dimensions SUBARU FORESTER 2004 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 382 of 2870

BS-16

BODY STRUCTURE

Datum Dimensions

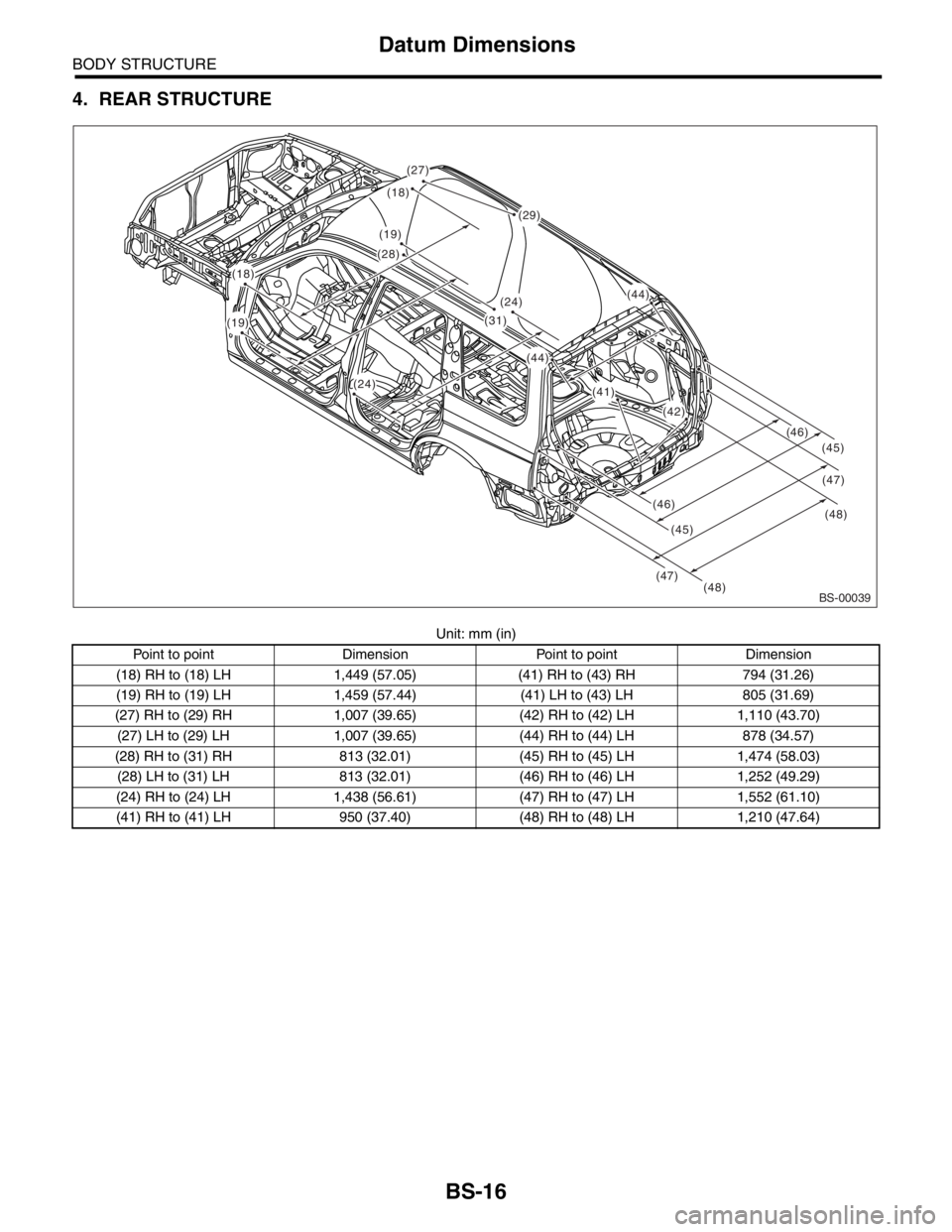

4. REAR STRUCTURE

Unit: mm (in)

Point to point Dimension Point to point Dimension

(18) RH to (18) LH 1,449 (57.05) (41) RH to (43) RH 794 (31.26)

(19) RH to (19) LH 1,459 (57.44) (41) LH to (43) LH 805 (31.69)

(27) RH to (29) RH 1,007 (39.65) (42) RH to (42) LH 1,110 (43.70)

(27) LH to (29) LH 1,007 (39.65) (44) RH to (44) LH 878 (34.57)

(28) RH to (31) RH 813 (32.01) (45) RH to (45) LH 1,474 (58.03)

(28) LH to (31) LH 813 (32.01) (46) RH to (46) LH 1,252 (49.29)

(24) RH to (24) LH 1,438 (56.61) (47) RH to (47) LH 1,552 (61.10)

(41) RH to (41) LH 950 (37.40) (48) RH to (48) LH 1,210 (47.64)

BS-00039(48)(48) (47)

(47) (46)(46)

(45)(45) (18)

(29)

(44)

(41)

(42)

(44)

(31)

(24)

(24)

(28)

(18)

(19)

(27)

(19)

Page 691 of 2870

SPC-2

SPECIFICATION

Forester

1. Forester

A: DIMENSIONS

★: With sunroof

B: ENGINE

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Overall length mm (in) 4,450 (175.2)

Overall width mm (in) 1,735 (68.3)

Overall height (at C.W.) mm (in) 1,590 (62.6) 1,585 (62.4) 1,590 (62.6)

CompartmentLength mm (in) 1,795 (70.7)

Width mm (in) 1,455 (57.3)

Height mm (in)

1,245 (49.0), 1,210 (47.6)

★

Wheelbase mm (in) 2,525 (99.4)

Tread Front mm (in) 1,495 (58.9)

Rear mm (in) 1,485 (58.5)

Minimum road clearance mm (in) 190 (7.5) 195 (7.7) 200 (7.9)

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Engine type Horizontally opposed, liquid cooled, 4-cylinder, 4-stroke gasoline engine

Valve arrangement Overhead camshaft type

Bore×Stroke mm (in) 92×75 (3.62×2.95) 99.5×79 (3.92×3.11)

Displacement

cm

3 (cu in)1,994 (121.67) 2,457 (149.94)

Compression ratio 10.0±0.2 8.0±0.2 10.0±0.2 8.2±0.2

Firing order 1 — 3 — 2 — 4

Idle speed at Park or Neu-

tral positionrpm 650±100 700±100 650±100 700±100

Maximum output kW (PS)/rpm 92 (125)/5,600 130 (177)/5,600 115 (156)/5,600 155 (211)/5,600

Maximum torque N⋅m (kgf-m, ft-lb)/rpm184 (18.8, 41.4)/

3,600245 (25.0, 55.1)/

3,200223 (22.7, 50.1)/

3,600320 (32.6, 71.8)/

3,600

Page 959 of 2870

ME(H4SO)-88

MECHANICAL

Cylinder Block

Connecting rod oil clearance:

Standard

0.0158 — 0.0438 mm (0.0006 — 0.0017 in)

Limit

0.05 mm (0.0020 in)

6) Inspect the bushing at connecting rod small end,

and replace if worn or damaged. Also measure the

piston pin clearance at connecting rod small end.

Clearance between piston pin and bushing:

Standard

0 — 0.022 mm (0 — 0.0009 in)

Limit

0.030 mm (0.0012 in)

7) Replacement procedure is as follows.

(1) Remove the bushing from connecting rod

with ST and press.(2) Press the bushing with ST after applying oil

on the periphery of bushing.

ST 499037100 CONNECTING ROD BUSH-

ING REMOVER AND IN-

STALLER

(3) Make two 3 mm (0.12 in) holes in bushing.

Ream the inside of bushing.

(4) After the completion of reaming, clean the

bushing to remove chips.

6. CRANKSHAFT AND CRANKSHAFT

BEARING

1) Clean the crankshaft completely and check for

cracks by means of red lead check etc., and re-

place if defective.

2) Measure the crankshaft bend, and correct or re-

place if it exceeds the limit.

NOTE:

If a suitable V-block is not available, install the #1

and #5 crankshaft bearing on cylinder block, posi-

tion the crankshaft on these bearings and measure

the crankshaft bend using a dial gauge.

Crankshaft bend limit:

0.035 mm (0.0014 in)

3) Inspect the crank journal and crank pin for wear.

If they are not within the specifications, replace the

bearing with a suitable (undersize) one, and then

replace or recondition the crankshaft as necessary.

When grinding the crank journal or crank pin, finish

them to specified dimensions according to the un-

dersize bearing to be used.

Unit: mm (in)

BearingBearing size

(Thickness at cen-

ter)Outer diameter of

crank pin

Standard1.492 — 1.501

(0.0587 — 0.0591)51.984 — 52.000

(2.0466 — 2.0472)

0.03

(0.0012)

undersize1.510 — 1.513

(0.0594 — 0.0596)51.954 — 51.970

(2.0454 — 2.0461)

0.05

(0.0020)

undersize1.520 — 1.523

(0.0598 — 0.0600)51.934 — 51.950

(2.0446 — 2.0453)

0.25

(0.0098)

undersize1.620 — 1.623

(0.0638 — 0.0639)51.734 — 51.750

(2.0368 — 2.0374)

ME-00181

ME-00174

ME-00182

ST

ME-00183

Page 986 of 2870

CO(H4SO)-3

COOLING

General Description

★1: For option code, refer to ID section.

Core dimensions Width×Height×Thickness691.5×360×16 mm

(27.22×14.17×0.63 in)

Pressure range in which cap valve is openAbove: 108±15 kPa

(1.1±0.15 kg/cm

2, 16±2 psi)

Below: −1.0 to −4.9 kPa

(−0.01 to −0.05 kg/cm

2, −0.1 to −0.7 psi)

Fins Corrugated fin type

Reservoir

tankCapacity 0.52 (0.5 US qt, 0.4 Imp qt)

Page 1571 of 2870

ME(H4DOTC)-111

MECHANICAL

Cylinder Block

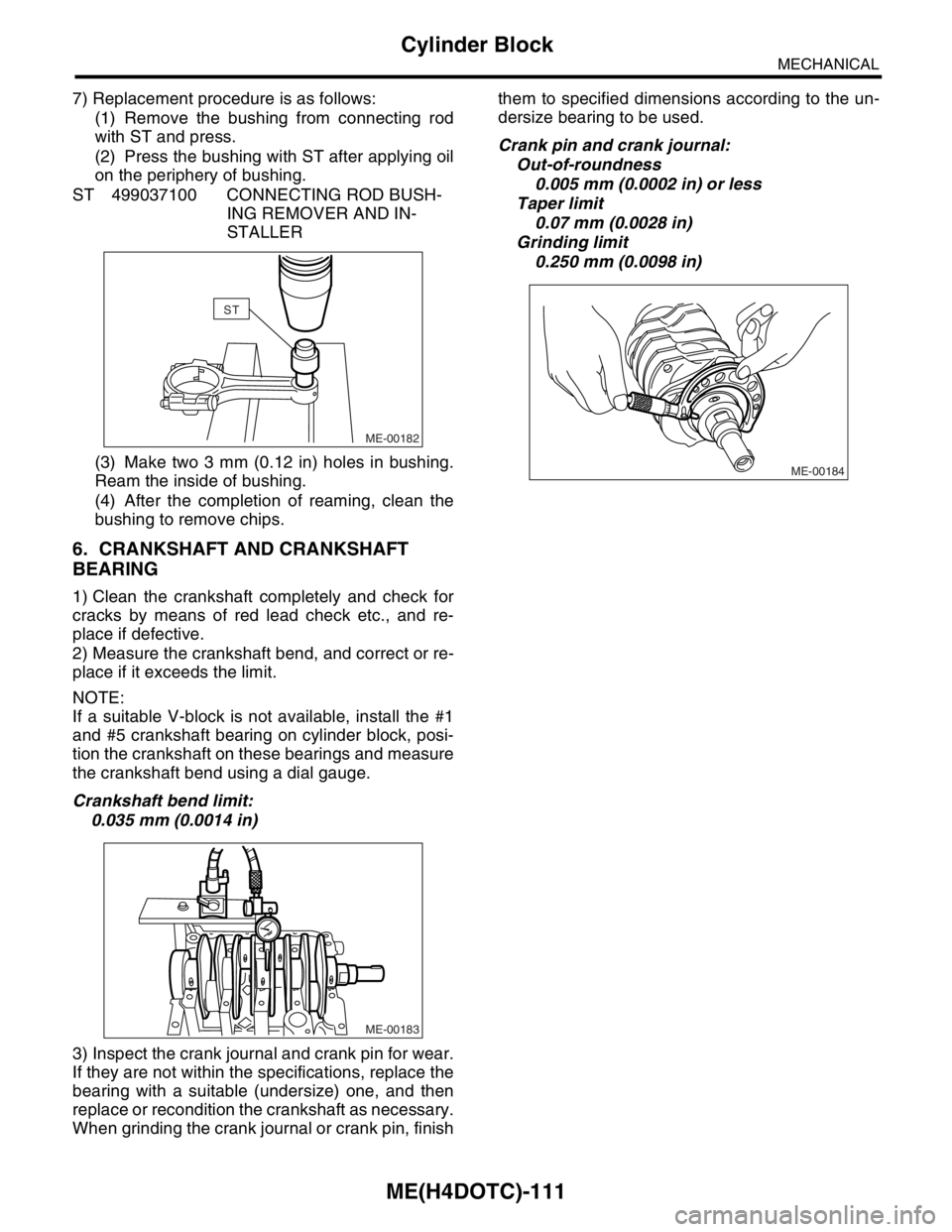

7) Replacement procedure is as follows:

(1) Remove the bushing from connecting rod

with ST and press.

(2) Press the bushing with ST after applying oil

on the periphery of bushing.

ST 499037100 CONNECTING ROD BUSH-

ING REMOVER AND IN-

STALLER

(3) Make two 3 mm (0.12 in) holes in bushing.

Ream the inside of bushing.

(4) After the completion of reaming, clean the

bushing to remove chips.

6. CRANKSHAFT AND CRANKSHAFT

BEARING

1) Clean the crankshaft completely and check for

cracks by means of red lead check etc., and re-

place if defective.

2) Measure the crankshaft bend, and correct or re-

place if it exceeds the limit.

NOTE:

If a suitable V-block is not available, install the #1

and #5 crankshaft bearing on cylinder block, posi-

tion the crankshaft on these bearings and measure

the crankshaft bend using a dial gauge.

Crankshaft bend limit:

0.035 mm (0.0014 in)

3) Inspect the crank journal and crank pin for wear.

If they are not within the specifications, replace the

bearing with a suitable (undersize) one, and then

replace or recondition the crankshaft as necessary.

When grinding the crank journal or crank pin, finishthem to specified dimensions according to the un-

dersize bearing to be used.

Crank pin and crank journal:

Out-of-roundness

0.005 mm (0.0002 in) or less

Taper limit

0.07 mm (0.0028 in)

Grinding limit

0.250 mm (0.0098 in)

ME-00182

ST

ME-00183

ME-00184