clutch SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 4 of 2870

AC-2

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

1. General Description

A: SPECIFICATION

1. HEATER SYSTEM

2. A/C SYSTEM

AUTO A/C MODEL

Item Specifications Condition

Heating capacity5.0 kW (4,300 kcal/h,

17,062 BTU/h) or more• Mode selector switch: HEAT

• Temperature control switch: FULL HOT

• Temperature difference between hot water

and inlet air: 65°C (149°F)

• Hot water flow rate: 3602 (95.1 US gal, 79.2

Imp gal)/h

Air flow rate

280 m

3 (9,888 cu ft)/hHeat mode (FRESH), FULL HOT at 12.5 V

Max air flow rate

480 m

3 (16,951 cu ft)/h• Temperature control switch: FULL COLD

• Blower fan speed: 4th position

• Mode selector lever: RECIRC

Heater core size

(height×length×width)134.1×224.3×32 mm

(5.28×8.83×1.26 in)—

Blower motorTy p eAuto A/C (Brushless motor)

230 W or less12.5 V

Manual A/C (Cylinder motor)

260 W or less12.5 V

Fan type and size

(diameter×width)Sirocco fan type

150×75 mm (5.91×2.95 in)—

Item Specifications

Type of air conditioner Reheat air-mix type

Cooling capacity5.1 kW

(4,386 kcal/h, 17,403 BTU/h)

RefrigerantHFC-134a (CH

2FCF3)

[0.6±0.05 kg (1.32±0.11 lb)]

CompressorType Vane rotary, fix volume (DKV-14G)

Discharge

140 cm

3 (8.54 cu in)/rev

Max. permissible speed 7,000 rpm

Magnet clutchType Dry, single-disc type

Power consumption 38 W (DC 12 V-25°C)

Type of belt V-belt 4 PK

Pulley dia. (effective dia.) 125 mm (4.92 in)

Pulley ratio 1.064

CondenserType Corrugated fin (Sub cool type)

Core face area

0.234 m

2 (2.52 sq ft)

Core thickness 16 mm (0.63 in)

Radiation area

5.6 m

2 (62.28 sq ft)

Receiver drier Effective inner capacity

220 cm

3 (13.42 cu in)

Expansion valve Type External equalizing

EvaporatorType Single tank

Dimensions (W×H×T)176.5×266×60 mm

(6.95×10.47×2.36 in)

Blower fanFan type Sirocco fan

Outer diameter×width 150×75 mm (5.91×2.95 in)

Power consumption 230 W or less at 12.5 V

Page 5 of 2870

AC-3

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

MANUAL A/C MODEL

Condenser fan (Sub fan)Motor type Magnet

Power consumption2.5 L turbo model and turbo AT model for EC and

EK:

120 W at 12 V

Other model than above:

70 W at 12 V

Fan outer diameter 320 mm (12.6 in)

Radiator fan (Main fan)Motor type Magnet

Power consumption2.5 L turbo model and turbo AT model for EC and

EK:

120 W at 12 V

Other model than above:

70 W at 12 V

Fan outer diameter 320 mm (12.6 in)

Idling speed (A/C ON) MPFI model 800±100 rpm

Triple switch

(Pressure switch)Low-pressure switch

operating pressureON → OFF177±25 kPa

(1.80±0.25 kg/cm

2, 25.60±3.56 psi)

OFF → ON206±30 kPa

(2.10±0.31 kg/cm

2, 29.86±4.41 psi)

High-pressure switch

operating pressureON → OFF2,940±200 kPa

(29.98±2.03 kg/cm

2, 426.32±28.87 psi)

OFF → ON590±200 kPa

(6.02±2.03 kg/cm

2, 85.6±28.87 psi)

Middle pressure switch

operating pressureON → OFF1370±120 kPa

(13.97±1.22 kg/cm

2, 198.65±17.35 psi)

OFF → ON1,770±100 kPa

(18.05±1.02 kg/cm

2, 256.81±14.50 psi)

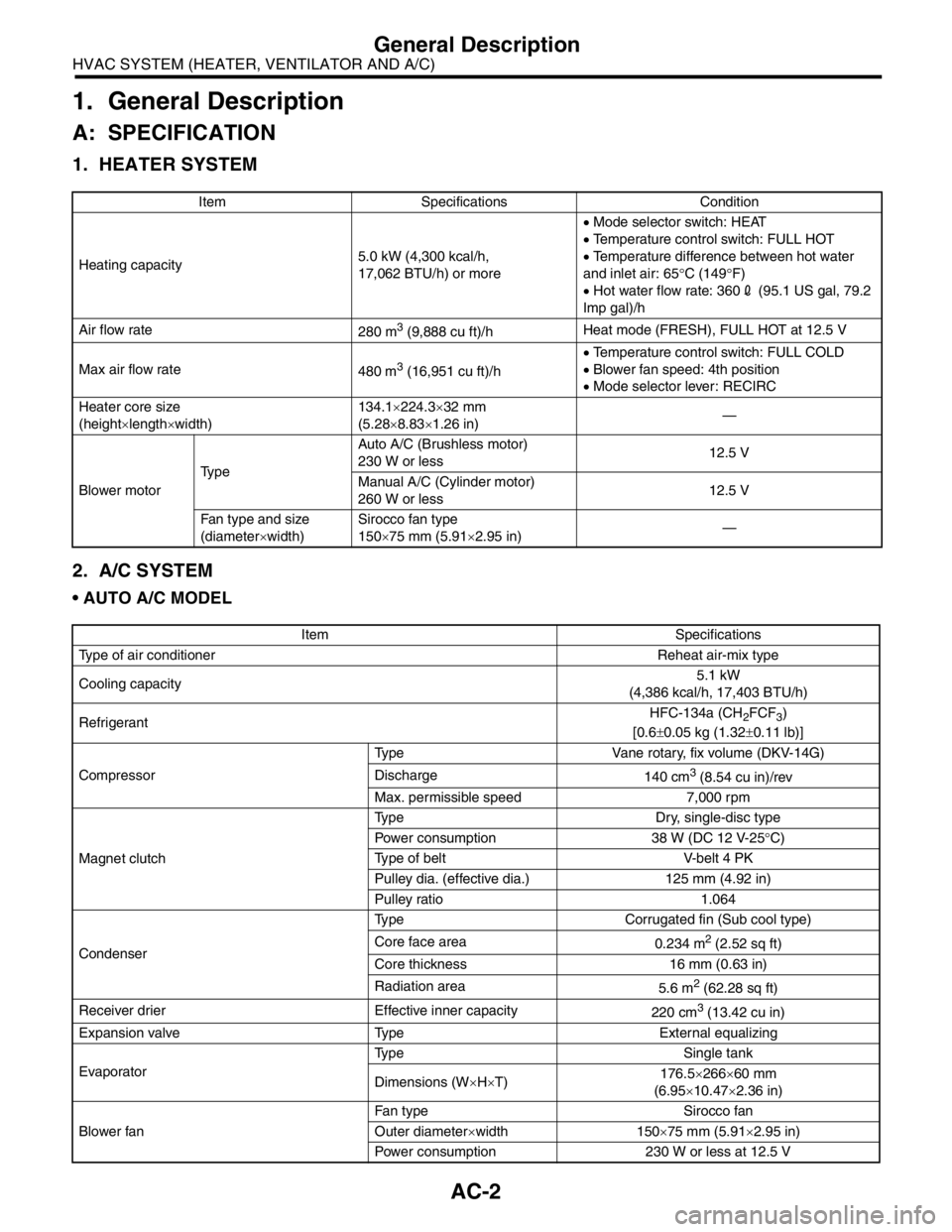

Thermo control amplifier working temperature

(Evaporator outlet air)

Item Specifications

Type of air conditioner Reheat air-mix type

Cooling capacity 5.1 kW (4,386 kcal/h, 17,403 BTU/h)

RefrigerantHFC-134a (CH

2FCF3)

[600±50 g (1.32±0.11 lb)]

CompressorType Vane rotary, fix volume (DKV-14G)

Discharge

140 cm

3 (8.54 cu in)/rev

Max. permissible speed 7,000 rpm

Magnet clutchType Dry, single-disc type

Power consumption 38 W (DC12 V — 25°C)

Type of belt V-belt 4 PK

Pulley dia. (effective dia.) 125 mm (4.92 in)

Pulley ratio 1.064 Item Specifications

AC-00082

OFFON

3.0

0.3

Page 32 of 2870

AC-30

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Leak Check

5. Refrigerant Leak Check

A: INSPECTION

1) Operate the A/C system for approx. 10 minutes,

and confirm that the high-pressure side shows at

least 690 kPa (7.03 kg/cm

2, 100 psi). Then stop the

engine to start the leak test.

2) Starting from the connection between the high-

pressure pipe and evaporator, check the system for

leaks along the high-pressure side through the

compressor. The following items must be checked

thoroughly.

3) Check the joint and seam between the pressure

switch (triple pressure switch) and high-pressure

pipe.

4) Check the connections between the condenser

and pipes, and welded joints on the condenser.

The leak tester may detect the oil on the condenser

fins as a leak.

5) Check the joint between the compressor and

hoses.

6) Check the machined area of compressor and

other joints on the compressor.

7) Check the compressor shaft seal at the area

near the center of compressor clutch pulley.

Some shaft seals show a slight amount of leakage

about 28 g (1.0 oz) per year. This is not a problem.

8) Starting from the connection between the low-

pressure pipe and evaporator, check the system for

leakage along the low-pressure side through the

compressor. The following items must be checked

thoroughly.

Connection between two parts

Connection between the pipe and plate

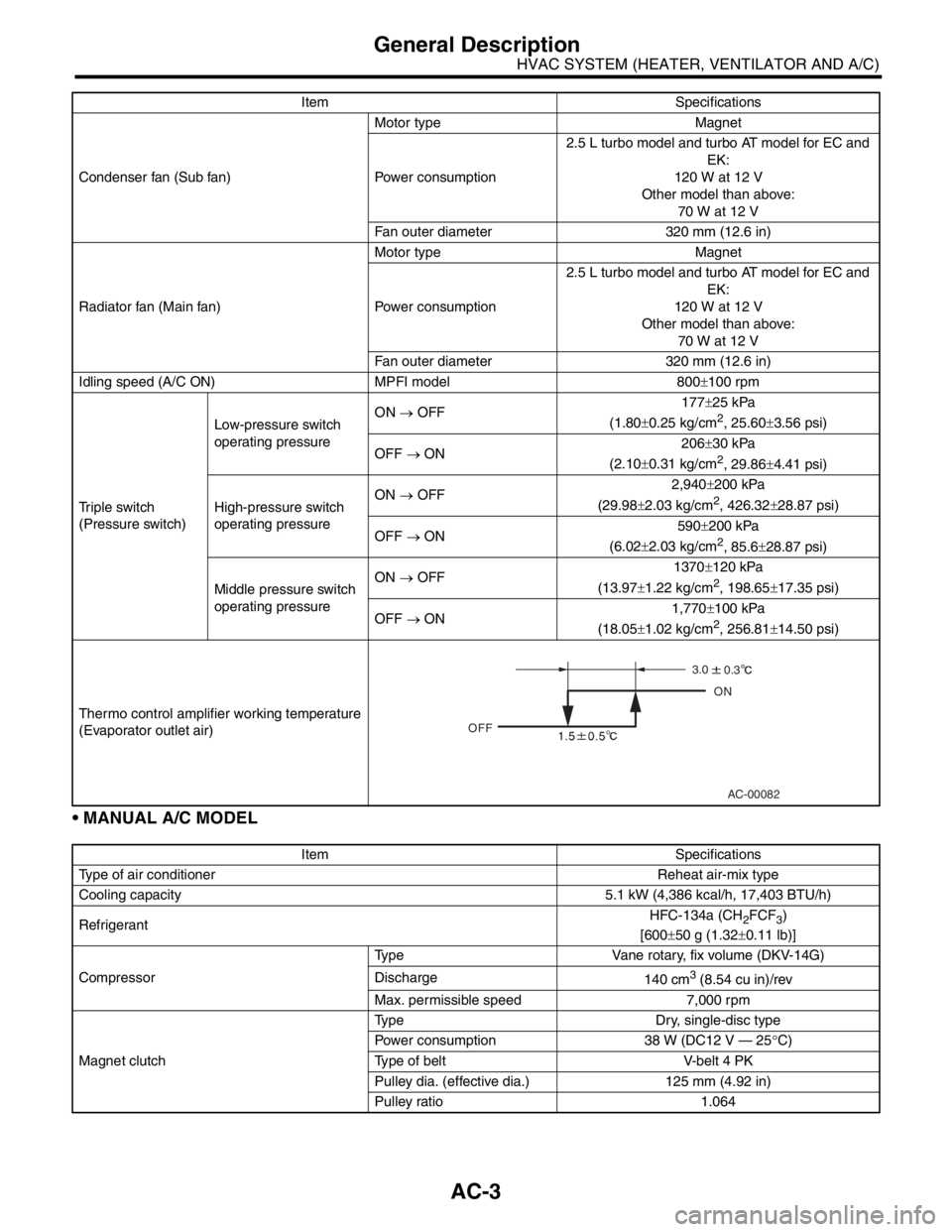

9) Visually check the rubber area of the flexible

hose for cracks.

Check the entire length of the flexible hose, espe-

cially the connection with the metal hose end.CAUTION:

Carefully check the external surface of hoses

and tubes at approx. 25 mm (0.98 in) per sec-

ond.

10) Disconnect the drain hose from the heater

case, and check the hose end for at least 10 sec-

onds.

After the test is finished, reconnect the drain hose.

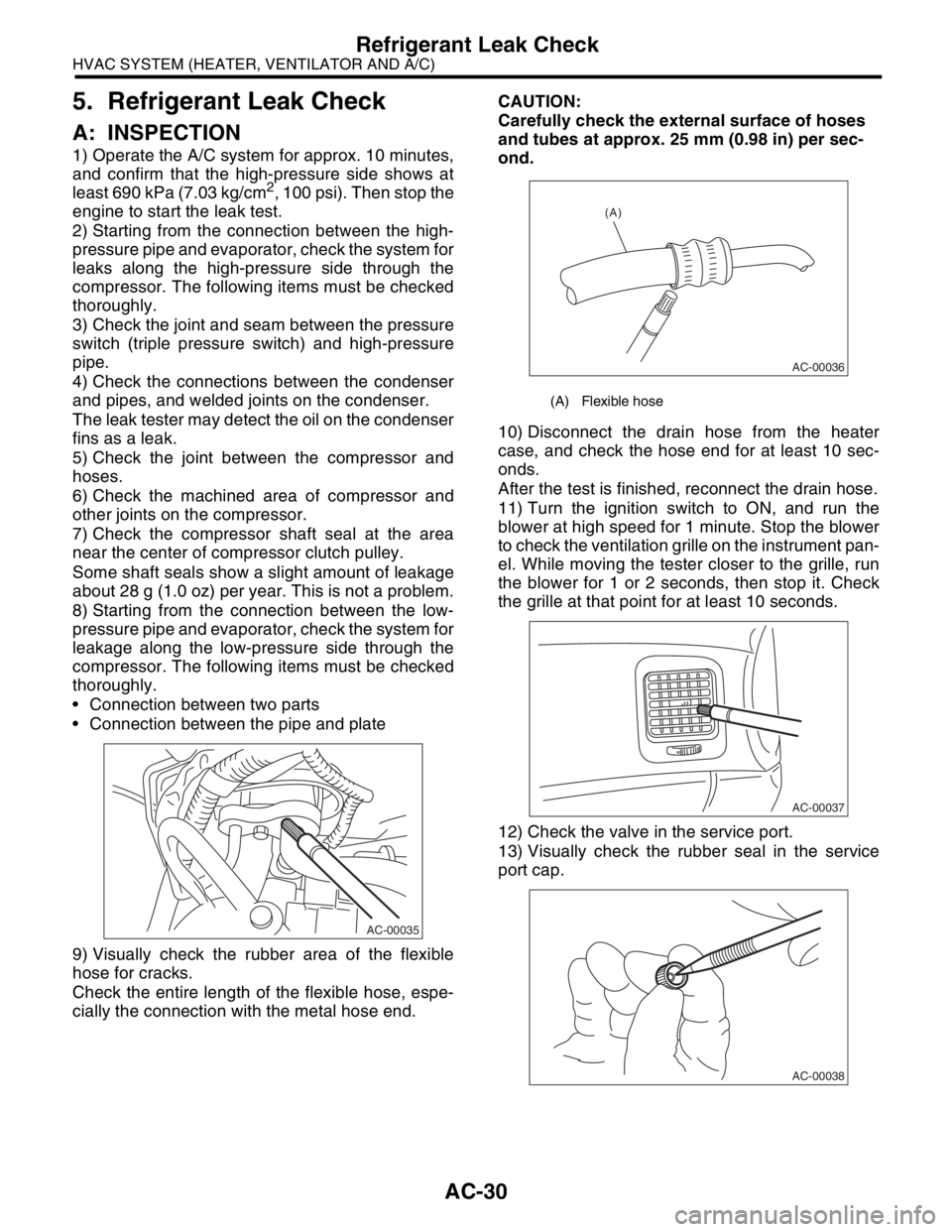

11) Turn the ignition switch to ON, and run the

blower at high speed for 1 minute. Stop the blower

to check the ventilation grille on the instrument pan-

el. While moving the tester closer to the grille, run

the blower for 1 or 2 seconds, then stop it. Check

the grille at that point for at least 10 seconds.

12) Check the valve in the service port.

13) Visually check the rubber seal in the service

port cap.

AC-00035

(A) Flexible hose

AC-00036

(A)

AC-00037

AC-00038

Page 38 of 2870

AC-36

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Compressor

11.Compressor

A: INSPECTION

1. MAGNETIC CLUTCH CLEARANCE

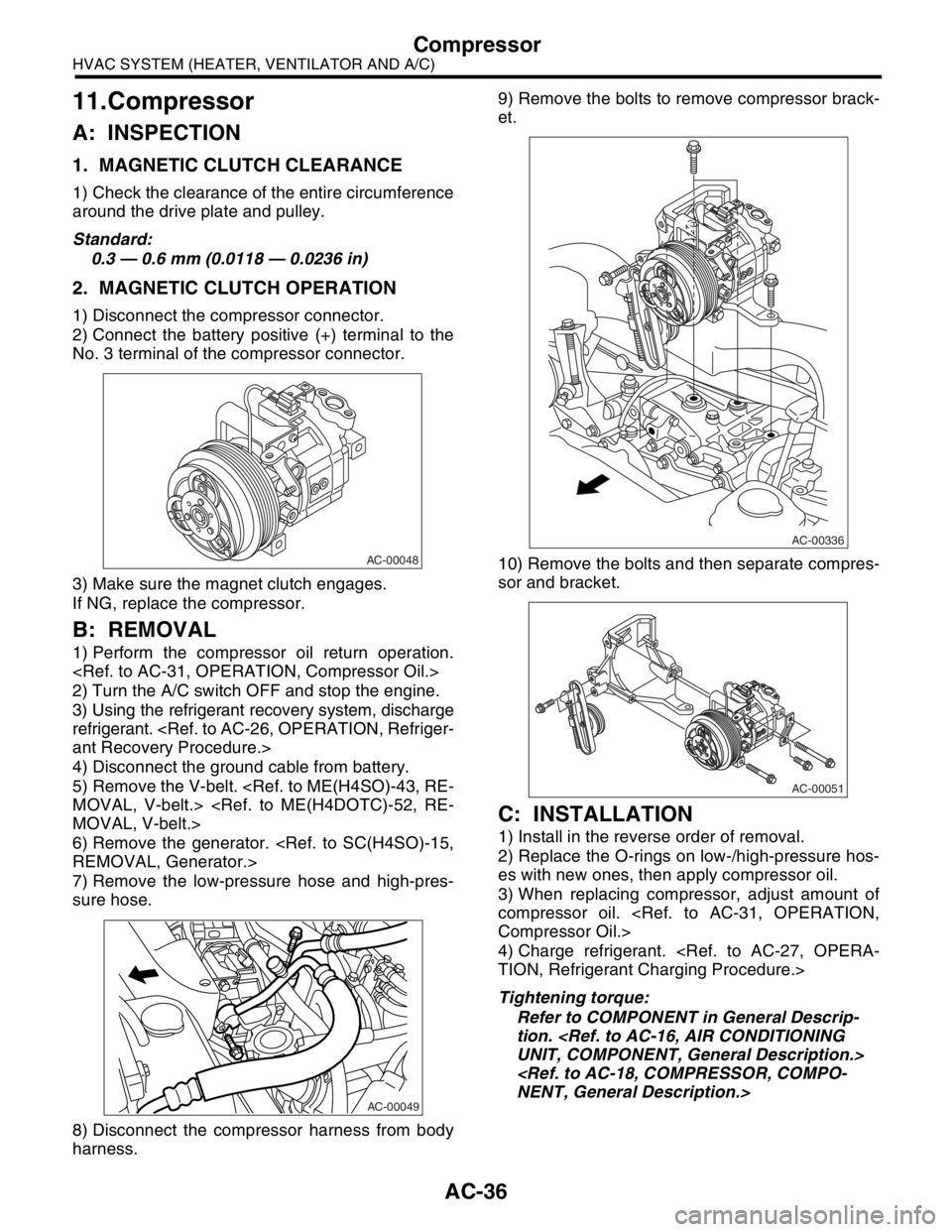

1) Check the clearance of the entire circumference

around the drive plate and pulley.

Standard:

0.3 — 0.6 mm (0.0118 — 0.0236 in)

2. MAGNETIC CLUTCH OPERATION

1) Disconnect the compressor connector.

2) Connect the battery positive (+) terminal to the

No. 3 terminal of the compressor connector.

3) Make sure the magnet clutch engages.

If NG, replace the compressor.

B: REMOVAL

1) Perform the compressor oil return operation.

2) Turn the A/C switch OFF and stop the engine.

3) Using the refrigerant recovery system, discharge

refrigerant.

4) Disconnect the ground cable from battery.

5) Remove the V-belt.

6) Remove the generator.

7) Remove the low-pressure hose and high-pres-

sure hose.

8) Disconnect the compressor harness from body

harness.9) Remove the bolts to remove compressor brack-

et.

10) Remove the bolts and then separate compres-

sor and bracket.

C: INSTALLATION

1) Install in the reverse order of removal.

2) Replace the O-rings on low-/high-pressure hos-

es with new ones, then apply compressor oil.

3) When replacing compressor, adjust amount of

compressor oil.

4) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

AC-00048

AC-00049

AC-00336

AC-00051

Page 52 of 2870

AC-50

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Diagnostics

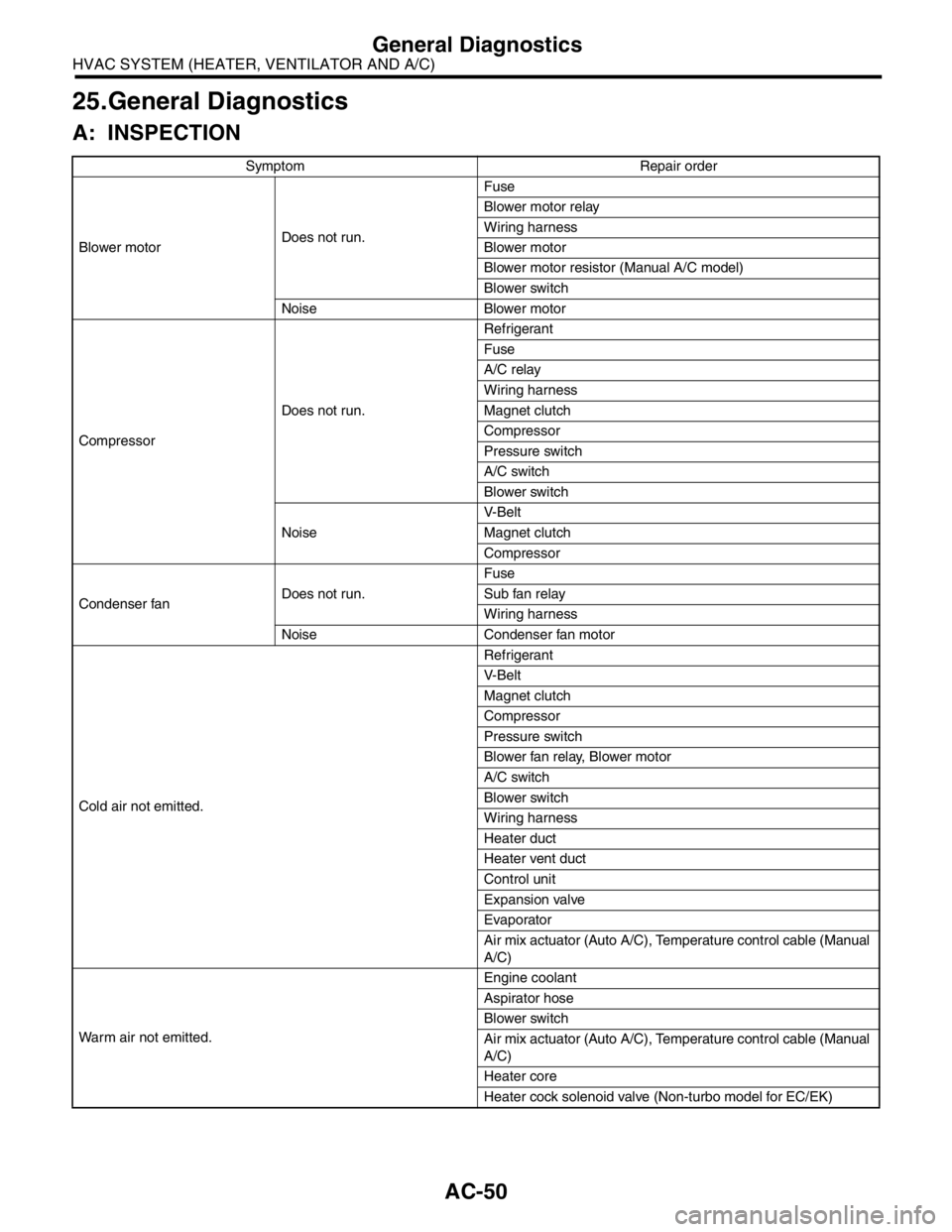

25.General Diagnostics

A: INSPECTION

Symptom Repair order

Blower motorDoes not run.Fuse

Blower motor relay

Wiring harness

Blower motor

Blower motor resistor (Manual A/C model)

Blower switch

Noise Blower motor

CompressorDoes not run.Refrigerant

Fuse

A/C relay

Wiring harness

Magnet clutch

Compressor

Pressure switch

A/C switch

Blower switch

NoiseV- B e l t

Magnet clutch

Compressor

Condenser fanDoes not run.Fuse

Sub fan relay

Wiring harness

Noise Condenser fan motor

Cold air not emitted.Refrigerant

V- B e l t

Magnet clutch

Compressor

Pressure switch

Blower fan relay, Blower motor

A/C switch

Blower switch

Wiring harness

Heater duct

Heater vent duct

Control unit

Expansion valve

Evaporator

Air mix actuator (Auto A/C), Temperature control cable (Manual

A/C)

Warm air not emitted.Engine coolant

Aspirator hose

Blower switch

Air mix actuator (Auto A/C), Temperature control cable (Manual

A/C)

Heater core

Heater cock solenoid valve (Non-turbo model for EC/EK)

Page 66 of 2870

AC-10

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Chart for Self-Diagnosis

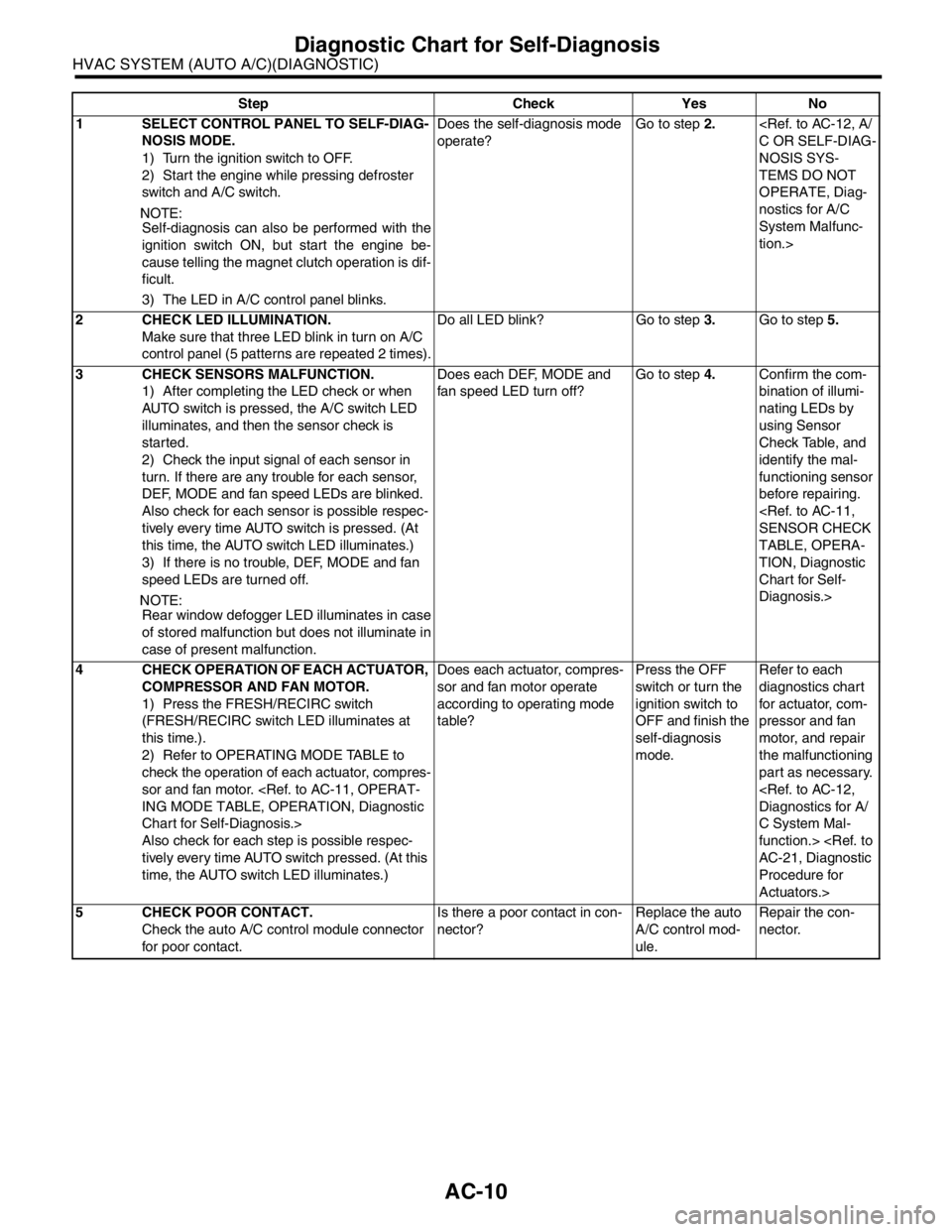

Step Check Yes No

1 SELECT CONTROL PANEL TO SELF-DIAG-

NOSIS MODE.

1) Turn the ignition switch to OFF.

2) Start the engine while pressing defroster

switch and A/C switch.

N

OTE:

Self-diagnosis can also be performed with the

ignition switch ON, but start the engine be-

cause telling the magnet clutch operation is dif-

ficult.

3) The LED in A/C control panel blinks.Does the self-diagnosis mode

operate?Go to step 2.

NOSIS SYS-

TEMS DO NOT

OPERATE, Diag-

nostics for A/C

System Malfunc-

tion.>

2 CHECK LED ILLUMINATION.

Make sure that three LED blink in turn on A/C

control panel (5 patterns are repeated 2 times).Do all LED blink? Go to step 3.Go to step 5.

3 CHECK SENSORS MALFUNCTION.

1) After completing the LED check or when

AUTO switch is pressed, the A/C switch LED

illuminates, and then the sensor check is

started.

2) Check the input signal of each sensor in

turn. If there are any trouble for each sensor,

DEF, MODE and fan speed LEDs are blinked.

Also check for each sensor is possible respec-

tively every time AUTO switch is pressed. (At

this time, the AUTO switch LED illuminates.)

3) If there is no trouble, DEF, MODE and fan

speed LEDs are turned off.

N

OTE:

Rear window defogger LED illuminates in case

of stored malfunction but does not illuminate in

case of present malfunction.Does each DEF, MODE and

fan speed LED turn off?Go to step 4.Confirm the com-

bination of illumi-

nating LEDs by

using Sensor

Check Table, and

identify the mal-

functioning sensor

before repairing.

TABLE, OPERA-

TION, Diagnostic

Chart for Self-

Diagnosis.>

4 CHECK OPERATION OF EACH ACTUATOR,

COMPRESSOR AND FAN MOTOR.

1) Press the FRESH/RECIRC switch

(FRESH/RECIRC switch LED illuminates at

this time.).

2) Refer to OPERATING MODE TABLE to

check the operation of each actuator, compres-

sor and fan motor.

Chart for Self-Diagnosis.>

Also check for each step is possible respec-

tively every time AUTO switch pressed. (At this

time, the AUTO switch LED illuminates.)Does each actuator, compres-

sor and fan motor operate

according to operating mode

table?Press the OFF

switch or turn the

ignition switch to

OFF and finish the

self-diagnosis

mode.Refer to each

diagnostics chart

for actuator, com-

pressor and fan

motor, and repair

the malfunctioning

par t as necessary.

C System Mal-

function.>

Procedure for

Actuators.>

5 CHECK POOR CONTACT.

Check the auto A/C control module connector

for poor contact.Is there a poor contact in con-

nector?Replace the auto

A/C control mod-

ule.Repair the con-

nector.

Page 67 of 2870

AC-11

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Chart for Self-Diagnosis

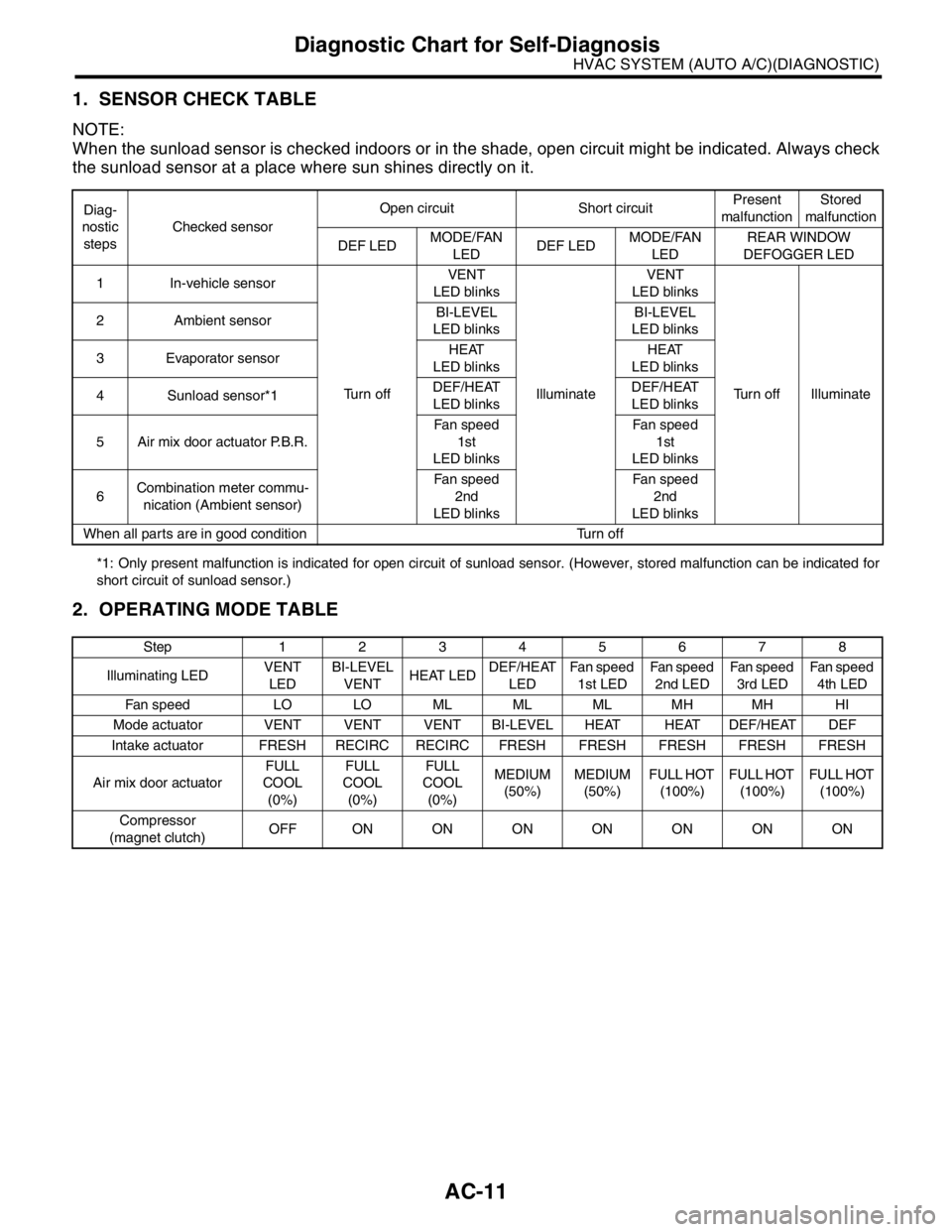

1. SENSOR CHECK TABLE

NOTE:

When the sunload sensor is checked indoors or in the shade, open circuit might be indicated. Always check

the sunload sensor at a place where sun shines directly on it.

*1: Only present malfunction is indicated for open circuit of sunload sensor. (However, stored malfunction can be indicated for

short circuit of sunload sensor.)

2. OPERATING MODE TABLE

Diag-

nostic

stepsChecked sensorOpen circuit Short circuitPresent

malfunctionStored

malfunction

DEF LEDMODE/FAN

LEDDEF LEDMODE/FAN

LEDREAR WINDOW

DEFOGGER LED

1 In-vehicle sensor

Tu r n o f fVENT

LED blinks

IlluminateVENT

LED blinks

Turn off Illuminate 2 Ambient sensorBI-LEVEL

LED blinksBI-LEVEL

LED blinks

3 Evaporator sensorHEAT

LED blinksHEAT

LED blinks

4 Sunload sensor*1DEF/HEAT

LED blinksDEF/HEAT

LED blinks

5 Air mix door actuator P.B.R.Fan speed

1st

LED blinksFan speed

1st

LED blinks

6Combination meter commu-

nication (Ambient sensor)Fan speed

2nd

LED blinksFan speed

2nd

LED blinks

When all parts are in good condition Turn off

Step 12345678

Illuminating LEDVENT

LEDBI-LEVEL

VENTHEAT LEDDEF/HEAT

LEDFan speed

1st LEDFan speed

2nd LEDFan speed

3rd LEDFan speed

4th LED

Fan speed LO LO ML ML ML MH MH HI

Mode actuator VENT VENT VENT BI-LEVEL HEAT HEAT DEF/HEAT DEF

Intake actuator FRESH RECIRC RECIRC FRESH FRESH FRESH FRESH FRESH

Air mix door actuatorFULL

COOL

(0%)FULL

COOL

(0%)FULL

COOL

(0%)MEDIUM

(50%)MEDIUM

(50%)FULL HOT

(100%)FULL HOT

(100%)FULL HOT

(100%)

Compressor

(magnet clutch)OFFONONONONONONON

Page 72 of 2870

AC-16

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

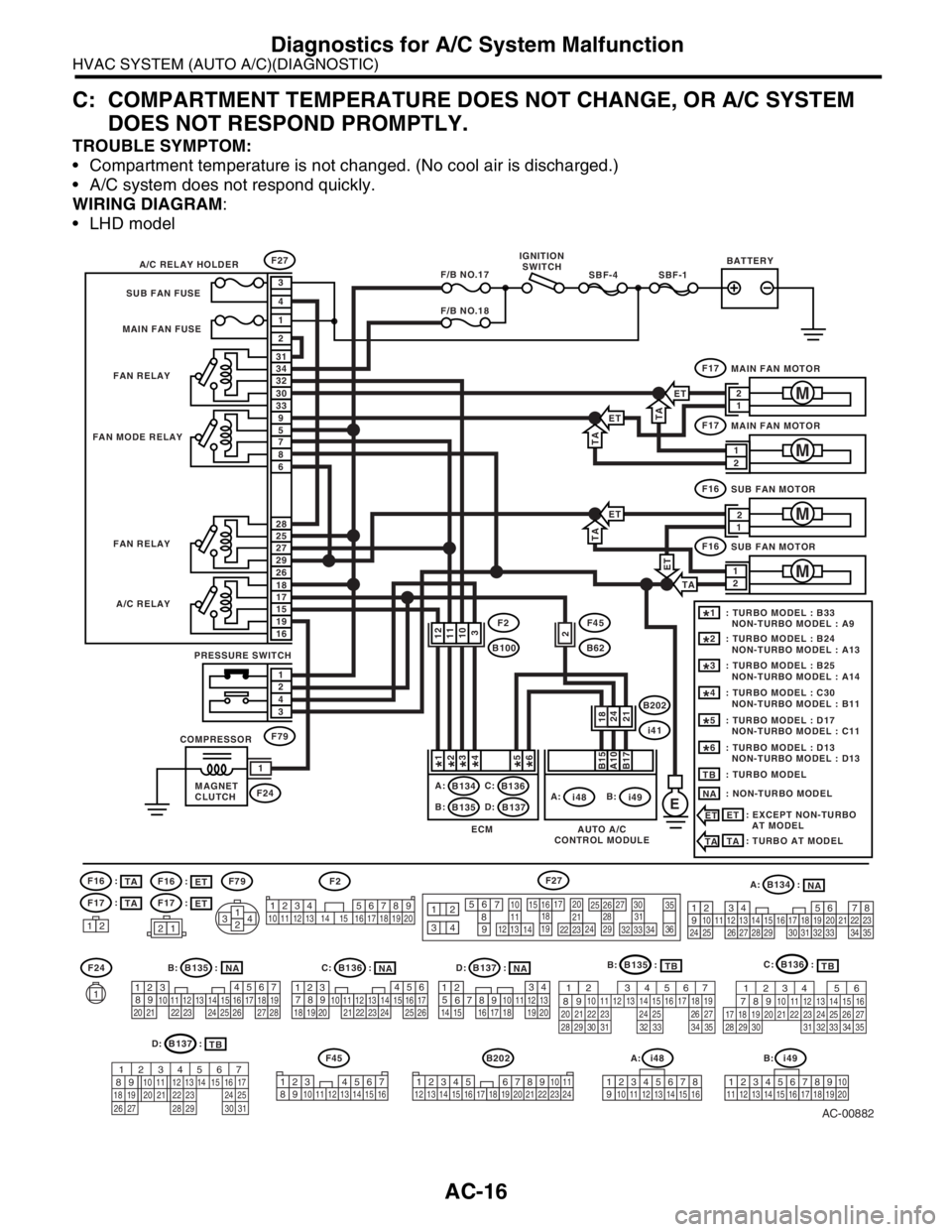

C: COMPARTMENT TEMPERATURE DOES NOT CHANGE, OR A/C SYSTEM

DOES NOT RESPOND PROMPTLY.

TROUBLE SYMPTOM:

Compartment temperature is not changed. (No cool air is discharged.)

A/C system does not respond quickly.

WIRING DIAGRAM:

LHD model

AC-00882

A: B134 :

B: B135 :

B202

D: B137 :C: B136 :

F2F27

EA:

i48

F27

F17

F79

F45

B62

B202

i41

F24

F24

F16F79

F45

F17

B:

i49A:

B134 B136

B135 B137C:

B:D:IGNITION

SWITCHBATTERY

A/C RELAY HOLDER

FAN RELAY

FAN RELAY

A/C RELAY

PRESSURE SWITCH

COMPRESSOR

MAGNET

CLUTCH FAN MODE RELAYSUB FAN FUSE

MAIN FAN FUSE

MAIN FAN MOTOR

1

M

SBF-1SBF-4F/B NO.17

F/B NO.18

1

2

3

2

1

4

3033

32 31

34

86

7 9

5

2926

27 28

25

1916

15 18

17

43

21

B15A10B17

F17

MAIN FAN MOTOR

M

F16

SUB FAN MOTOR

M

F16

SUB FAN MOTOR

M

1

2112 1314

15 16171819

20

10

1121222324

2526272829

3031323334

35

36

12

93456

7

82 314

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

4

1

53

2618 15 167891011

17 19

20121314

1234567891011121314151617181920212223242526272829303132333435

AUTO A/C

CONTROL MODULE ECM

2421

1234 5678910 11 12 13 14 15 16 17 18 19 20

123 4567

8910 11 12 13 14 15 16

56

78 2 1

94

310

24 22 23 251112131415

261617181920 21

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

D: B137 :

B: B135 :C: B136 :

A: i48

12345678

910 11 12 13 14 15 16

B: i49

12345678910

11 12 13 14 15 1617 18 19 20

: TURBO MODEL : B33

NON-TURBO MODEL : A91*

: TURBO MODEL : B24

NON-TURBO MODEL : A132*

: TURBO MODEL : B25

NON-TURBO MODEL : A143*

: TURBO MODEL : C30

NON-TURBO MODEL : B114*

: TURBO MODEL : D17

NON-TURBO MODEL : C115*

: TURBO MODEL : D13

NON-TURBO MODEL : D136*

: TURBO MODELTB

: NON-TURBO MODEL

NA

: EXCEPT NON-TURBO

AT MODEL

ET

ETNA

TB

TBNANANATB

1112

10

3

18 1

*2*3*4*5*6*

2F2

B100

ET

ETTA

TA

ET

TA

ET

: TURBO AT MODEL

TATA

TA

ET

:

ET :

F16

F17

TA :

TA :

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 3556

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

12

1

2

2 1

12

Page 73 of 2870

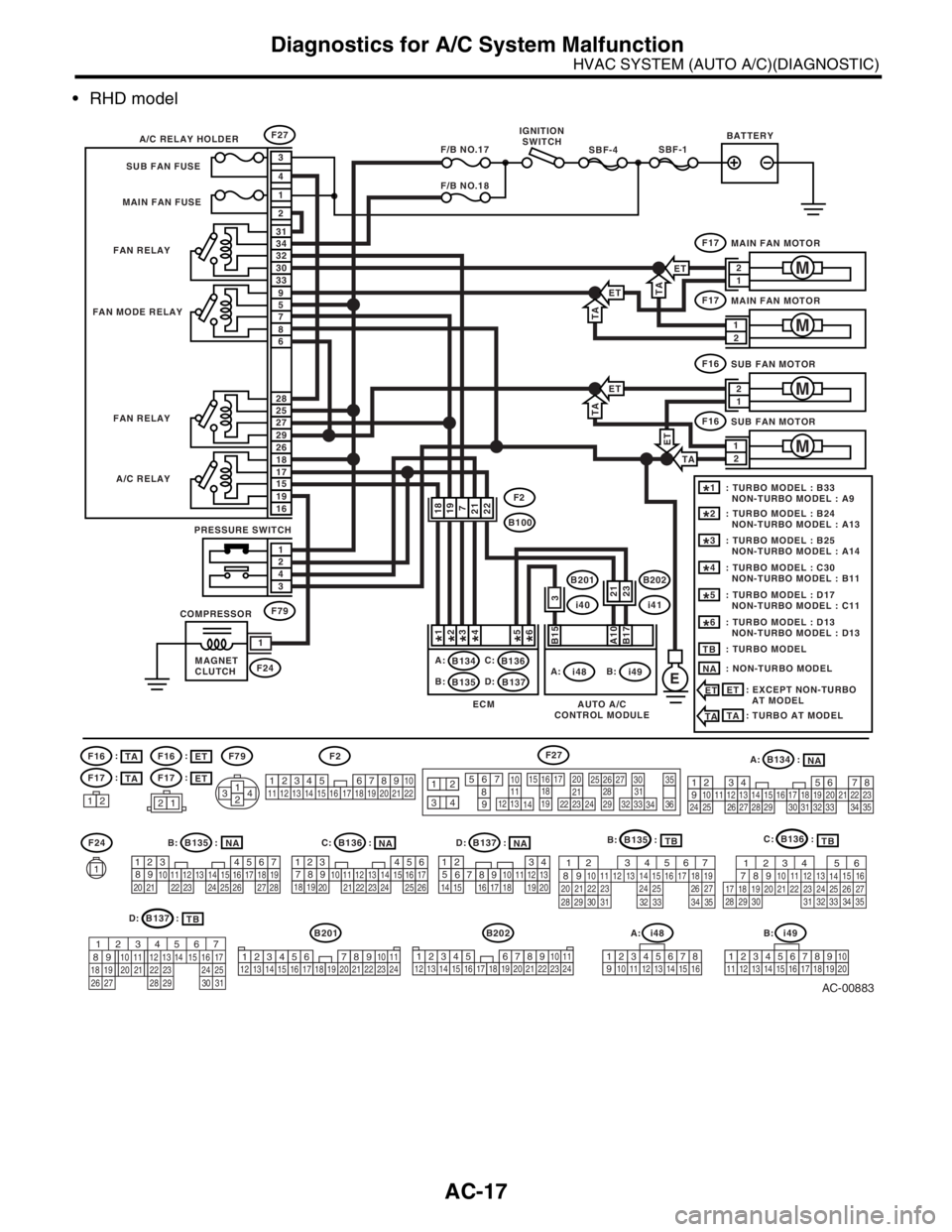

AC-17

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

RHD model

AC-00883

A: B134 :

B: B135 :

B202

D: B137 :C: B136 :

F2F27

EA:

i48

F27

F17

F79

B202

i41

B201

i40

F24

F16F79

B201

F17

B:

i49A:

B134 B136

B135 B137C:

B:D:IGNITION

SWITCHBATTERY

A/C RELAY HOLDER

FAN RELAY

FAN RELAY

A/C RELAY

PRESSURE SWITCH

COMPRESSOR

MAGNET

CLUTCH FAN MODE RELAYSUB FAN FUSE

MAIN FAN FUSE

MAIN FAN MOTOR

1

M

SBF-1SBF-4F/B NO.17

F/B NO.18

1

2

3

2

1

4

3033

32 31

34

86

7 9

5

2926

27 28

25

1916

15 18

17

43

21

B15A10B17

F17

MAIN FAN MOTOR

M

F16

SUB FAN MOTOR

M2

1

F16

SUB FAN MOTOR

M

2112 1314

15 16171819

20

10

1121222324

2526272829

3031323334

35

36

12

93456

7

82 314

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

4

1

53

2618 15 167891011

17 19

20121314

1234567891011121314151617181920212223242526272829303132333435

AUTO A/C

CONTROL MODULE ECM

2123

56

78 2 1

94

310

24 22 23 251112131415

261617181920 21

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

D: B137 :

B: B135 :C: B136 :

A: i48

12345678

910 11 12 13 14 15 16

B: i49

12345678910

11 12 13 14 15 1617 18 19 20

: TURBO MODEL : B33

NON-TURBO MODEL : A91*

: TURBO MODEL : B24

NON-TURBO MODEL : A132*

: TURBO MODEL : B25

NON-TURBO MODEL : A143*

: TURBO MODEL : C30

NON-TURBO MODEL : B114*

: TURBO MODEL : D17

NON-TURBO MODEL : C115*

: TURBO MODEL : D13

NON-TURBO MODEL : D136*

: TURBO MODELTB

: NON-TURBO MODEL

NA

: EXCEPT NON-TURBO

AT MODEL

ET

ETNA

TB

TBNANANATB

1918

7

2122

3 1

*2*3*4*5*6*

F2

B100

ET

ETTA

TA

ET

TA

ET

: TURBO AT MODEL

TATA

TA

ET

:

ET :

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 3556

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

12345 678910

11

1219 20 21

13 14 151617

18 22

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

F24

1

F16

F17

TA :

TA :

12

2 1

2 1

Page 74 of 2870

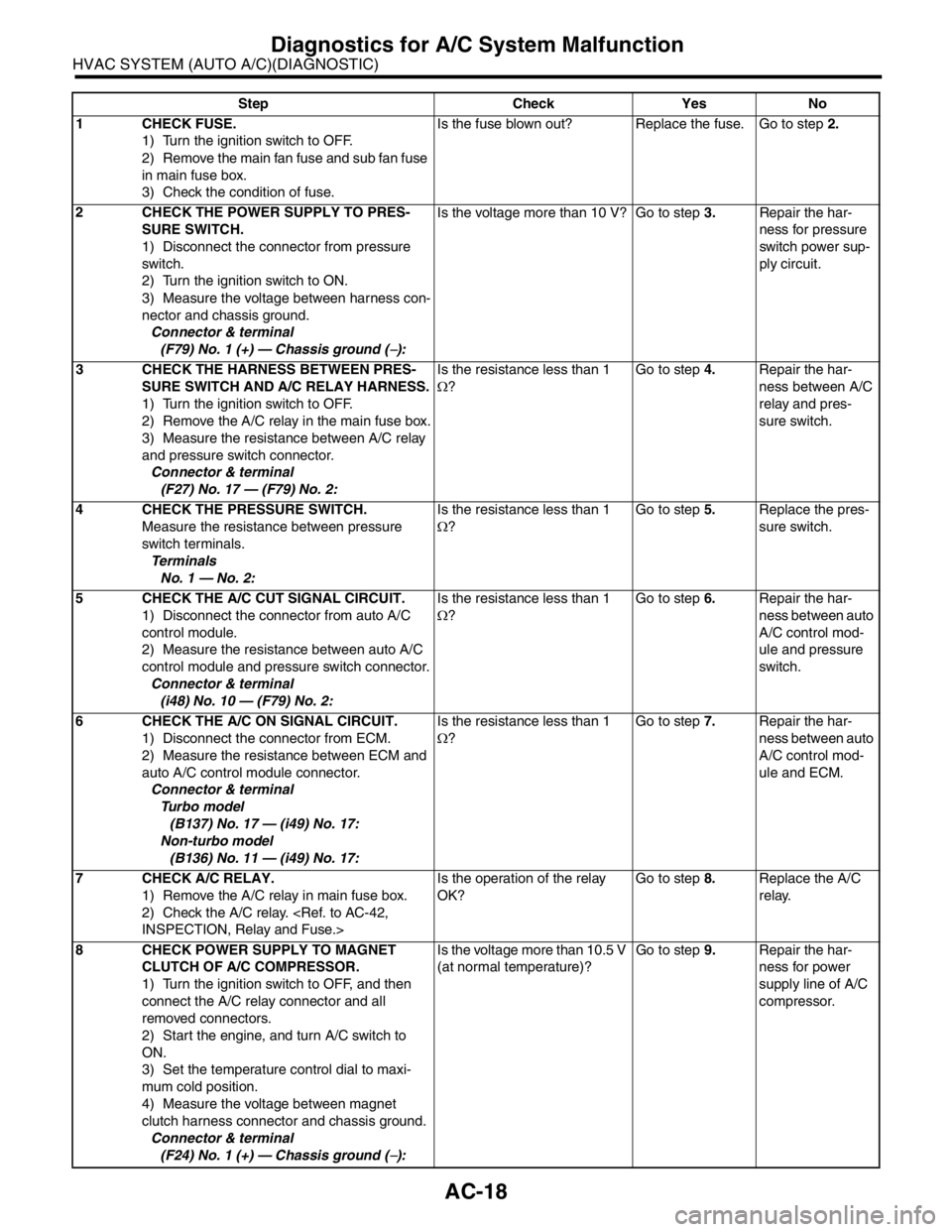

AC-18

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

Step Check Yes No

1 CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the main fan fuse and sub fan fuse

in main fuse box.

3) Check the condition of fuse.Is the fuse blown out? Replace the fuse. Go to step 2.

2 CHECK THE POWER SUPPLY TO PRES-

SURE SWITCH.

1) Disconnect the connector from pressure

switch.

2) Turn the ignition switch to ON.

3) Measure the voltage between harness con-

nector and chassis ground.

Connector & terminal

(F79) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 3.Repair the har-

ness for pressure

switch power sup-

ply circuit.

3 CHECK THE HARNESS BETWEEN PRES-

SURE SWITCH AND A/C RELAY HARNESS.

1) Turn the ignition switch to OFF.

2) Remove the A/C relay in the main fuse box.

3) Measure the resistance between A/C relay

and pressure switch connector.

Connector & terminal

(F27) No. 17 — (F79) No. 2:Is the resistance less than 1

Ω?Go to step 4.Repair the har-

ness between A/C

relay and pres-

sure switch.

4 CHECK THE PRESSURE SWITCH.

Measure the resistance between pressure

switch terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance less than 1

Ω?Go to step 5.Replace the pres-

sure switch.

5 CHECK THE A/C CUT SIGNAL CIRCUIT.

1) Disconnect the connector from auto A/C

control module.

2) Measure the resistance between auto A/C

control module and pressure switch connector.

Connector & terminal

(i48) No. 10 — (F79) No. 2:Is the resistance less than 1

Ω?Go to step 6.Repair the har-

ness between auto

A/C control mod-

ule and pressure

switch.

6 CHECK THE A/C ON SIGNAL CIRCUIT.

1) Disconnect the connector from ECM.

2) Measure the resistance between ECM and

auto A/C control module connector.

Connector & terminal

Turbo model

(B137) No. 17 — (i49) No. 17:

Non-turbo model

(B136) No. 11 — (i49) No. 17:Is the resistance less than 1

Ω?Go to step 7.Repair the har-

ness between auto

A/C control mod-

ule and ECM.

7 CHECK A/C RELAY.

1) Remove the A/C relay in main fuse box.

2) Check the A/C relay.

OK?Go to step 8.Replace the A/C

relay.

8 CHECK POWER SUPPLY TO MAGNET

CLUTCH OF A/C COMPRESSOR.

1) Turn the ignition switch to OFF, and then

connect the A/C relay connector and all

removed connectors.

2) Start the engine, and turn A/C switch to

ON.

3) Set the temperature control dial to maxi-

mum cold position.

4) Measure the voltage between magnet

clutch harness connector and chassis ground.

Connector & terminal

(F24) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10.5 V

(at normal temperature)?Go to step 9.Repair the har-

ness for power

supply line of A/C

compressor.