tires SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 127 of 2870

AB-27

AIRBAG SYSTEM

Disposal of Airbag Module (Deploying After Removal from Vehicle)

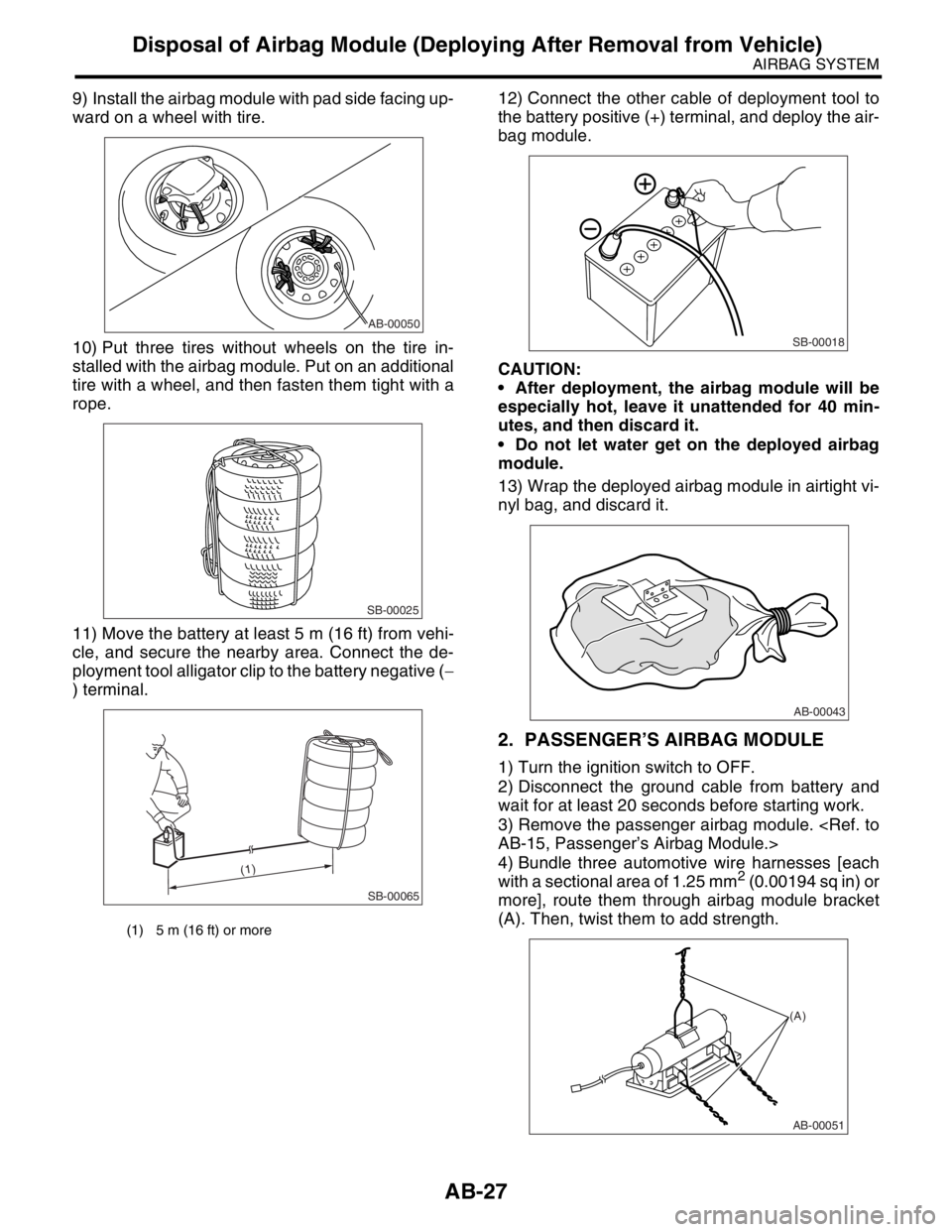

9) Install the airbag module with pad side facing up-

ward on a wheel with tire.

10) Put three tires without wheels on the tire in-

stalled with the airbag module. Put on an additional

tire with a wheel, and then fasten them tight with a

rope.

11) Move the battery at least 5 m (16 ft) from vehi-

cle, and secure the nearby area. Connect the de-

ployment tool alligator clip to the battery negative (−

) terminal.12) Connect the other cable of deployment tool to

the battery positive (+) terminal, and deploy the air-

bag module.

CAUTION:

After deployment, the airbag module will be

especially hot, leave it unattended for 40 min-

utes, and then discard it.

Do not let water get on the deployed airbag

module.

13) Wrap the deployed airbag module in airtight vi-

nyl bag, and discard it.

2. PASSENGER’S AIRBAG MODULE

1) Turn the ignition switch to OFF.

2) Disconnect the ground cable from battery and

wait for at least 20 seconds before starting work.

3) Remove the passenger airbag module.

4) Bundle three automotive wire harnesses [each

with a sectional area of 1.25 mm

2 (0.00194 sq in) or

more], route them through airbag module bracket

(A). Then, twist them to add strength.

(1) 5 m (16 ft) or more

AB-00050

SB-00025

SB-00065

(1)

SB-00018

AB-00043

AB-00051

(A)

Page 128 of 2870

AB-28

AIRBAG SYSTEM

Disposal of Airbag Module (Deploying After Removal from Vehicle)

5) Short the terminal to alligator clip furnished as

deployment tool (A)

6) Connect the deployment tool and deployment

adapter E (B).

CAUTION:

The deployment tool should be kept shorted

terminals until just before deployment of airbag

module.

7) Connect the deployment adapter E connector to

the airbag module.

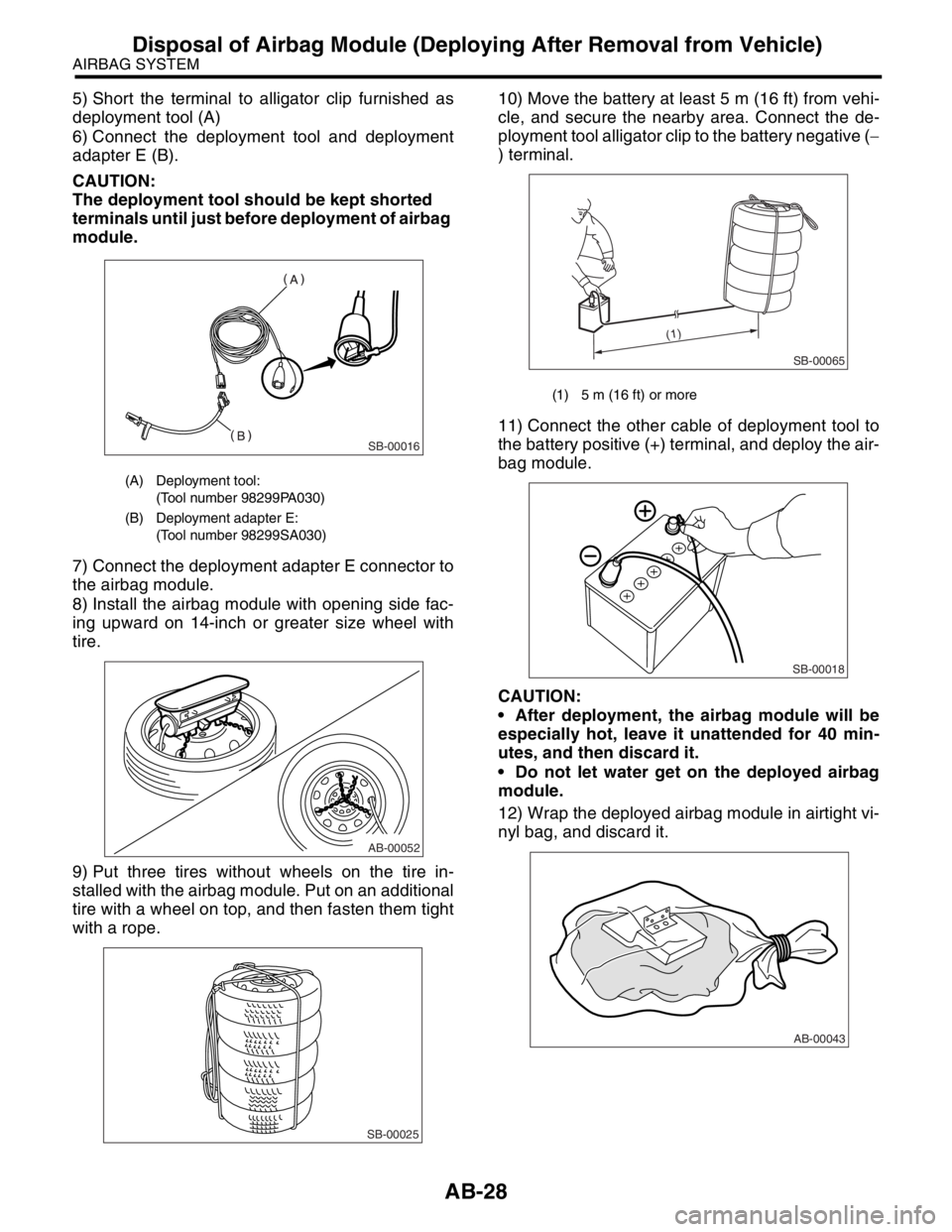

8) Install the airbag module with opening side fac-

ing upward on 14-inch or greater size wheel with

tire.

9) Put three tires without wheels on the tire in-

stalled with the airbag module. Put on an additional

tire with a wheel on top, and then fasten them tight

with a rope.10) Move the battery at least 5 m (16 ft) from vehi-

cle, and secure the nearby area. Connect the de-

ployment tool alligator clip to the battery negative (−

) terminal.

11) Connect the other cable of deployment tool to

the battery positive (+) terminal, and deploy the air-

bag module.

CAUTION:

After deployment, the airbag module will be

especially hot, leave it unattended for 40 min-

utes, and then discard it.

Do not let water get on the deployed airbag

module.

12) Wrap the deployed airbag module in airtight vi-

nyl bag, and discard it.

(A) Deployment tool:

(Tool number 98299PA030)

(B) Deployment adapter E:

(Tool number 98299SA030)

SB-00016

AB-00052

SB-00025

(1) 5 m (16 ft) or more

SB-00065

(1)

SB-00018

AB-00043

Page 129 of 2870

AB-29

AIRBAG SYSTEM

Disposal of Airbag Module (Deploying After Removal from Vehicle)

3. SIDE AIRBAG MODULE

1) Turn the ignition switch to OFF.

2) Disconnect the ground cable from battery and

wait for at least 20 seconds before starting work.

3) Remove the front seats.

4) Remove the side airbag module.

5) Bundle three automotive wire harnesses [each

with a sectional area of 1.25 mm

2 (0.00194 sq in) or

more], and then bind them through the holes in air-

bag module bracket.

6) Short the terminal to alligator clip furnished as

deployment tool (A)

7) Connect the deployment tool and deployment

adapter A (B).

CAUTION:

The deployment tool should be kept shorted

terminals until just before deployment of airbag

module.

8) Connect the deployment adapter A connector to

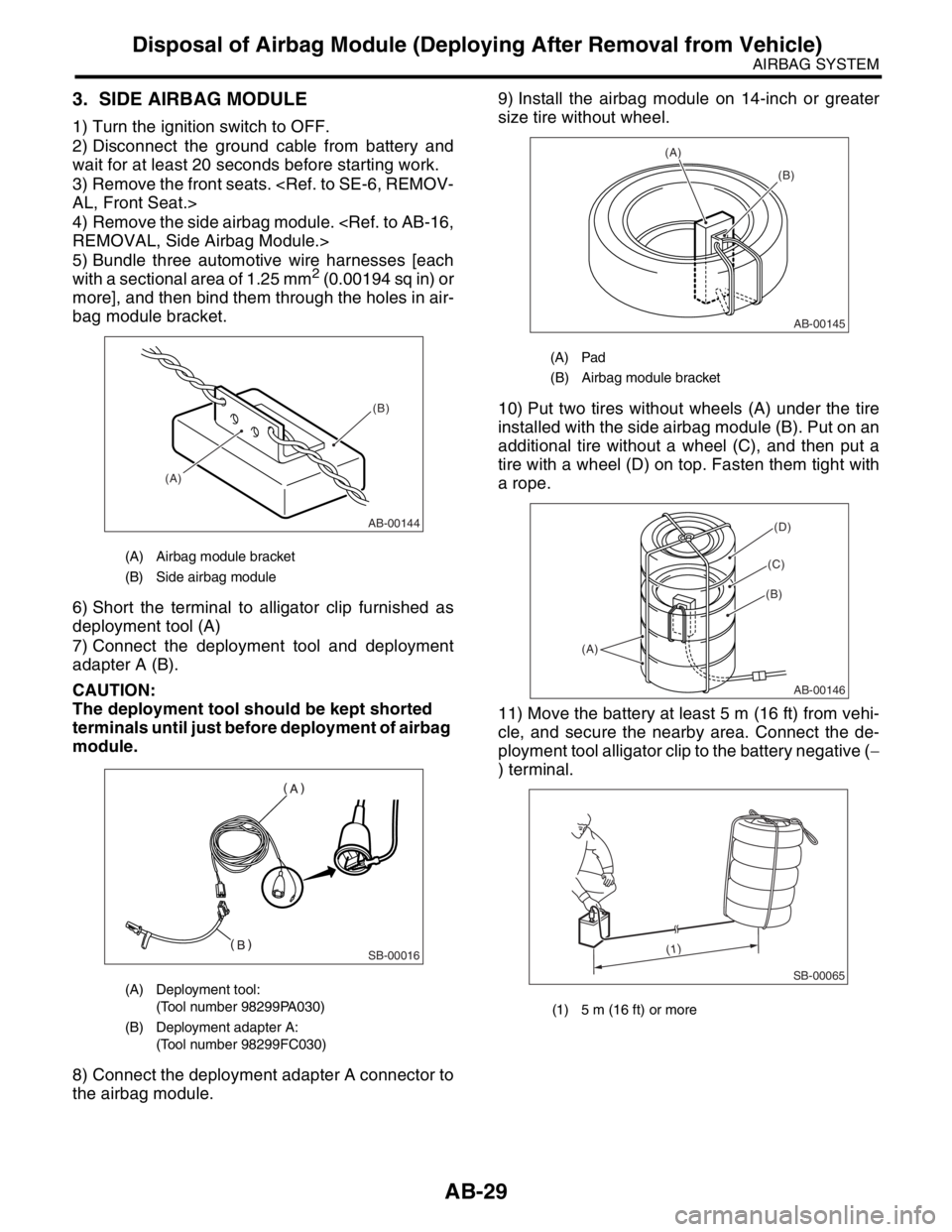

the airbag module.9) Install the airbag module on 14-inch or greater

size tire without wheel.

10) Put two tires without wheels (A) under the tire

installed with the side airbag module (B). Put on an

additional tire without a wheel (C), and then put a

tire with a wheel (D) on top. Fasten them tight with

a rope.

11) Move the battery at least 5 m (16 ft) from vehi-

cle, and secure the nearby area. Connect the de-

ployment tool alligator clip to the battery negative (−

) terminal.

(A) Airbag module bracket

(B) Side airbag module

(A) Deployment tool:

(Tool number 98299PA030)

(B) Deployment adapter A:

(Tool number 98299FC030)

AB-00144

(A)(B)

SB-00016

(A) Pad

(B) Airbag module bracket

(1) 5 m (16 ft) or more

AB-00145

(A)

(B)

AB-00146

(A)

(B)

(C)

(D)

SB-00065

(1)

Page 250 of 2870

SB-16

SEAT BELT SYSTEM

Disposal of Pretensioner

2. DEPLOYING OF RETRACTOR PRETEN-

SIONER AFTER REMOVAL FROM VEHICLE

1) Fold backrest all the way forward, then move

front seat all the way forward.

2) Turn the ignition switch to OFF, disconnect the

ground cable from battery, and wait for more than

20 seconds before starting work.

3) Remove the front outer belt.

4) Cut off the seat belt as close to retractor as pos-

sible.

5) Short the terminal to alligator clip furnished as a

deployment tool.

6) Connect the deployment tool (A) and deploy-

ment adapter D (B).

CAUTION:

The deployment tool terminals should be kept

shorted until just before deployment of the pre-

tensioner.

7) Connect the deployment adapter D connector

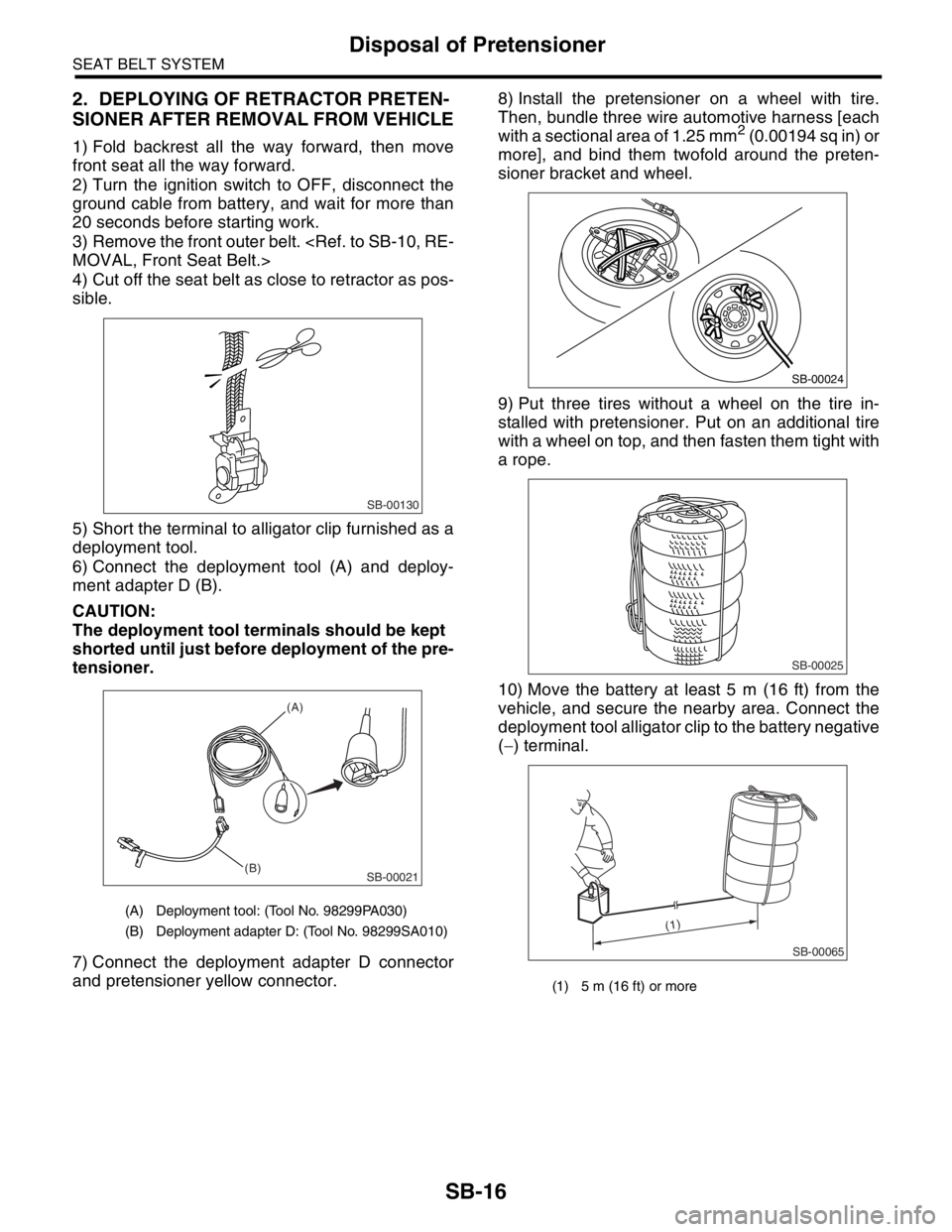

and pretensioner yellow connector.8) Install the pretensioner on a wheel with tire.

Then, bundle three wire automotive harness [each

with a sectional area of 1.25 mm

2 (0.00194 sq in) or

more], and bind them twofold around the preten-

sioner bracket and wheel.

9) Put three tires without a wheel on the tire in-

stalled with pretensioner. Put on an additional tire

with a wheel on top, and then fasten them tight with

a rope.

10) Move the battery at least 5 m (16 ft) from the

vehicle, and secure the nearby area. Connect the

deployment tool alligator clip to the battery negative

(−) terminal.

(A) Deployment tool: (Tool No. 98299PA030)

(B) Deployment adapter D: (Tool No. 98299SA010)

SB-00130

SB-00021

(A)

(B)

(1) 5 m (16 ft) or more

SB-00024

SB-00025

SB-00065

(1)

Page 251 of 2870

SB-17

SEAT BELT SYSTEM

Disposal of Pretensioner

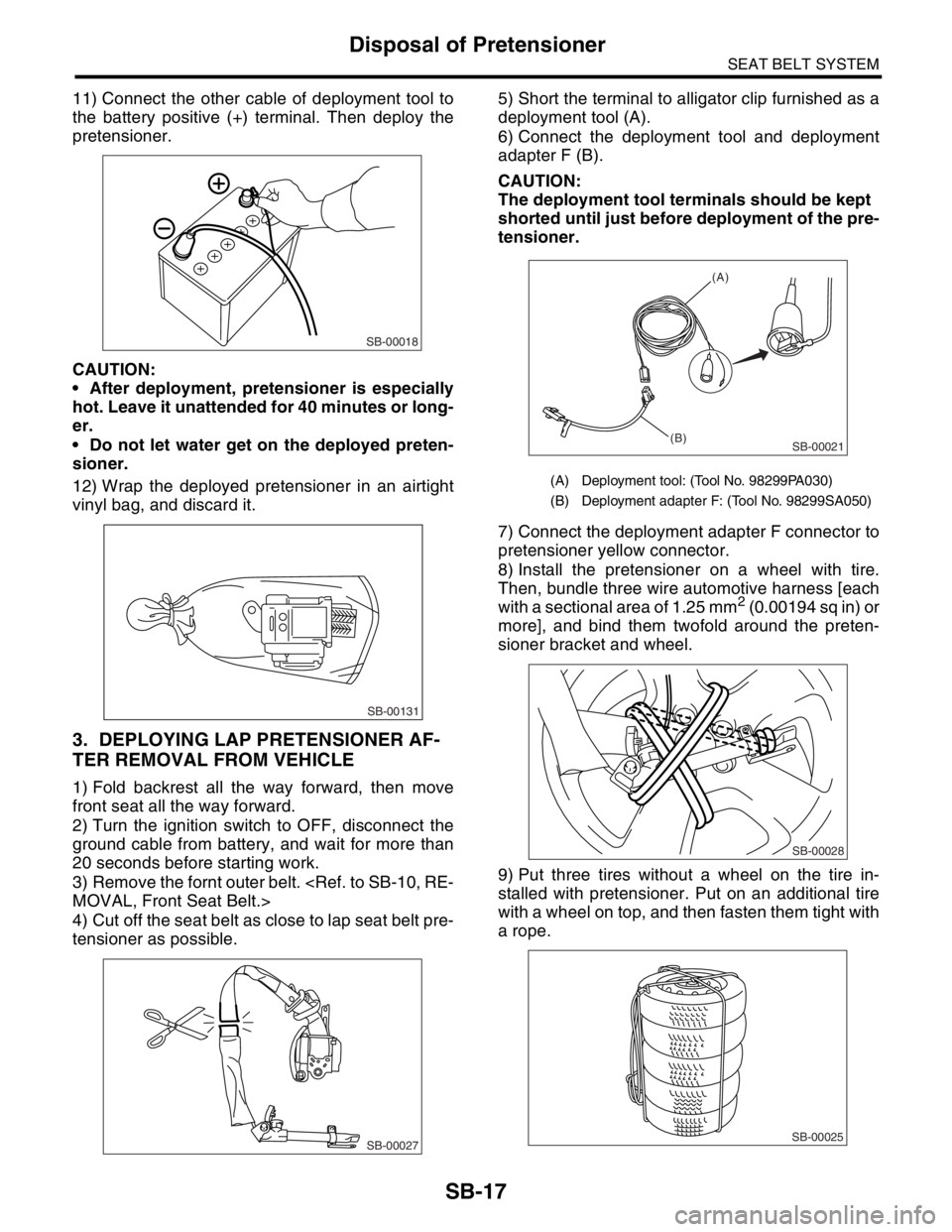

11) Connect the other cable of deployment tool to

the battery positive (+) terminal. Then deploy the

pretensioner.

CAUTION:

After deployment, pretensioner is especially

hot. Leave it unattended for 40 minutes or long-

er.

Do not let water get on the deployed preten-

sioner.

12) Wrap the deployed pretensioner in an airtight

vinyl bag, and discard it.

3. DEPLOYING LAP PRETENSIONER AF-

TER REMOVAL FROM VEHICLE

1) Fold backrest all the way forward, then move

front seat all the way forward.

2) Turn the ignition switch to OFF, disconnect the

ground cable from battery, and wait for more than

20 seconds before starting work.

3) Remove the fornt outer belt.

4) Cut off the seat belt as close to lap seat belt pre-

tensioner as possible.5) Short the terminal to alligator clip furnished as a

deployment tool (A).

6) Connect the deployment tool and deployment

adapter F (B).

CAUTION:

The deployment tool terminals should be kept

shorted until just before deployment of the pre-

tensioner.

7) Connect the deployment adapter F connector to

pretensioner yellow connector.

8) Install the pretensioner on a wheel with tire.

Then, bundle three wire automotive harness [each

with a sectional area of 1.25 mm

2 (0.00194 sq in) or

more], and bind them twofold around the preten-

sioner bracket and wheel.

9) Put three tires without a wheel on the tire in-

stalled with pretensioner. Put on an additional tire

with a wheel on top, and then fasten them tight with

a rope.

SB-00018

SB-00131

SB-00027

(A) Deployment tool: (Tool No. 98299PA030)

(B) Deployment adapter F: (Tool No. 98299SA050)

SB-00021

(A)

(B)

SB-00028

SB-00025

Page 268 of 2870

LI-14

LIGHTING SYSTEM

Headlight Assembly

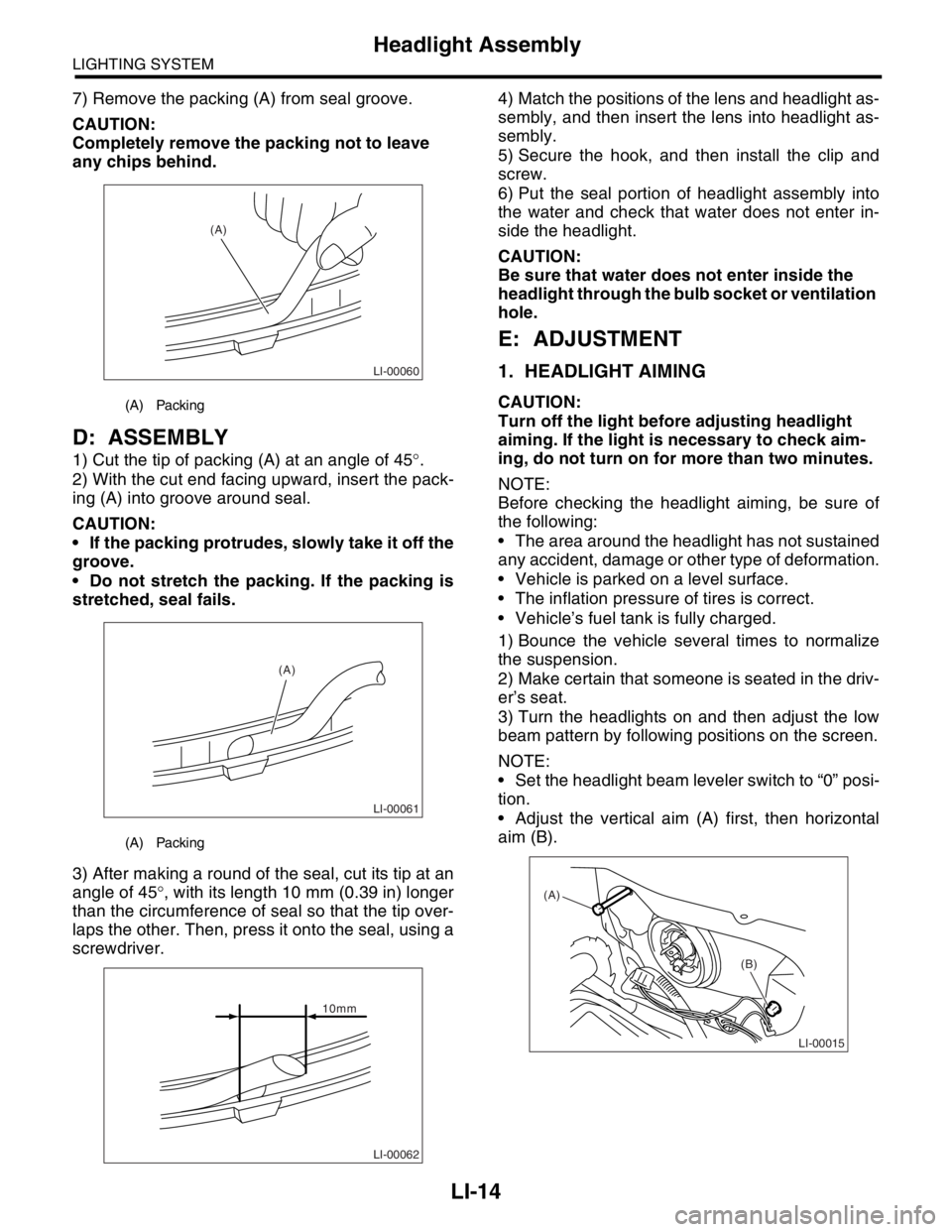

7) Remove the packing (A) from seal groove.

CAUTION:

Completely remove the packing not to leave

any chips behind.

D: ASSEMBLY

1) Cut the tip of packing (A) at an angle of 45°.

2) With the cut end facing upward, insert the pack-

ing (A) into groove around seal.

CAUTION:

If the packing protrudes, slowly take it off the

groove.

Do not stretch the packing. If the packing is

stretched, seal fails.

3) After making a round of the seal, cut its tip at an

angle of 45°, with its length 10 mm (0.39 in) longer

than the circumference of seal so that the tip over-

laps the other. Then, press it onto the seal, using a

screwdriver.4) Match the positions of the lens and headlight as-

sembly, and then insert the lens into headlight as-

sembly.

5) Secure the hook, and then install the clip and

screw.

6) Put the seal portion of headlight assembly into

the water and check that water does not enter in-

side the headlight.

CAUTION:

Be sure that water does not enter inside the

headlight through the bulb socket or ventilation

hole.

E: ADJUSTMENT

1. HEADLIGHT AIMING

CAUTION:

Turn off the light before adjusting headlight

aiming. If the light is necessary to check aim-

ing, do not turn on for more than two minutes.

NOTE:

Before checking the headlight aiming, be sure of

the following:

The area around the headlight has not sustained

any accident, damage or other type of deformation.

Vehicle is parked on a level surface.

The inflation pressure of tires is correct.

Vehicle’s fuel tank is fully charged.

1) Bounce the vehicle several times to normalize

the suspension.

2) Make certain that someone is seated in the driv-

er’s seat.

3) Turn the headlights on and then adjust the low

beam pattern by following positions on the screen.

NOTE:

Set the headlight beam leveler switch to “0” posi-

tion.

Adjust the vertical aim (A) first, then horizontal

aim (B).(A) Packing

(A) Packing

LI-00060

(A)

LI-00061

(A)

LI-00062

10mm

LI-00015

(A)

(B)

Page 726 of 2870

PI-3

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

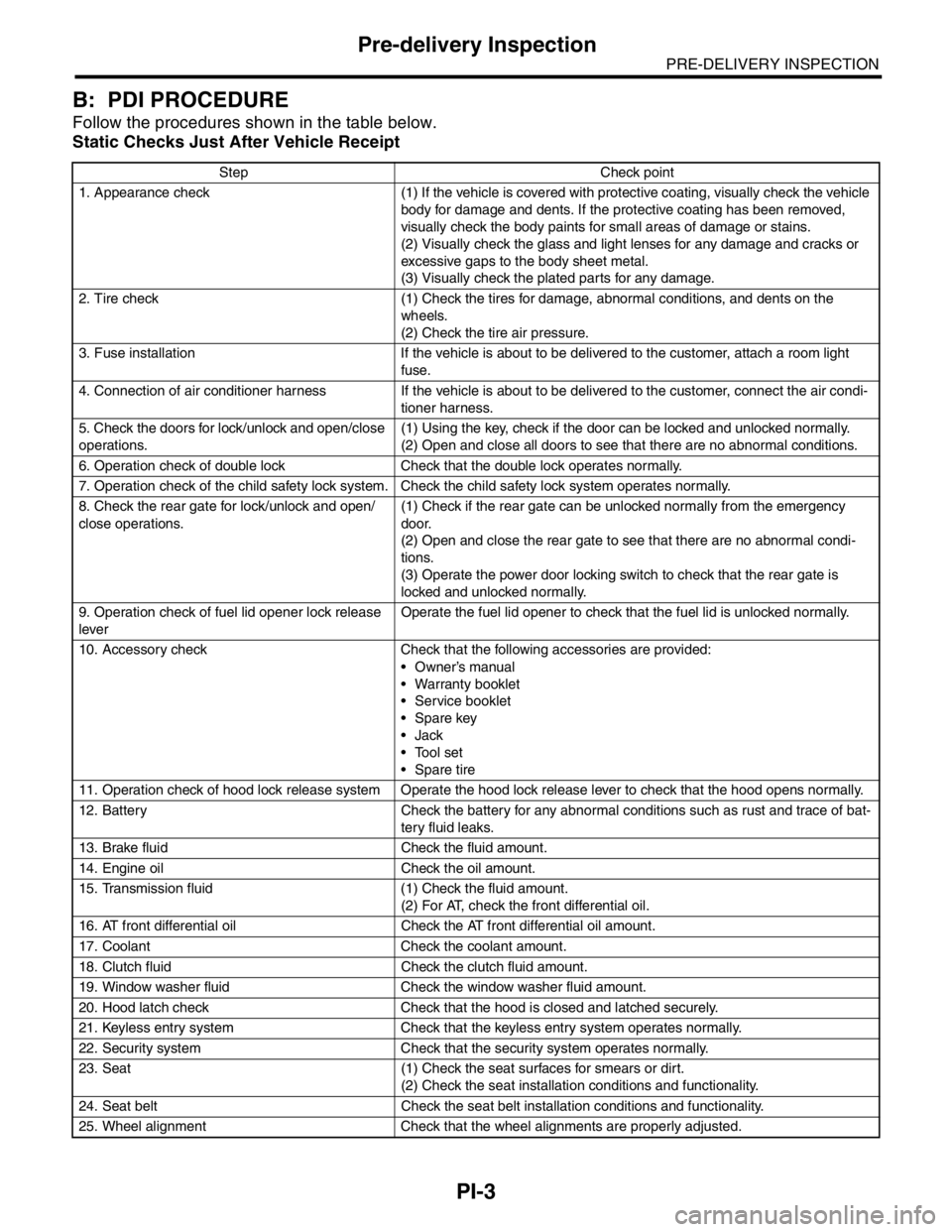

B: PDI PROCEDURE

Follow the procedures shown in the table below.

Static Checks Just After Vehicle Receipt

Step Check point

1. Appearance check (1) If the vehicle is covered with protective coating, visually check the vehicle

body for damage and dents. If the protective coating has been removed,

visually check the body paints for small areas of damage or stains.

(2) Visually check the glass and light lenses for any damage and cracks or

excessive gaps to the body sheet metal.

(3) Visually check the plated parts for any damage.

2. Tire check (1) Check the tires for damage, abnormal conditions, and dents on the

wheels.

(2) Check the tire air pressure.

3. Fuse installation If the vehicle is about to be delivered to the customer, attach a room light

fuse.

4. Connection of air conditioner harness If the vehicle is about to be delivered to the customer, connect the air condi-

tioner harness.

5. Check the doors for lock/unlock and open/close

operations.(1) Using the key, check if the door can be locked and unlocked normally.

(2) Open and close all doors to see that there are no abnormal conditions.

6. Operation check of double lock Check that the double lock operates normally.

7. Operation check of the child safety lock system. Check the child safety lock system operates normally.

8. Check the rear gate for lock/unlock and open/

close operations.(1) Check if the rear gate can be unlocked normally from the emergency

door.

(2) Open and close the rear gate to see that there are no abnormal condi-

tions.

(3) Operate the power door locking switch to check that the rear gate is

locked and unlocked normally.

9. Operation check of fuel lid opener lock release

leverOperate the fuel lid opener to check that the fuel lid is unlocked normally.

10. Accessory check Check that the following accessories are provided:

Owner’s manual

Warranty booklet

Service booklet

Spare key

Jack

Tool set

Spare tire

11. Operation check of hood lock release system Operate the hood lock release lever to check that the hood opens normally.

12. Battery Check the battery for any abnormal conditions such as rust and trace of bat-

tery fluid leaks.

13. Brake fluid Check the fluid amount.

14. Engine oil Check the oil amount.

15. Transmission fluid (1) Check the fluid amount.

(2) For AT, check the front differential oil.

16. AT front differential oil Check the AT front differential oil amount.

17. Coolant Check the coolant amount.

18. Clutch fluid Check the clutch fluid amount.

19. Window washer fluid Check the window washer fluid amount.

20. Hood latch check Check that the hood is closed and latched securely.

21. Keyless entry system Check that the keyless entry system operates normally.

22. Security system Check that the security system operates normally.

23. Seat (1) Check the seat surfaces for smears or dirt.

(2) Check the seat installation conditions and functionality.

24. Seat belt Check the seat belt installation conditions and functionality.

25. Wheel alignment Check that the wheel alignments are properly adjusted.

Page 777 of 2870

PM-40

PERIODIC MAINTENANCE SERVICE

Tire Rotation

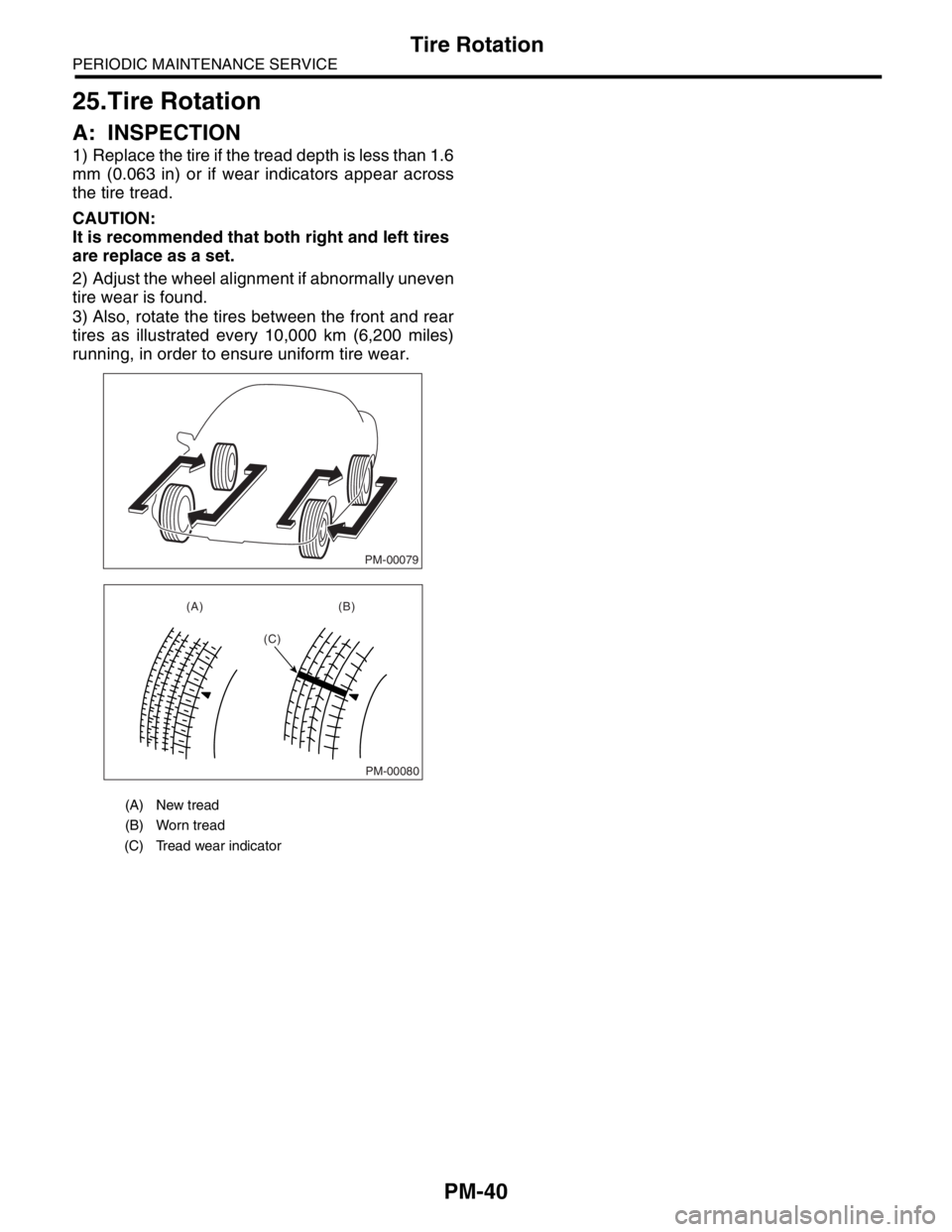

25.Tire Rotation

A: INSPECTION

1) Replace the tire if the tread depth is less than 1.6

mm (0.063 in) or if wear indicators appear across

the tire tread.

CAUTION:

It is recommended that both right and left tires

are replace as a set.

2) Adjust the wheel alignment if abnormally uneven

tire wear is found.

3) Also, rotate the tires between the front and rear

tires as illustrated every 10,000 km (6,200 miles)

running, in order to ensure uniform tire wear.

(A) New tread

(B) Worn tread

(C) Tread wear indicator

PM-00079

PM-00080

(A) (B)

(C)