air bleeding SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 769 of 2870

PM-32

PERIODIC MAINTENANCE SERVICE

Brake Fluid

19.Brake Fluid

A: REPLACEMENT

1) Lift-up the vehicle.

2) Remove both front and rear wheels.

3) Draw out the brake fluid from master cylinder

with syringe.

4) Refill the reservoir tank with recommended

brake fluid.

Recommended brake fluid:

FMVSS No. 116, fresh DOT3 or DOT4 brake

fluid

CAUTION:

Avoid mixing different brands of brake fluid

to prevent degrading the quality of the fluid.

Be careful not to allow dirt or dust to get into

the reservoir tank.

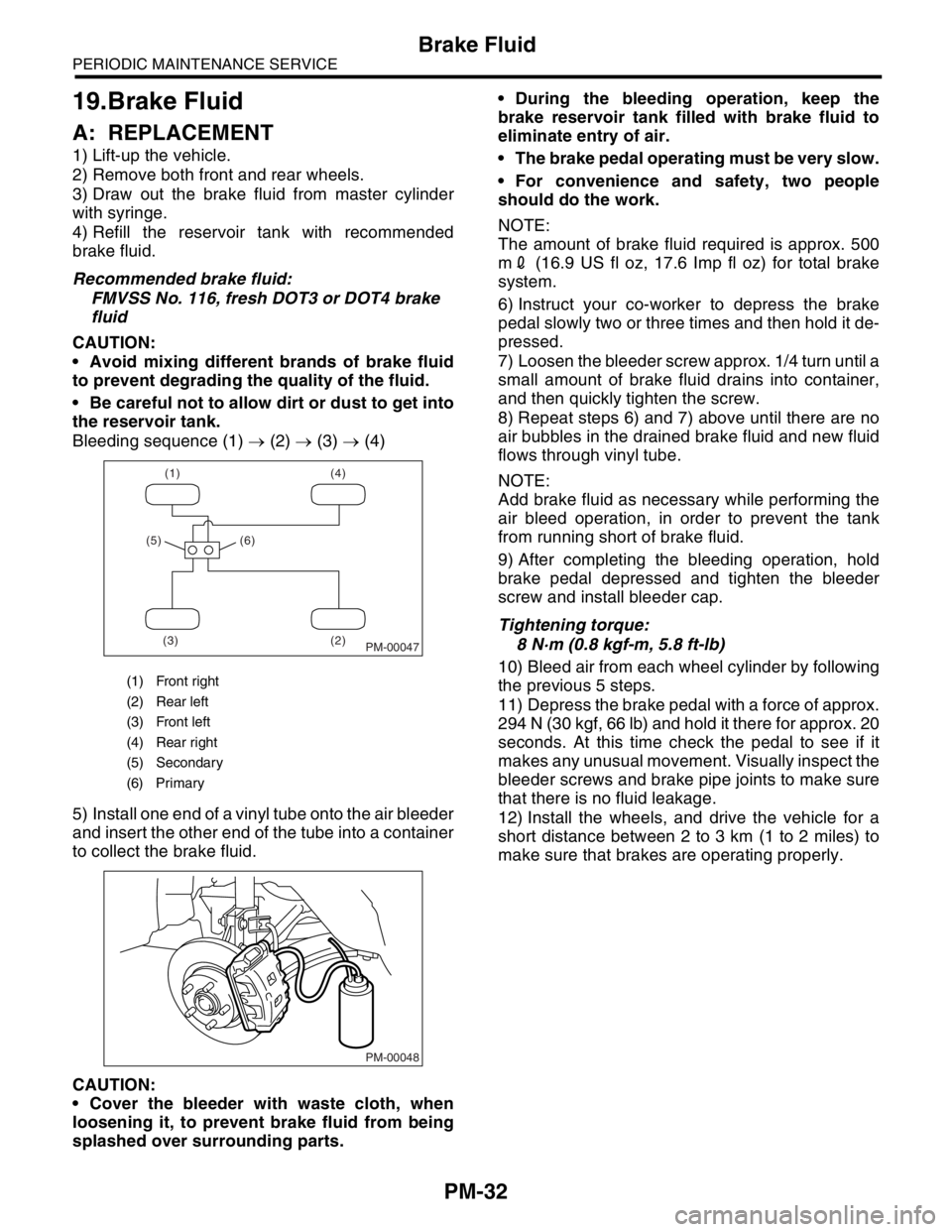

Bleeding sequence (1) → (2) → (3) → (4)

5) Install one end of a vinyl tube onto the air bleeder

and insert the other end of the tube into a container

to collect the brake fluid.

CAUTION:

Cover the bleeder with waste cloth, when

loosening it, to prevent brake fluid from being

splashed over surrounding parts. During the bleeding operation, keep the

brake reservoir tank filled with brake fluid to

eliminate entry of air.

The brake pedal operating must be very slow.

For convenience and safety, two people

should do the work.

NOTE:

The amount of brake fluid required is approx. 500

m2 (16.9 US fl oz, 17.6 Imp fl oz) for total brake

system.

6) Instruct your co-worker to depress the brake

pedal slowly two or three times and then hold it de-

pressed.

7) Loosen the bleeder screw approx. 1/4 turn until a

small amount of brake fluid drains into container,

and then quickly tighten the screw.

8) Repeat steps 6) and 7) above until there are no

air bubbles in the drained brake fluid and new fluid

flows through vinyl tube.

NOTE:

Add brake fluid as necessary while performing the

air bleed operation, in order to prevent the tank

from running short of brake fluid.

9) After completing the bleeding operation, hold

brake pedal depressed and tighten the bleeder

screw and install bleeder cap.

Tightening torque:

8 N·m (0.8 kgf-m, 5.8 ft-lb)

10) Bleed air from each wheel cylinder by following

the previous 5 steps.

11) Depress the brake pedal with a force of approx.

294 N (30 kgf, 66 lb) and hold it there for approx. 20

seconds. At this time check the pedal to see if it

makes any unusual movement. Visually inspect the

bleeder screws and brake pipe joints to make sure

that there is no fluid leakage.

12) Install the wheels, and drive the vehicle for a

short distance between 2 to 3 km (1 to 2 miles) to

make sure that brakes are operating properly.

(1) Front right

(2) Rear left

(3) Front left

(4) Rear right

(5) Secondary

(6) Primary

(1) (4)

(2) (3) (5) (6)

PM-00047

PM-00048

Page 772 of 2870

PM-35

PERIODIC MAINTENANCE SERVICE

Brake Linings and Drums

2) Check the disk rotor for wear, dents or other

damage. If the inside surface of disk rotor is

streaked, correct the surface with emery cloth

(#200 or more). If it is unevenly worn or tapered,

correct or replace it.

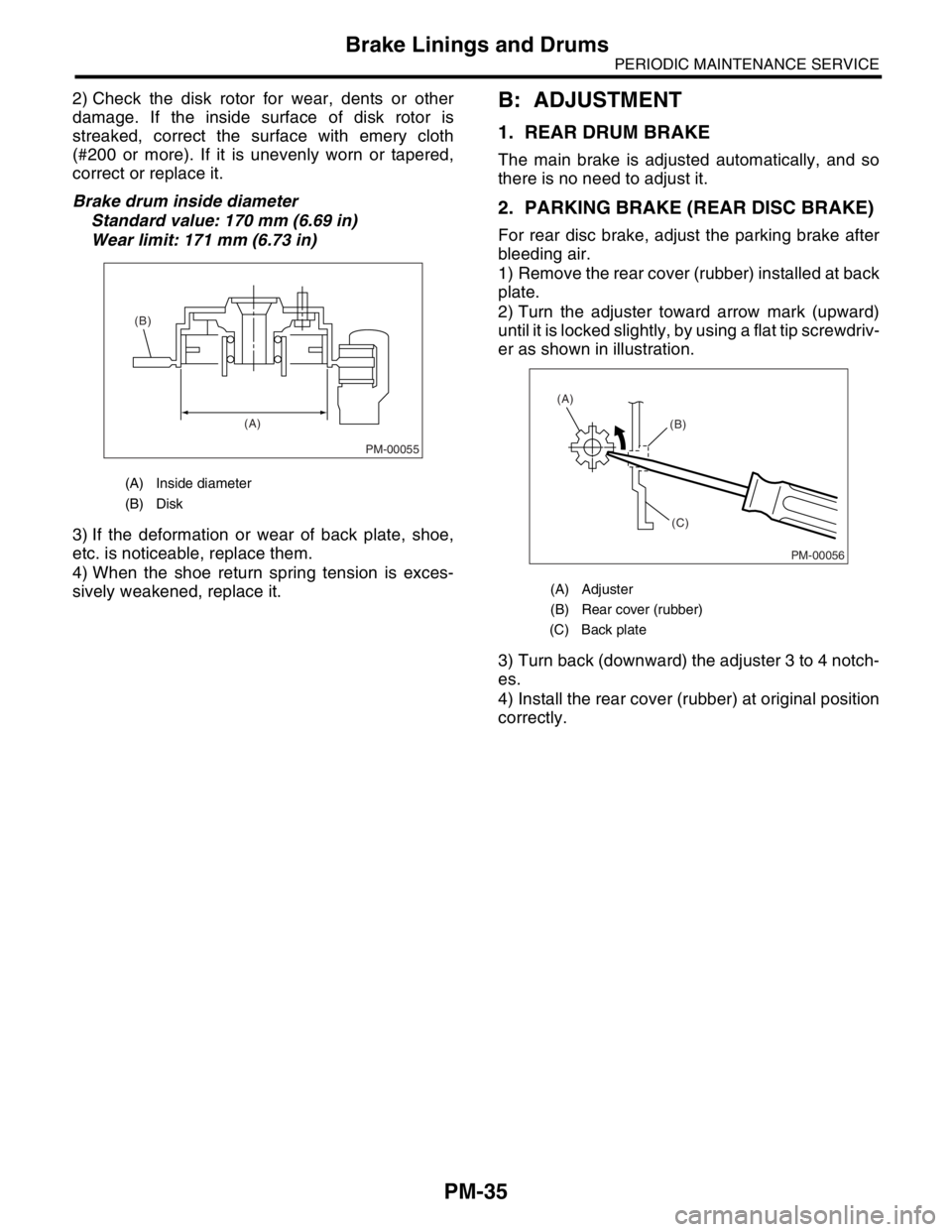

Brake drum inside diameter

Standard value: 170 mm (6.69 in)

Wear limit: 171 mm (6.73 in)

3) If the deformation or wear of back plate, shoe,

etc. is noticeable, replace them.

4) When the shoe return spring tension is exces-

sively weakened, replace it.B: ADJUSTMENT

1. REAR DRUM BRAKE

The main brake is adjusted automatically, and so

there is no need to adjust it.

2. PARKING BRAKE (REAR DISC BRAKE)

For rear disc brake, adjust the parking brake after

bleeding air.

1) Remove the rear cover (rubber) installed at back

plate.

2) Turn the adjuster toward arrow mark (upward)

until it is locked slightly, by using a flat tip screwdriv-

er as shown in illustration.

3) Turn back (downward) the adjuster 3 to 4 notch-

es.

4) Install the rear cover (rubber) at original position

correctly.

(A) Inside diameter

(B) Disk

PM-00055

(A) (B)

(A) Adjuster

(B) Rear cover (rubber)

(C) Back plate

PM-00056

(B)

(C) (A)

Page 2313 of 2870

AUTOMATIC TRANSMISSION

4AT

Page

1. General Description ....................................................................................2

2. Automatic Transmission Fluid ...................................................................30

3. Differential Gear Oil...................................................................................31

4. Road Test..................................................................................................32

5. Stall Test ...................................................................................................33

6. Time Lag Test ...........................................................................................35

7. Line Pressure Test ....................................................................................36

8. Transfer Clutch Pressure Test ..................................................................38

9. Automatic Transmission Assembly ...........................................................39

10. Transmission Mounting System ................................................................47

11. Extension Case Oil Seal ...........................................................................49

12. Differential Side Retainer Oil Seal.............................................................50

13. Inhibitor Switch ..........................................................................................51

14. Front Vehicle Speed Sensor .....................................................................55

15. Rear Vehicle Speed Sensor ......................................................................59

16. Torque Converter Turbine Speed Sensor .................................................60

17. Control Valve Body ...................................................................................61

18. Air Bleeding of Control Valve ....................................................................70

19.

Shift Solenoids, Duty Solenoids and ATF Temperature Sensor.........................71

20. Transfer Duty Solenoid and Valve Body ...................................................73

21. ATF Filter ..................................................................................................76

22. Transmission Control Module (TCM) ........................................................77

23. Dropping Resistor .....................................................................................78

24. ATF Cooler Pipe and Hose .......................................................................79

25. ATF Cooler (With Warmer Function).........................................................84

26. Air Breather Hose......................................................................................87

27. Oil Charger Pipe........................................................................................88

28. Torque Converter Clutch Assembly ..........................................................89

29. Extension Case .........................................................................................90

30. Transfer Clutch..........................................................................................92

31. Reduction Driven Gear..............................................................................97

32. Reduction Drive Gear................................................................................99

33. Parking Pawl ...........................................................................................101

34. Torque Converter Clutch Case ...............................................................102

35. Oil Pump Housing ...................................................................................105

36. Drive Pinion Shaft Assembly ...................................................................111

37. Front Differential......................................................................................117

38. AT Main Case .........................................................................................123

39. Transmission Control Device ..................................................................142

Page 2378 of 2870

4AT-65

AUTOMATIC TRANSMISSION

Control Valve Body

6) Fill liquid gasket to holes except for bolt holes

(three) of transmission case.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

7) Install the oil pan with equally tighten the bolts.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

8) Pour ATF from the ATF charge pipe.

Recommended fluid:

DEXRON III type automatic transmission flu-

id

Capacity:

Pour fluid as same amount as drained fluid

from drain plug hole.

9) Bleed the air of control valve.

10) Check the ATF level.

11) Execute the learning control promotion.

ING CONTROL, OPERATION, Subaru Select

Monitor.>

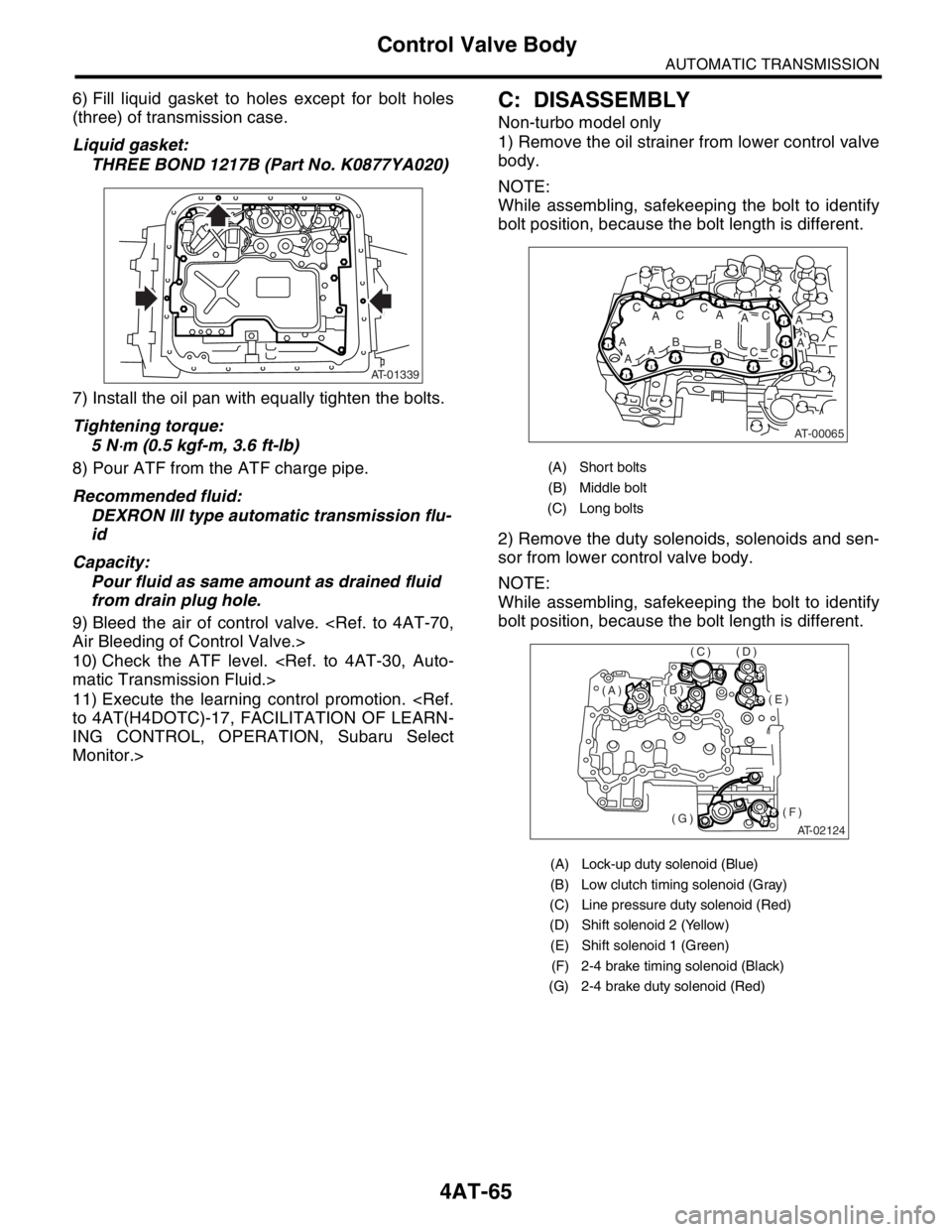

C: DISASSEMBLY

Non-turbo model only

1) Remove the oil strainer from lower control valve

body.

NOTE:

While assembling, safekeeping the bolt to identify

bolt position, because the bolt length is different.

2) Remove the duty solenoids, solenoids and sen-

sor from lower control valve body.

NOTE:

While assembling, safekeeping the bolt to identify

bolt position, because the bolt length is different.

AT-01339

(A) Short bolts

(B) Middle bolt

(C) Long bolts

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

AT-00065

A

ABAA

AC

ACC

AB

AC

CC

AT-02124

(E)

(F)(G)

(D)(C)

(B)(A)

Page 2383 of 2870

4AT-70

AUTOMATIC TRANSMISSION

Air Bleeding of Control Valve

18.Air Bleeding of Control Valve

A: PROCEDURE

1) Lift-up the vehicle with shifting the select lever to

“P” range and applying the parking brake.

2) Connect the Subaru Select Monitor to the vehi-

cle.

3) Make sure there is no trouble code using Subaru

Select Monitor.

4) Using Subaru Select Monitor, check that the

ATF temperature is in less than 60°C (140°F).

5) Power OFF the Subaru Select Monitor.

6) Turn the ignition switch to “OFF”.

7) Shift the select lever to “R” range.

8) Depress the brake pedal fully until the air bleed-

ing is completed.

9) Turn the ignition switch to ON.

10) Shift the select lever to “P” range, and then wait

for more than 3 seconds.

11) Shift the select lever to “R” range, and then wait

for more than 3 seconds.

12) Shift the select lever to “N” range, and then wait

for more than 3 seconds.

13) Shift the select lever to “D” range, and then wait

for more than 3 seconds.

14) Shift the select lever to “N” range, and then wait

for more than 3 seconds.

15) Slightly depress the accelerator pedal fully.

16) Slightly release the accelerator pedal fully.

17) Start the engine.

18) Shift the select lever to “D” range.

19) Turn the Subaru Select Monitor switch to ON.

20) Select {Each System Check} in «Main Menu»

of Subaru Select Monitor.

21) On the «System Selection Menu» display

screen, select the “Transmission”. Air bleeding of

control valve starts on transmission. At this time,

the POWER indicator light in combination meter

blinks at 2 Hz. When the POWER indicator light

does not blink, repeat the procedures from step 4).

22) Air bleeding of control valve is finished when

blinking of POWER indicator light in combination

meter changes from 2 Hz to 0.5 Hz.

NOTE:

When blinking of POWER indicator light changes

from 2 Hz to 4 Hz during air bleeding, repeat the

procedure from step 4).

23) Shift the select lever to “N” range, and then turn

the ignition switch to OFF.

24) Shift the select lever to the “P” range, and then

finish the air bleeding.

Page 2827 of 2870

CLUTCH SYSTEM

CL

Page

1. General Description ....................................................................................2

2. Clutch Disc and Cover ..............................................................................16

3. Flywheel ....................................................................................................19

4. Release Bearing and Lever.......................................................................20

5. Operating Cylinder ....................................................................................24

6. Master Cylinder .........................................................................................26

7. Clutch Pipe and Hose ...............................................................................29

8. Clutch Fluid ...............................................................................................31

9. Clutch Fluid Air Bleeding ...........................................................................32

10. Clutch Pedal ..............................................................................................34

11. Clutch Switch ............................................................................................41

12. General Diagnostic Table..........................................................................42

Page 2851 of 2870

CL-25

CLUTCH SYSTEM

Operating Cylinder

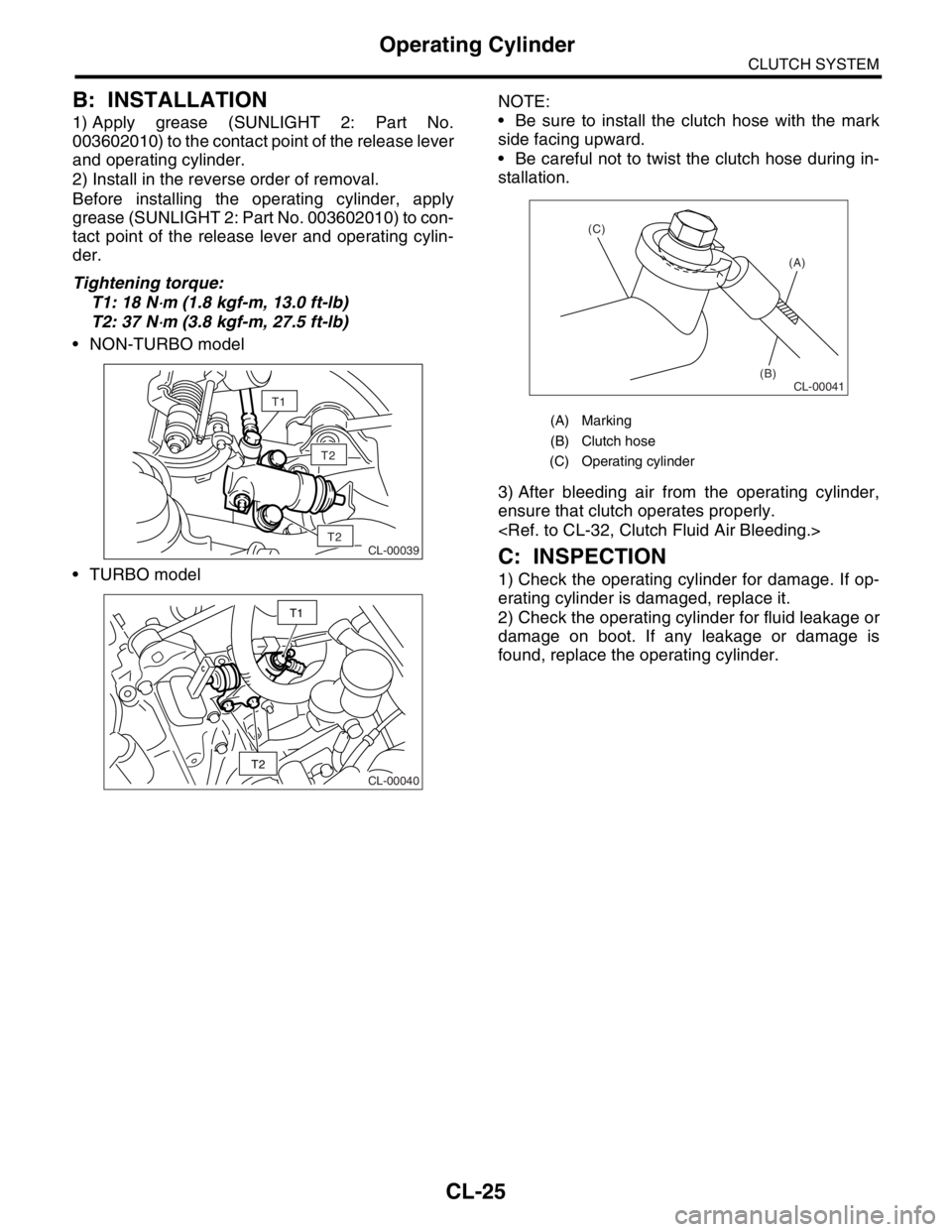

B: INSTALLATION

1) Apply grease (SUNLIGHT 2: Part No.

003602010) to the contact point of the release lever

and operating cylinder.

2) Install in the reverse order of removal.

Before installing the operating cylinder, apply

grease (SUNLIGHT 2: Part No. 003602010) to con-

tact point of the release lever and operating cylin-

der.

Tightening torque:

T1: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

T2: 37 N

⋅m (3.8 kgf-m, 27.5 ft-lb)

NON-TURBO model

TURBO modelNOTE:

Be sure to install the clutch hose with the mark

side facing upward.

Be careful not to twist the clutch hose during in-

stallation.

3) After bleeding air from the operating cylinder,

ensure that clutch operates properly.

C: INSPECTION

1) Check the operating cylinder for damage. If op-

erating cylinder is damaged, replace it.

2) Check the operating cylinder for fluid leakage or

damage on boot. If any leakage or damage is

found, replace the operating cylinder.

T2

CL-00039T2

T1

CL-00040

T2

T1

(A) Marking

(B) Clutch hose

(C) Operating cylinder

CL-00041

(A)

(B) (C)

Page 2852 of 2870

CL-26

CLUTCH SYSTEM

Master Cylinder

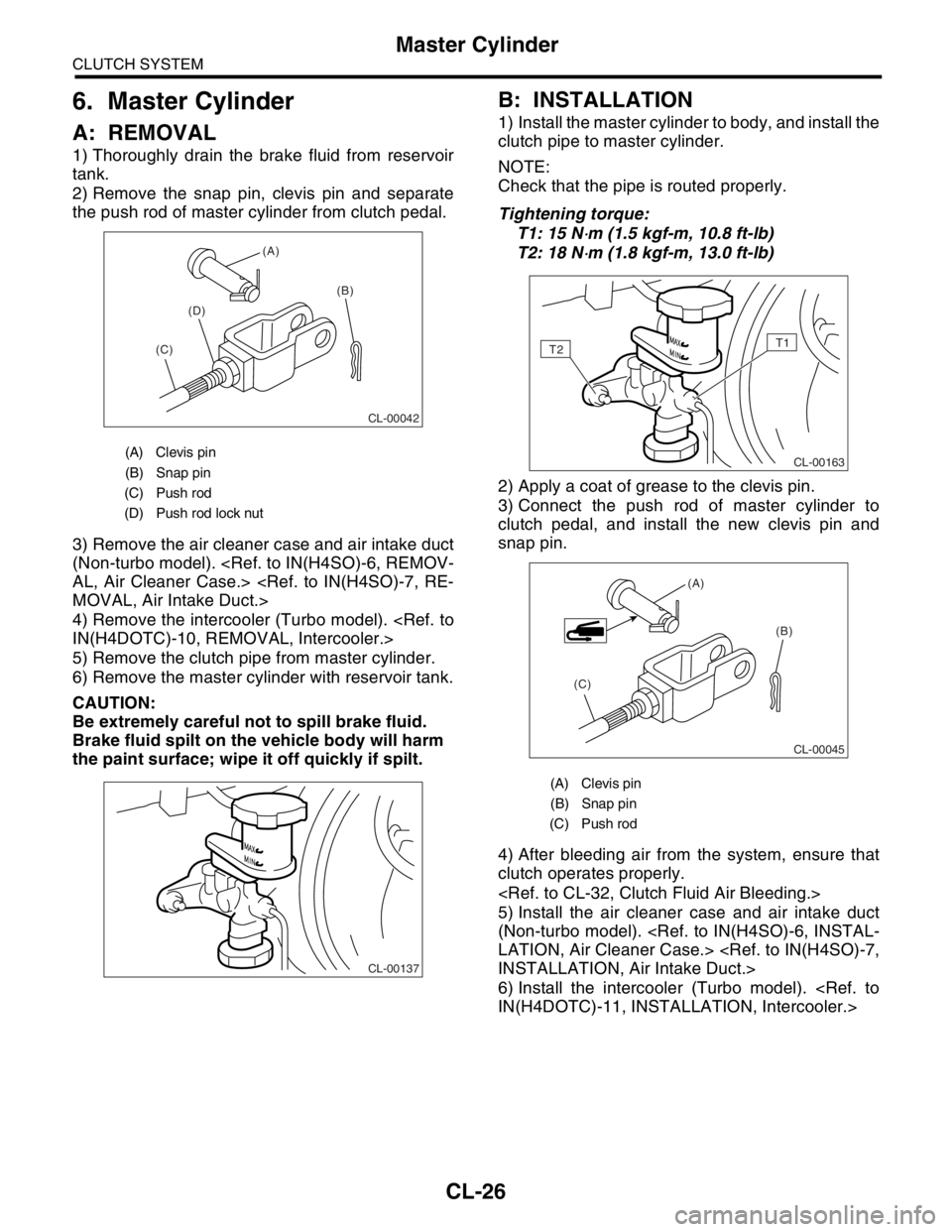

6. Master Cylinder

A: REMOVAL

1) Thoroughly drain the brake fluid from reservoir

tank.

2) Remove the snap pin, clevis pin and separate

the push rod of master cylinder from clutch pedal.

3) Remove the air cleaner case and air intake duct

(Non-turbo model).

4) Remove the intercooler (Turbo model).

5) Remove the clutch pipe from master cylinder.

6) Remove the master cylinder with reservoir tank.

CAUTION:

Be extremely careful not to spill brake fluid.

Brake fluid spilt on the vehicle body will harm

the paint surface; wipe it off quickly if spilt.

B: INSTALLATION

1) Install the master cylinder to body, and install the

clutch pipe to master cylinder.

NOTE:

Check that the pipe is routed properly.

Tightening torque:

T1: 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

T2: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

2) Apply a coat of grease to the clevis pin.

3) Connect the push rod of master cylinder to

clutch pedal, and install the new clevis pin and

snap pin.

4) After bleeding air from the system, ensure that

clutch operates properly.

5) Install the air cleaner case and air intake duct

(Non-turbo model).

6) Install the intercooler (Turbo model).

(A) Clevis pin

(B) Snap pin

(C) Push rod

(D) Push rod lock nut

CL-00042

(A)

(B)

(C)(D)

CL-00137

(A) Clevis pin

(B) Snap pin

(C) Push rod

CL-00163

T2T1

CL-00045

(A)

(B)

(C)

Page 2857 of 2870

CL-31

CLUTCH SYSTEM

Clutch Fluid

8. Clutch Fluid

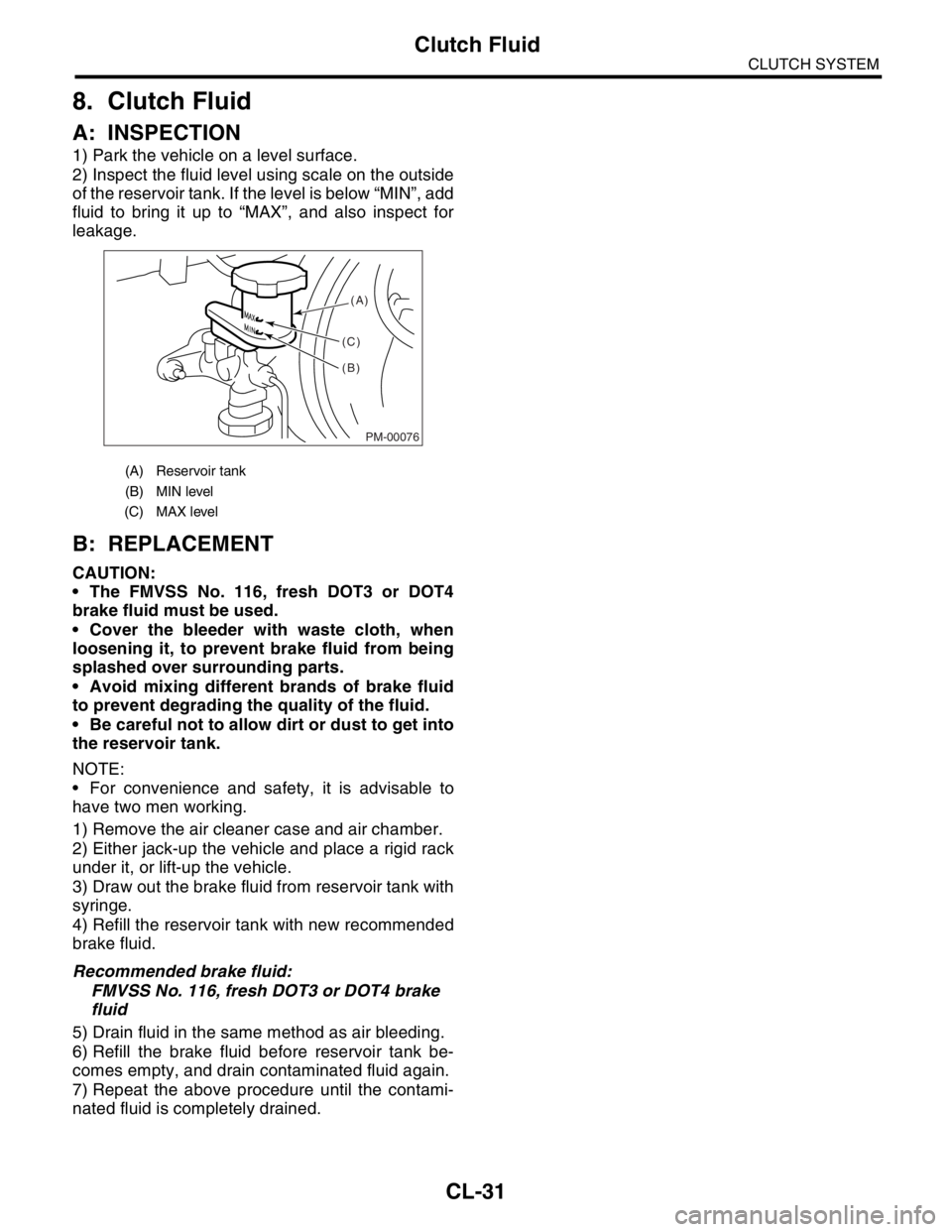

A: INSPECTION

1) Park the vehicle on a level surface.

2) Inspect the fluid level using scale on the outside

of the reservoir tank. If the level is below “MIN”, add

fluid to bring it up to “MAX”, and also inspect for

leakage.

B: REPLACEMENT

CAUTION:

The FMVSS No. 116, fresh DOT3 or DOT4

brake fluid must be used.

Cover the bleeder with waste cloth, when

loosening it, to prevent brake fluid from being

splashed over surrounding parts.

Avoid mixing different brands of brake fluid

to prevent degrading the quality of the fluid.

Be careful not to allow dirt or dust to get into

the reservoir tank.

NOTE:

For convenience and safety, it is advisable to

have two men working.

1) Remove the air cleaner case and air chamber.

2) Either jack-up the vehicle and place a rigid rack

under it, or lift-up the vehicle.

3) Draw out the brake fluid from reservoir tank with

syringe.

4) Refill the reservoir tank with new recommended

brake fluid.

Recommended brake fluid:

FMVSS No. 116, fresh DOT3 or DOT4 brake

fluid

5) Drain fluid in the same method as air bleeding.

6) Refill the brake fluid before reservoir tank be-

comes empty, and drain contaminated fluid again.

7) Repeat the above procedure until the contami-

nated fluid is completely drained.

(A) Reservoir tank

(B) MIN level

(C) MAX level

PM-00076

(A)

(B) (C)

Page 2858 of 2870

CL-32

CLUTCH SYSTEM

Clutch Fluid Air Bleeding

9. Clutch Fluid Air Bleeding

A: PROCEDURE

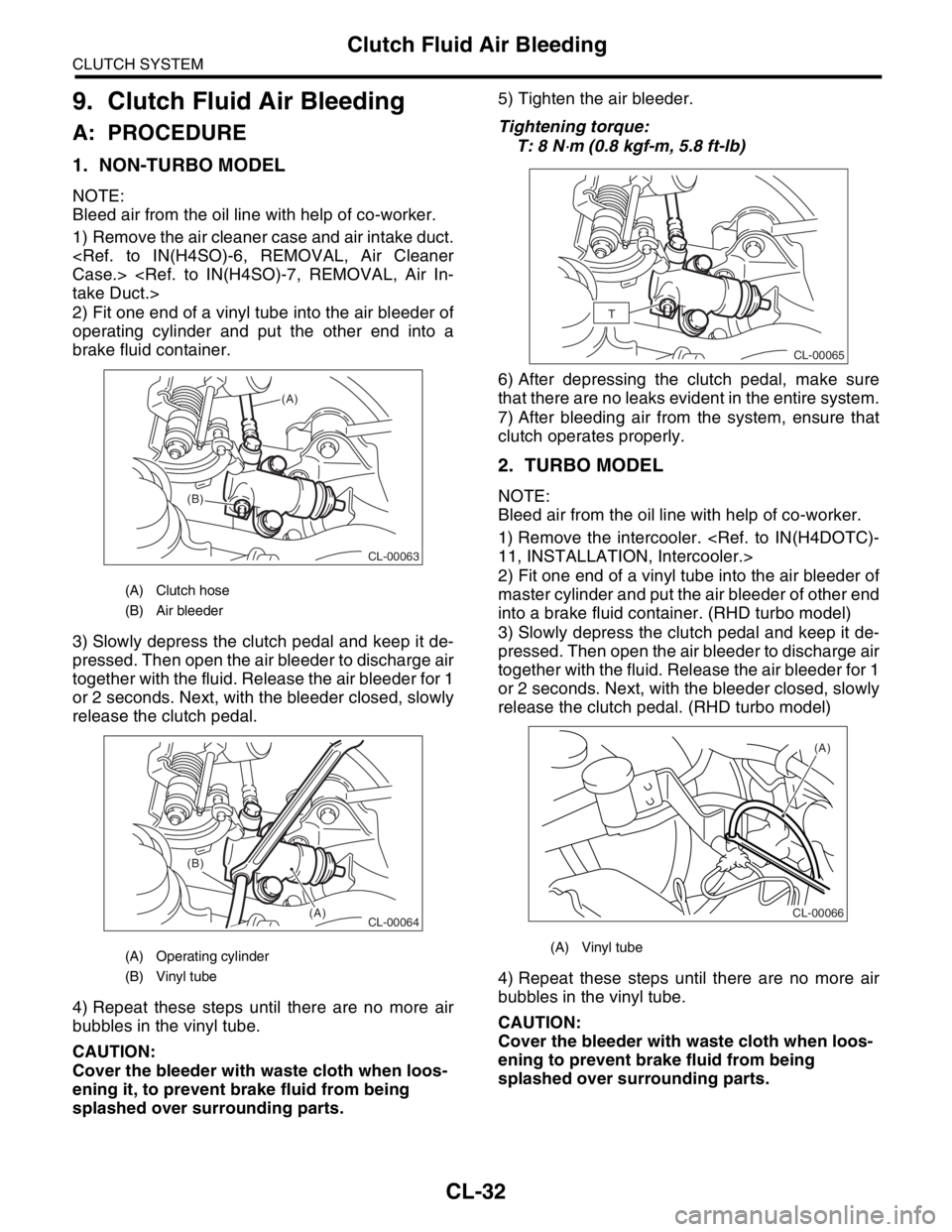

1. NON-TURBO MODEL

NOTE:

Bleed air from the oil line with help of co-worker.

1) Remove the air cleaner case and air intake duct.

2) Fit one end of a vinyl tube into the air bleeder of

operating cylinder and put the other end into a

brake fluid container.

3) Slowly depress the clutch pedal and keep it de-

pressed. Then open the air bleeder to discharge air

together with the fluid. Release the air bleeder for 1

or 2 seconds. Next, with the bleeder closed, slowly

release the clutch pedal.

4) Repeat these steps until there are no more air

bubbles in the vinyl tube.

CAUTION:

Cover the bleeder with waste cloth when loos-

ening it, to prevent brake fluid from being

splashed over surrounding parts.5) Tighten the air bleeder.

Tightening torque:

T: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

6) After depressing the clutch pedal, make sure

that there are no leaks evident in the entire system.

7) After bleeding air from the system, ensure that

clutch operates properly.

2. TURBO MODEL

NOTE:

Bleed air from the oil line with help of co-worker.

1) Remove the intercooler.

2) Fit one end of a vinyl tube into the air bleeder of

master cylinder and put the air bleeder of other end

into a brake fluid container. (RHD turbo model)

3) Slowly depress the clutch pedal and keep it de-

pressed. Then open the air bleeder to discharge air

together with the fluid. Release the air bleeder for 1

or 2 seconds. Next, with the bleeder closed, slowly

release the clutch pedal. (RHD turbo model)

4) Repeat these steps until there are no more air

bubbles in the vinyl tube.

CAUTION:

Cover the bleeder with waste cloth when loos-

ening to prevent brake fluid from being

splashed over surrounding parts.

(A) Clutch hose

(B) Air bleeder

(A) Operating cylinder

(B) Vinyl tube

CL-00063

(B)(A)

CL-00064

(B)

(A)

(A) Vinyl tube

CL-00065

T

(A)

CL-00066