sensor SUBARU FORESTER 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 93 of 2870

AC-37

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Procedure for Sensors

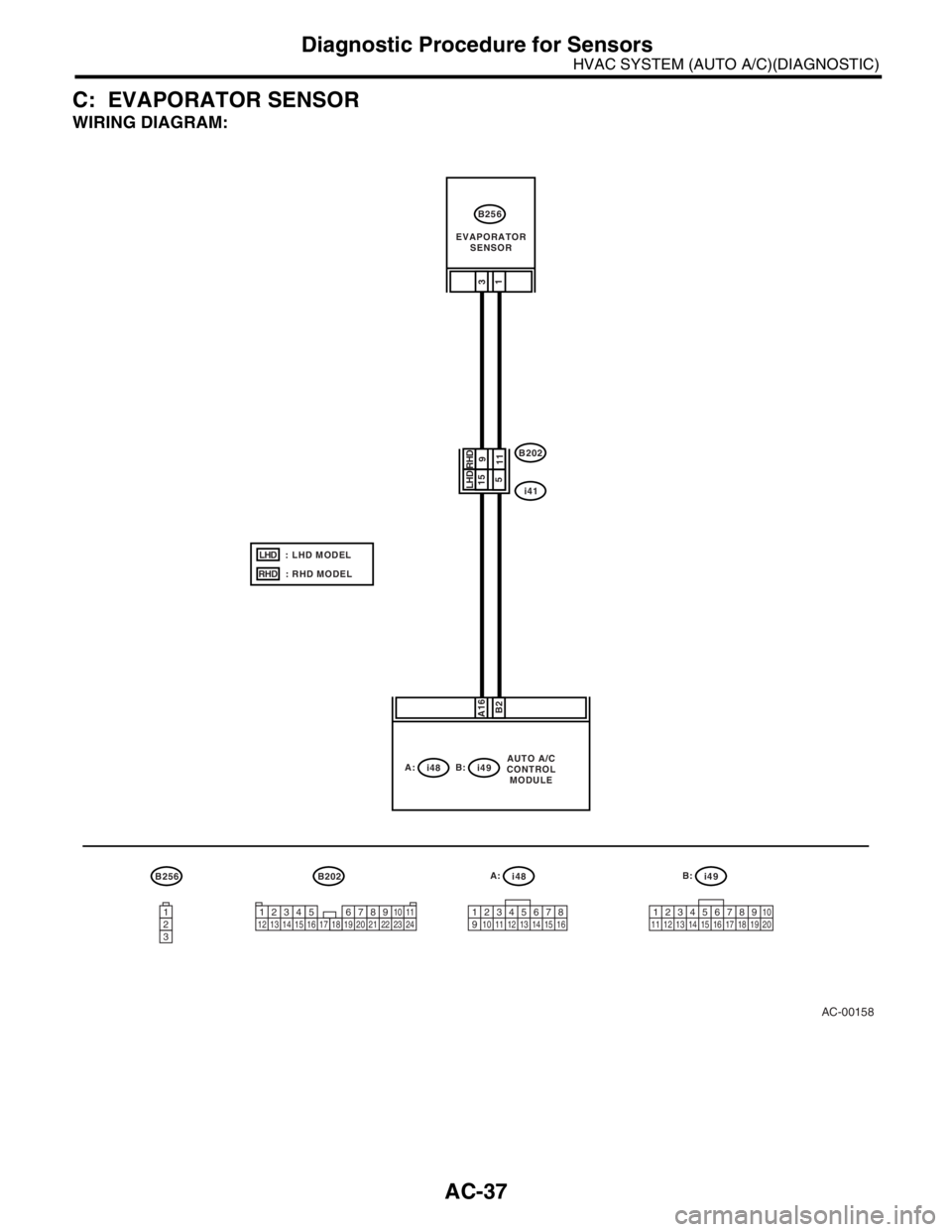

C: EVAPORATOR SENSOR

WIRING DIAGRAM:

AC-00158

A:

i48B:

i49B256

12345678

910 11 12 13 14 15 1612345678910

11 12 13 14 15 16 17 18 19 203

4 128910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

B202

B202

i41

B256

A:

i48B:

i49

A16

5

1

B23

15

123

EVAPORATOR

SENSOR

AUTO A/C

CONTROL

MODULE

119RHD LHD

: LHD MODEL

: RHD MODELLHD

RHD

Page 94 of 2870

AC-38

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Procedure for Sensors

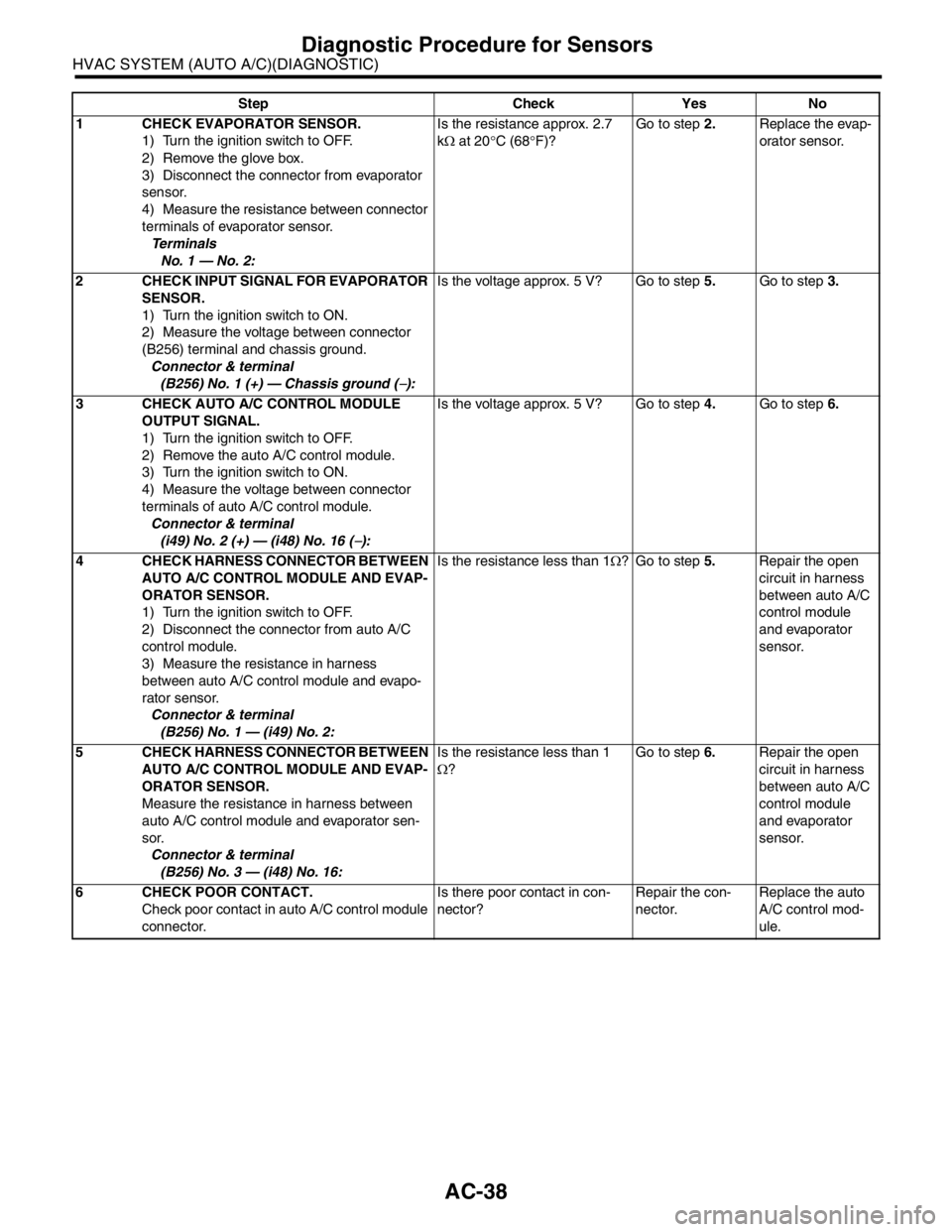

Step Check Yes No

1 CHECK EVAPORATOR SENSOR.

1) Turn the ignition switch to OFF.

2) Remove the glove box.

3) Disconnect the connector from evaporator

sensor.

4) Measure the resistance between connector

terminals of evaporator sensor.

Te r m i n a l s

No. 1 — No. 2:Is the resistance approx. 2.7

kΩ at 20°C (68°F)?Go to step 2.Replace the evap-

orator sensor.

2 CHECK INPUT SIGNAL FOR EVAPORATOR

SENSOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between connector

(B256) terminal and chassis ground.

Connector & terminal

(B256) No. 1 (+) — Chassis ground (

−):Is the voltage approx. 5 V? Go to step 5.Go to step 3.

3 CHECK AUTO A/C CONTROL MODULE

OUTPUT SIGNAL.

1) Turn the ignition switch to OFF.

2) Remove the auto A/C control module.

3) Turn the ignition switch to ON.

4) Measure the voltage between connector

terminals of auto A/C control module.

Connector & terminal

(i49) No. 2 (+) — (i48) No. 16 (

−):Is the voltage approx. 5 V? Go to step 4.Go to step 6.

4 CHECK HARNESS CONNECTOR BETWEEN

AUTO A/C CONTROL MODULE AND EVAP-

ORATOR SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from auto A/C

control module.

3) Measure the resistance in harness

between auto A/C control module and evapo-

rator sensor.

Connector & terminal

(B256) No. 1 — (i49) No. 2:Is the resistance less than 1Ω? Go to step 5.Repair the open

circuit in harness

between auto A/C

control module

and evaporator

sensor.

5 CHECK HARNESS CONNECTOR BETWEEN

AUTO A/C CONTROL MODULE AND EVAP-

ORATOR SENSOR.

Measure the resistance in harness between

auto A/C control module and evaporator sen-

sor.

Connector & terminal

(B256) No. 3 — (i48) No. 16:Is the resistance less than 1

Ω?Go to step 6.Repair the open

circuit in harness

between auto A/C

control module

and evaporator

sensor.

6 CHECK POOR CONTACT.

Check poor contact in auto A/C control module

connector.Is there poor contact in con-

nector?Repair the con-

nector.Replace the auto

A/C control mod-

ule.

Page 95 of 2870

AC-39

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Procedure for Sensors

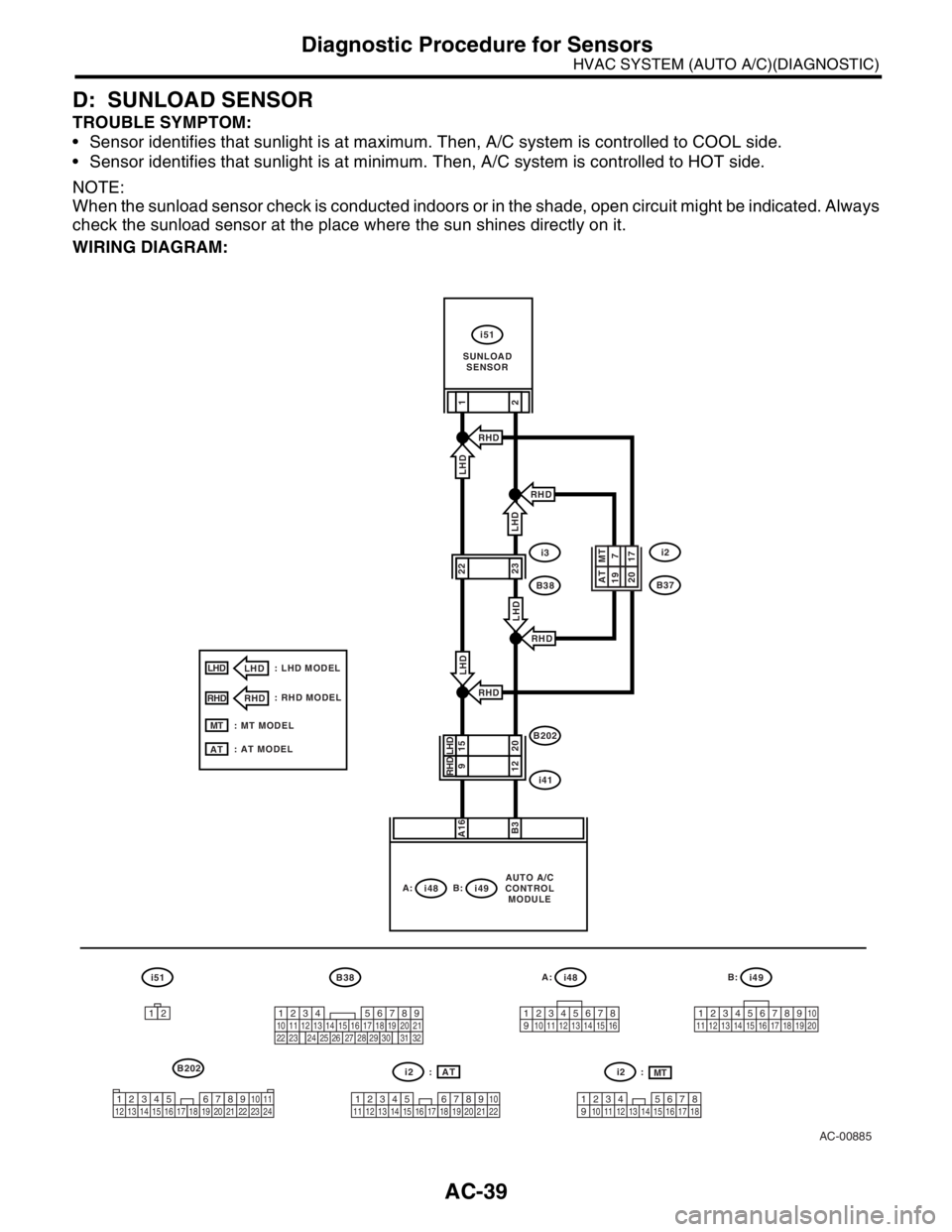

D: SUNLOAD SENSOR

TROUBLE SYMPTOM:

Sensor identifies that sunlight is at maximum. Then, A/C system is controlled to COOL side.

Sensor identifies that sunlight is at minimum. Then, A/C system is controlled to HOT side.

NOTE:

When the sunload sensor check is conducted indoors or in the shade, open circuit might be indicated. Always

check the sunload sensor at the place where the sun shines directly on it.

WIRING DIAGRAM:

AC-00885

A:

i48B:

i49

12345678

910 11 12 13 14 15 1612345678910

11 12 13 14 15 16 17 18 19 20

3

4 128910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

B202

B202

i41

i51

A:

i48B:

i49

A16

9

2

B31

12

2223

i3

B38

i51

12

SUNLOAD

SENSOR

AUTO A/C

CONTROL

MODULE

B38

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

RHD

1520LHD

LHD

LHD

RHD

RHD

LHD

RHD

LHD

RHD

2019

177i2

B37

: LHD MODEL

: RHD MODEL

LHD

RHD

LHD

RHD

3

4 128910

11 12 13 14 15 16 17 18 19 20 21 22567

i2 :

3

4 128

910 11 12 13 14 15 16 17 18567

i2 :ATMT

AT

: MT MODEL

: AT MODEL

ATMT

MT

Page 96 of 2870

AC-40

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Procedure for Sensors

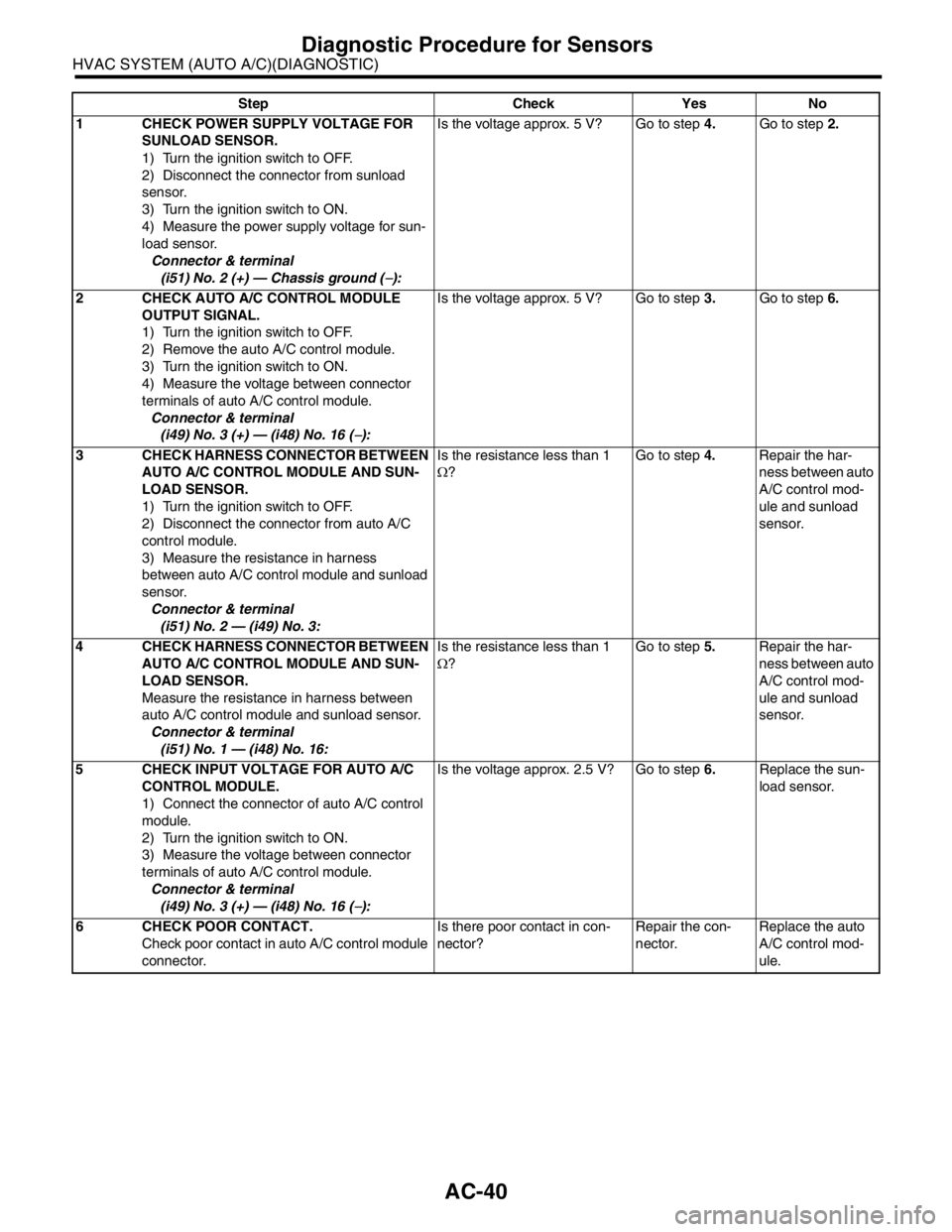

Step Check Yes No

1 CHECK POWER SUPPLY VOLTAGE FOR

SUNLOAD SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from sunload

sensor.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage for sun-

load sensor.

Connector & terminal

(i51) No. 2 (+) — Chassis ground (

−):Is the voltage approx. 5 V? Go to step 4.Go to step 2.

2 CHECK AUTO A/C CONTROL MODULE

OUTPUT SIGNAL.

1) Turn the ignition switch to OFF.

2) Remove the auto A/C control module.

3) Turn the ignition switch to ON.

4) Measure the voltage between connector

terminals of auto A/C control module.

Connector & terminal

(i49) No. 3 (+) — (i48) No. 16 (

−):Is the voltage approx. 5 V? Go to step 3.Go to step 6.

3 CHECK HARNESS CONNECTOR BETWEEN

AUTO A/C CONTROL MODULE AND SUN-

LOAD SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from auto A/C

control module.

3) Measure the resistance in harness

between auto A/C control module and sunload

sensor.

Connector & terminal

(i51) No. 2 — (i49) No. 3:Is the resistance less than 1

Ω?Go to step 4.Repair the har-

ness between auto

A/C control mod-

ule and sunload

sensor.

4 CHECK HARNESS CONNECTOR BETWEEN

AUTO A/C CONTROL MODULE AND SUN-

LOAD SENSOR.

Measure the resistance in harness between

auto A/C control module and sunload sensor.

Connector & terminal

(i51) No. 1 — (i48) No. 16:Is the resistance less than 1

Ω?Go to step 5.Repair the har-

ness between auto

A/C control mod-

ule and sunload

sensor.

5 CHECK INPUT VOLTAGE FOR AUTO A/C

CONTROL MODULE.

1) Connect the connector of auto A/C control

module.

2) Turn the ignition switch to ON.

3) Measure the voltage between connector

terminals of auto A/C control module.

Connector & terminal

(i49) No. 3 (+) — (i48) No. 16 (

−):Is the voltage approx. 2.5 V? Go to step 6.Replace the sun-

load sensor.

6 CHECK POOR CONTACT.

Check poor contact in auto A/C control module

connector.Is there poor contact in con-

nector?Repair the con-

nector.Replace the auto

A/C control mod-

ule.

Page 97 of 2870

AC-41

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

General Diagnostic Table

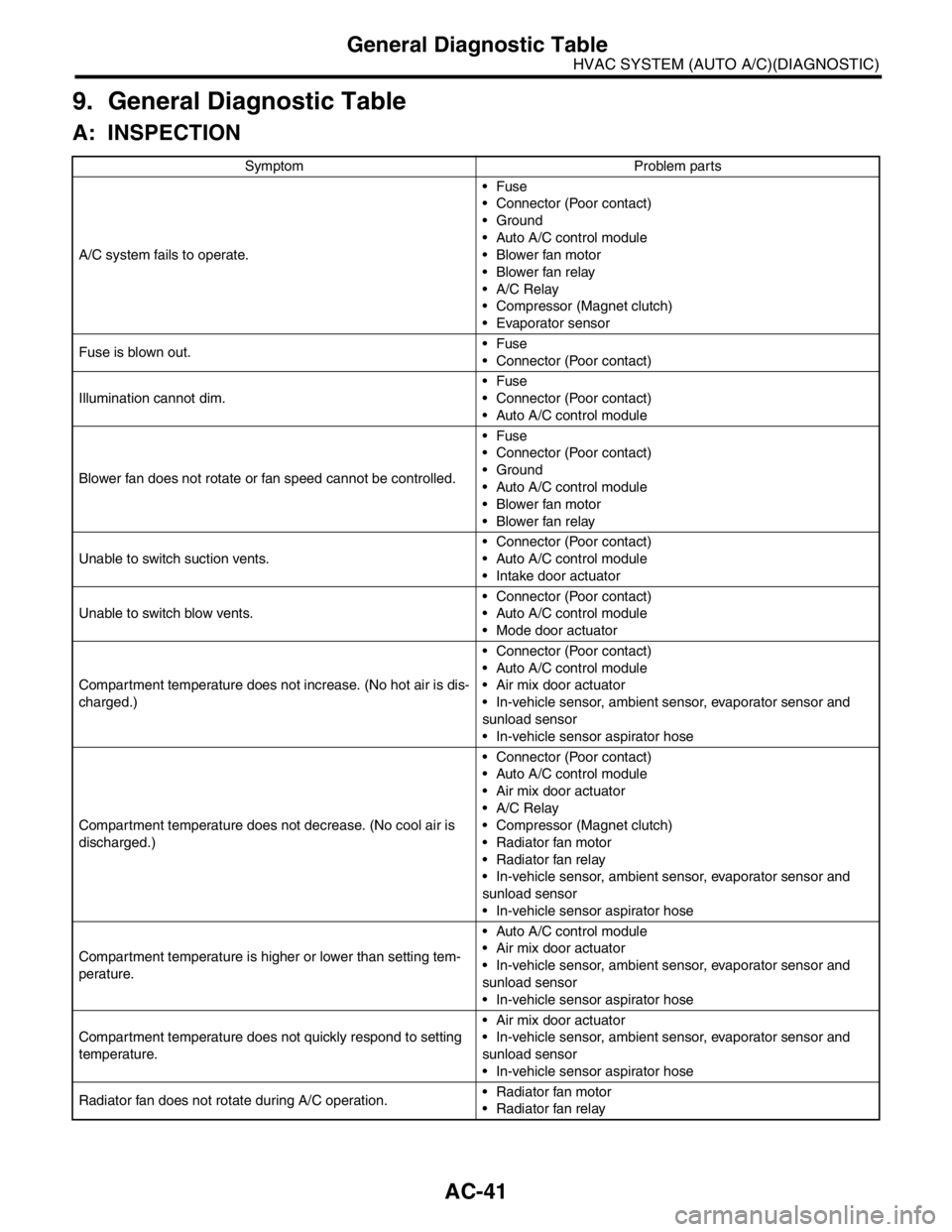

9. General Diagnostic Table

A: INSPECTION

Symptom Problem parts

A/C system fails to operate.Fuse

Connector (Poor contact)

Ground

Auto A/C control module

Blower fan motor

Blower fan relay

A/C Relay

Compressor (Magnet clutch)

Evaporator sensor

Fuse is blown out.Fuse

Connector (Poor contact)

Illumination cannot dim.Fuse

Connector (Poor contact)

Auto A/C control module

Blower fan does not rotate or fan speed cannot be controlled.Fuse

Connector (Poor contact)

Ground

Auto A/C control module

Blower fan motor

Blower fan relay

Unable to switch suction vents. Connector (Poor contact)

Auto A/C control module

Intake door actuator

Unable to switch blow vents. Connector (Poor contact)

Auto A/C control module

Mode door actuator

Compartment temperature does not increase. (No hot air is dis-

charged.) Connector (Poor contact)

Auto A/C control module

Air mix door actuator

In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

In-vehicle sensor aspirator hose

Compartment temperature does not decrease. (No cool air is

discharged.) Connector (Poor contact)

Auto A/C control module

Air mix door actuator

A/C Relay

Compressor (Magnet clutch)

Radiator fan motor

Radiator fan relay

In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

In-vehicle sensor aspirator hose

Compartment temperature is higher or lower than setting tem-

perature. Auto A/C control module

Air mix door actuator

In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

In-vehicle sensor aspirator hose

Compartment temperature does not quickly respond to setting

temperature. Air mix door actuator

In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

In-vehicle sensor aspirator hose

Radiator fan does not rotate during A/C operation. Radiator fan motor

Radiator fan relay

Page 101 of 2870

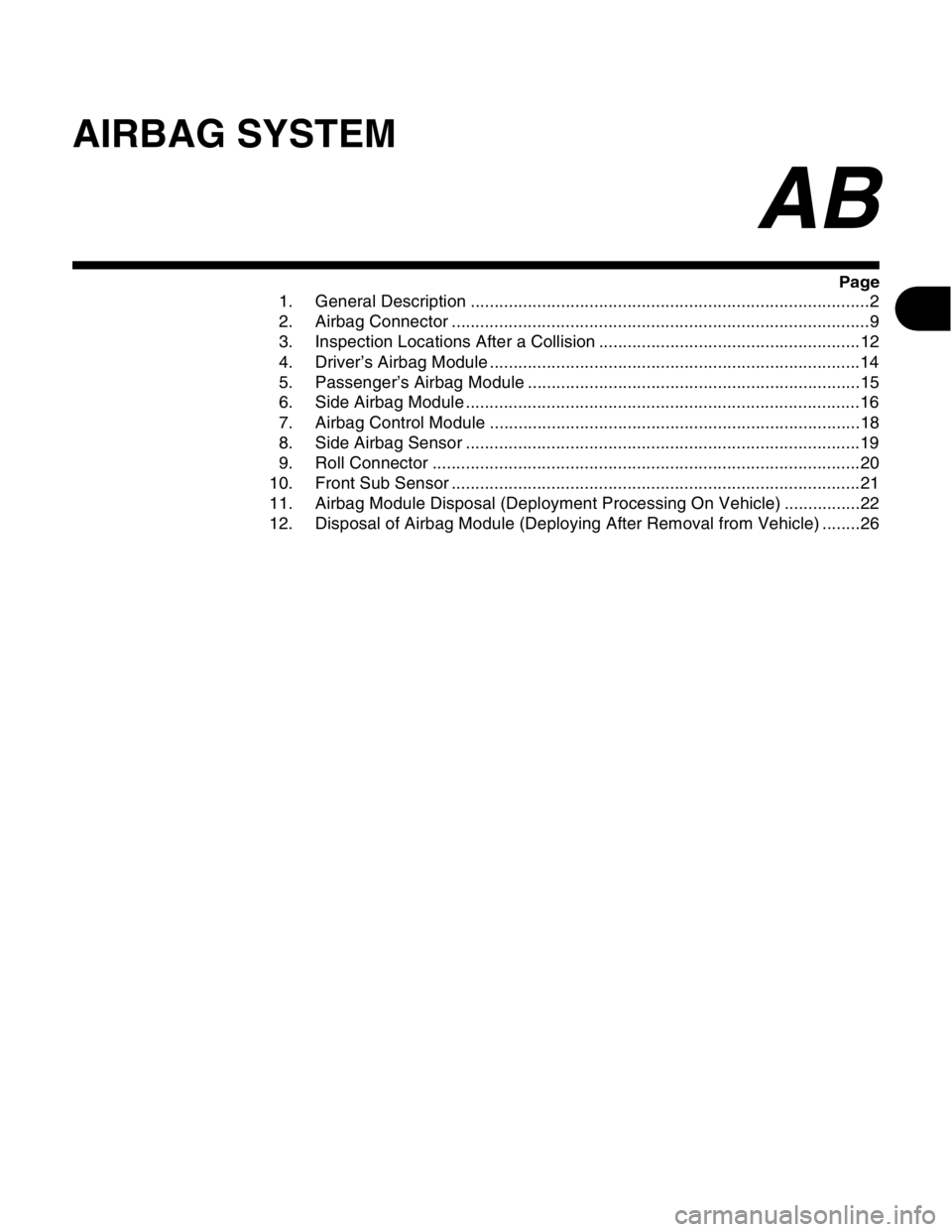

AIRBAG SYSTEM

AB

Page

1. General Description ....................................................................................2

2. Airbag Connector ........................................................................................9

3. Inspection Locations After a Collision .......................................................12

4. Driver’s Airbag Module ..............................................................................14

5. Passenger’s Airbag Module ......................................................................15

6. Side Airbag Module ...................................................................................16

7. Airbag Control Module ..............................................................................18

8. Side Airbag Sensor ...................................................................................19

9. Roll Connector ..........................................................................................20

10. Front Sub Sensor ......................................................................................21

11. Airbag Module Disposal (Deployment Processing On Vehicle) ................22

12. Disposal of Airbag Module (Deploying After Removal from Vehicle) ........26

Page 102 of 2870

AB-2

AIRBAG SYSTEM

General Description

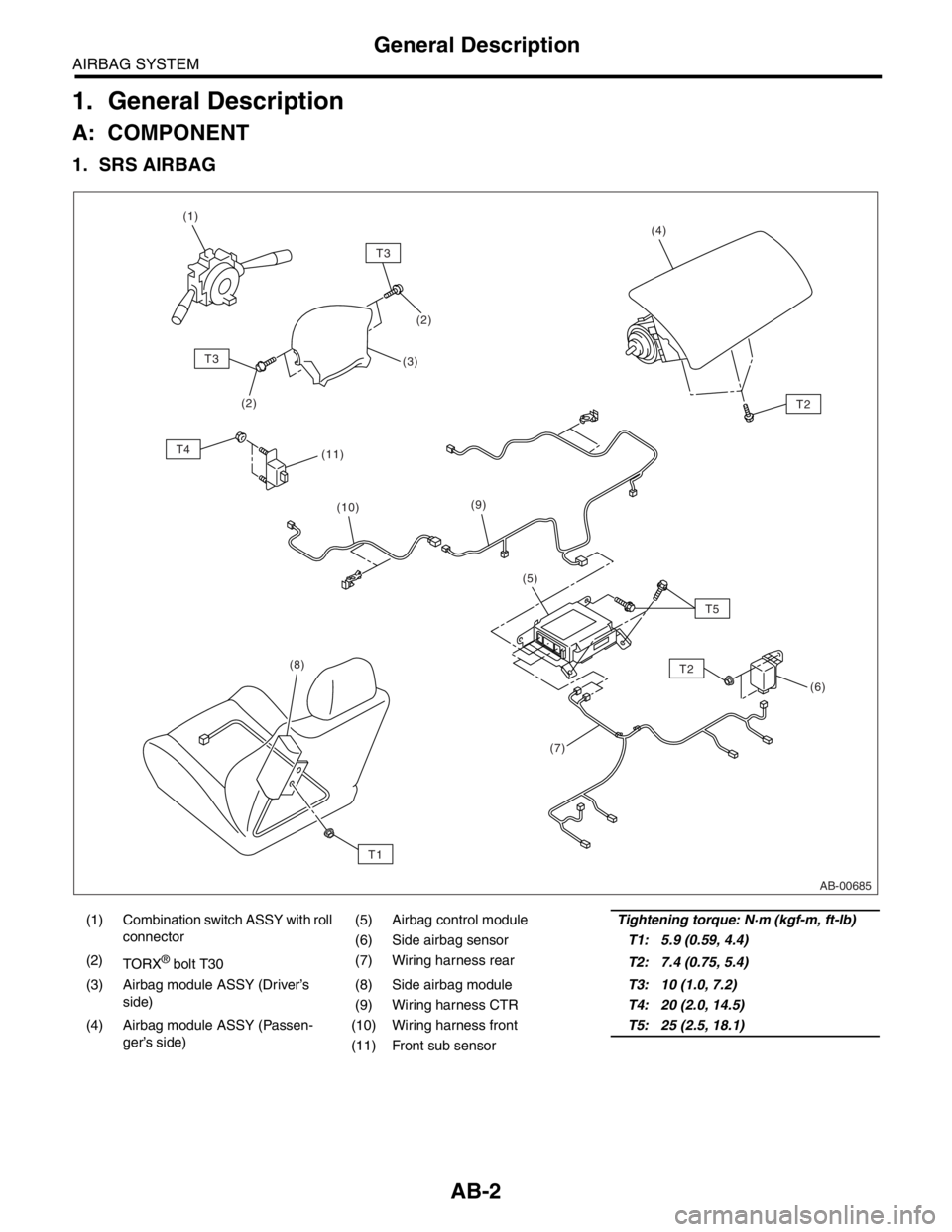

1. General Description

A: COMPONENT

1. SRS AIRBAG

(1) Combination switch ASSY with roll

connector(5) Airbag control moduleTightening torque: N·m (kgf-m, ft-lb)

(6) Side airbag sensorT1: 5.9 (0.59, 4.4)

(2)

TORX

® bolt T30(7) Wiring harness rear

T2: 7.4 (0.75, 5.4)

(3) Airbag module ASSY (Driver’s

side)(8) Side airbag moduleT3: 10 (1.0, 7.2)

(9) Wiring harness CTRT4: 20 (2.0, 14.5)

(4) Airbag module ASSY (Passen-

ger’s side)(10) Wiring harness frontT5: 25 (2.5, 18.1)

(11) Front sub sensor

AB-00685

T3

T2

T5

T3

T4(2)(4)

(3) (1)

(2)

(10)

(11)

(9)

(7)(6) (5)

(8)T2

T1

Page 103 of 2870

AB-3

AIRBAG SYSTEM

General Description

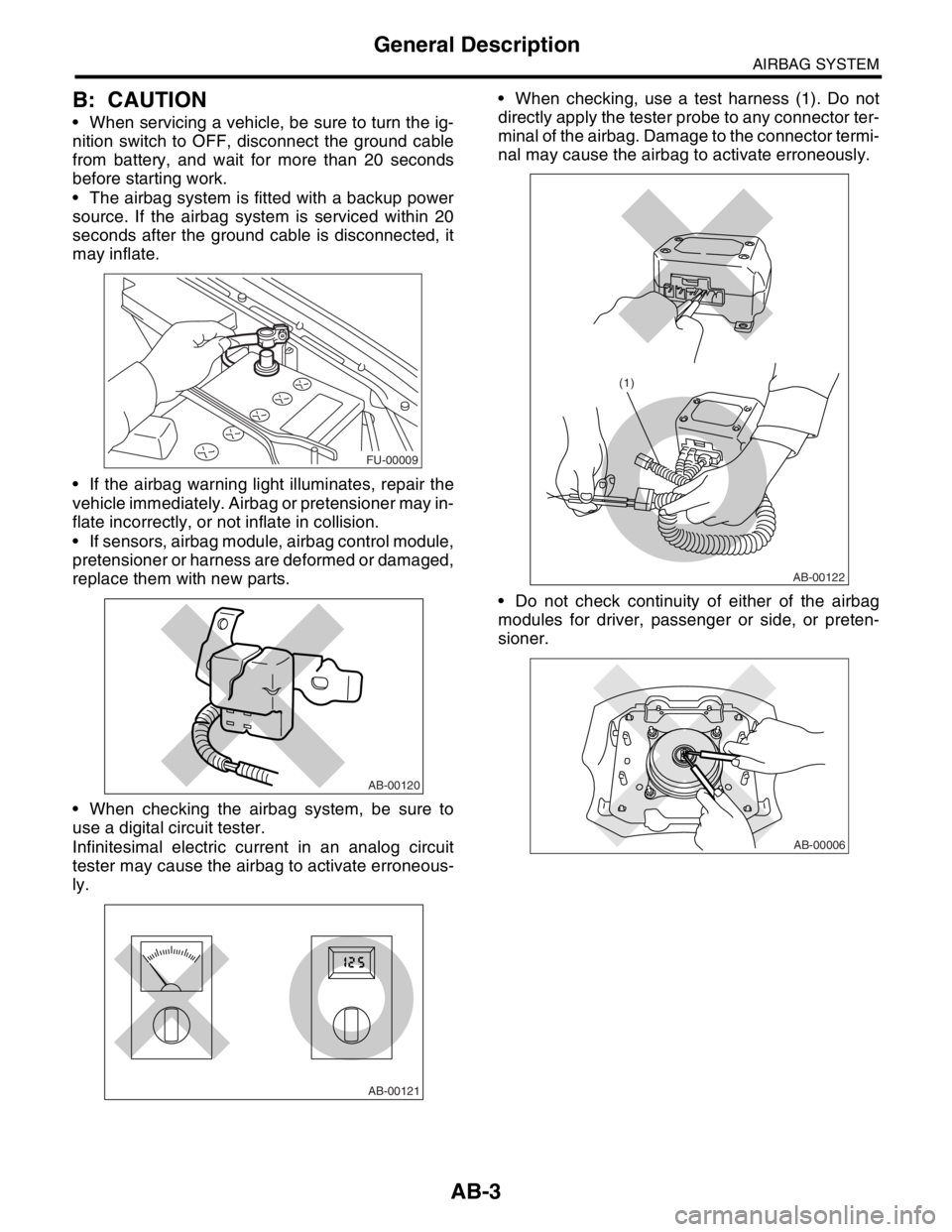

B: CAUTION

When servicing a vehicle, be sure to turn the ig-

nition switch to OFF, disconnect the ground cable

from battery, and wait for more than 20 seconds

before starting work.

The airbag system is fitted with a backup power

source. If the airbag system is serviced within 20

seconds after the ground cable is disconnected, it

may inflate.

If the airbag warning light illuminates, repair the

vehicle immediately. Airbag or pretensioner may in-

flate incorrectly, or not inflate in collision.

If sensors, airbag module, airbag control module,

pretensioner or harness are deformed or damaged,

replace them with new parts.

When checking the airbag system, be sure to

use a digital circuit tester.

Infinitesimal electric current in an analog circuit

tester may cause the airbag to activate erroneous-

ly. When checking, use a test harness (1). Do not

directly apply the tester probe to any connector ter-

minal of the airbag. Damage to the connector termi-

nal may cause the airbag to activate erroneously.

Do not check continuity of either of the airbag

modules for driver, passenger or side, or preten-

sioner.

FU-00009

AB-00120

AB-00121

AB-00122

(1)

AB-00006

Page 104 of 2870

AB-4

AIRBAG SYSTEM

General Description

Do not drop the airbag modulator parts, subject

them to high temperature over 93°C (199°F), or let

water, oil, or grease get on them; otherwise, the in-

ternal parts may be damaged and reliability greatly

lowered.

If any damage, opening, or rust is found on the

airbag system wire harness, do not attempt to re-

pair using soldering equipment. Be sure to replace

the faulty harness with a new genuine part.

Install the wire harness securely with the speci-

fied clips to avoid interference or tangled up with

other parts. Do not allow water or oil to come in contact with

the connector terminals. Do not touch the connec-

tor terminals.

Either of the airbag modules for driver, passen-

ger or side, or pretensioner must not be disassem-

bled.

The removed front seat with the airbag module

must be kept at least 200 mm (8 in) away from walls

and other objects.

Do not use the airbag or pretensioner parts from

other vehicles. Always replace defective parts with

new ones.

Never reuse a deployed airbag or pretensioner.

When painting or performing sheet metal work

on the front part of the vehicle, including the front

wheel apron, front fender, and front side frame, re-

move the front sub sensors and wire harness of the

airbag system.

AB-00123

AB-00124

AB-00125

(1) More than 200 mm (8 in)

AB-00126

AB-00779

AB-00128

(1)

Page 105 of 2870

AB-5

AIRBAG SYSTEM

General Description

When painting or performing sheet metal work

on the side of the vehicle, including the side sill,

center pillar, and front and rear doors, remove the

side airbag sensors and wire harness of the airbag

system.

AB-00129