air condition SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 4 of 2870

AC-2

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

1. General Description

A: SPECIFICATION

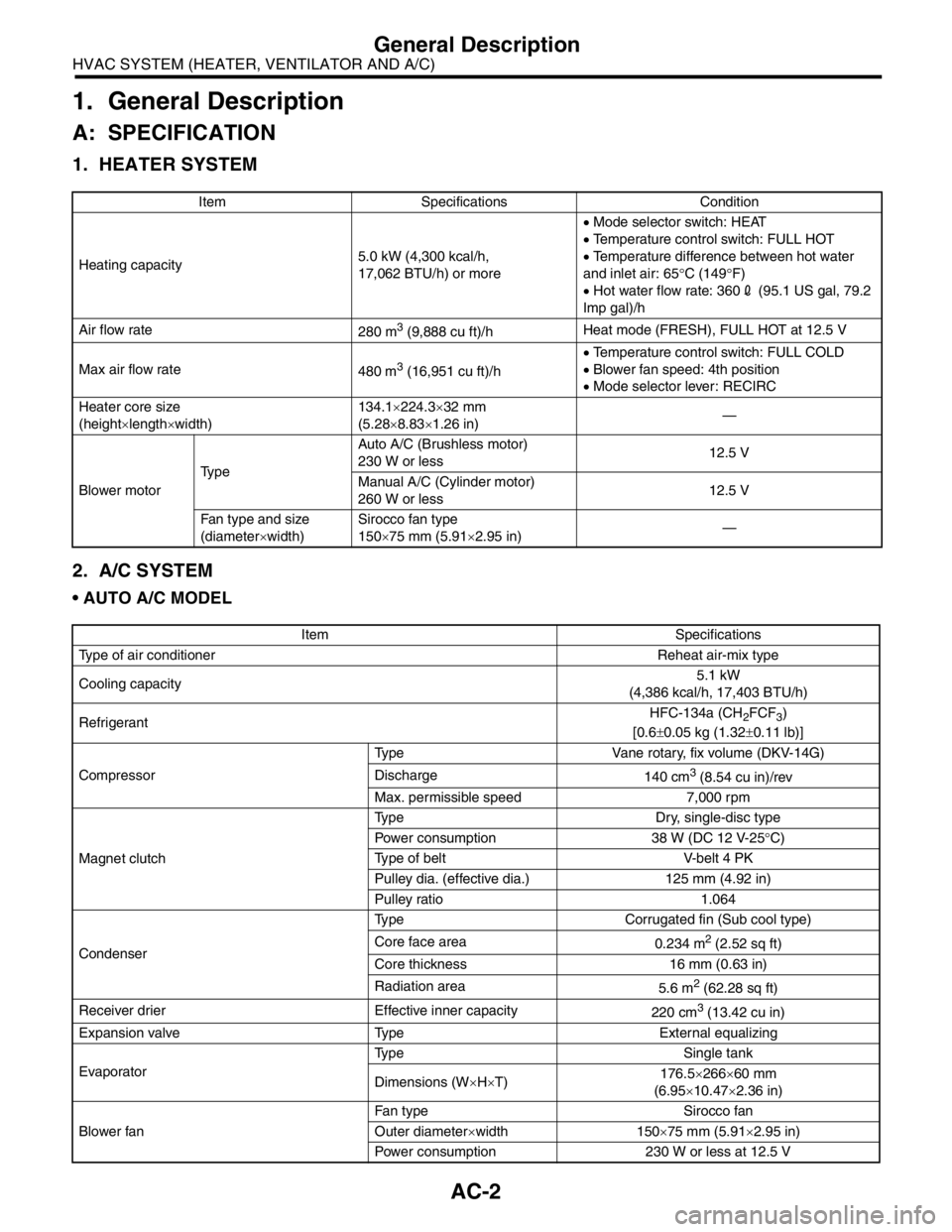

1. HEATER SYSTEM

2. A/C SYSTEM

AUTO A/C MODEL

Item Specifications Condition

Heating capacity5.0 kW (4,300 kcal/h,

17,062 BTU/h) or more• Mode selector switch: HEAT

• Temperature control switch: FULL HOT

• Temperature difference between hot water

and inlet air: 65°C (149°F)

• Hot water flow rate: 3602 (95.1 US gal, 79.2

Imp gal)/h

Air flow rate

280 m

3 (9,888 cu ft)/hHeat mode (FRESH), FULL HOT at 12.5 V

Max air flow rate

480 m

3 (16,951 cu ft)/h• Temperature control switch: FULL COLD

• Blower fan speed: 4th position

• Mode selector lever: RECIRC

Heater core size

(height×length×width)134.1×224.3×32 mm

(5.28×8.83×1.26 in)—

Blower motorTy p eAuto A/C (Brushless motor)

230 W or less12.5 V

Manual A/C (Cylinder motor)

260 W or less12.5 V

Fan type and size

(diameter×width)Sirocco fan type

150×75 mm (5.91×2.95 in)—

Item Specifications

Type of air conditioner Reheat air-mix type

Cooling capacity5.1 kW

(4,386 kcal/h, 17,403 BTU/h)

RefrigerantHFC-134a (CH

2FCF3)

[0.6±0.05 kg (1.32±0.11 lb)]

CompressorType Vane rotary, fix volume (DKV-14G)

Discharge

140 cm

3 (8.54 cu in)/rev

Max. permissible speed 7,000 rpm

Magnet clutchType Dry, single-disc type

Power consumption 38 W (DC 12 V-25°C)

Type of belt V-belt 4 PK

Pulley dia. (effective dia.) 125 mm (4.92 in)

Pulley ratio 1.064

CondenserType Corrugated fin (Sub cool type)

Core face area

0.234 m

2 (2.52 sq ft)

Core thickness 16 mm (0.63 in)

Radiation area

5.6 m

2 (62.28 sq ft)

Receiver drier Effective inner capacity

220 cm

3 (13.42 cu in)

Expansion valve Type External equalizing

EvaporatorType Single tank

Dimensions (W×H×T)176.5×266×60 mm

(6.95×10.47×2.36 in)

Blower fanFan type Sirocco fan

Outer diameter×width 150×75 mm (5.91×2.95 in)

Power consumption 230 W or less at 12.5 V

Page 5 of 2870

AC-3

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

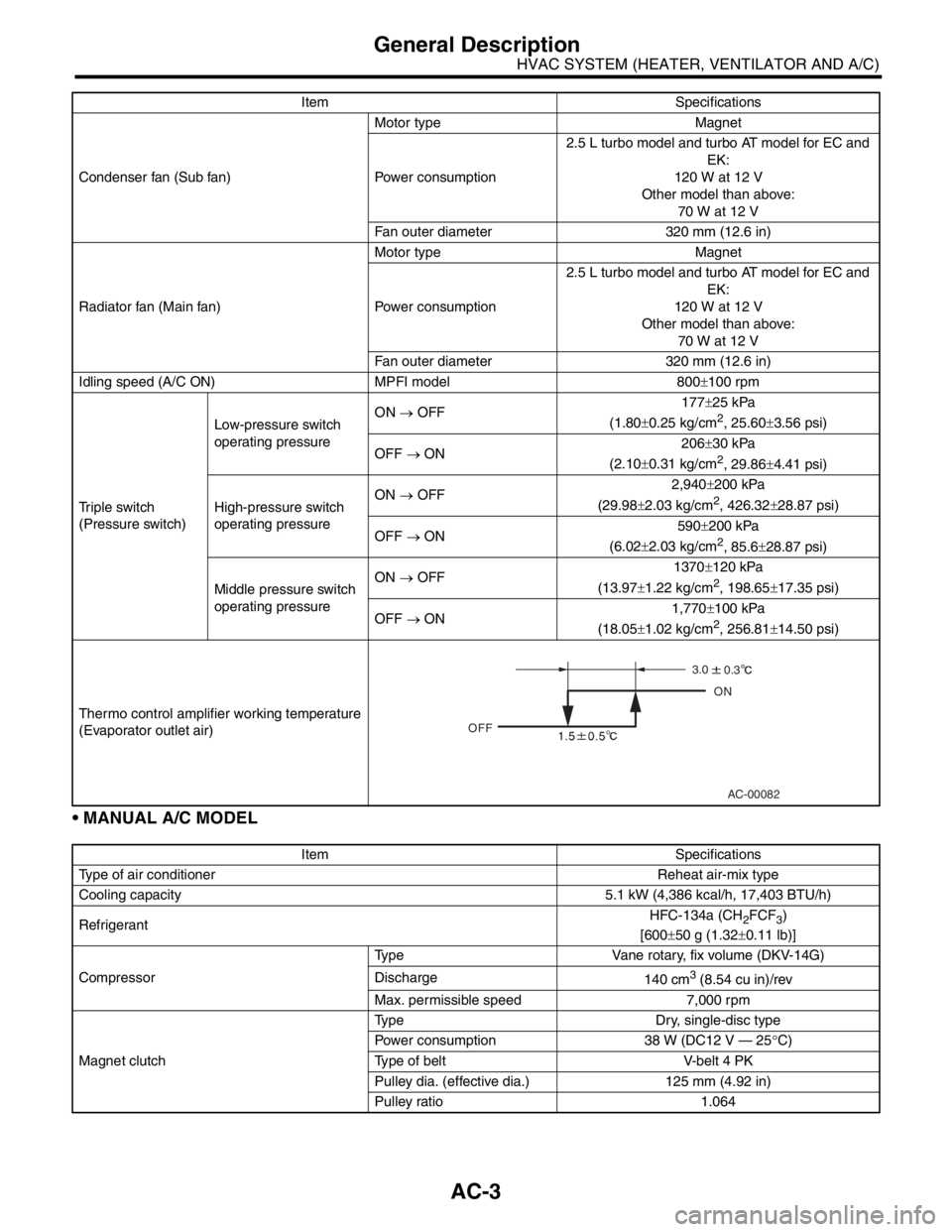

MANUAL A/C MODEL

Condenser fan (Sub fan)Motor type Magnet

Power consumption2.5 L turbo model and turbo AT model for EC and

EK:

120 W at 12 V

Other model than above:

70 W at 12 V

Fan outer diameter 320 mm (12.6 in)

Radiator fan (Main fan)Motor type Magnet

Power consumption2.5 L turbo model and turbo AT model for EC and

EK:

120 W at 12 V

Other model than above:

70 W at 12 V

Fan outer diameter 320 mm (12.6 in)

Idling speed (A/C ON) MPFI model 800±100 rpm

Triple switch

(Pressure switch)Low-pressure switch

operating pressureON → OFF177±25 kPa

(1.80±0.25 kg/cm

2, 25.60±3.56 psi)

OFF → ON206±30 kPa

(2.10±0.31 kg/cm

2, 29.86±4.41 psi)

High-pressure switch

operating pressureON → OFF2,940±200 kPa

(29.98±2.03 kg/cm

2, 426.32±28.87 psi)

OFF → ON590±200 kPa

(6.02±2.03 kg/cm

2, 85.6±28.87 psi)

Middle pressure switch

operating pressureON → OFF1370±120 kPa

(13.97±1.22 kg/cm

2, 198.65±17.35 psi)

OFF → ON1,770±100 kPa

(18.05±1.02 kg/cm

2, 256.81±14.50 psi)

Thermo control amplifier working temperature

(Evaporator outlet air)

Item Specifications

Type of air conditioner Reheat air-mix type

Cooling capacity 5.1 kW (4,386 kcal/h, 17,403 BTU/h)

RefrigerantHFC-134a (CH

2FCF3)

[600±50 g (1.32±0.11 lb)]

CompressorType Vane rotary, fix volume (DKV-14G)

Discharge

140 cm

3 (8.54 cu in)/rev

Max. permissible speed 7,000 rpm

Magnet clutchType Dry, single-disc type

Power consumption 38 W (DC12 V — 25°C)

Type of belt V-belt 4 PK

Pulley dia. (effective dia.) 125 mm (4.92 in)

Pulley ratio 1.064 Item Specifications

AC-00082

OFFON

3.0

0.3

Page 18 of 2870

AC-16

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

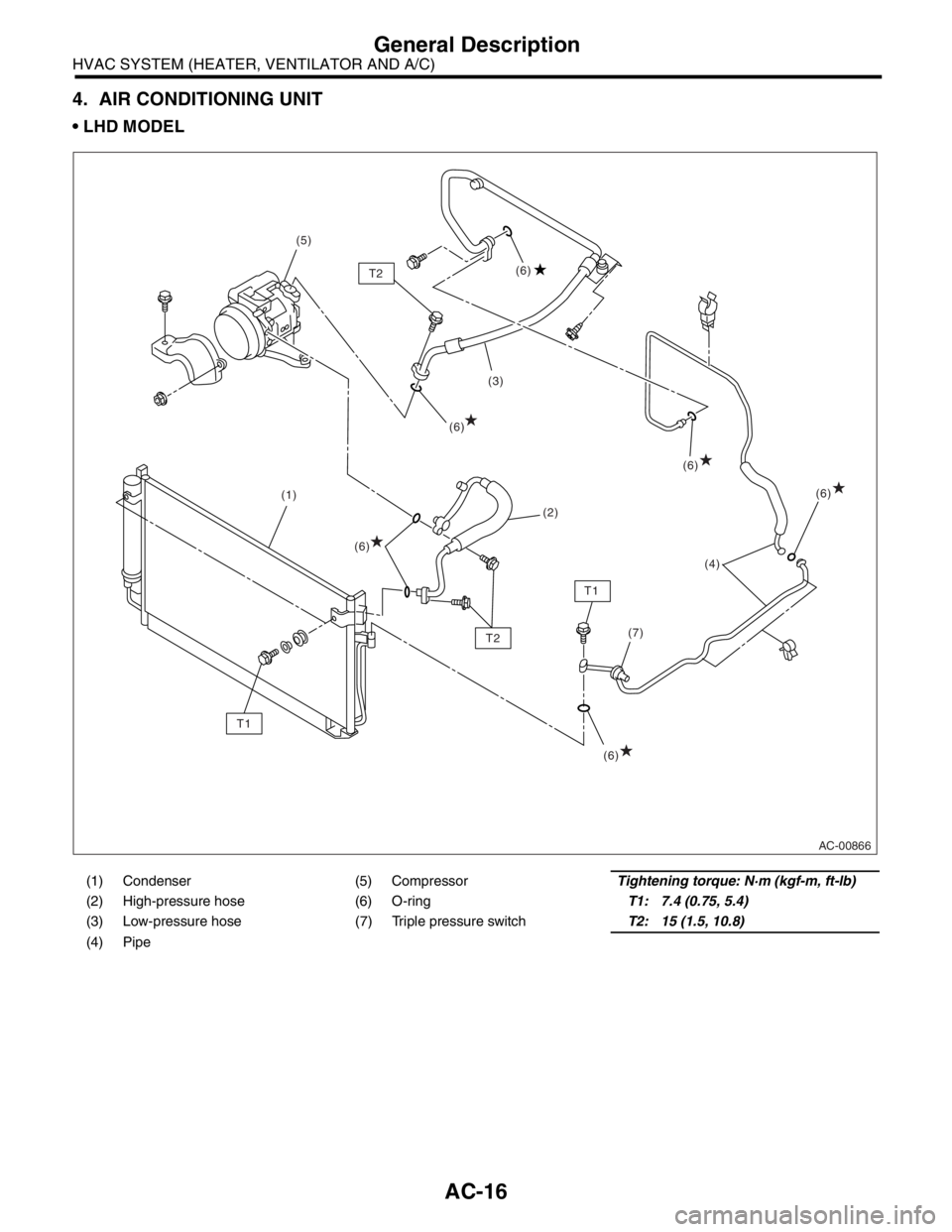

4. AIR CONDITIONING UNIT

LHD MODEL

(1) Condenser (5) CompressorTightening torque: N·m (kgf-m, ft-lb)

(2) High-pressure hose (6) O-ringT1: 7.4 (0.75, 5.4)

(3) Low-pressure hose (7) Triple pressure switchT2: 15 (1.5, 10.8)

(4) Pipe

AC-00866

(1)(3)

(4)

(7) (5)

(2)

T1

T1T2(6) (6)

(6)(6)

(6) T2(6)

Page 27 of 2870

AC-25

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Pressure with Manifold Gauge Set

2. Refrigerant Pressure with Manifold Gauge Set

A: OPERATION

1) Place the vehicle in the shade and draftless condition.

2) Connect the manifold gauge set.

3) Open the front windows and close all doors.

4) Open the hood.

5) Increase the engine speed to 1,500 rpm.

6) Turn ON the A/C switch.

7) Turn the temperature control dial to MAX COOL.

8) Set the air inlet select switch to RECIRC position.

9) Turn the fan dial to HI.

10) Read the gauge.

Standard:

Low pressure: 127 — 196 kPa (1.3 — 2.0 kg/cm

2, 18 — 28 psi)

High pressure: 1,471 — 1, 667 kPa (15 — 17 kg/cm2, 213 — 242 psi)

Ambient temperature: 30 — 35

°C (86 — 95°F)

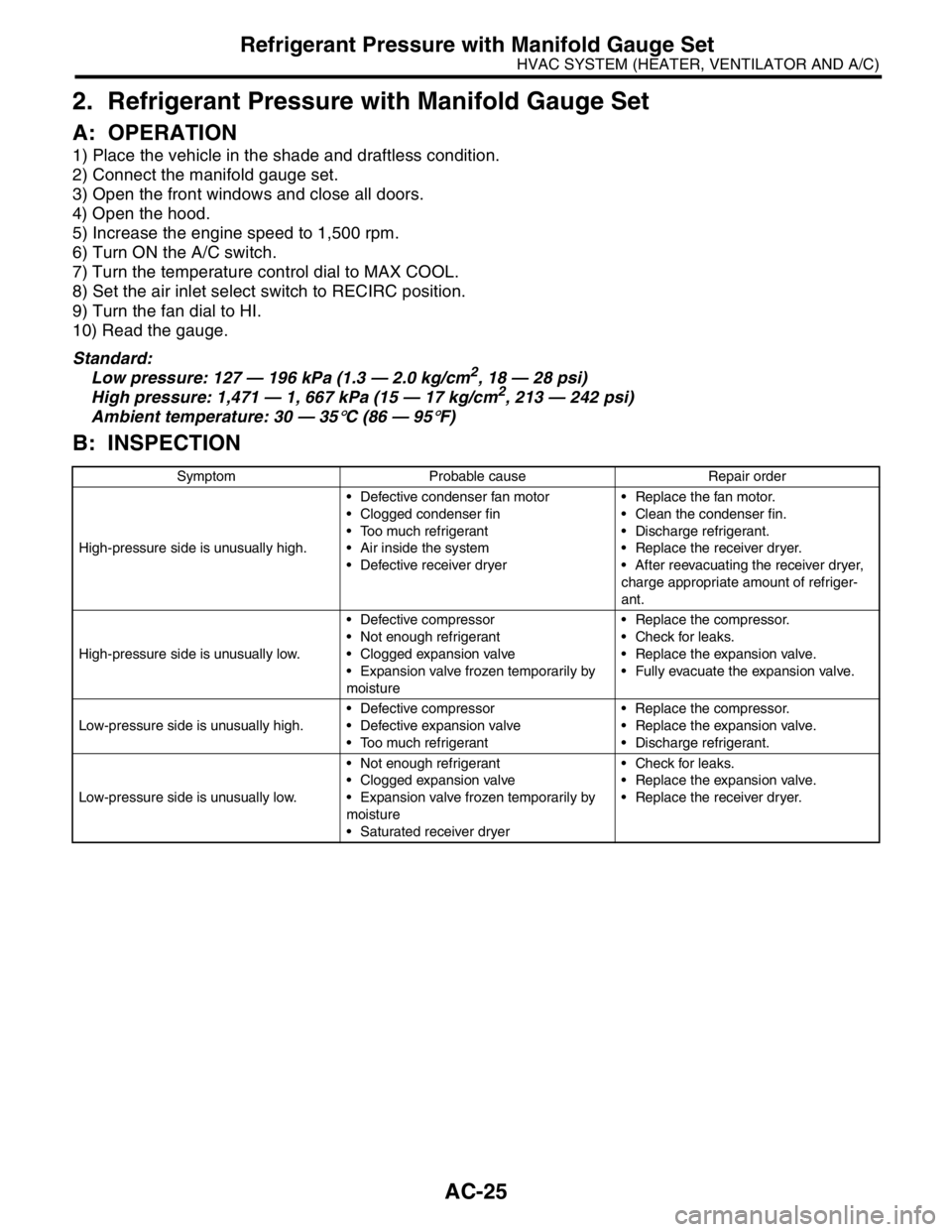

B: INSPECTION

Symptom Probable cause Repair order

High-pressure side is unusually high. Defective condenser fan motor

Clogged condenser fin

Too much refrigerant

Air inside the system

Defective receiver dryer Replace the fan motor.

Clean the condenser fin.

Discharge refrigerant.

Replace the receiver dryer.

After reevacuating the receiver dryer,

charge appropriate amount of refriger-

ant.

High-pressure side is unusually low. Defective compressor

Not enough refrigerant

Clogged expansion valve

Expansion valve frozen temporarily by

moisture Replace the compressor.

Check for leaks.

Replace the expansion valve.

Fully evacuate the expansion valve.

Low-pressure side is unusually high. Defective compressor

Defective expansion valve

Too much refrigerant Replace the compressor.

Replace the expansion valve.

Discharge refrigerant.

Low-pressure side is unusually low. Not enough refrigerant

Clogged expansion valve

Expansion valve frozen temporarily by

moisture

Saturated receiver dryer Check for leaks.

Replace the expansion valve.

Replace the receiver dryer.

Page 33 of 2870

AC-31

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Compressor Oil

6. Compressor Oil

A: OPERATION

NOTE:

Before making repairs, conduct the oil return oper-

ation to return the compressor oil in circulation with

the refrigerant to the compressor.

1) Increase the engine speed to 1,500 rpm.

2) Turn ON the A/C switch.

3) Turn the temperature control dial to MAX COOL.

4) Set the air inlet select switch to RECIRC posi-

tion.

5) Turn the fan dial to HI.

6) Leave in this condition for 10 minutes.

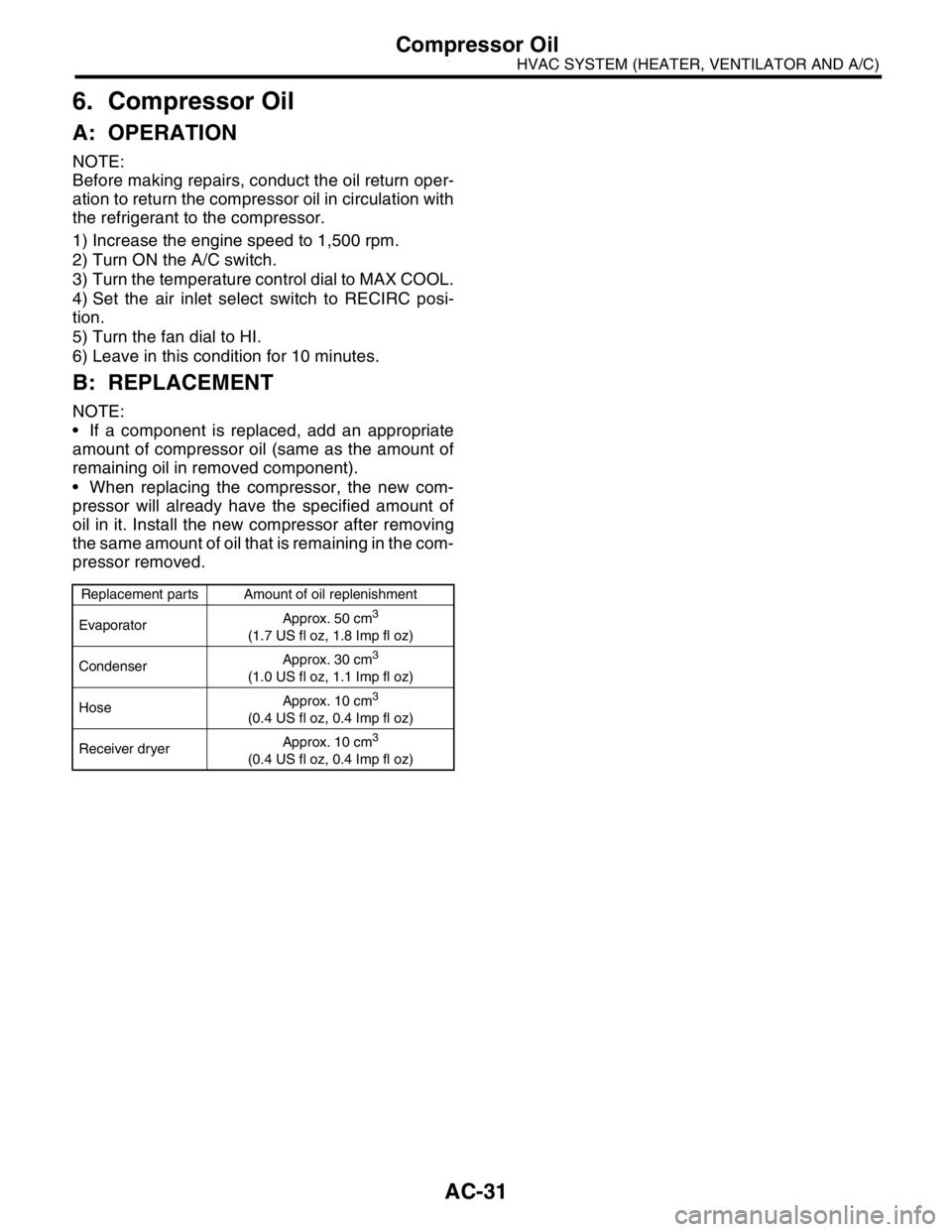

B: REPLACEMENT

NOTE:

If a component is replaced, add an appropriate

amount of compressor oil (same as the amount of

remaining oil in removed component).

When replacing the compressor, the new com-

pressor will already have the specified amount of

oil in it. Install the new compressor after removing

the same amount of oil that is remaining in the com-

pressor removed.

Replacement parts Amount of oil replenishment

EvaporatorApprox. 50 cm

3

(1.7 US fl oz, 1.8 Imp fl oz)

CondenserApprox. 30 cm

3

(1.0 US fl oz, 1.1 Imp fl oz)

HoseApprox. 10 cm

3

(0.4 US fl oz, 0.4 Imp fl oz)

Receiver dryerApprox. 10 cm

3

(0.4 US fl oz, 0.4 Imp fl oz)

Page 38 of 2870

AC-36

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Compressor

11.Compressor

A: INSPECTION

1. MAGNETIC CLUTCH CLEARANCE

1) Check the clearance of the entire circumference

around the drive plate and pulley.

Standard:

0.3 — 0.6 mm (0.0118 — 0.0236 in)

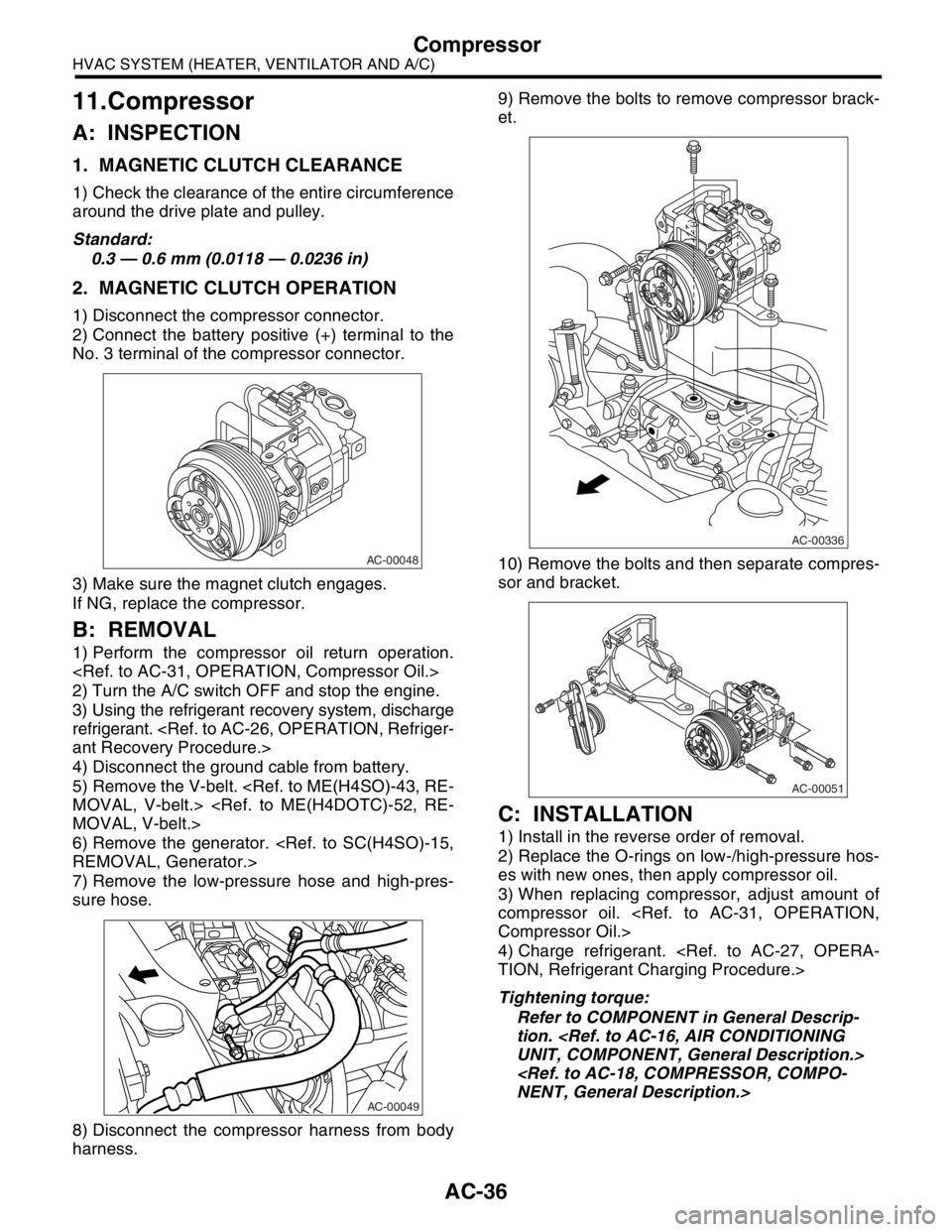

2. MAGNETIC CLUTCH OPERATION

1) Disconnect the compressor connector.

2) Connect the battery positive (+) terminal to the

No. 3 terminal of the compressor connector.

3) Make sure the magnet clutch engages.

If NG, replace the compressor.

B: REMOVAL

1) Perform the compressor oil return operation.

2) Turn the A/C switch OFF and stop the engine.

3) Using the refrigerant recovery system, discharge

refrigerant.

4) Disconnect the ground cable from battery.

5) Remove the V-belt.

6) Remove the generator.

7) Remove the low-pressure hose and high-pres-

sure hose.

8) Disconnect the compressor harness from body

harness.9) Remove the bolts to remove compressor brack-

et.

10) Remove the bolts and then separate compres-

sor and bracket.

C: INSTALLATION

1) Install in the reverse order of removal.

2) Replace the O-rings on low-/high-pressure hos-

es with new ones, then apply compressor oil.

3) When replacing compressor, adjust amount of

compressor oil.

4) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

AC-00048

AC-00049

AC-00336

AC-00051

Page 39 of 2870

AC-37

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Condenser

12.Condenser

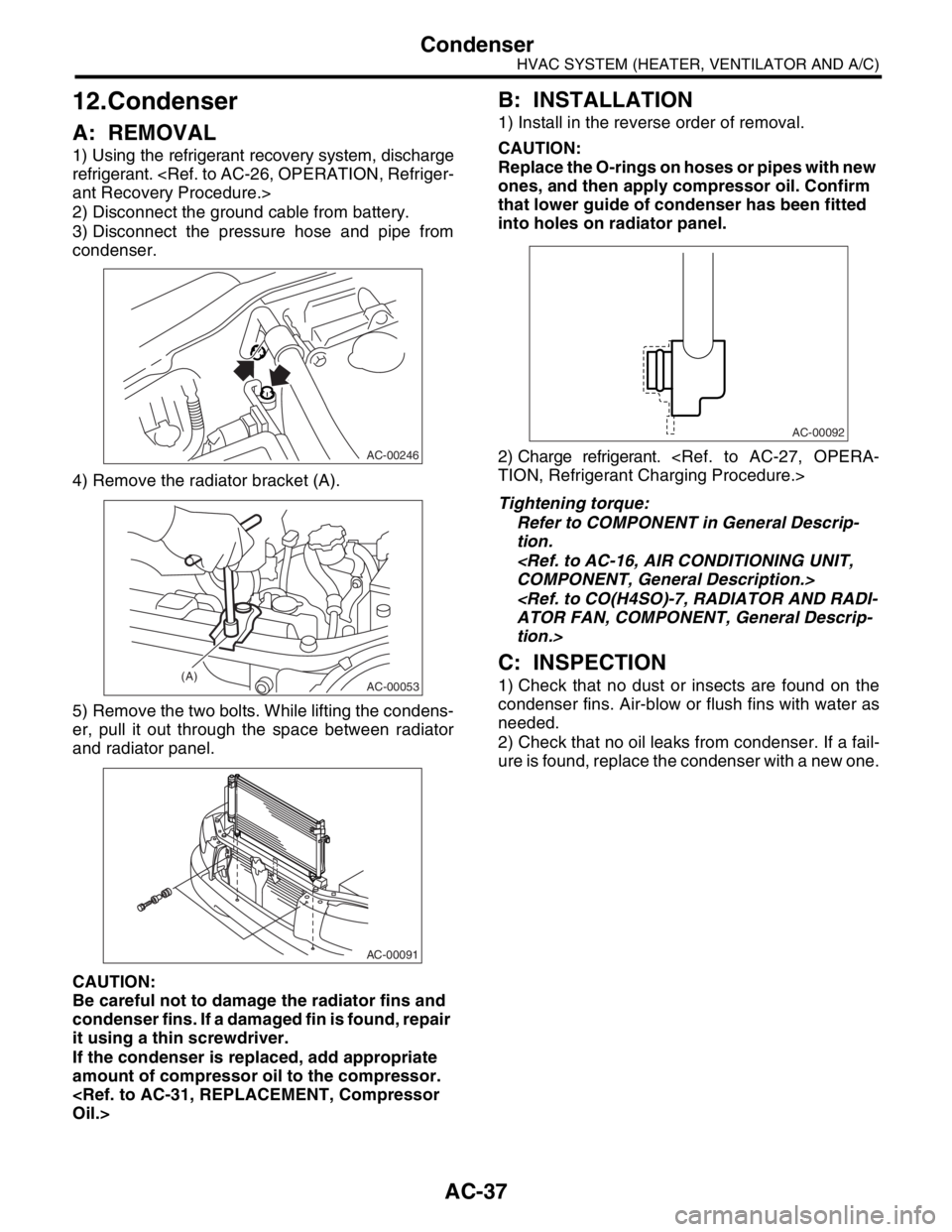

A: REMOVAL

1) Using the refrigerant recovery system, discharge

refrigerant.

2) Disconnect the ground cable from battery.

3) Disconnect the pressure hose and pipe from

condenser.

4) Remove the radiator bracket (A).

5) Remove the two bolts. While lifting the condens-

er, pull it out through the space between radiator

and radiator panel.

CAUTION:

Be careful not to damage the radiator fins and

condenser fins. If a damaged fin is found, repair

it using a thin screwdriver.

If the condenser is replaced, add appropriate

amount of compressor oil to the compressor.

B: INSTALLATION

1) Install in the reverse order of removal.

CAUTION:

Replace the O-rings on hoses or pipes with new

ones, and then apply compressor oil. Confirm

that lower guide of condenser has been fitted

into holes on radiator panel.

2) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

tion.>

C: INSPECTION

1) Check that no dust or insects are found on the

condenser fins. Air-blow or flush fins with water as

needed.

2) Check that no oil leaks from condenser. If a fail-

ure is found, replace the condenser with a new one.

AC-00246

AC-00053(A)

AC-00091

AC-00092

Page 43 of 2870

AC-41

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Hose and Tube

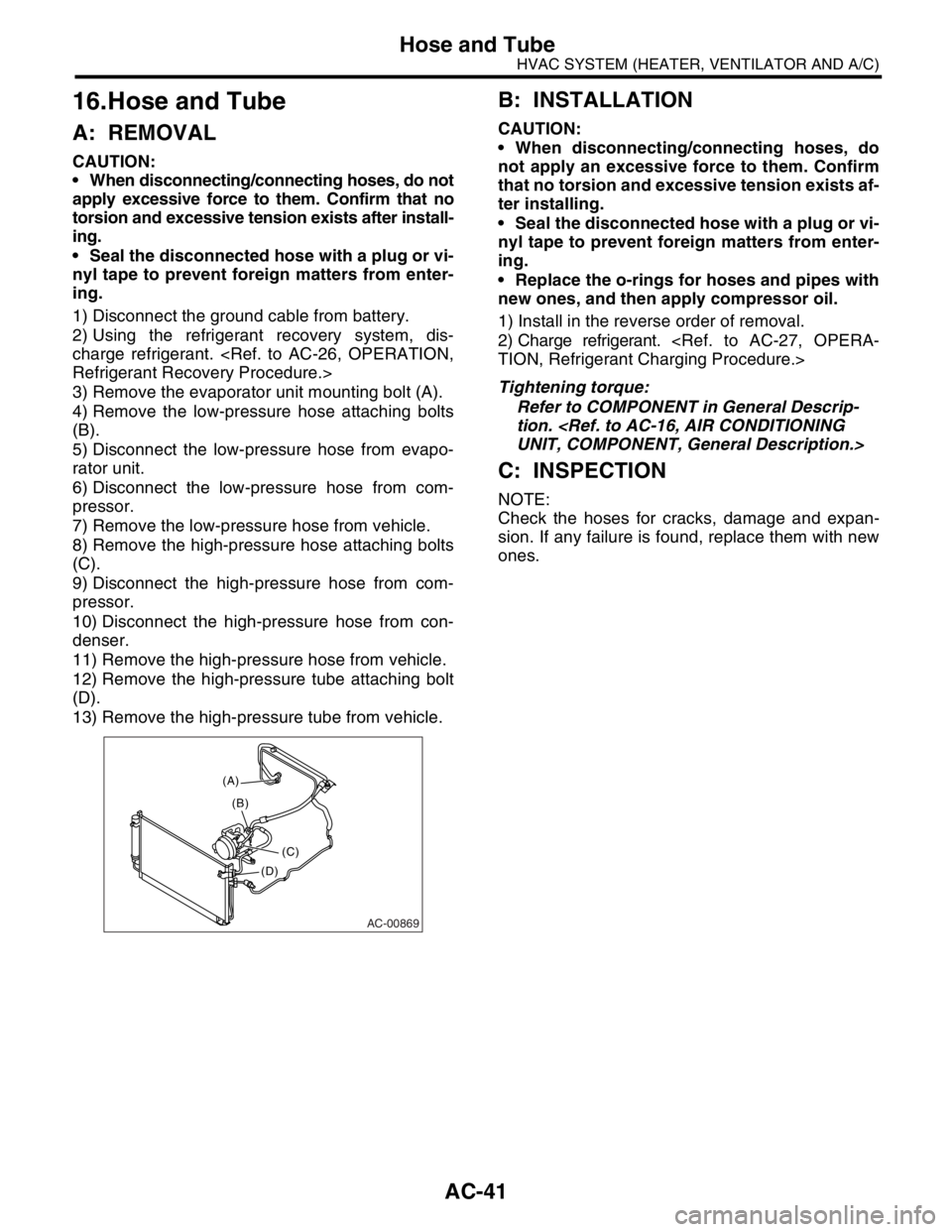

16.Hose and Tube

A: REMOVAL

CAUTION:

When disconnecting/connecting hoses, do not

apply excessive force to them. Confirm that no

torsion and excessive tension exists after install-

ing.

Seal the disconnected hose with a plug or vi-

nyl tape to prevent foreign matters from enter-

ing.

1) Disconnect the ground cable from battery.

2) Using the refrigerant recovery system, dis-

charge refrigerant.

3) Remove the evaporator unit mounting bolt (A).

4) Remove the low-pressure hose attaching bolts

(B).

5) Disconnect the low-pressure hose from evapo-

rator unit.

6) Disconnect the low-pressure hose from com-

pressor.

7) Remove the low-pressure hose from vehicle.

8) Remove the high-pressure hose attaching bolts

(C).

9) Disconnect the high-pressure hose from com-

pressor.

10) Disconnect the high-pressure hose from con-

denser.

11) Remove the high-pressure hose from vehicle.

12) Remove the high-pressure tube attaching bolt

(D).

13) Remove the high-pressure tube from vehicle.

B: INSTALLATION

CAUTION:

When disconnecting/connecting hoses, do

not apply an excessive force to them. Confirm

that no torsion and excessive tension exists af-

ter installing.

Seal the disconnected hose with a plug or vi-

nyl tape to prevent foreign matters from enter-

ing.

Replace the o-rings for hoses and pipes with

new ones, and then apply compressor oil.

1) Install in the reverse order of removal.

2) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

C: INSPECTION

NOTE:

Check the hoses for cracks, damage and expan-

sion. If any failure is found, replace them with new

ones.

AC-00869

(A)

(C) (B)

(D)

Page 55 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB