tire type SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 268 of 2870

LI-14

LIGHTING SYSTEM

Headlight Assembly

7) Remove the packing (A) from seal groove.

CAUTION:

Completely remove the packing not to leave

any chips behind.

D: ASSEMBLY

1) Cut the tip of packing (A) at an angle of 45°.

2) With the cut end facing upward, insert the pack-

ing (A) into groove around seal.

CAUTION:

If the packing protrudes, slowly take it off the

groove.

Do not stretch the packing. If the packing is

stretched, seal fails.

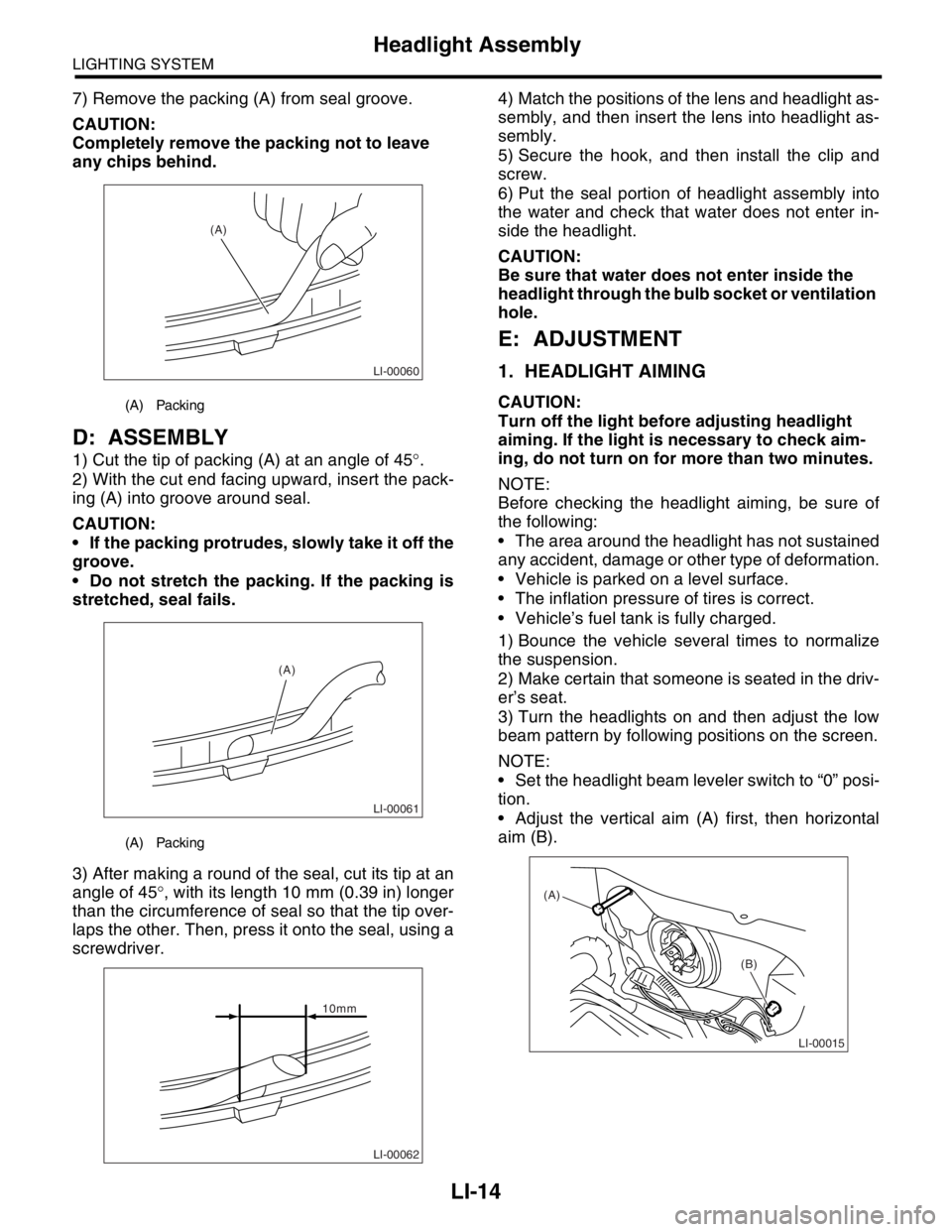

3) After making a round of the seal, cut its tip at an

angle of 45°, with its length 10 mm (0.39 in) longer

than the circumference of seal so that the tip over-

laps the other. Then, press it onto the seal, using a

screwdriver.4) Match the positions of the lens and headlight as-

sembly, and then insert the lens into headlight as-

sembly.

5) Secure the hook, and then install the clip and

screw.

6) Put the seal portion of headlight assembly into

the water and check that water does not enter in-

side the headlight.

CAUTION:

Be sure that water does not enter inside the

headlight through the bulb socket or ventilation

hole.

E: ADJUSTMENT

1. HEADLIGHT AIMING

CAUTION:

Turn off the light before adjusting headlight

aiming. If the light is necessary to check aim-

ing, do not turn on for more than two minutes.

NOTE:

Before checking the headlight aiming, be sure of

the following:

The area around the headlight has not sustained

any accident, damage or other type of deformation.

Vehicle is parked on a level surface.

The inflation pressure of tires is correct.

Vehicle’s fuel tank is fully charged.

1) Bounce the vehicle several times to normalize

the suspension.

2) Make certain that someone is seated in the driv-

er’s seat.

3) Turn the headlights on and then adjust the low

beam pattern by following positions on the screen.

NOTE:

Set the headlight beam leveler switch to “0” posi-

tion.

Adjust the vertical aim (A) first, then horizontal

aim (B).(A) Packing

(A) Packing

LI-00060

(A)

LI-00061

(A)

LI-00062

10mm

LI-00015

(A)

(B)

Page 693 of 2870

SPC-4

SPECIFICATION

Forester

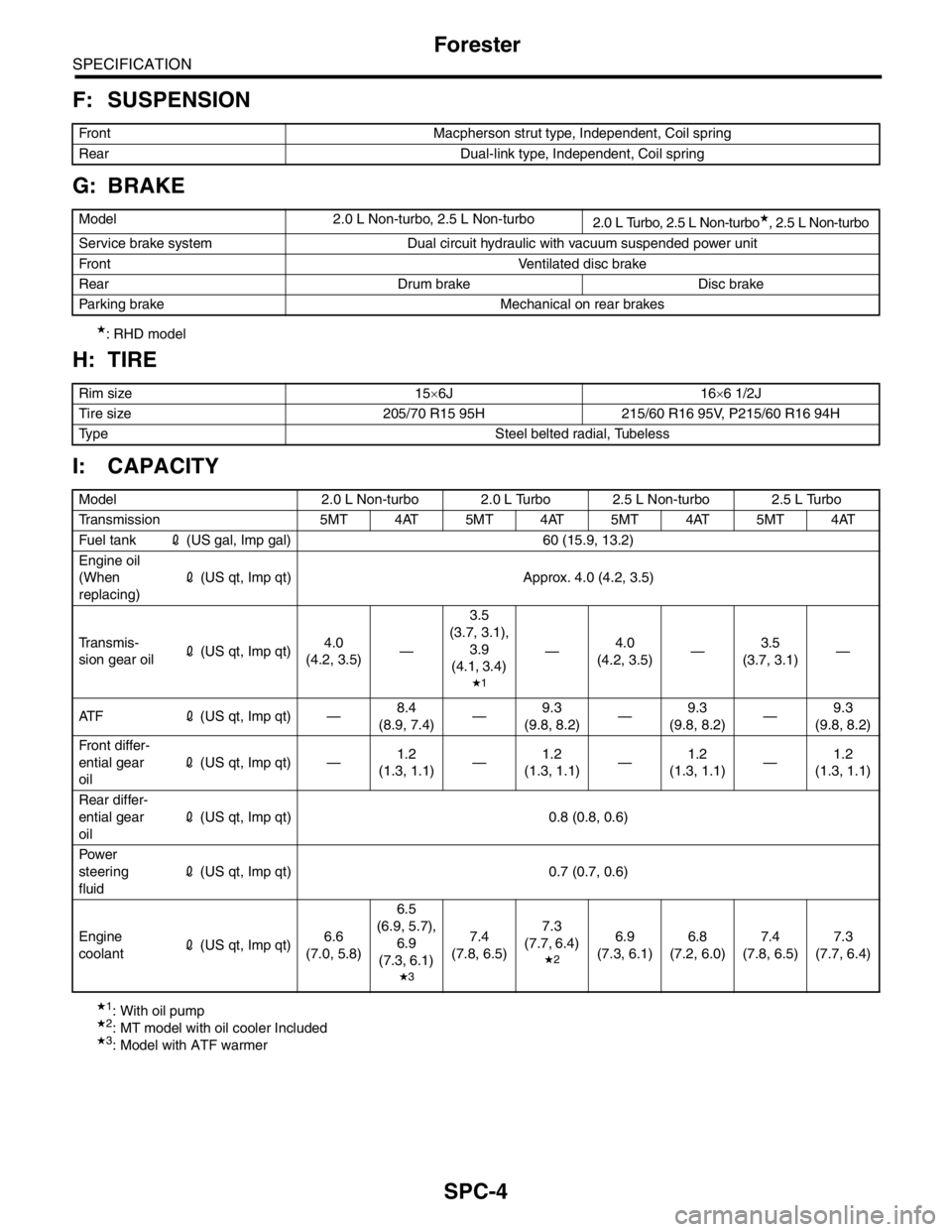

F: SUSPENSION

G: BRAKE

★: RHD model

H: TIRE

I: CAPACITY

★1: With oil pump★2: MT model with oil cooler Included★3: Model with ATF warmer Front Macpherson strut type, Independent, Coil spring

Rear Dual-link type, Independent, Coil spring

Model 2.0 L Non-turbo, 2.5 L Non-turbo

2.0 L Turbo, 2.5 L Non-turbo

★, 2.5 L Non-turbo

Service brake system Dual circuit hydraulic with vacuum suspended power unit

Front Ventilated disc brake

Rear Drum brake Disc brake

Parking brake Mechanical on rear brakes

Rim size 15×6J 16×6 1/2J

Tire size 205/70 R15 95H 215/60 R16 95V, P215/60 R16 94H

Type Steel belted radial, Tubeless

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Tr a n s m i s s i o n 5 M T 4 AT 5 M T 4 AT 5 M T 4 AT 5 M T 4 AT

Fuel tank2 (US gal, Imp gal) 60 (15.9, 13.2)

Engine oil

(When

replacing)2 (US qt, Imp qt) Approx. 4.0 (4.2, 3.5)

Tr a n s m i s -

sion gear oil2 (US qt, Imp qt)4.0

(4.2, 3.5)—3.5

(3.7, 3.1),

3.9

(4.1, 3.4)

★1

—4.0

(4.2, 3.5)—3.5

(3.7, 3.1)—

AT F2 (US qt, Imp qt) —8.4

(8.9, 7.4)—9.3

(9.8, 8.2)—9.3

(9.8, 8.2)—9.3

(9.8, 8.2)

Front differ-

ential gear

oil2 (US qt, Imp qt) —1.2

(1.3, 1.1)—1.2

(1.3, 1.1)—1.2

(1.3, 1.1)—1.2

(1.3, 1.1)

Rear differ-

ential gear

oil2 (US qt, Imp qt) 0.8 (0.8, 0.6)

Pow er

steering

fluid2 (US qt, Imp qt) 0.7 (0.7, 0.6)

Engine

coolant2 (US qt, Imp qt)6.6

(7.0, 5.8)6.5

(6.9, 5.7),

6.9

(7.3, 6.1)

★3

7.4

(7.8, 6.5)7.3

(7.7, 6.4)

★2

6.9

(7.3, 6.1)6.8

(7.2, 6.0)7.4

(7.8, 6.5)7.3

(7.7, 6.4)

Page 2377 of 2870

4AT-64

AUTOMATIC TRANSMISSION

Control Valve Body

7) Fill liquid gasket to holes except for bolt holes

(three) of transmission case.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

8) Install the oil pan with equally tighten the bolts.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

9) Pour ATF from the ATF charge pipe.

Recommended fluid:

DEXRON III type automatic transmission flu-

id

Capacity:

Pour fluid as same amount as drained fluid

from drain plug hole.

10) Inspect the level of ATF.

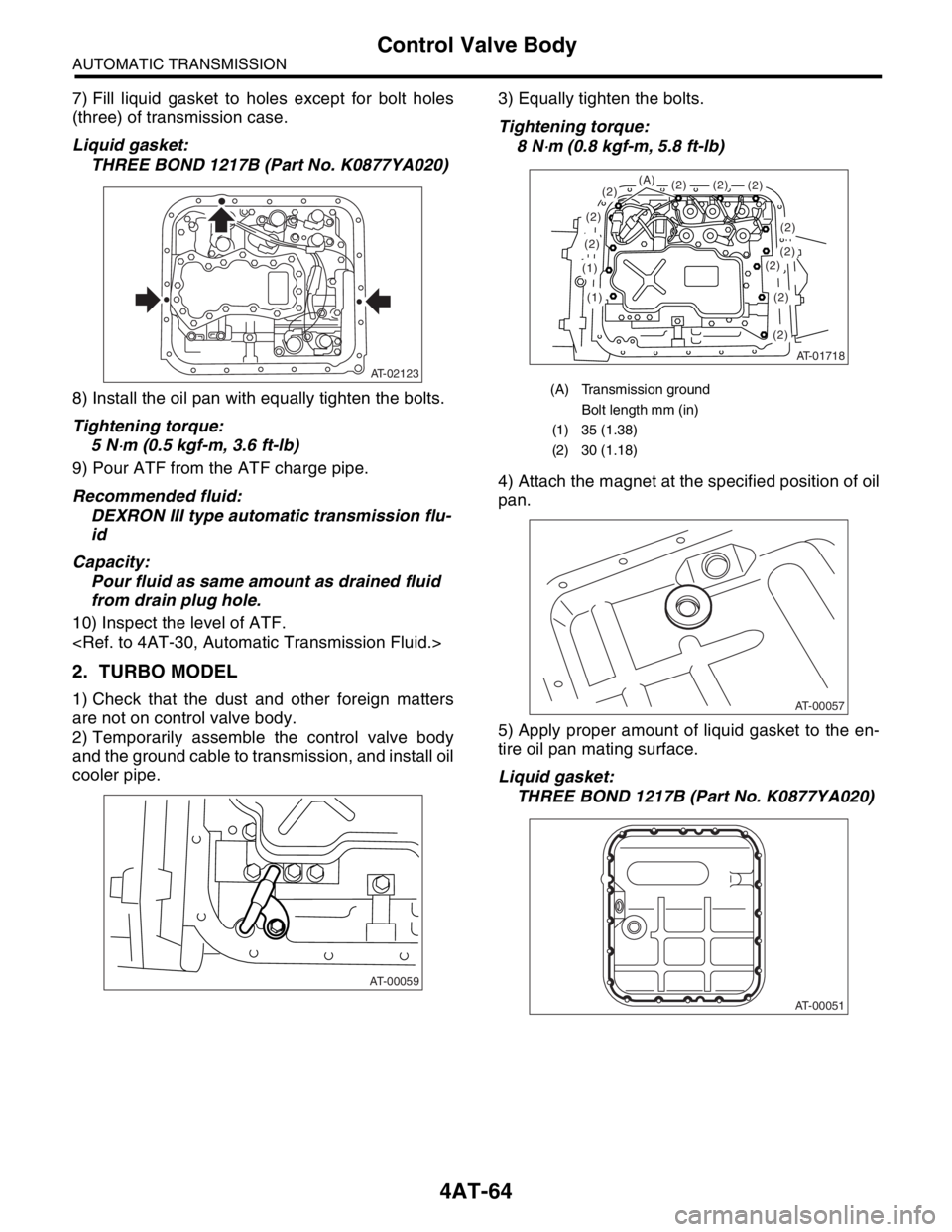

2. TURBO MODEL

1) Check that the dust and other foreign matters

are not on control valve body.

2) Temporarily assemble the control valve body

and the ground cable to transmission, and install oil

cooler pipe.3) Equally tighten the bolts.

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

4) Attach the magnet at the specified position of oil

pan.

5) Apply proper amount of liquid gasket to the en-

tire oil pan mating surface.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

AT-02123

AT-00059

(A) Transmission ground

Bolt length mm (in)

(1) 35 (1.38)

(2) 30 (1.18)

AT-01718

(1)

(1)

(2)

(2)

(2)(2)

(2)

(2)(2)(2)(2)

(2)

(2)

(A)

AT-00057

AT-00051