transmission SUBARU FORESTER 2004 Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1014 of 2870

CO(H4SO)-31

COOLING

Radiator

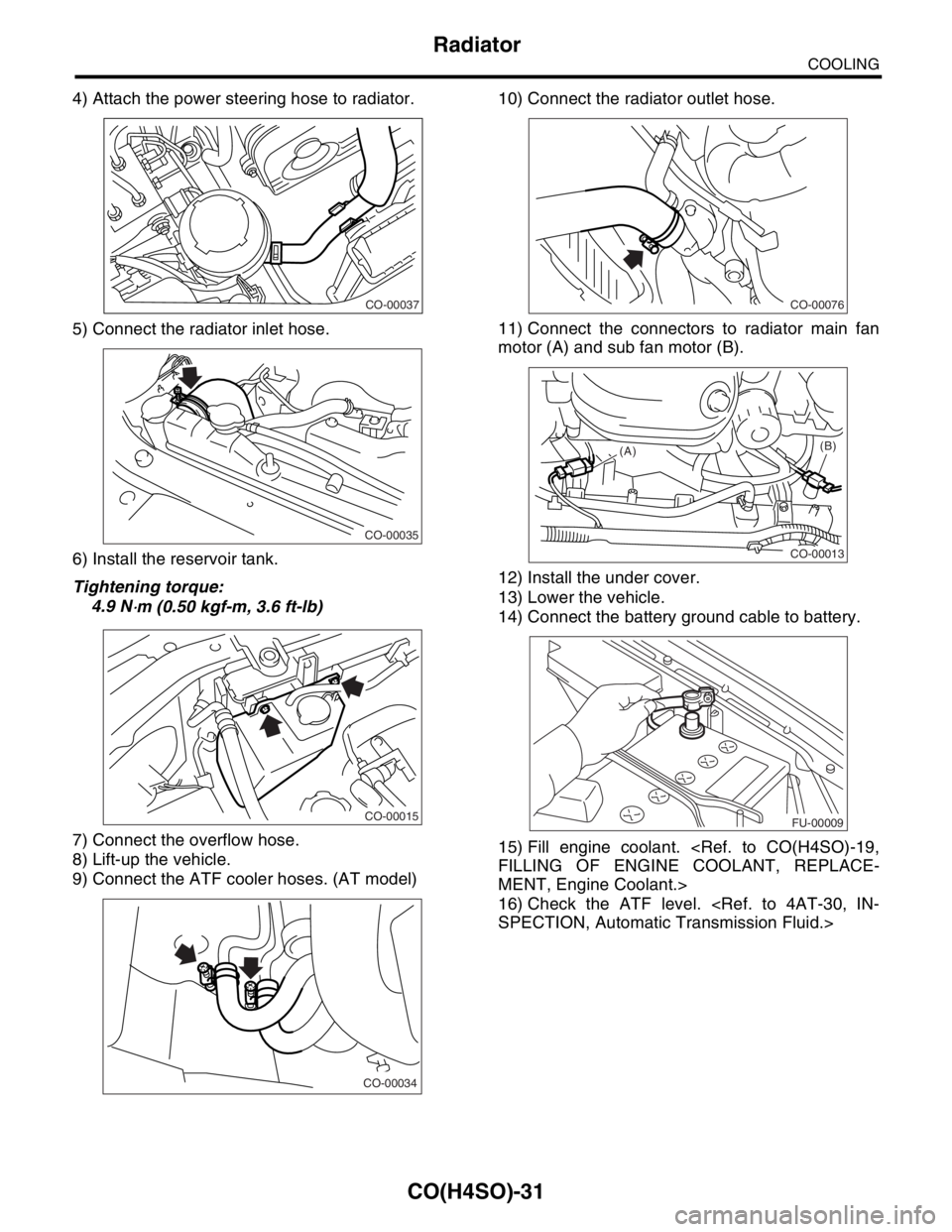

4) Attach the power steering hose to radiator.

5) Connect the radiator inlet hose.

6) Install the reservoir tank.

Tightening torque:

4.9 N

⋅m (0.50 kgf-m, 3.6 ft-lb)

7) Connect the overflow hose.

8) Lift-up the vehicle.

9) Connect the ATF cooler hoses. (AT model)10) Connect the radiator outlet hose.

11) Connect the connectors to radiator main fan

motor (A) and sub fan motor (B).

12) Install the under cover.

13) Lower the vehicle.

14) Connect the battery ground cable to battery.

15) Fill engine coolant.

MENT, Engine Coolant.>

16) Check the ATF level.

CO-00037

CO-00035

CO-00015

CO-00034

CO-00076

CO-00013

(A)(B)

FU-00009

Page 1016 of 2870

CO(H4SO)-33

COOLING

Radiator

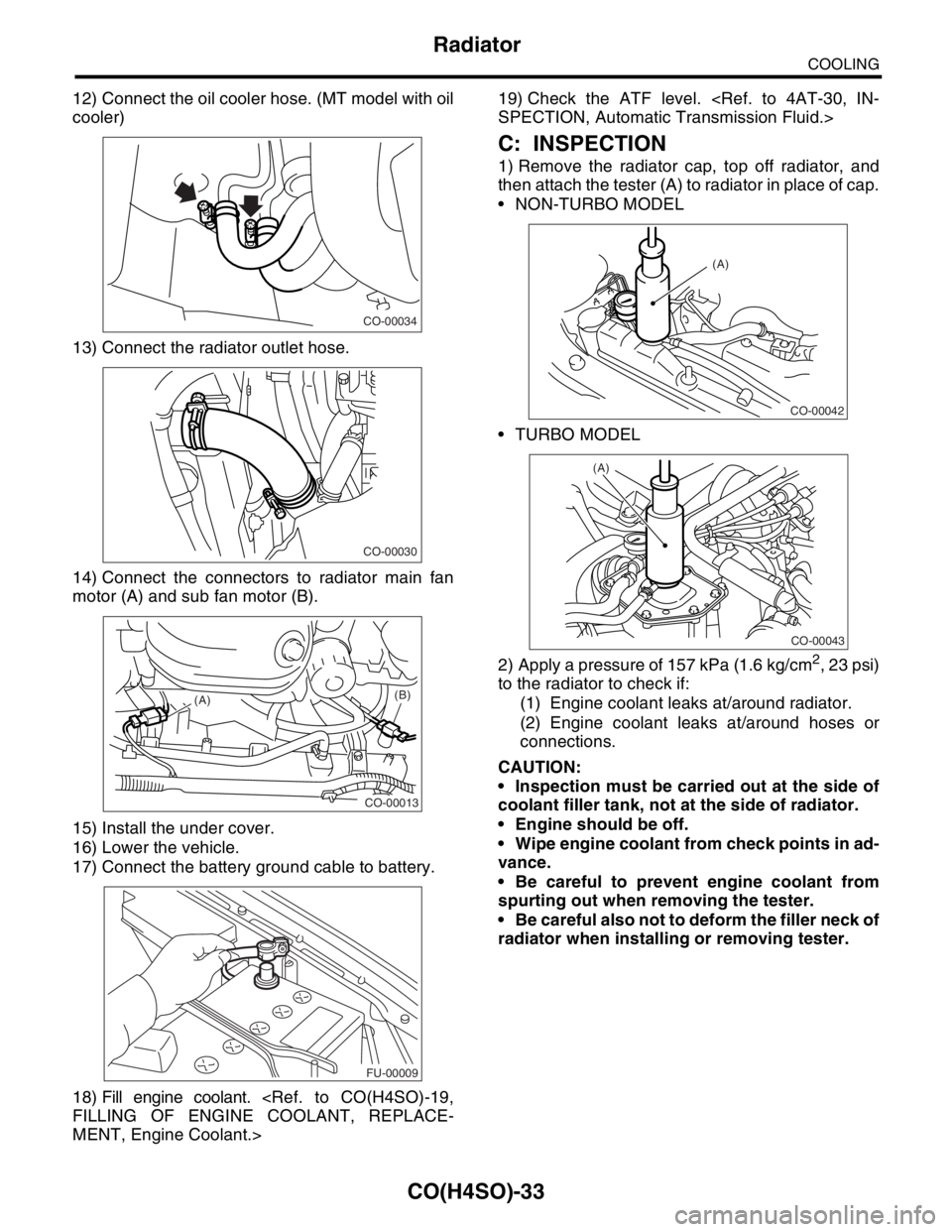

12) Connect the oil cooler hose. (MT model with oil

cooler)

13) Connect the radiator outlet hose.

14) Connect the connectors to radiator main fan

motor (A) and sub fan motor (B).

15) Install the under cover.

16) Lower the vehicle.

17) Connect the battery ground cable to battery.

18) Fill engine coolant.

MENT, Engine Coolant.>19) Check the ATF level.

C: INSPECTION

1) Remove the radiator cap, top off radiator, and

then attach the tester (A) to radiator in place of cap.

NON-TURBO MODEL

TURBO MODEL

2) Apply a pressure of 157 kPa (1.6 kg/cm

2, 23 psi)

to the radiator to check if:

(1) Engine coolant leaks at/around radiator.

(2) Engine coolant leaks at/around hoses or

connections.

CAUTION:

Inspection must be carried out at the side of

coolant filler tank, not at the side of radiator.

Engine should be off.

Wipe engine coolant from check points in ad-

vance.

Be careful to prevent engine coolant from

spurting out when removing the tester.

Be careful also not to deform the filler neck of

radiator when installing or removing tester.

CO-00034

CO-00030

CO-00013

(A)(B)

FU-00009

CO-00042

(A)

CO-00043

(A)

Page 1081 of 2870

SC(H4SO)-6

STARTING/CHARGING SYSTEM

Starter

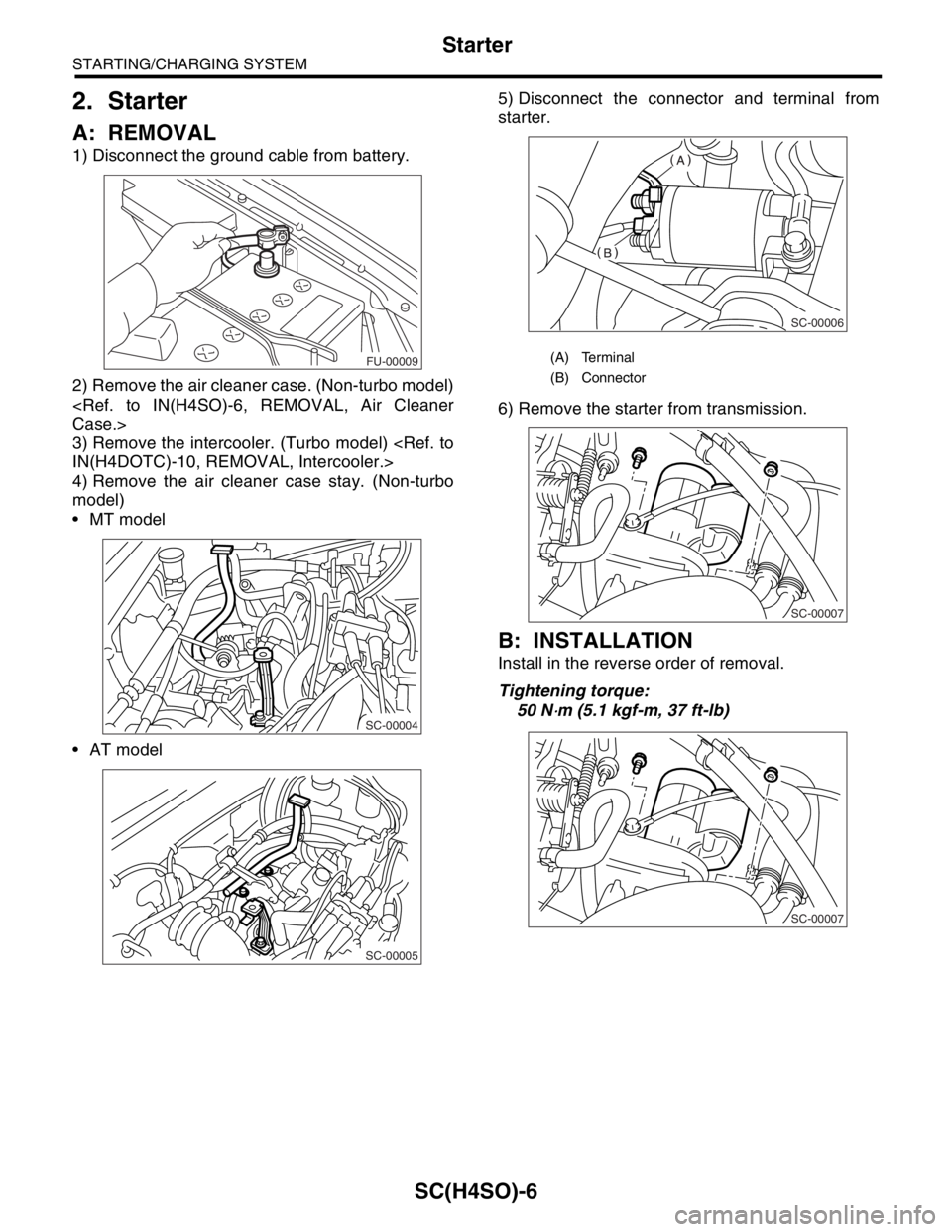

2. Starter

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air cleaner case. (Non-turbo model)

3) Remove the intercooler. (Turbo model)

4) Remove the air cleaner case stay. (Non-turbo

model)

MT model

AT model5) Disconnect the connector and terminal from

starter.

6) Remove the starter from transmission.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 37 ft-lb)

FU-00009

SC-00004

SC-00005

(A) Terminal

(B) Connector

SC-00006

SC-00007

SC-00007

Page 1099 of 2870

ENGINE (DIAGNOSTIC)

EN(H4SO)

Page

1. Basic Diagnostics Procedure ......................................................................2

2. Check List for Interview ...............................................................................4

3. General Description ....................................................................................6

4. Electrical Component Location ...................................................................9

5. Engine Control Module (ECM) I/O Signal .................................................21

6. Engine Condition Data ..............................................................................24

7. Transmission Control Module (TCM) I/O Signal .......................................25

8. Data Link Connector .................................................................................26

9. OBD-II General Scan Tool ........................................................................27

10. Subaru Select Monitor...............................................................................29

11. Read Diagnostic Trouble Code (DTC) ......................................................36

12. Inspection Mode ........................................................................................37

13. Drive Cycle ................................................................................................42

14. Clear Memory Mode..................................................................................44

15. Compulsory Valve Operation Check Mode ...............................................45

16. Malfunction Indicator Light ........................................................................47

17. Diagnostics for Engine Starting Failure .....................................................57

18. List of Diagnostic Trouble Code (DTC) .....................................................72

19. Diagnostic Procedure with Diagnostic Trouble Code (DTC) .....................78

20. General Diagnostic Table........................................................................255

Page 1101 of 2870

EN(H4SO)-3

ENGINE (DIAGNOSTIC)

Basic Diagnostics Procedure

2. AUTOMATIC TRANSMISSION

When the DTC about automatic transmission is

shown on display, carry out the following basic

check. After that, carry out the replacement or re-

pair work.

1) ATF level check

2) Differential gear oil level check

3) ATF leak check

4) Differential gear oil level check

5) Stall Test

6) Line Pressure Test

7) Transfer Clutch Pressure Test

8) Time Lag Test

9) Road Test

10) Shift characteristics

Page 1105 of 2870

EN(H4SO)-7

ENGINE (DIAGNOSTIC)

General Description

The antenna feeder must be placed as far

apart as possible from the ECM and MFI har-

ness.

Carefully adjust the antenna for correct

matching.

When mounting a large power type radio, pay

special attention to the three items above men-

tioned.

Incorrect installation of the radio may affect

the operation of the ECM.

13) Before disconnecting the fuel hose, disconnect

the fuel pump connector and crank the engine for

more than five seconds to release pressure in the

fuel system. If engine starts during this operation,

run it until it stops.

14) Problems in the electronic-controlled automatic

transmission may be caused by failure of the en-

gine, the electronic control system, the transmis-

sion proper, or by a combination of these. These

three causes must be distinguished clearly when

performing diagnostics.

15) Diagnostics should be conducted by rotating

with simple, easy operations and proceeding to

complicated, difficult operations. The most impor-

tant thing in diagnostics is to understand the cus-

tomer’s complaint, and distinguish between the

three causes.

16) In AT models, do not continue the stall for more

than five seconds. (from closed throttle, fully open

throttle to stall engine speed.)

17) On the model with ABS, when performing driv-

ing test in jacked-up or lifted-up position, some-

times the warning light may be lit, but this is not a

malfunction of the system. The reason for this is the

speed difference between the front and rear

wheels. After diagnosis of engine control system,

perform the ABS memory clearance procedure of

self-diagnosis function.

B: INSPECTION

Before performing diagnostics, check the following

items which might affect engine problems:

1. BATTERY

1) Measure battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

2) Check the condition of the main and other fuses,

and harnesses and connectors. Also check for

proper grounding.

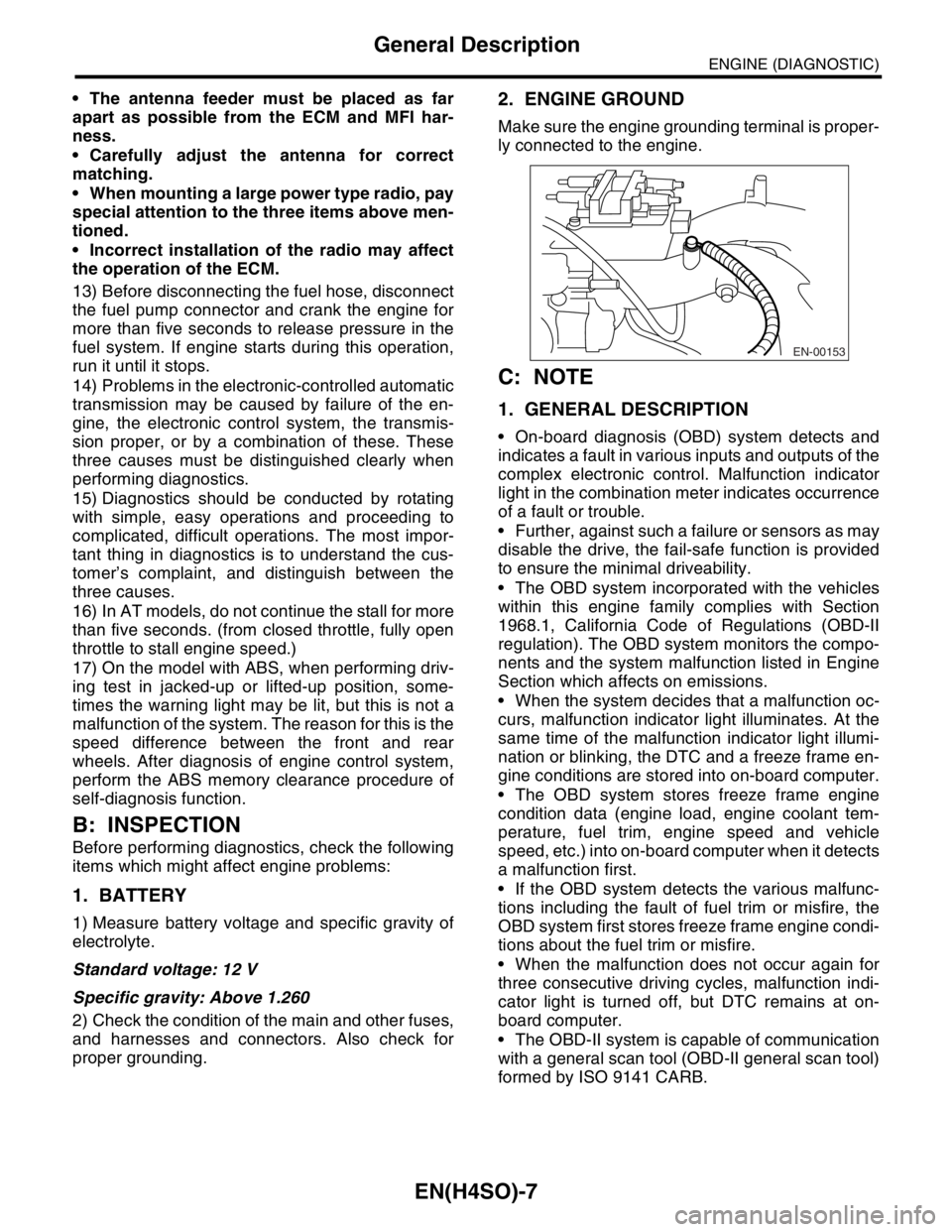

2. ENGINE GROUND

Make sure the engine grounding terminal is proper-

ly connected to the engine.

C: NOTE

1. GENERAL DESCRIPTION

On-board diagnosis (OBD) system detects and

indicates a fault in various inputs and outputs of the

complex electronic control. Malfunction indicator

light in the combination meter indicates occurrence

of a fault or trouble.

Further, against such a failure or sensors as may

disable the drive, the fail-safe function is provided

to ensure the minimal driveability.

The OBD system incorporated with the vehicles

within this engine family complies with Section

1968.1, California Code of Regulations (OBD-II

regulation). The OBD system monitors the compo-

nents and the system malfunction listed in Engine

Section which affects on emissions.

When the system decides that a malfunction oc-

curs, malfunction indicator light illuminates. At the

same time of the malfunction indicator light illumi-

nation or blinking, the DTC and a freeze frame en-

gine conditions are stored into on-board computer.

The OBD system stores freeze frame engine

condition data (engine load, engine coolant tem-

perature, fuel trim, engine speed and vehicle

speed, etc.) into on-board computer when it detects

a malfunction first.

If the OBD system detects the various malfunc-

tions including the fault of fuel trim or misfire, the

OBD system first stores freeze frame engine condi-

tions about the fuel trim or misfire.

When the malfunction does not occur again for

three consecutive driving cycles, malfunction indi-

cator light is turned off, but DTC remains at on-

board computer.

The OBD-II system is capable of communication

with a general scan tool (OBD-II general scan tool)

formed by ISO 9141 CARB.

EN-00153

Page 1106 of 2870

EN(H4SO)-8

ENGINE (DIAGNOSTIC)

General Description

The OBD-II diagnostics procedure is different

from the usual diagnosis procedure. When trouble-

shooting the OBD-II models, connect Subaru Se-

lect Monitor or the OBD-II general scan tool to the

vehicle.

2. ENGINE AND EMISSION CONTROL SYS-

TEM

MFI system is a system that supplies the opti-

mum air-fuel mixture to the engine for all the vari-

ous operating conditions through the use of the

latest electronic technology.

With this system fuel, which is pressurized at a con-

stant pressure, is injected into the intake air pas-

sage of the cylinder head. The injection quantity of

fuel is controlled by an intermittent injection system

where the electro-magnetic injection valve (fuel in-

jector) opens only for a short period of time, de-

pending on the quantity of air required for one cycle

of operation. In actual operation, the injection quan-

tity is determined by the duration of an electric sig-

nal applied to the fuel injector and this permits

simple, yet highly precise metering of the fuel.

Further, all the operating conditions of the engine

are converted into electric signals, and this results

in additional features of the system, such as large

improved adaptability, easier addition of compen-

sating element, etc.The MFI system also has the following features:

Reduced emission of harmful exhaust gases.

Reduced in fuel consumption.

Increased engine output.

Superior acceleration and deceleration.

Excellent engine start and warm-up perfor-

mance by the correction of engine coolant tem-

perature and intake air temperature.3. AUTOMATIC TRANSMISSION AND

ELECTRONIC-HYDRAULIC CONTROL SYS-

TEM

The electronic-hydraulic control system consists of

various sensors and switches, TCM and the hy-

draulic controller including solenoid valves. The

system controls the transmission body including

shift control, lock-up control, overrunning clutch

control, line pressure control and shift timing con-

trol. It also controls the AWD transfer clutch. In oth-

er words, the system detects various operating

conditions from various input signals and sends

output signals to shift solenoids 1, 2 and low clutch

timing solenoid and 2-4 brake timing solenoid, line

pressure duty solenoid, lock-up duty solenoid,

transfer duty solenoid and 2-4 brake duty solenoid

(a total of eight solenoids).

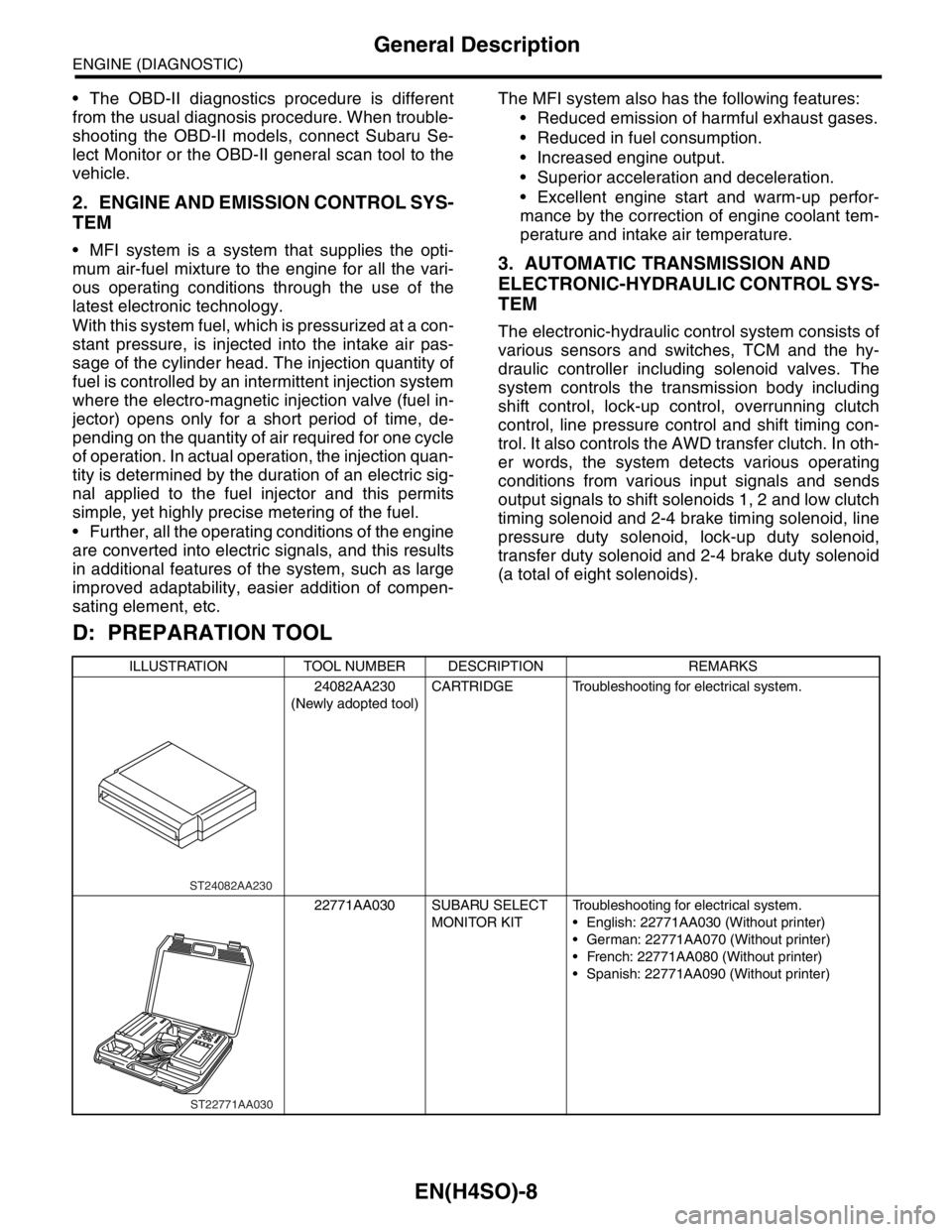

D: PREPARATION TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

24082AA230

(Newly adopted tool)CARTRIDGE Troubleshooting for electrical system.

22771AA030 SUBARU SELECT

MONITOR KITTroubleshooting for electrical system.

English: 22771AA030 (Without printer)

German: 22771AA070 (Without printer)

French: 22771AA080 (Without printer)

Spanish: 22771AA090 (Without printer)

ST24082AA230

ST22771AA030

Page 1116 of 2870

EN(H4SO)-18

ENGINE (DIAGNOSTIC)

Electrical Component Location

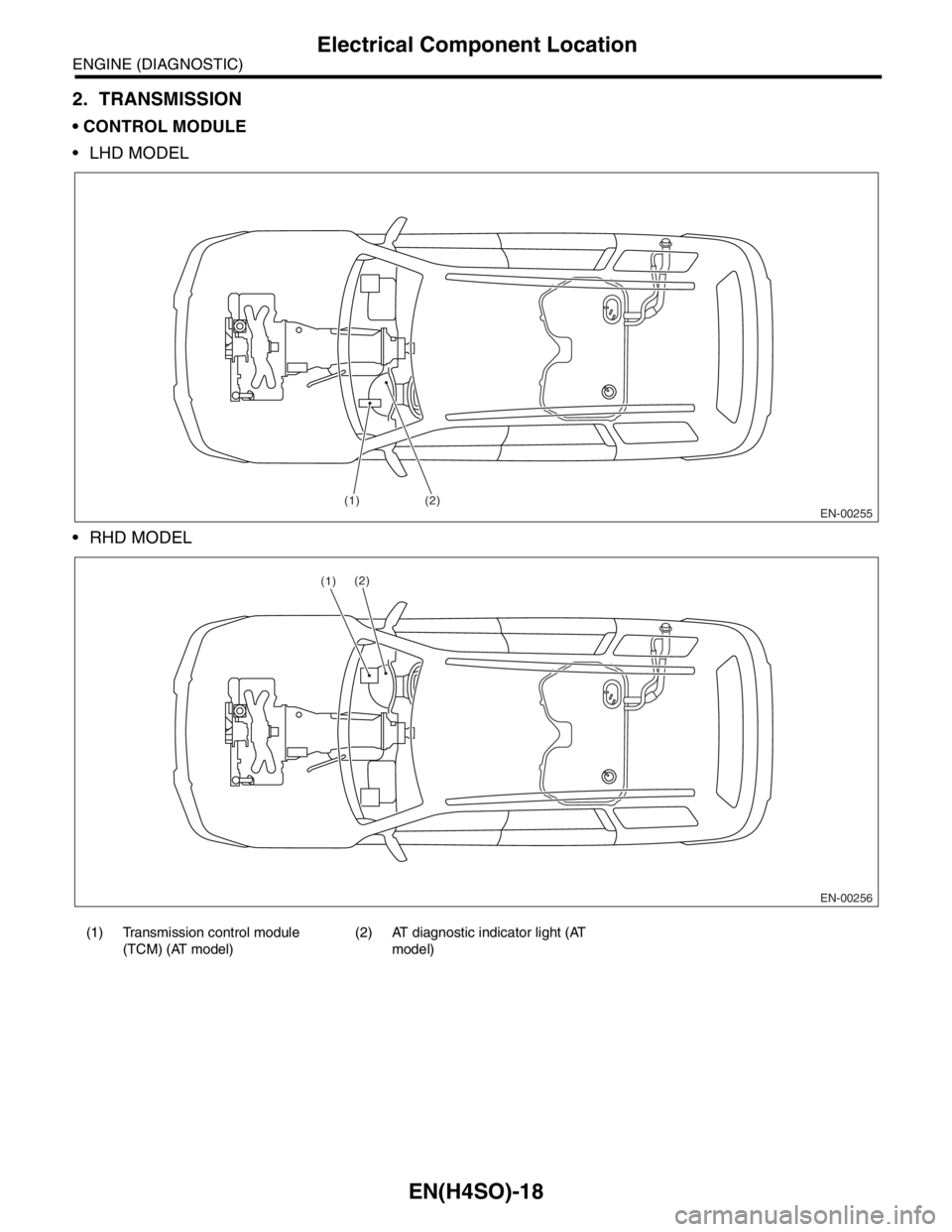

2. TRANSMISSION

CONTROL MODULE

LHD MODEL

RHD MODEL

(1) Transmission control module

(TCM) (AT model)(2) AT diagnostic indicator light (AT

model)

EN-00255(1)(2)

EN-00256 (1)(2)

Page 1123 of 2870

EN(H4SO)-25

ENGINE (DIAGNOSTIC)

Transmission Control Module (TCM) I/O Signal

7. Transmission Control Module (TCM) I/O Signal

A: ELECTRICAL SPECIFICATION

For the electrical specification of TCM I/O signal, refer to 4AT(H4SO) section.

Page 1133 of 2870

![SUBARU FORESTER 2004 Service Service Manual EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sel SUBARU FORESTER 2004 Service Service Manual EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sel](/img/17/57426/w960_57426-1132.png)

EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Transmission} and press the [YES] key.

3) Press the [YES] key after the information of transmission type is displayed.

4) On the «Transmission Diagnosis» display screen, select the {Current Data Display & Save} and press the

[YES] key.

5) On the «Transmission Diagnosis» display screen, select the {Data Display} and press the [YES] key.

6) Using the scroll key, scroll the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

Description Display Unit of measure

Battery voltage Battery Voltage V

Rear vehicle speed sensor signal Rear Wheel Speed km/h or MPH

Front vehicle speed sensor signal Front Wheel Speed km/h or MPH

Engine speed signal Engine speed rpm

ATF temperature signal ATF Temp.°C or °F

Throttle position sensor Throttle Sensor Voltage V

Gear Position Gear position —

Line pressure control duty ratio Line pressure duty %

Lock up clutch control duty ratio L/U Duty %

Transfer clutch control duty ratio AWD duty %

Throttle position sensor power supply Throttle sensor power supply V

Turbine revolution signal Turbine Revolution Speed rpm

2-4 Brake timing pressure control duty ratio 2-4 B Pressure Duty %

Intake manifold pressure sensor voltage Mani. Relative Voltage V

FWD switch signal FWD SW ON or OFF

Kick down switch signal Kick Down Switch ON or OFF

Stop light switch signal Stop Light SW ON or OFF

Anti lock brake system signal ABS signal ON or OFF

Cruise control system signal Cruise Control Signal ON or OFF

Neutral/Parking range signal N/P range ON or OFF

Reverse range signal R Range ON or OFF

Drive range signal D Range ON or OFF

3rd range signal 3rd Range Signal ON or OFF

2nd range signal 2nd Range Signal ON or OFF

1st range signal 1st Range Signal ON or OFF

Shift control solenoid A Shift Solenoid #1 ON or OFF

Shift control solenoid B Shift Solenoid #2 ON or OFF

Torque control output signal #1 Torque control output signal 1 ON or OFF

Torque control output signal #2 Torque control output signal 2 ON or OFF

Torque control cut signal Torque Control Cut Sig ON or OFF

2-4 brake timing control solenoid valve 2-4B Timing Solenoid ON or OFF

Low clutch timing control solenoid valve L/C timing solenoid ON or OFF

Automatic transmission diagnosis light output signal Diagnosis Lamp ON or OFF