lock SUBARU IMPREZA 2016 5.G Owners Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2016, Model line: IMPREZA, Model: SUBARU IMPREZA 2016 5.GPages: 594, PDF Size: 5.36 MB

Page 501 of 594

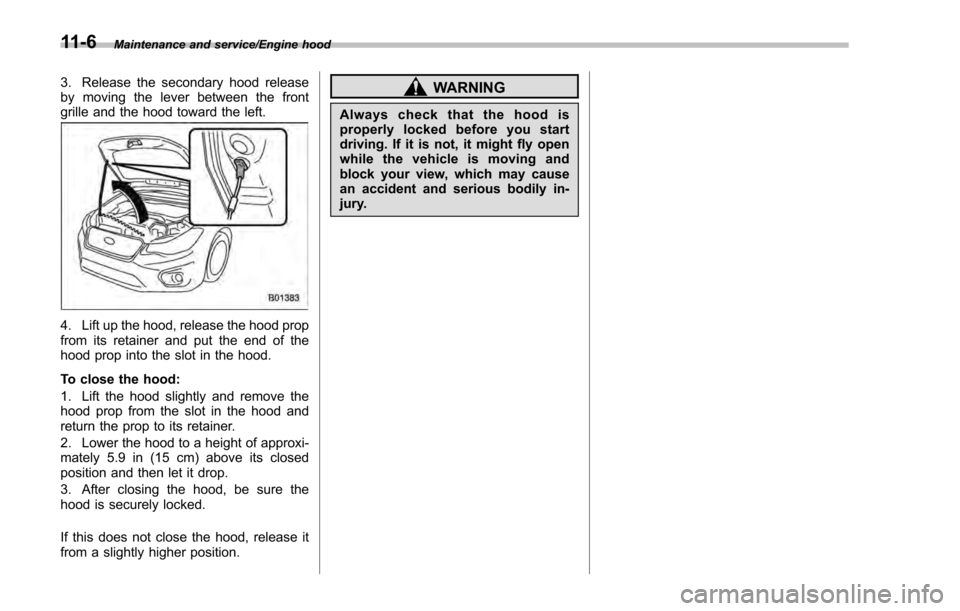

Maintenance and service/Engine hood

3. Release the secondary hood release

by moving the lever between the front

grille and the hood toward the left.

4. Lift up the hood, release the hood prop

from its retainer and put the end of the

hood prop into the slot in the hood.

To close the hood:

1. Lift the hood slightly and remove the

hood prop from the slot in the hood and

return the prop to its retainer.

2. Lower the hood to a height of approxi-

mately 5.9 in (15 cm) above its closed

position and then let it drop.

3. After closing the hood, be sure the

hood is securely locked.

If this does not close the hood, release it

from a slightly higher position.

WARNING

Always check that the hood is

properly locked before you start

driving. If it is not, it might fly open

while the vehicle is moving and

block your view, which may cause

an accident and serious bodily in-

jury.

11-6

Page 503 of 594

Maintenance and service/Engine oil

Engine oil

CAUTION

.If the level gauge cannot be

pulled out easily, twist the level

gauge right and left, then gently

pull it out. Otherwise, you may be

injured accidentally straining

yourself.

. Use only engine oil with the

recommended grade and vis-

cosity.

. Be careful not to spill engine oil

when adding it. If oil touches the

exhaust pipe, it may cause a bad

smell, smoke, and/or a fire. If

engine oil gets on the exhaust

pipe, be sure to wipe it off.

& Engine oil consumption

Some engine oil will be consumed while

driving. The rate of consumption can be

affected by such factors as transmission

type, driving style, terrain and tempera-

ture. Under the following conditions, oil

consumption can be increased and thus

require refilling between maintenance

intervals:

. When the engine is new and within the break-in period

.

When the engine oil is of lower quality

. When the incorrect oil viscosity is used

. When engine brakin g is employed

(repeatedly)

. When the engine is operated at high

engine speeds (for extended periods of

time)

. When the engine is operated under

heavy loads (for extended periods of time)

. When towing a trailer (Crosstrek mod-

els)

. When the engine idles for extended

periods of time

. When the vehicle is operated in stop

and go and/or heavy traffic situations

. When the vehicle is used under severe

thermal conditions

. When the vehicle accelerates and

decelerates frequently

Under these or similar conditions, you

should check your oil at least every 2nd

fuel fill-up and change your engine oil

more frequently. Different drivers in the

same car may experience different results.

If your oil consumption rate is greater than

expected, contact your authorized

SUBARU retailer who may perform a test

under controlled conditions.

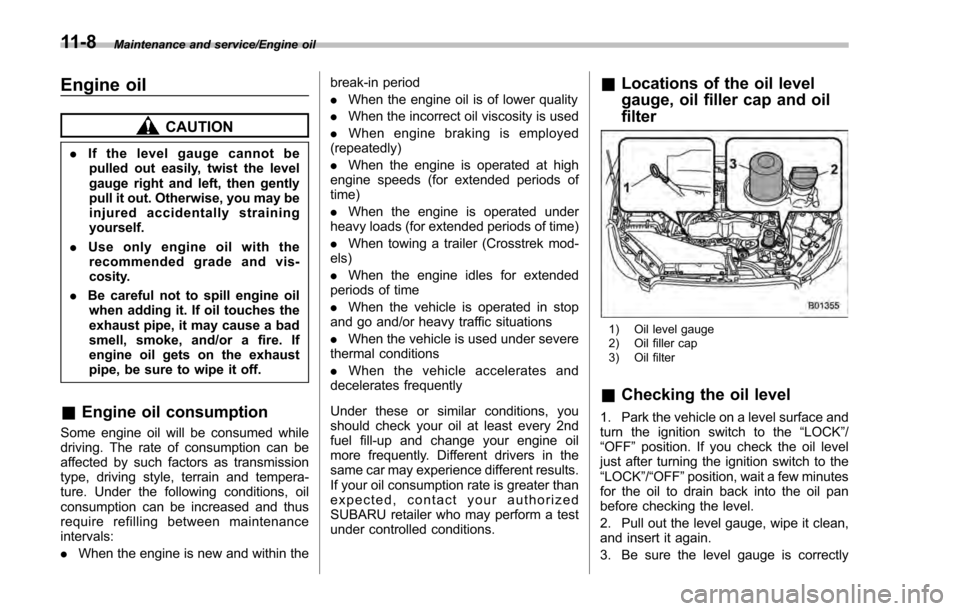

& Locations of the oil level

gauge, oil filler cap and oil

filter

1) Oil level gauge

2) Oil filler cap

3) Oil filter

&Checking the oil level

1. Park the vehicle on a level surface and

turn the ignition switch to the “LOCK”/

“OFF ”position. If you check the oil level

just after turning the ignition switch to the

“LOCK ”/“OFF ”position, wait a few minutes

for the oil to drain back into the oil pan

before checking the level.

2. Pull out the level gauge, wipe it clean,

and insert it again.

3. Be sure the level gauge is correctly

11-8

Page 513 of 594

Maintenance and service/Brake booster

Brake booster

If the brake booster does not operate as

described in the following, have it checked

by your SUBARU dealer.

1. With the ignition switch in the“LOCK” /

“ OFF ”position, depress the brake pedal

several times, applying the same pedal

force each time. The distance the pedal

travels should not vary.

2. With the brake pedal depressed, start

the engine. The pedal should move

slightly down to the floor.

3. With the brake pedal depressed, stop

the engine and keep the pedal depressed

for 30 seconds. The pedal height should

not change.

4. Start the engine again and run for

approximately one minute then turn it off.

Depress the brake pedal several times to

check the brake booster. The brake

booster operates properly if the pedal

stroke decreases with each depression.

Brake pedal

Check the brake pedal free play and

reserve distance according to the main-

tenance schedule in the “Warranty and

Maintenance Booklet ”.

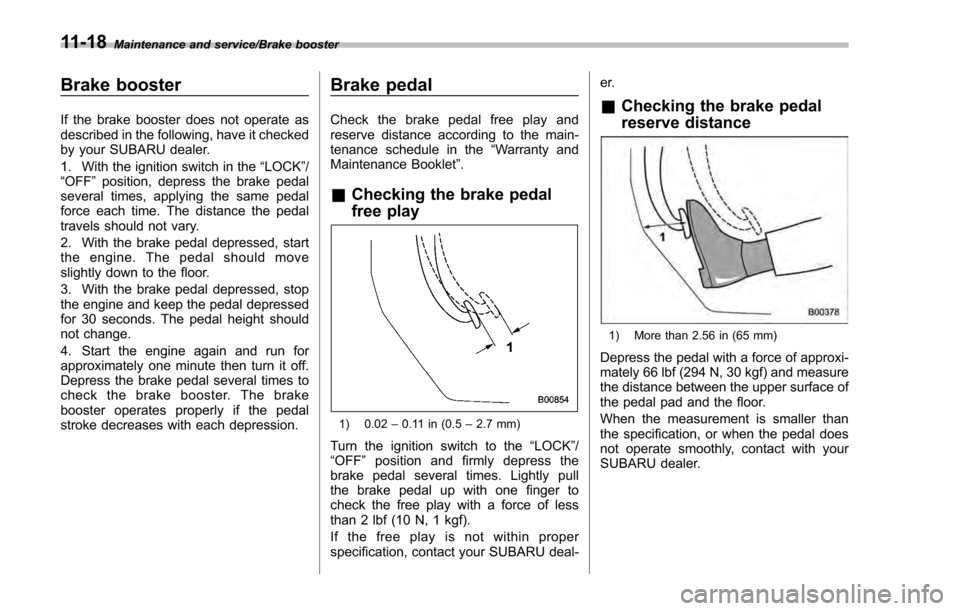

&Checking the brake pedal

free play

1) 0.02 –0.11 in (0.5 –2.7 mm)

Turn the ignition switch to the “LOCK”/

“OFF ”position and firmly depress the

brake pedal several times. Lightly pull

the brake pedal up with one finger to

check the free play with a force of less

than 2 lbf (10 N, 1 kgf).

If the free play is not within proper

specification, contact your SUBARU deal- er.

&

Checking the brake pedal

reserve distance

1) More than 2.56 in (65 mm)

Depress the pedal with a force of approxi-

mately 66 lbf (294 N, 30 kgf) and measure

the distance between the upper surface of

the pedal pad and the floor.

When the measurement is smaller than

the specification, or when the pedal does

not operate smoothly, contact with your

SUBARU dealer.

11-18

Page 515 of 594

Maintenance and service/Replacement of brake pad and lining

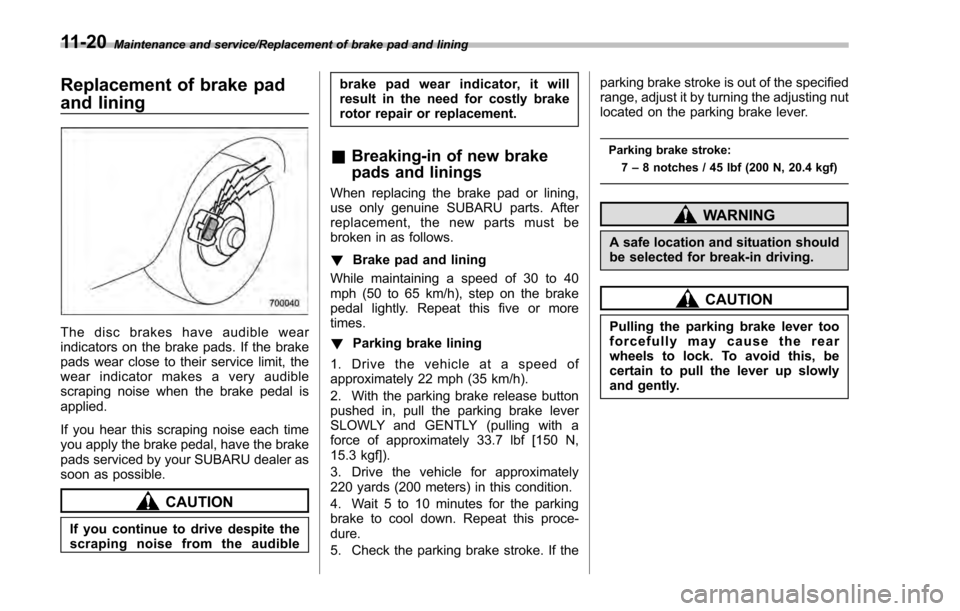

Replacement of brake pad

and lining

The disc brakes have audible wear

indicators on the brake pads. If the brake

pads wear close to their service limit, the

wear indicator makes a very audible

scraping noise when the brake pedal is

applied.

If you hear this scraping noise each time

you apply the brake pedal, have the brake

pads serviced by your SUBARU dealer as

soon as possible.

CAUTION

If you continue to drive despite the

scraping noise from the audiblebrake pad wear indicator, it will

result in the need for costly brake

rotor repair or replacement.

&

Breaking-in of new brake

pads and linings

When replacing the brake pad or lining,

use only genuine SUBARU parts. After

replacement, the new parts must be

broken in as follows.

! Brake pad and lining

While maintaining a speed of 30 to 40

mph (50 to 65 km/h), step on the brake

pedal lightly. Repeat this five or more

times.

! Parking brake lining

1. Drive the vehicle at a speed of

approximately 22 mph (35 km/h).

2. With the parking brake release button

pushed in, pull the parking brake lever

SLOWLY and GENTLY (pulling with a

force of approximately 33.7 lbf [150 N,

15.3 kgf]).

3. Drive the vehicle for approximately

220 yards (200 meters) in this condition.

4. Wait 5 to 10 minutes for the parking

brake to cool down. Repeat this proce-

dure.

5. Check the parking brake stroke. If the parking brake stroke is out of the specified

range, adjust it by turning the adjusting nut

located on the parking brake lever.

Parking brake stroke:

7–8 notches / 45 lbf (200 N, 20.4 kgf)

WARNING

A safe location and situation should

be selected for break-in driving.

CAUTION

Pulling the parking brake lever too

forcefully may cause the rear

wheels to lock. To avoid this, be

certain to pull the lever up slowly

and gently.

11-20

Page 524 of 594

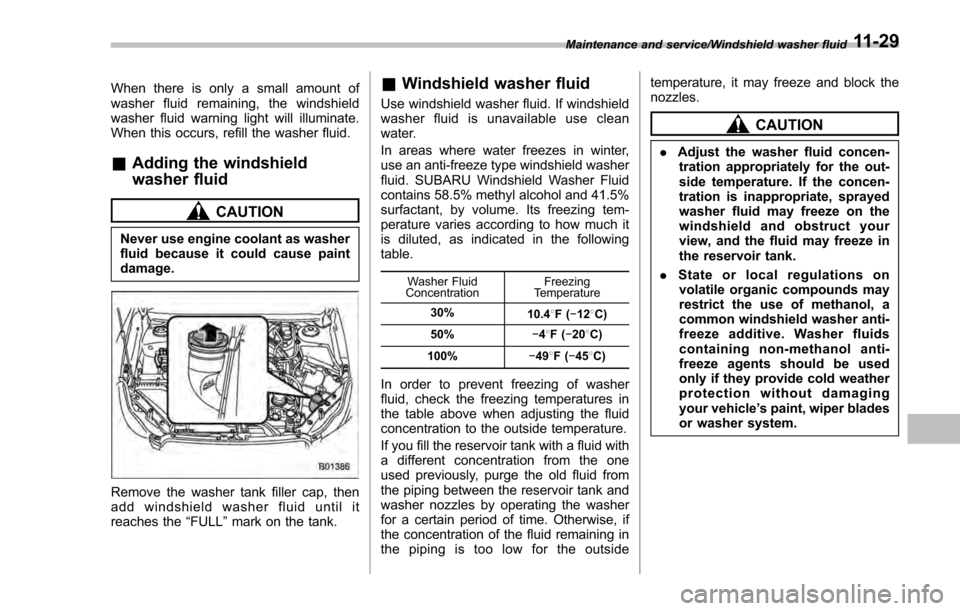

When there is only a small amount of

washer fluid remaining, the windshield

washer fluid warning light will illuminate.

When this occurs, refill the washer fluid.

&Adding the windshield

washer fluid

CAUTION

Never use engine coolant as washer

fluid because it could cause paint

damage.

Remove the washer tank filler cap, then

add windshield washer fluid until it

reaches the “FULL”mark on the tank.

& Windshield washer fluid

Use windshield washer fluid. If windshield

washer fluid is unavailable use clean

water.

In areas where water freezes in winter,

use an anti-freeze type windshield washer

fluid. SUBARU Windshield Washer Fluid

contains 58.5% methyl alcohol and 41.5%

surfactant, by volume. Its freezing tem-

perature varies according to how much it

is diluted, as indicated in the following

table.

Washer Fluid

Concentration Freezing

Temperature

30% 10.48F( −12 8C)

50% −48F( −20 8C)

100% −498F( −45 8C)

In order to prevent freezing of washer

fluid, check the freezing temperatures in

the table above when adjusting the fluid

concentration to the outside temperature.

If you fill the reservoir tank with a fluid with

a different concentration from the one

used previously, purge the old fluid from

the piping between the reservoir tank and

washer nozzles by operating the washer

for a certain period of time. Otherwise, if

the concentration of the fluid remaining in

the piping is too low for the outside temperature, it may freeze and block the

nozzles.

CAUTION

.

Adjust the washer fluid concen-

tration appropriately for the out-

side temperature. If the concen-

tration is inappropriate, sprayed

washer fluid may freeze on the

windshield and obstruct your

view, and the fluid may freeze in

the reservoir tank.

. State or local regulations on

volatile organic compounds may

restrict the use of methanol, a

common windshield washer anti-

freeze additive. Washer fluids

containing non-methanol anti-

freeze agents should be used

only if they provide cold weather

protection without damaging

your vehicle ’s paint, wiper blades

or washer system.

Maintenance and service/Windshield washer fluid11-29

Page 525 of 594

Maintenance and service/Replacement of wiper blades

Replacement of wiper blades

Grease, wax, insects, or other material on

the windshield or the wiper blade results in

jerky wiper operation and streaking on the

glass. If you cannot remove the streaks

after operating the windshield washer or if

the wiper operation is jerky, clean the

outer surface of the windshield (or rear

window) and the wiper blades using a

sponge or soft cloth with a neutral

detergent or mild-abrasive cleaner. After

cleaning, rinse the windshield and wiper

blades with clean water. The windshield is

clean if beads do not form when you rinse

the windshield with water.

CAUTION

.Do not clean the wiper blades

with gasoline or a solvent, such

as paint thinner or benzine. This

will cause deterioration of the

wiper blades.

. While removing the wiper blades

from the wiper arms, do not

return the wiper arms to the

original positions. Otherwise,

the windshield surface may be

scratched.

. When returning the raised wiper

arms to the original positions, carefully return the wiper arms

on the windshield by hand. You

should not return the wiper arms

to the windshield only by the

return spring. Otherwise, the wi-

per arms may be deformed and/

or the windshield surface may be

scratched.

If you cannot eliminate the streaking even

after following this method, replace the

wiper blades using the following proce-

dures.

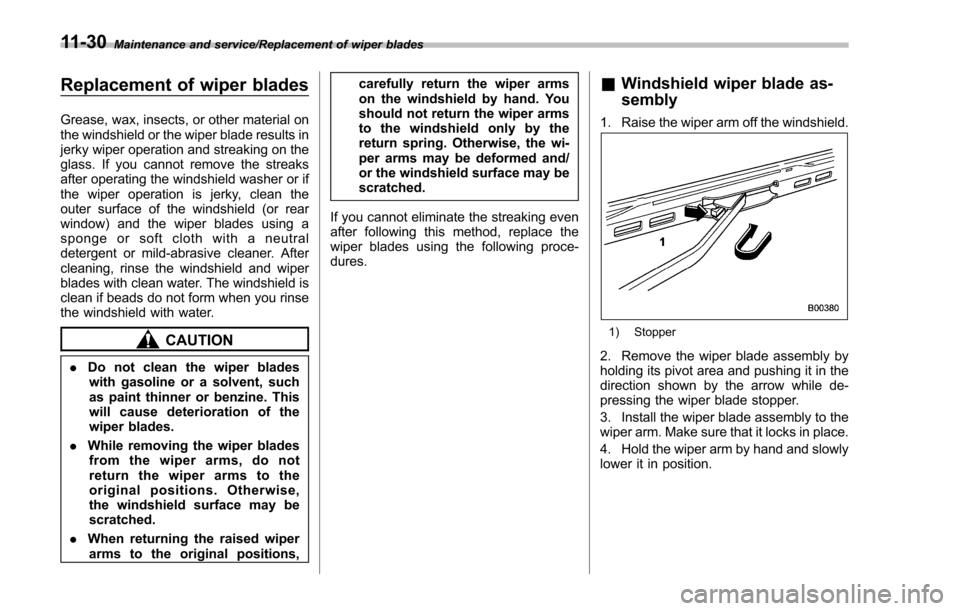

& Windshield wiper blade as-

sembly

1. Raise the wiper arm off the windshield.

1) Stopper

2. Remove the wiper blade assembly by

holding its pivot area and pushing it in the

direction shown by the arrow while de-

pressing the wiper blade stopper.

3. Install the wiper blade assembly to the

wiper arm. Make sure that it locks in place.

4. Hold the wiper arm by hand and slowly

lower it in position.

11-30

Page 526 of 594

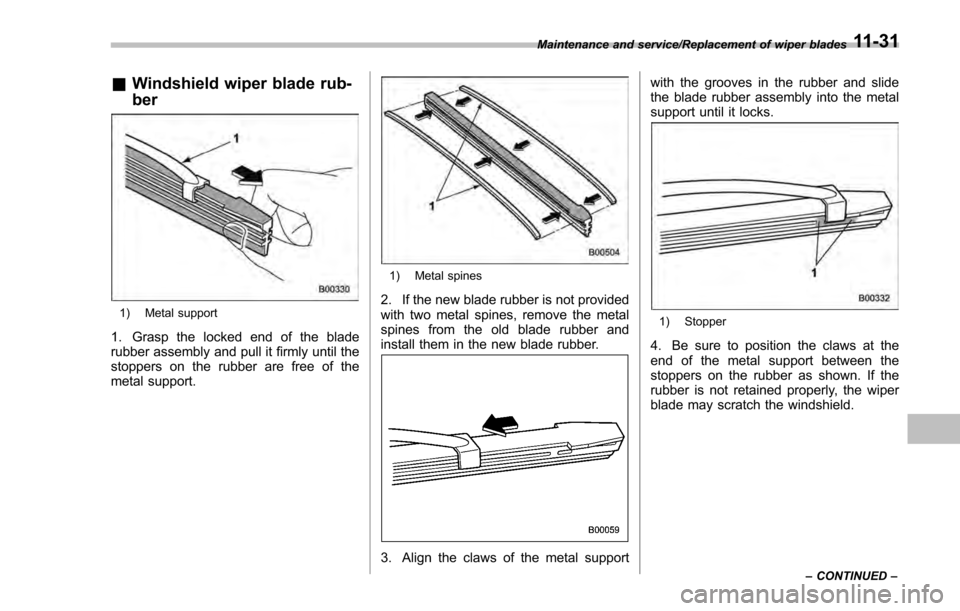

&Windshield wiper blade rub-

ber

1) Metal support

1. Grasp the locked end of the blade

rubber assembly and pull it firmly until the

stoppers on the rubber are free of the

metal support.

1) Metal spines

2. If the new blade rubber is not provided

with two metal spines, remove the metal

spines from the old blade rubber and

install them in the new blade rubber.

3. Align the claws of the metal support with the grooves in the rubber and slide

the blade rubber assembly into the metal

support until it locks.

1) Stopper

4. Be sure to position the claws at the

end of the metal support between the

stoppers on the rubber as shown. If the

rubber is not retained properly, the wiper

blade may scratch the windshield.

Maintenance and service/Replacement of wiper blades

–CONTINUED –11-31

Page 527 of 594

Maintenance and service/Replacement of wiper blades

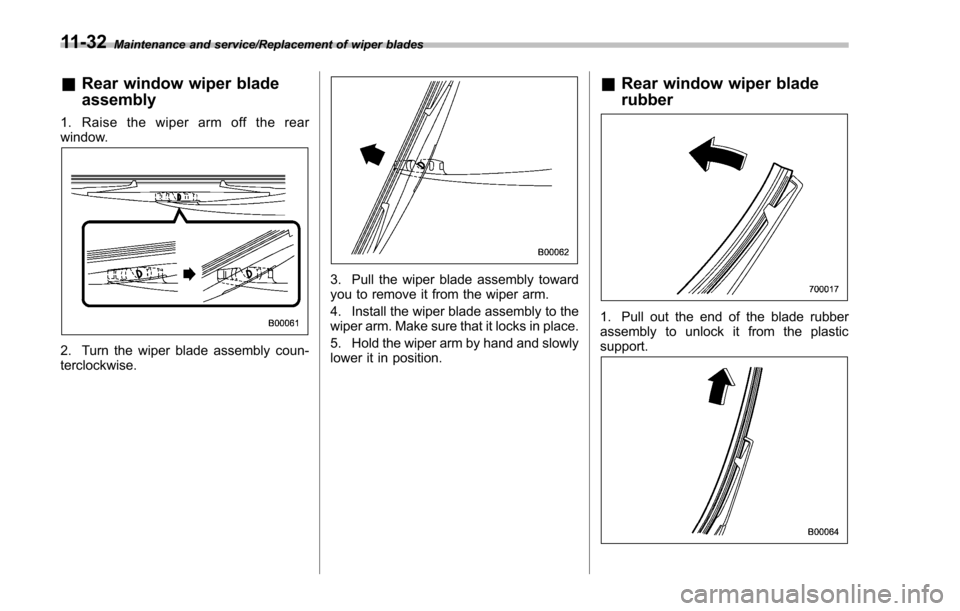

&Rear window wiper blade

assembly

1. Raise the wiper arm off the rear

window.

2. Turn the wiper blade assembly coun-

terclockwise.

3. Pull the wiper blade assembly toward

you to remove it from the wiper arm.

4. Install the wiper blade assembly to the

wiper arm. Make sure that it locks in place.

5. Hold the wiper arm by hand and slowly

lower it in position.

&Rear window wiper blade

rubber

1. Pull out the end of the blade rubber

assembly to unlock it from the plastic

support.

11-32

Page 528 of 594

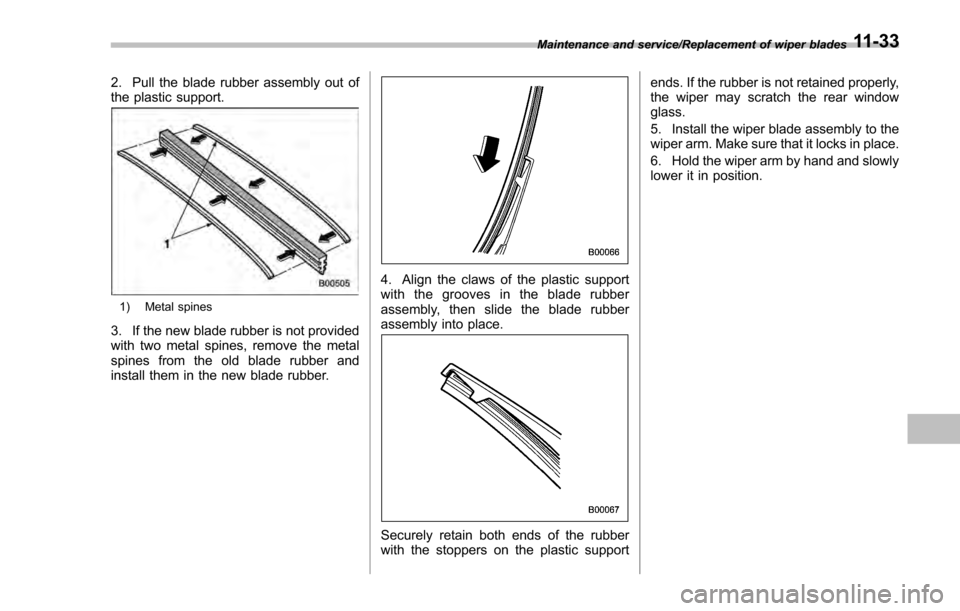

2. Pull the blade rubber assembly out of

the plastic support.

1) Metal spines

3. If the new blade rubber is not provided

with two metal spines, remove the metal

spines from the old blade rubber and

install them in the new blade rubber.

4. Align the claws of the plastic support

with the grooves in the blade rubber

assembly, then slide the blade rubber

assembly into place.

Securely retain both ends of the rubber

with the stoppers on the plastic supportends. If the rubber is not retained properly,

the wiper may scratch the rear window

glass.

5. Install the wiper blade assembly to the

wiper arm. Make sure that it locks in place.

6. Hold the wiper arm by hand and slowly

lower it in position.

Maintenance and service/Replacement of wiper blades11-33

Page 530 of 594

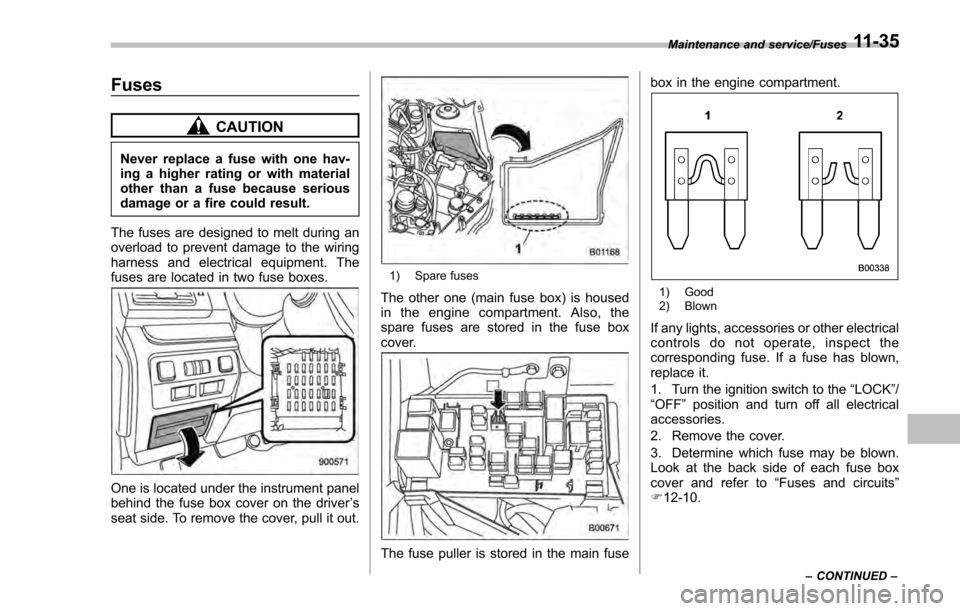

Fuses

CAUTION

Never replace a fuse with one hav-

ing a higher rating or with material

other than a fuse because serious

damage or a fire could result.

The fuses are designed to melt during an

overload to prevent damage to the wiring

harness and electrical equipment. The

fuses are located in two fuse boxes.

One is located under the instrument panel

behind the fuse box cover on the driver ’s

seat side. To remove the cover, pull it out.

1) Spare fuses

The other one (main fuse box) is housed

in the engine compartment. Also, the

spare fuses are stored in the fuse box

cover.

The fuse puller is stored in the main fuse box in the engine compartment.

1) Good

2) Blown

If any lights, accessories or other electrical

controls do not operate, inspect the

corresponding fuse. If a fuse has blown,

replace it.

1. Turn the ignition switch to the

“LOCK”/

“OFF ”position and turn off all electrical

accessories.

2. Remove the cover.

3. Determine which fuse may be blown.

Look at the back side of each fuse box

cover and refer to “Fuses and circuits”

F 12-10.

Maintenance and service/Fuses

–CONTINUED –11-35