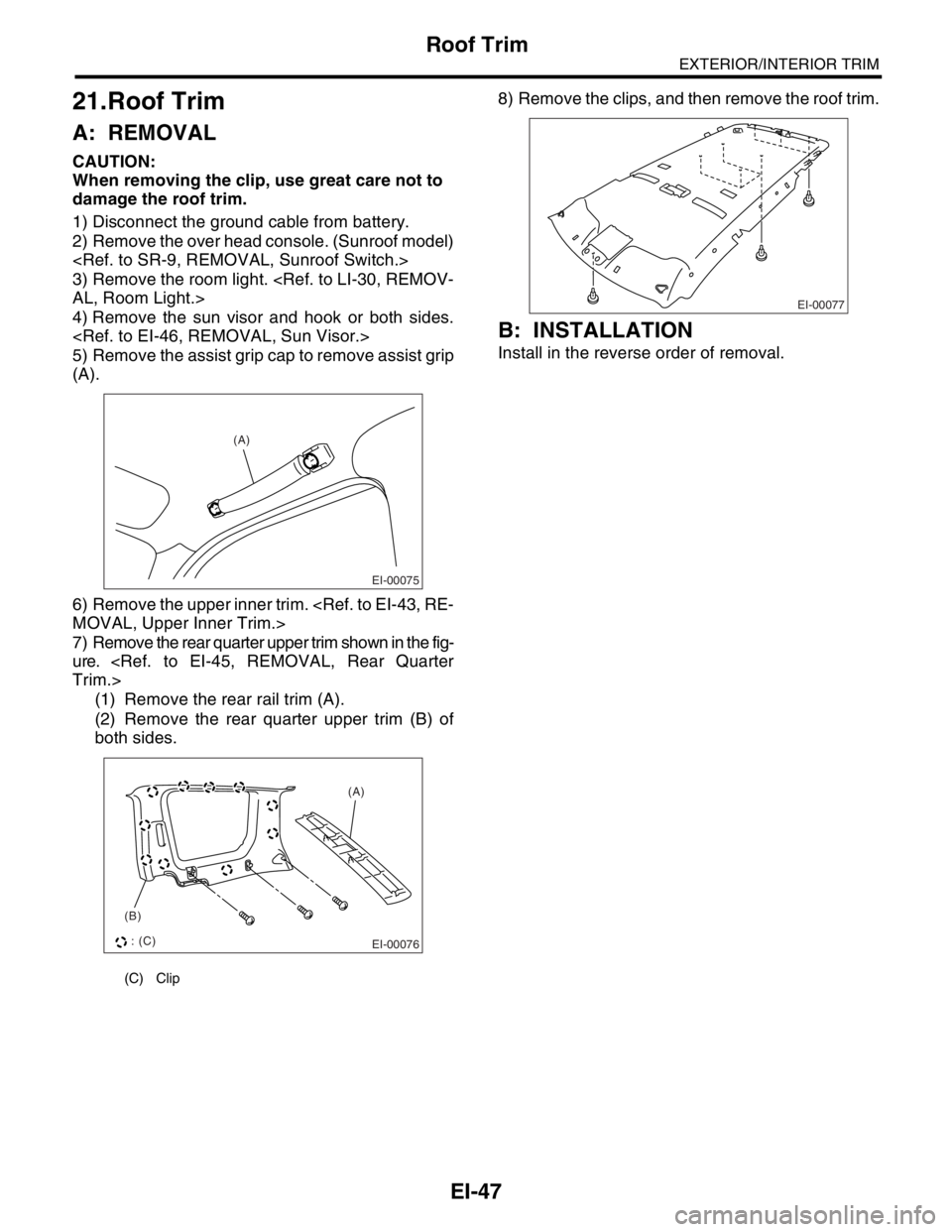

21.Roof Trim

A: REMOVAL

CAUTION:

When removing the clip, use great care not to

damage the roof trim.

1) Disconnect the ground cable from battery.

2) Remove the over head console. (Sunroof model)

3) Remove the room light.

4) Remove the sun visor and hook or both sides.

5) Remove the assist grip cap to remove assist grip

(A).

6) Remove the upper inner trim.

7) Remove the rear quarter upper trim shown in the fig-

ure.

(1) Remove the rear rail trim (A).

(2) Remove the rear quarter upper trim (B) of

both sides.8) Remove the clips, and then remove the roof trim.

B: INSTALLATION

Install in the reverse order of removal.

(C) Clip

EI-00075

(A)

EI-00076

(A)

(B)

: (C)EI-00077

Page 734 of 2870

PI-11

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

29.CLOCK

Check the clock for normal operations and enough

accuracy.

30.RADIO

Check the radio for full functionality and normal

noise level. Also check the CD unit operations.

31.FRONT ACCESSORY POWER SUPPLY

SOCKET

Check the front accessory power supply socket op-

erations.

32.LIGHTING SYSTEM

Check the headlight operations.

Check the brake light operations.

Check the other lights for normal operations.

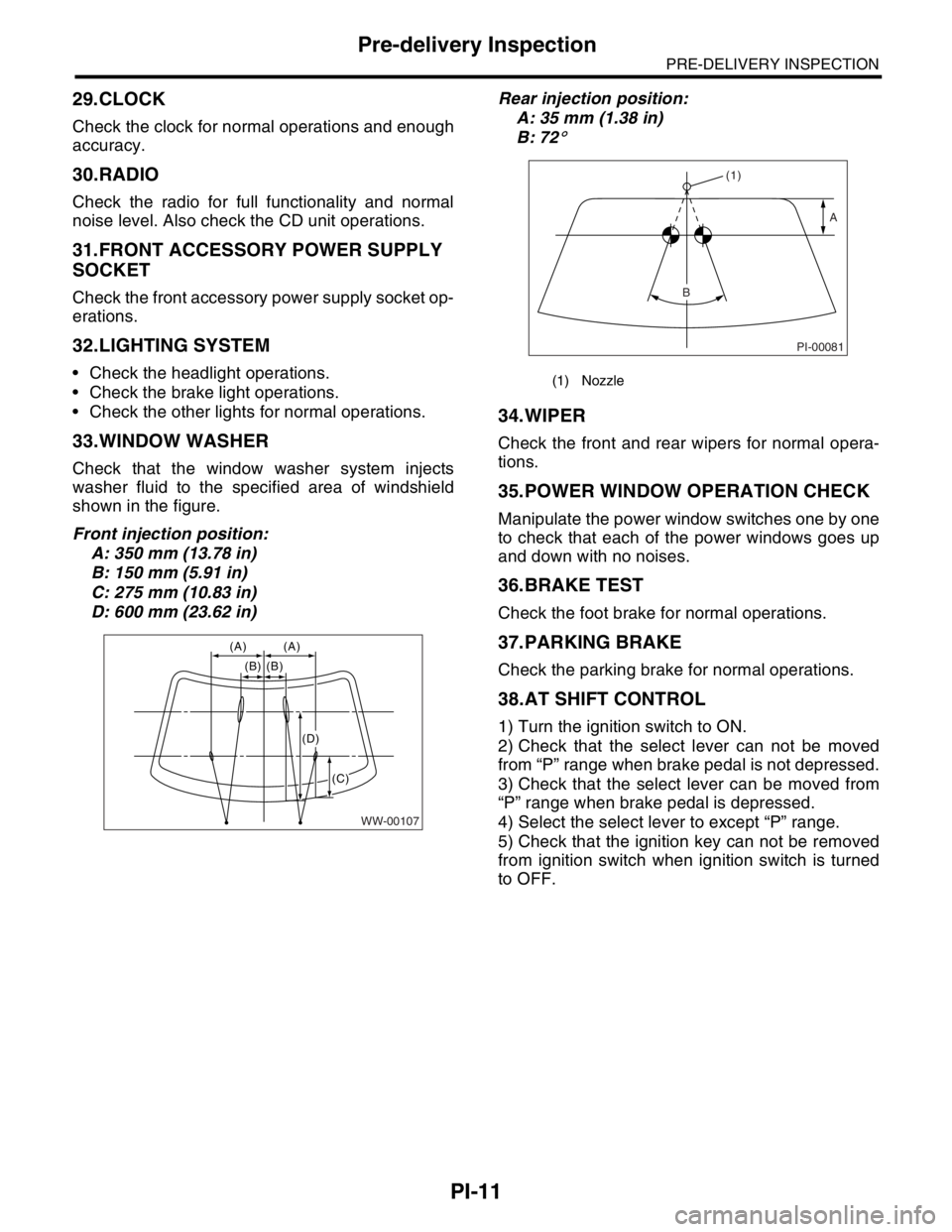

33.WINDOW WASHER

Check that the window washer system injects

washer fluid to the specified area of windshield

shown in the figure.

Front injection position:

A: 350 mm (13.78 in)

B: 150 mm (5.91 in)

C: 275 mm (10.83 in)

D: 600 mm (23.62 in)Rear injection position:

A: 35 mm (1.38 in)

B: 72

°

34.WIPER

Check the front and rear wipers for normal opera-

tions.

35.POWER WINDOW OPERATION CHECK

Manipulate the power window switches one by one

to check that each of the power windows goes up

and down with no noises.

36.BRAKE TEST

Check the foot brake for normal operations.

37.PARKING BRAKE

Check the parking brake for normal operations.

38.AT SHIFT CONTROL

1) Turn the ignition switch to ON.

2) Check that the select lever can not be moved

from “P” range when brake pedal is not depressed.

3) Check that the select lever can be moved from

“P” range when brake pedal is depressed.

4) Select the select lever to except “P” range.

5) Check that the ignition key can not be removed

from ignition switch when ignition switch is turned

to OFF.

WW-00107

(A) (A)

(B) (B)

(C)

(D)

(1) Nozzle

PI-00081

(1)

A

B