charging SUBARU FORESTER 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1064 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE2

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

ENGINE SECTION 1

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.FUEL INJECTION (FUEL SYSTEM) FU(H4SO)

EMISSION CONTROL

(AUX. EMISSION CONTROL DEVICE)EC(H4SO)

INTAKE (INDUCTION) IN(H4SO)

MECHANICAL ME(H4SO)

EXHAUST EX(H4SO)

COOLING CO(H4SO)

LUBRICATION LU(H4SO)

SPEED CONTROL SYSTEM SP(H4SO)

IGNITION IG(H4SO)

STARTING/CHARGING SYSTEM SC(H4SO)

ENGINE (DIAGNOSTIC) EN(H4SO)

Page 1075 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE2

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

ENGINE SECTION 1

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.FUEL INJECTION (FUEL SYSTEM) FU(H4SO)

EMISSION CONTROL

(AUX. EMISSION CONTROL DEVICE)EC(H4SO)

INTAKE (INDUCTION) IN(H4SO)

MECHANICAL ME(H4SO)

EXHAUST EX(H4SO)

COOLING CO(H4SO)

LUBRICATION LU(H4SO)

SPEED CONTROL SYSTEM SP(H4SO)

IGNITION IG(H4SO)

STARTING/CHARGING SYSTEM SC(H4SO)

ENGINE (DIAGNOSTIC) EN(H4SO)

Page 1076 of 2870

STARTING/CHARGING SYSTEM

SC(H4SO)

Page

1. General Description ....................................................................................2

2. Starter .........................................................................................................6

3. Generator ..................................................................................................15

4. Battery .......................................................................................................21

Page 1077 of 2870

SC(H4SO)-2

STARTING/CHARGING SYSTEM

General Description

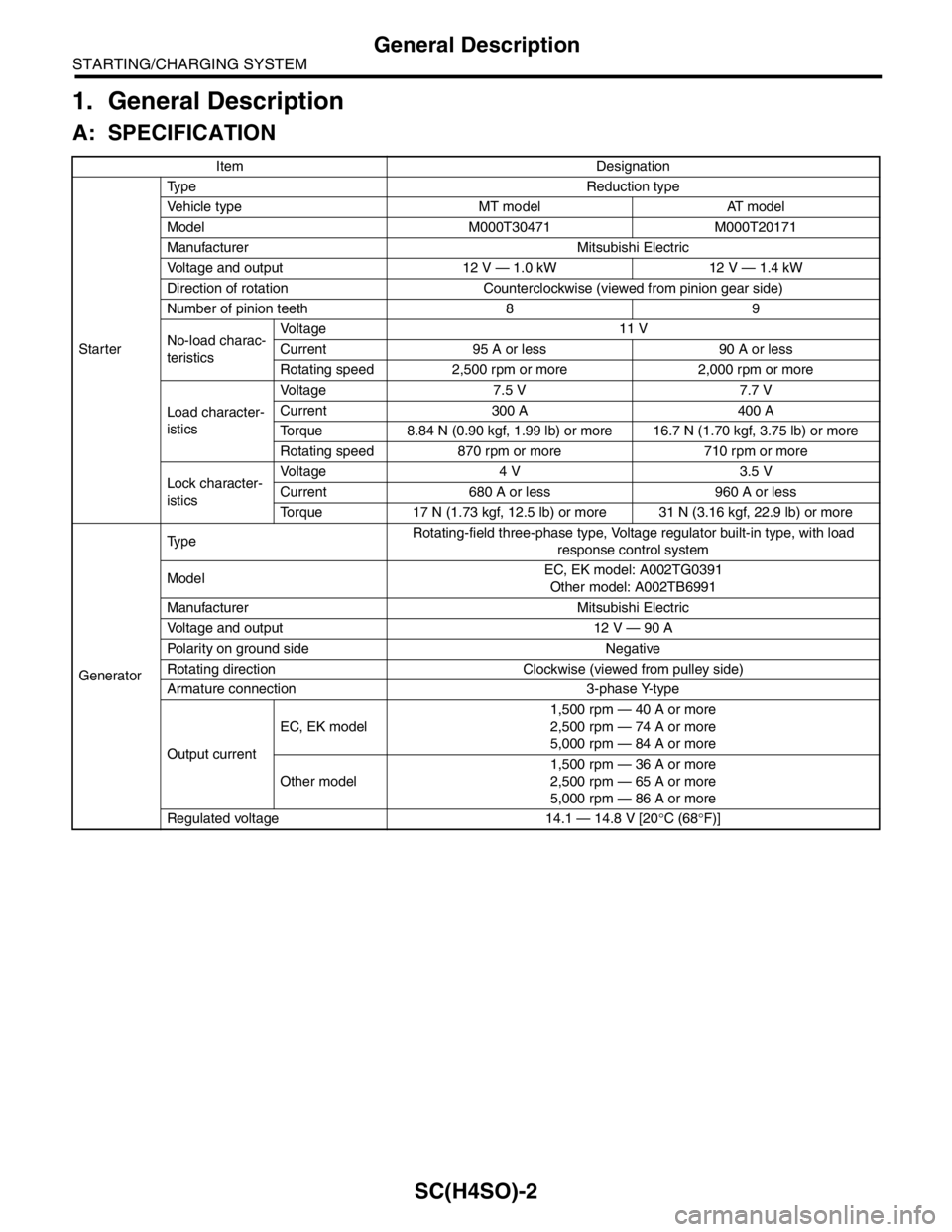

1. General Description

A: SPECIFICATION

Item Designation

StarterType Reduction type

Vehicle type MT model AT model

Model M000T30471 M000T20171

Manufacturer Mitsubishi Electric

Voltage and output 12 V — 1.0 kW 12 V — 1.4 kW

Direction of rotation Counterclockwise (viewed from pinion gear side)

Number of pinion teeth 8 9

No-load charac-

teristicsVo l t a g e 1 1 V

Current 95 A or less 90 A or less

Rotating speed 2,500 rpm or more 2,000 rpm or more

Load character-

isticsVoltage 7.5 V 7.7 V

Current 300 A 400 A

Torque 8.84 N (0.90 kgf, 1.99 lb) or more 16.7 N (1.70 kgf, 3.75 lb) or more

Rotating speed 870 rpm or more 710 rpm or more

Lock character-

isticsVo l t a g e 4 V 3 . 5 V

Current 680 A or less 960 A or less

Torque 17 N (1.73 kgf, 12.5 lb) or more 31 N (3.16 kgf, 22.9 lb) or more

GeneratorTy p eRotating-field three-phase type, Voltage regulator built-in type, with load

response control system

ModelEC, EK model: A002TG0391

Other model: A002TB6991

Manufacturer Mitsubishi Electric

Voltage and output 12 V — 90 A

Polarity on ground side Negative

Rotating direction Clockwise (viewed from pulley side)

Armature connection 3-phase Y-type

Output currentEC, EK model1,500 rpm — 40 A or more

2,500 rpm — 74 A or more

5,000 rpm — 84 A or more

Other model1,500 rpm — 36 A or more

2,500 rpm — 65 A or more

5,000 rpm — 86 A or more

Regulated voltage 14.1 — 14.8 V [20°C (68°F)]

Page 1078 of 2870

SC(H4SO)-3

STARTING/CHARGING SYSTEM

General Description

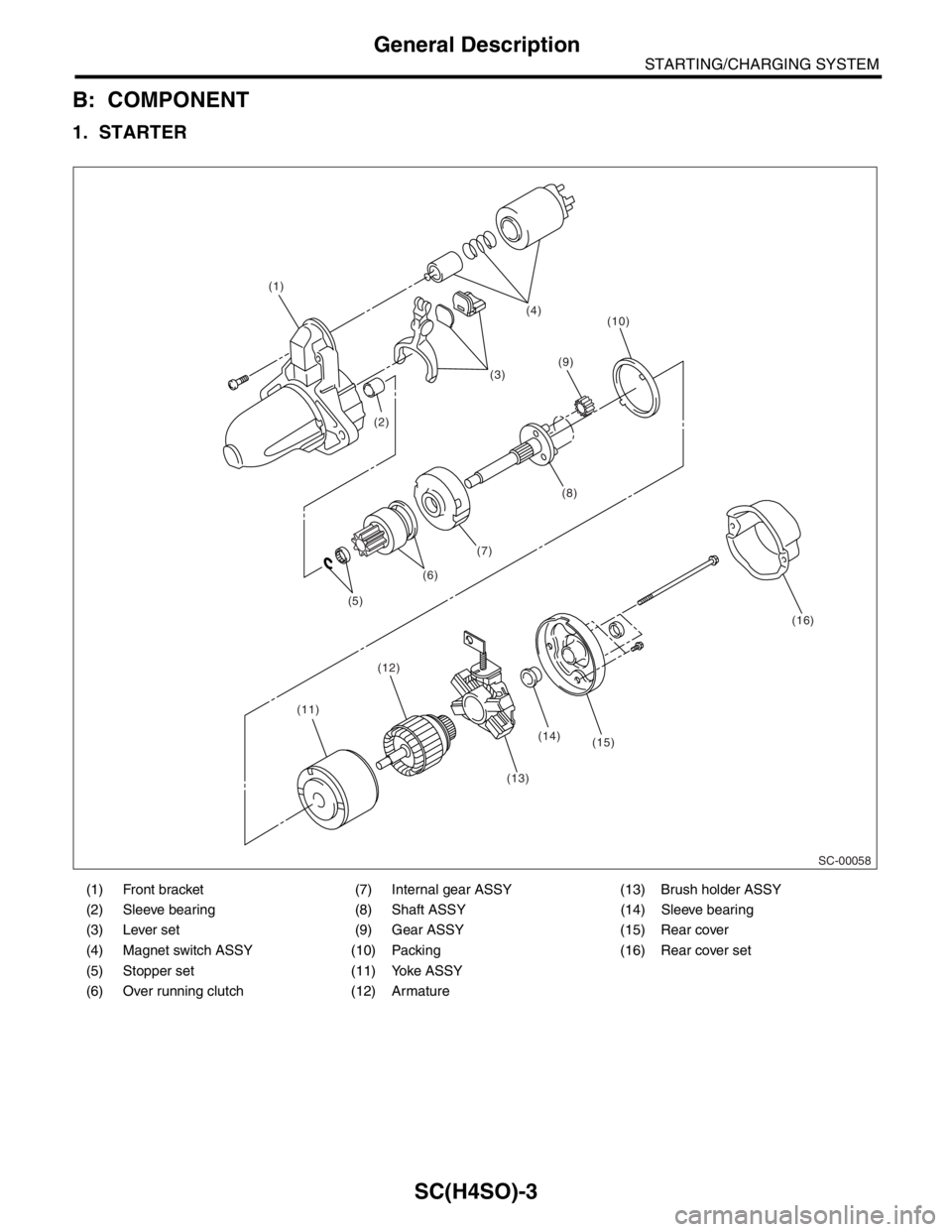

B: COMPONENT

1. STARTER

(1) Front bracket (7) Internal gear ASSY (13) Brush holder ASSY

(2) Sleeve bearing (8) Shaft ASSY (14) Sleeve bearing

(3) Lever set (9) Gear ASSY (15) Rear cover

(4) Magnet switch ASSY (10) Packing (16) Rear cover set

(5) Stopper set (11) Yoke ASSY

(6) Over running clutch (12) Armature

SC-00058

(14) (1)

(2)(3)(4)

(10)

(11)(12)

(13)(15)(16) (5)(6)(7)(8) (9)

Page 1079 of 2870

SC(H4SO)-4

STARTING/CHARGING SYSTEM

General Description

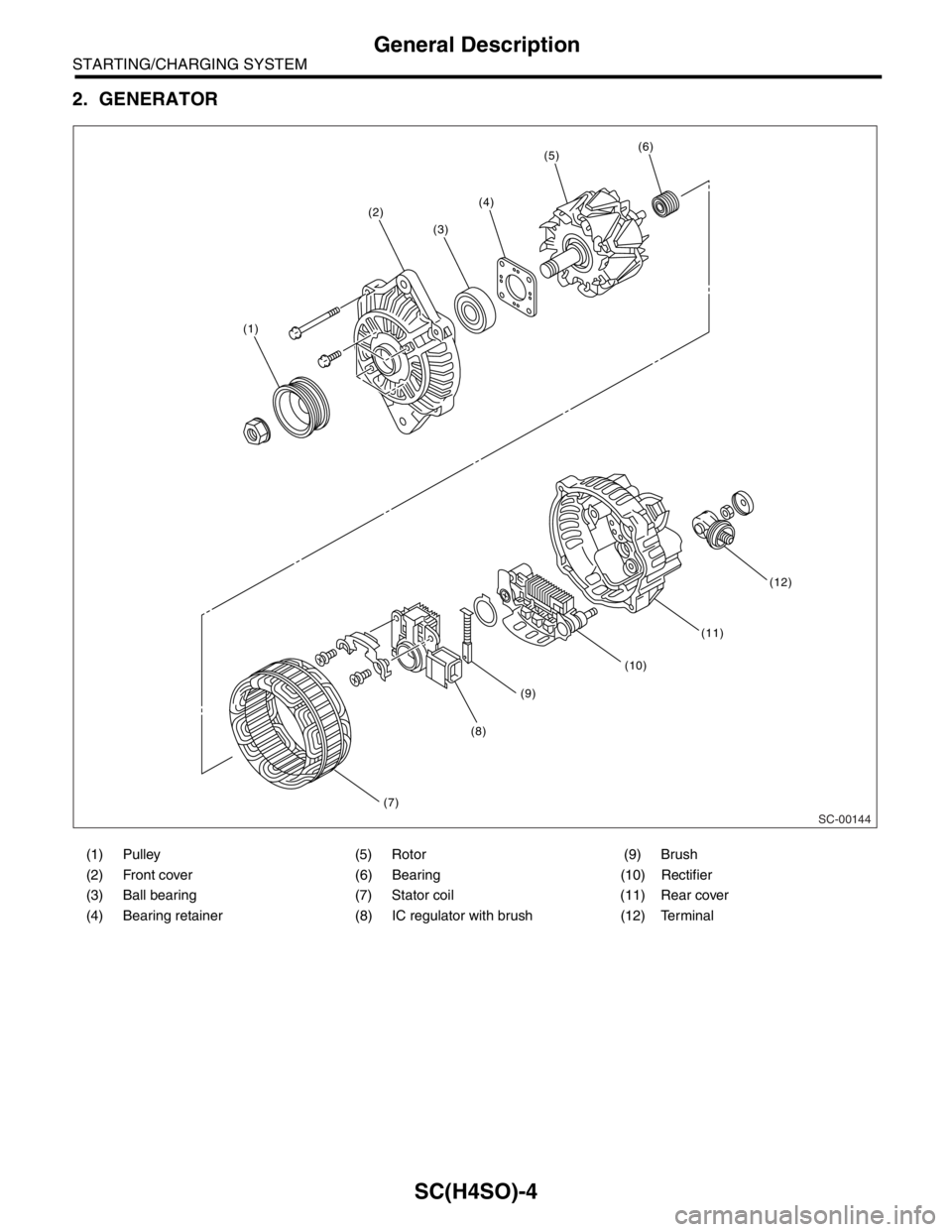

2. GENERATOR

(1) Pulley (5) Rotor (9) Brush

(2) Front cover (6) Bearing (10) Rectifier

(3) Ball bearing (7) Stator coil (11) Rear cover

(4) Bearing retainer (8) IC regulator with brush (12) Terminal

SC-00144

(1)

(2)

(7)

(8)

(9)

(10)

(11)

(12)

(3)

(4)

(5)(6)

Page 1080 of 2870

SC(H4SO)-5

STARTING/CHARGING SYSTEM

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn yourself, because each

part in the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

Page 1081 of 2870

SC(H4SO)-6

STARTING/CHARGING SYSTEM

Starter

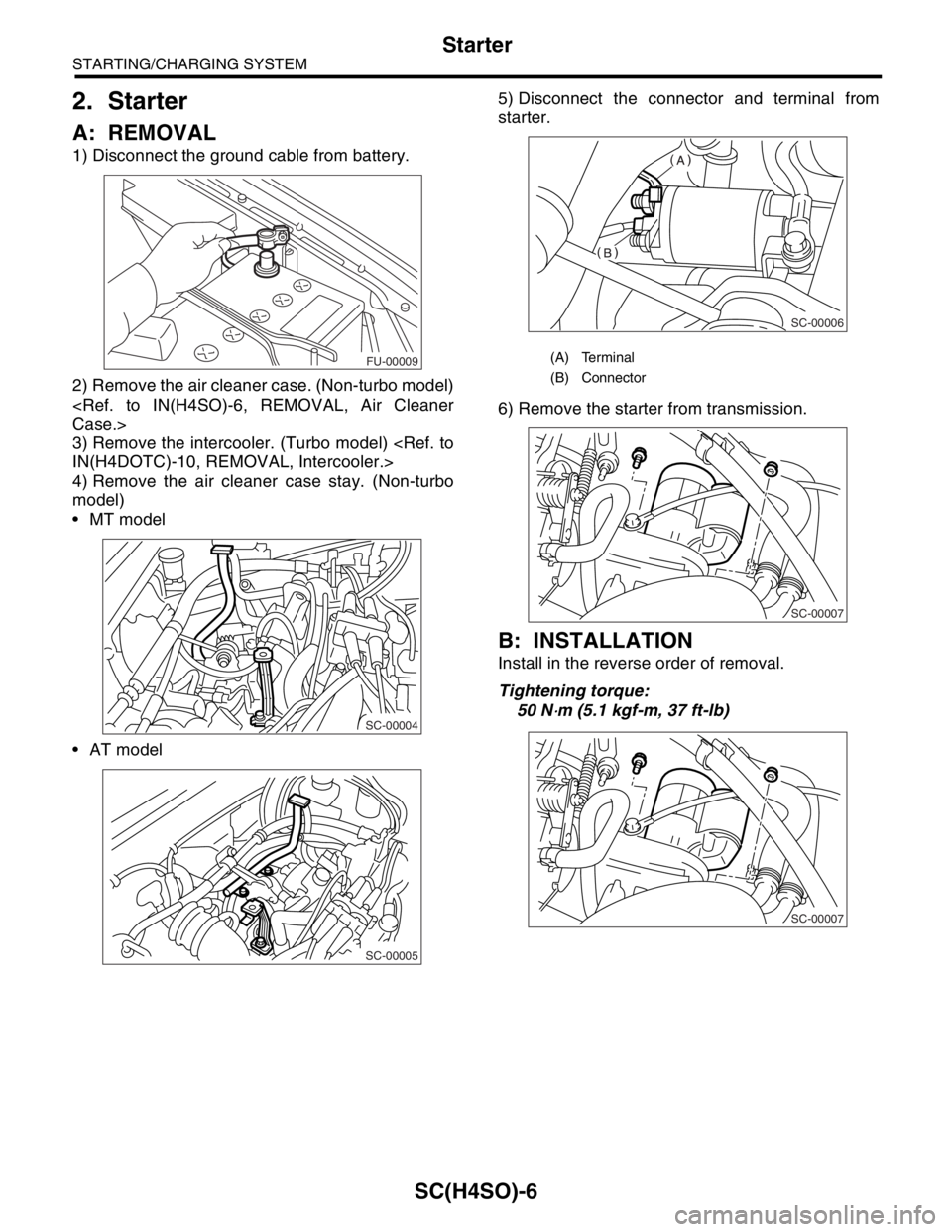

2. Starter

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air cleaner case. (Non-turbo model)

3) Remove the intercooler. (Turbo model)

4) Remove the air cleaner case stay. (Non-turbo

model)

MT model

AT model5) Disconnect the connector and terminal from

starter.

6) Remove the starter from transmission.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 37 ft-lb)

FU-00009

SC-00004

SC-00005

(A) Terminal

(B) Connector

SC-00006

SC-00007

SC-00007

Page 1082 of 2870

SC(H4SO)-7

STARTING/CHARGING SYSTEM

Starter

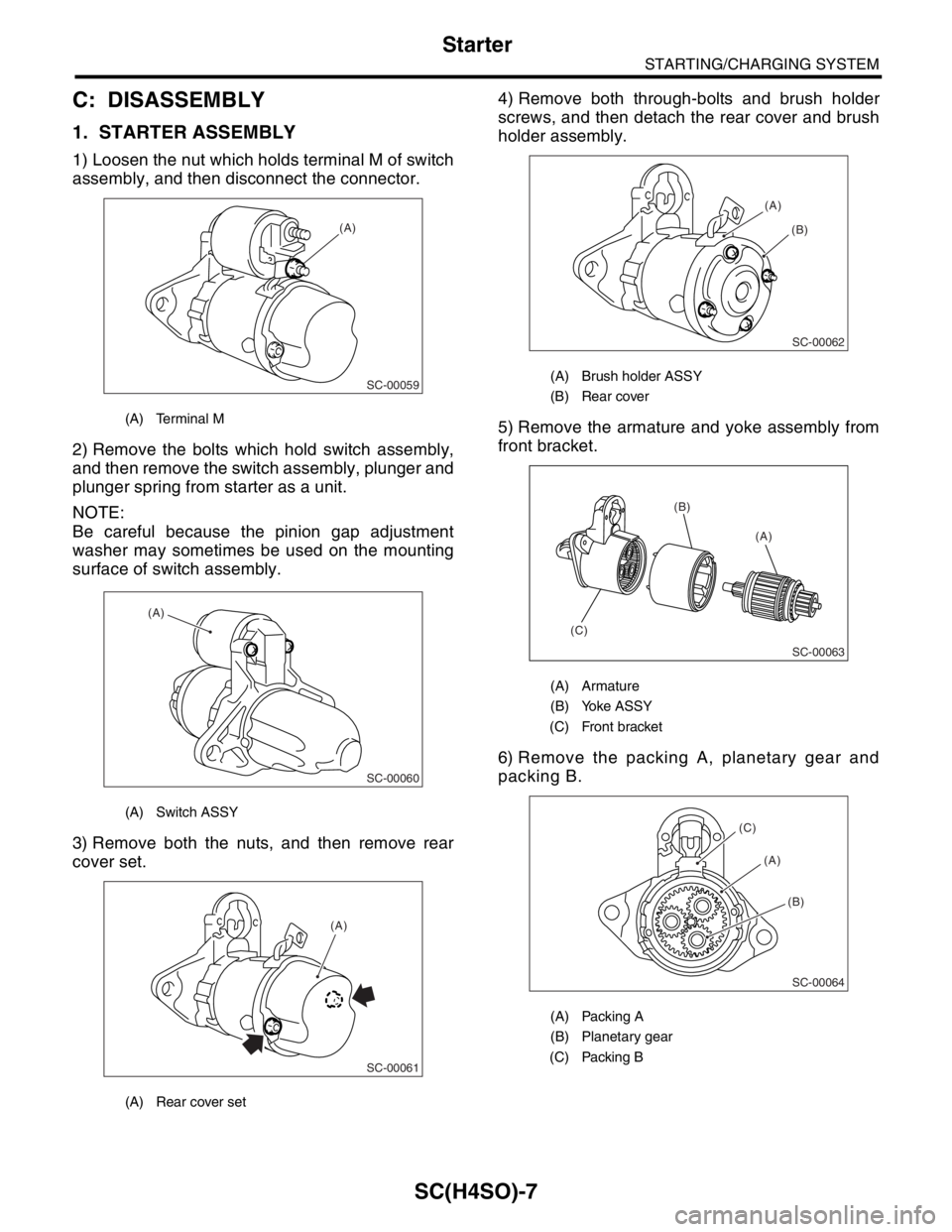

C: DISASSEMBLY

1. STARTER ASSEMBLY

1) Loosen the nut which holds terminal M of switch

assembly, and then disconnect the connector.

2) Remove the bolts which hold switch assembly,

and then remove the switch assembly, plunger and

plunger spring from starter as a unit.

NOTE:

Be careful because the pinion gap adjustment

washer may sometimes be used on the mounting

surface of switch assembly.

3) Remove both the nuts, and then remove rear

cover set.4) Remove both through-bolts and brush holder

screws, and then detach the rear cover and brush

holder assembly.

5) Remove the armature and yoke assembly from

front bracket.

6) Remove the packing A, planetary gear and

packing B.

(A) Terminal M

(A) Switch ASSY

(A) Rear cover set

SC-00059

(A)

SC-00060

(A)

SC-00061

(A)

(A) Brush holder ASSY

(B) Rear cover

(A) Armature

(B) Yoke ASSY

(C) Front bracket

(A) Packing A

(B) Planetary gear

(C) Packing B

SC-00062

(A)

(B)

(A) (B)

(C)

SC-00063

SC-00064

(A)

(C)

(B)

Page 1083 of 2870

SC(H4SO)-8

STARTING/CHARGING SYSTEM

Starter

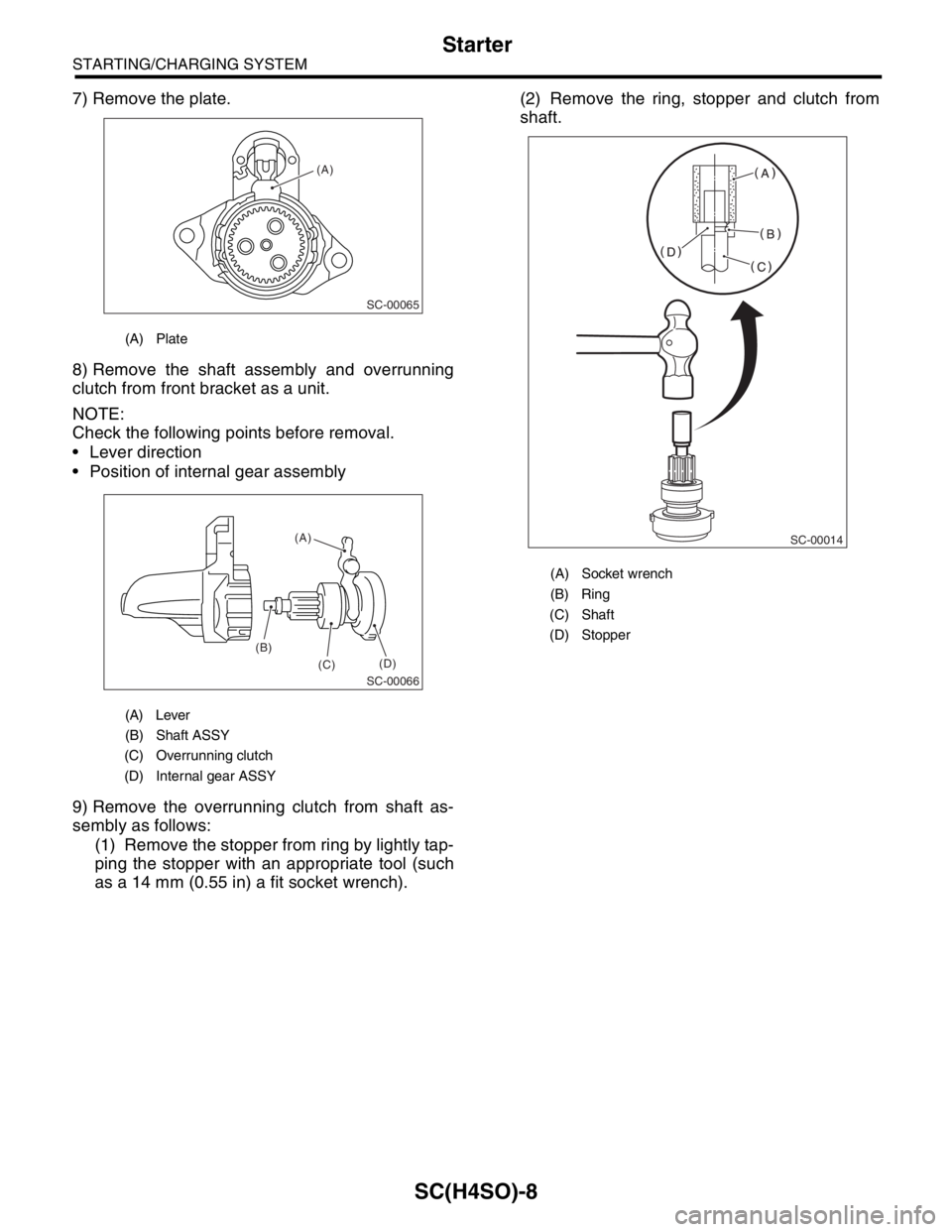

7) Remove the plate.

8) Remove the shaft assembly and overrunning

clutch from front bracket as a unit.

NOTE:

Check the following points before removal.

Lever direction

Position of internal gear assembly

9) Remove the overrunning clutch from shaft as-

sembly as follows:

(1) Remove the stopper from ring by lightly tap-

ping the stopper with an appropriate tool (such

as a 14 mm (0.55 in) a fit socket wrench).(2) Remove the ring, stopper and clutch from

shaft.

(A) Plate

(A) Lever

(B) Shaft ASSY

(C) Overrunning clutch

(D) Internal gear ASSY

SC-00065

(A)

SC-00066

(A)

(D)

(C) (B)

(A) Socket wrench

(B) Ring

(C) Shaft

(D) Stopper

SC-00014