tire type SUBARU IMPREZA 2016 5.G User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2016, Model line: IMPREZA, Model: SUBARU IMPREZA 2016 5.GPages: 594, PDF Size: 5.36 MB

Page 516 of 594

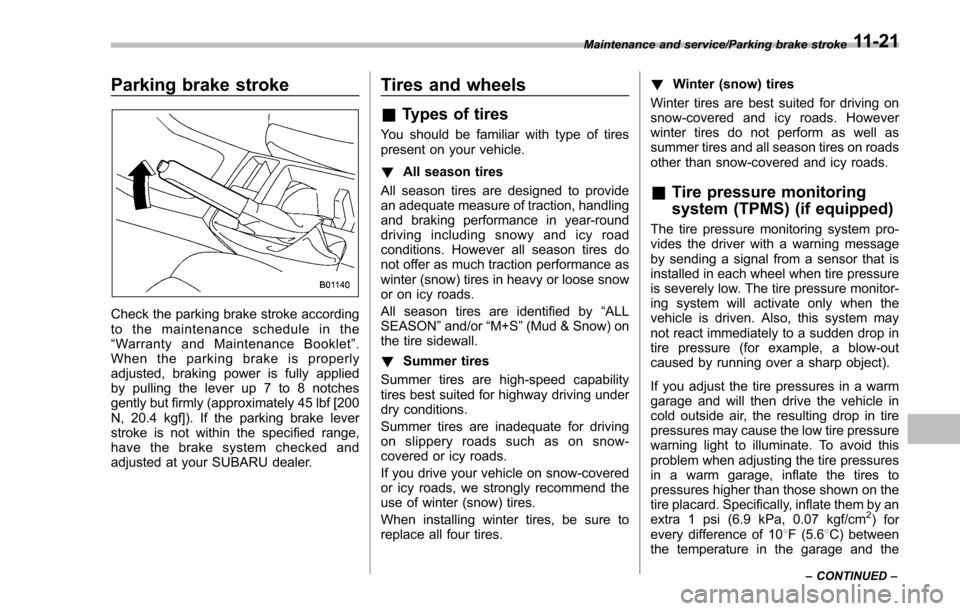

Parking brake stroke

Check the parking brake stroke according

to the maintenance schedule in the

“Warranty and Maintenance Booklet ”.

When the parking brake is properly

adjusted, braking power is fully applied

by pulling the lever up 7 to 8 notches

gently but firmly (approximately 45 lbf [200

N, 20.4 kgf]). If the parking brake lever

stroke is not within the specified range,

have the brake system checked and

adjusted at your SUBARU dealer.

Tires and wheels

& Types of tires

You should be familiar with type of tires

present on your vehicle.

! All season tires

All season tires are designed to provide

an adequate measure of traction, handling

and braking performance in year-round

driving including snowy and icy road

conditions. However all season tires do

not offer as much traction performance as

winter (snow) tires in heavy or loose snow

or on icy roads.

All season tires are identified by “ALL

SEASON ”and/or “M+S ”(Mud & Snow) on

the tire sidewall.

! Summer tires

Summer tires are high-speed capability

tires best suited for highway driving under

dry conditions.

Summer tires are inadequate for driving

on slippery roads such as on snow-

covered or icy roads.

If you drive your vehicle on snow-covered

or icy roads, we strongly recommend the

use of winter (snow) tires.

When installing winter tires, be sure to

replace all four tires. !

Winter (snow) tires

Winter tires are best suited for driving on

snow-covered and icy roads. However

winter tires do not perform as well as

summer tires and all season tires on roads

other than snow-covered and icy roads.

& Tire pressure monitoring

system (TPMS) (if equipped)

The tire pressure monitoring system pro-

vides the driver with a warning message

by sending a signal from a sensor that is

installed in each wheel when tire pressure

is severely low. The tire pressure monitor-

ing system will activate only when the

vehicle is driven. Also, this system may

not react immediately to a sudden drop in

tire pressure (for example, a blow-out

caused by running over a sharp object).

If you adjust the tire pressures in a warm

garage and will then drive the vehicle in

cold outside air, the resulting drop in tire

pressures may cause the low tire pressure

warning light to illuminate. To avoid this

problem when adjusting the tire pressures

in a warm garage, inflate the tires to

pressures higher than those shown on the

tire placard. Specifically, inflate them by an

extra 1 psi (6.9 kPa, 0.07 kgf/cm

2) for

every difference of 10 8F (5.6 8C) between

the temperature in the garage and the

Maintenance and service/Parking brake stroke

–CONTINUED –11-21

Page 518 of 594

a flat tire, replace it with a spare tire

as soon as possible.

When a spare tire is mounted or a

wheel rim is replaced without the

original pressure sensor/transmitter

being transferred, the low tire pres-

sure warning light will illuminate

steadily after blinking for approxi-

mately one minute. This indicates

the TPMS is unable to monitor all

four road wheels. Contact your

SUBARU dealer as soon as possible

for tire and sensor replacement and/

or system resetting. If the light

illuminates steadily after blinking

for approximately one minute,

promptly contact a SUBARU dealer

to have the system inspected.

&Tire inspection

Check on a daily basis that the tires are

free from serious damage, nails, and

stones. At the same time, check the tires

for abnormal wear.

Contact your SUBARU dealer immedi-

ately if you find any problem.

NOTE

. When the wheels and tires strike

curbs or are subjected to harsh treat-

ment as when the vehicle is driven on a rough surface, they can suffer damage

that cannot be seen with the naked eye.

This type of damage does not become

evident until time has passed. Try not

to drive over curbs, potholes or on

other rough surfaces. If doing so is

unavoidable, keep the vehicle

’s speed

down to a walking pace or less, and

approach the curbs as squarely as

possible. Also, make sure the tires are

not pressed against the curb when you

park the vehicle.

. If you feel unusual vibration while

driving or find it difficult to steer the

vehicle in a straight line, one of the

tires and/or wheels may be damaged.

Drive slowly to the nearest authorized

SUBARU dealer and have the vehicle

inspected.

& Tire pressures and wear

Maintaining the correct tire pressures

helps to maximize the tires ’service lives

and is essential for good running perfor-

mance. Check and, if necessary, adjust

the pressure of each tire (including the

spare - if equipped) at least once a month

(for example, during a fuel stop) and

before any long journey.

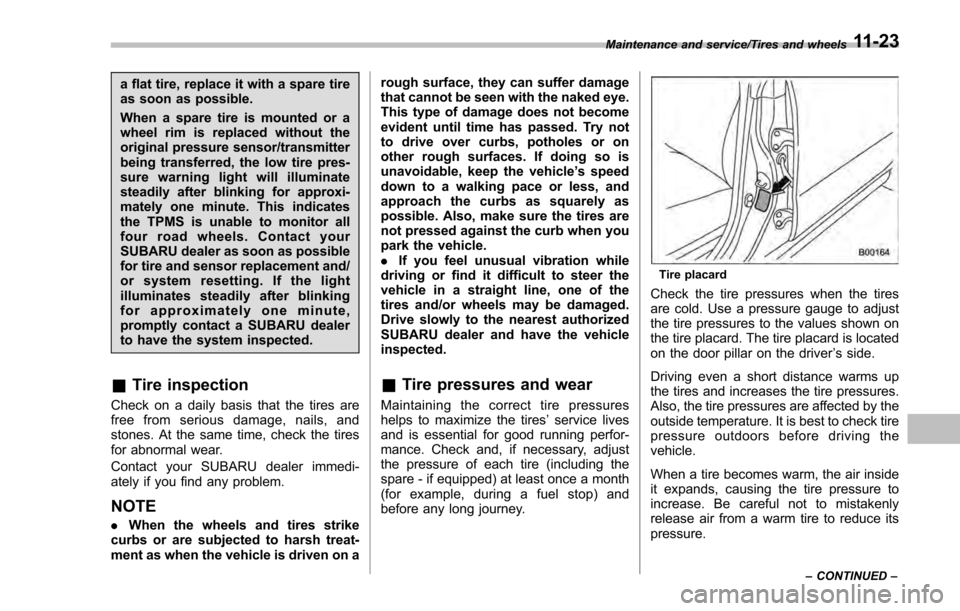

Tire placard

Check the tire pressures when the tires

are cold. Use a pressure gauge to adjust

the tire pressures to the values shown on

the tire placard. The tire placard is located

on the door pillar on the driver ’s side.

Driving even a short distance warms up

the tires and increases the tire pressures.

Also, the tire pressures are affected by the

outside temperature. It is best to check tire

pressure outdoors before driving the

vehicle.

When a tire becomes warm, the air inside

it expands, causing the tire pressure to

increase. Be careful not to mistakenly

release air from a warm tire to reduce its

pressure.

Maintenance and service/Tires and wheels

–CONTINUED –11-23

Page 523 of 594

Maintenance and service/Aluminum wheels

&Wheel replacement

When replacing wheels due, for example,

to damage, make sure the replacement

wheels match the specifications of the

wheels that are fitted as standard equip-

ment. Replacement wheels are available

from SUBARU dealers.

WARNING

Use only those wheels that are

specified for your vehicle. Wheels

not meeting specifications could

interfere with brake caliper opera-

tion and may cause the tires to rub

against the wheel well housing dur-

ing turns. The resulting loss of

vehicle control could lead to an

accident.

NOTE

When any of the wheels are removed

and replaced for tire rotation or for any

other reason, always check the tight-

ness of the wheel nuts after driving

approximately 600 miles (1,000 km). If

any nut is loose, tighten it to the

specified torque.

Aluminum wheels

Aluminum wheels can be scratched and

damaged easily. Handle them carefully to

maintain their appearance, performance,

and safety.

. When any of the wheels are removed

and replaced for tire rotation or to change

a flat tire, always check the tightness of

the wheel nuts after driving approximately

600 miles (1,000 km). If any nut is loose,

tighten it to the specified torque.

. Never apply oil to the threaded parts,

wheel nuts, or tapered surface of the

wheel.

. Never let the wheel rub against sharp

protrusions or curbs.

. When wheel nuts, balance weights, or

the center cap is replaced, be sure to

replace them with genuine SUBARU parts

designed for aluminum wheels.

Windshield washer fluid

Windshield washer fluid warning light

(type A)

Windshield washer fluid warning light

(type B)

11-28

Page 561 of 594

Consumer information and Reporting safety defects/For U.S.A.

For U.S.A.

The following information has been

compiled according to Code of

Federal Regulations“Title 49, Part

575 ”.

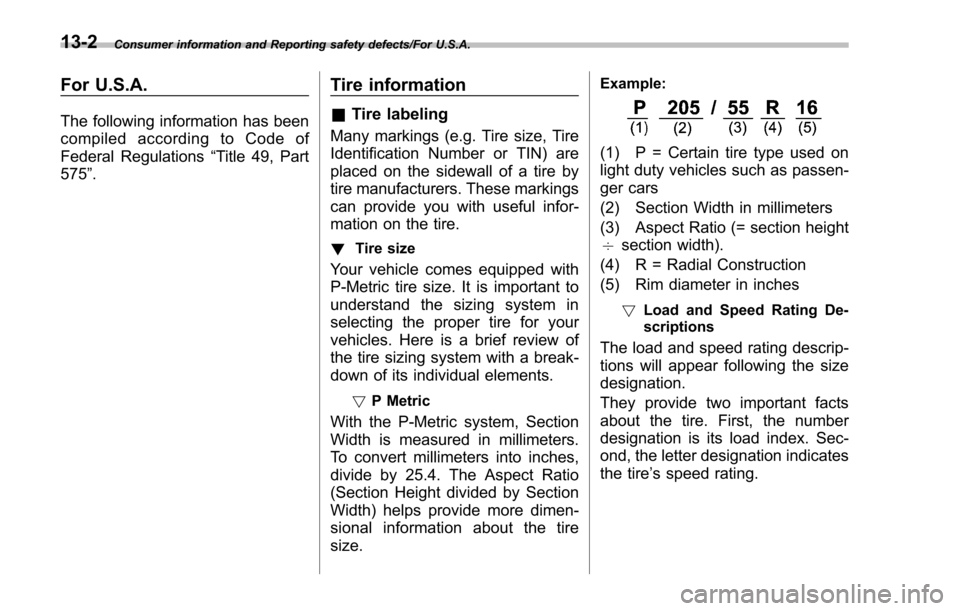

Tire information

& Tire labeling

Many markings (e.g. Tire size, Tire

Identification Number or TIN) are

placed on the sidewall of a tire by

tire manufacturers. These markings

can provide you with useful infor-

mation on the tire.

! Tire size

Your vehicle comes equipped with

P-Metric tire size. It is important to

understand the sizing system in

selecting the proper tire for your

vehicles. Here is a brief review of

the tire sizing system with a break-

down of its individual elements.

!P Metric

With the P-Metric system, Section

Width is measured in millimeters.

To convert millimeters into inches,

divide by 25.4. The Aspect Ratio

(Section Height divided by Section

Width) helps provide more dimen-

sional information about the tire

size.

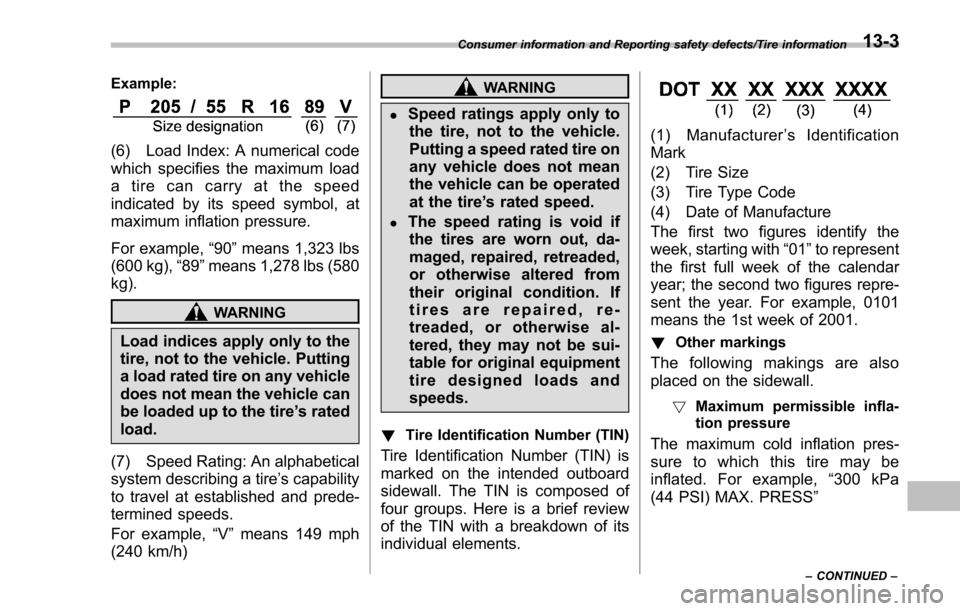

Example:

(1) P = Certain tire type used on

light duty vehicles such as passen-

ger cars

(2) Section Width in millimeters

(3) Aspect Ratio (= section height

7 section width).

(4) R = Radial Construction

(5) Rim diameter in inches

! Load and Speed Rating De-

scriptions

The load and speed rating descrip-

tions will appear following the size

designation.

They provide two important facts

about the tire. First, the number

designation is its load index. Sec-

ond, the letter designation indicates

the tire’ s speed rating.

13-2

Page 562 of 594

Example:

(6) Load Index: A numerical code

which specifies the maximum load

a tire can carry at the speed

indicated by its speed symbol, at

maximum inflation pressure.

For example,“90 ”means 1,323 lbs

(600 kg), “89 ”means 1,278 lbs (580

kg).

WARNING

Load indices apply only to the

tire, not to the vehicle. Putting

a load rated tire on any vehicle

does not mean the vehicle can

be loaded up to the tire ’s rated

load.

(7) Speed Rating: An alphabetical

system describing a tire ’s capability

to travel at established and prede-

termined speeds.

For example, “V ” means 149 mph

(240 km/h)

WARNING

.Speed ratings apply only to the tire, not to the vehicle.

Putting a speed rated tire on

any vehicle does not mean

the vehicle can be operated

at the tire ’s rated speed.

.The speed rating is void if

the tires are worn out, da-

maged, repaired, retreaded,

or otherwise altered from

their original condition. If

tires are repaired, re-

treaded, or otherwise al-

tered, they may not be sui-

table for original equipment

tire designed loads and

speeds.

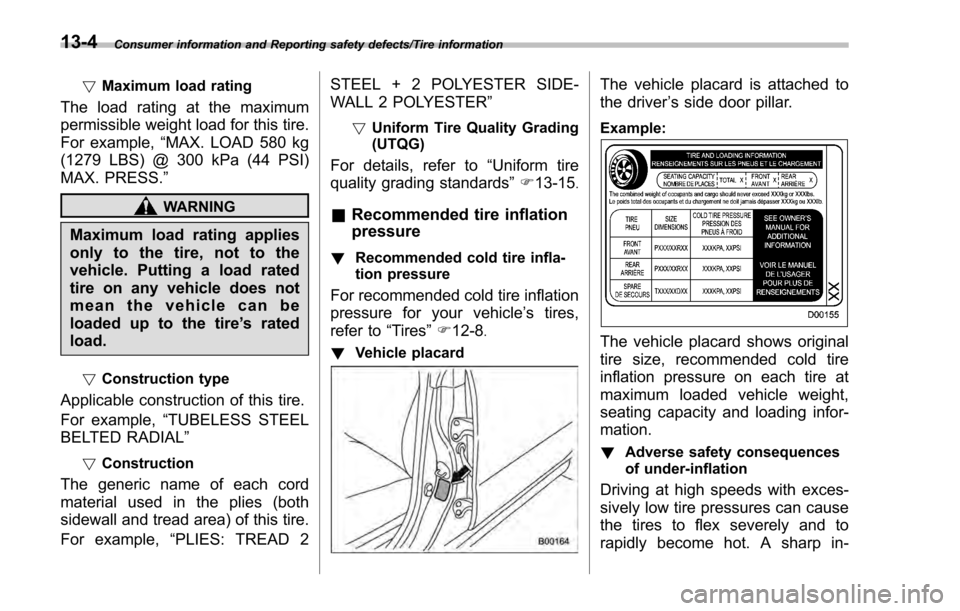

! Tire Identification Number (TIN)

Tire Identification Number (TIN) is

marked on the intended outboard

sidewall. The TIN is composed of

four groups. Here is a brief review

of the TIN with a breakdown of its

individual elements.

(1) Manufacturer ’s Identification

Mark

(2) Tire Size

(3) Tire Type Code

(4) Date of Manufacture

The first two figures identify the

week, starting with “01 ”to represent

the first full week of the calendar

year; the second two figures repre-

sent the year. For example, 0101

means the 1st week of 2001.

! Other markings

The following makings are also

placed on the sidewall.

!Maximum permissible infla-

tion pressure

The maximum cold inflation pres-

sure to which this tire may be

inflated. For example, “300 kPa

(44 PSI) MAX. PRESS ”

Consumer information and Reporting safety defects/Tire information

–CONTINUED –13-3

Page 563 of 594

Consumer information and Reporting safety defects/Tire information

!Maximum load rating

The load rating at the maximum

permissible weight load for this tire.

For example, “MAX. LOAD 580 kg

(1279 LBS) @ 300 kPa (44 PSI)

MAX. PRESS. ”

WARNING

Maximum load rating applies

only to the tire, not to the

vehicle. Putting a load rated

tire on any vehicle does not

mean the vehicle can be

loaded up to the tire ’s rated

load.

! Construction type

Applicable construction of this tire.

For example, “TUBELESS STEEL

BELTED RADIAL”

! Construction

The generic name of each cord

material used in the plies (both

sidewall and tread area) of this tire.

For example, “PLIES: TREAD 2 STEEL + 2 POLYESTER SIDE-

WALL 2 POLYESTER

”

!Uniform Tire Quality Grading

(UTQG)

For details, refer to “Uniform tire

quality grading standards ”F 13-15

.

& Recommended tire inflation

pressure

! Recommended cold tire infla-

tion pressure

For recommended cold tire inflation

pressure for your vehicle ’s tires,

refer to “Tires ”F 12-8

.

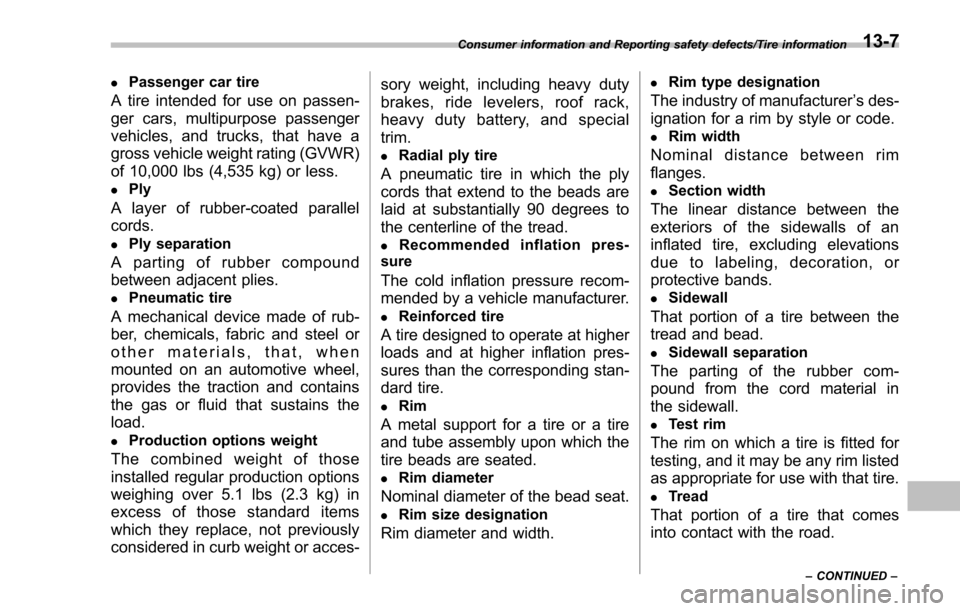

! Vehicle placard

The vehicle placard is attached to

the driver ’s side door pillar.

Example:

The vehicle placard shows original

tire size, recommended cold tire

inflation pressure on each tire at

maximum loaded vehicle weight,

seating capacity and loading infor-

mation.

! Adverse safety consequences

of under-inflation

Driving at high speeds with exces-

sively low tire pressures can cause

the tires to flex severely and to

rapidly become hot. A sharp in-

13-4

Page 566 of 594

.Passenger car tire

A tire intended for use on passen-

ger cars, multipurpose passenger

vehicles, and trucks, that have a

gross vehicle weight rating (GVWR)

of 10,000 lbs (4,535 kg) or less.

.Ply

A layer of rubber-coated parallel

cords.

.Ply separation

A parting of rubber compound

between adjacent plies.

.Pneumatic tire

A mechanical device made of rub-

ber, chemicals, fabric and steel or

other materials, that, when

mounted on an automotive wheel,

provides the traction and contains

the gas or fluid that sustains the

load.

.Production options weight

The combined weight of those

installed regular production options

weighing over 5.1 lbs (2.3 kg) in

excess of those standard items

which they replace, not previously

considered in curb weight or acces-sory weight, including heavy duty

brakes, ride levelers, roof rack,

heavy duty battery, and special

trim.

.Radial ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at substantially 90 degrees to

the centerline of the tread.

.Recommended inflation pres-

sure

The cold inflation pressure recom-

mended by a vehicle manufacturer.

.Reinforced tire

A tire designed to operate at higher

loads and at higher inflation pres-

sures than the corresponding stan-

dard tire.

.Rim

A metal support for a tire or a tire

and tube assembly upon which the

tire beads are seated.

.Rim diameter

Nominal diameter of the bead seat.

.Rim size designation

Rim diameter and width.

.Rim type designation

The industry of manufacturer ’s des-

ignation for a rim by style or code.

.Rim width

Nominal distance between rim

flanges.

.Section width

The linear distance between the

exteriors of the sidewalls of an

inflated tire, excluding elevations

due to labeling, decoration, or

protective bands.

.Sidewall

That portion of a tire between the

tread and bead.

.Sidewall separation

The parting of the rubber com-

pound from the cord material in

the sidewall.

.Test rim

The rim on which a tire is fitted for

testing, and it may be any rim listed

as appropriate for use with that tire.

.Tread

That portion of a tire that comes

into contact with the road.

Consumer information and Reporting safety defects/Tire information

–CONTINUED –13-7

Page 574 of 594

Uniform tire quality grading

standards

This information indicates the rela-

tive performance of passenger car

tires in the area of treadwear,

traction, and temperature resis-

tance. This is to aid the consumer

in making an informed choice in the

purchase of tires.

Quality grades can be found where

applicable on the tire sidewall be-

tween tread shoulder and maxi-

mum section width. For example:

Treadwear 200 Traction AA Tem-

perature A

The quality grades apply to new

pneumatic tires for use on passen-

ger cars. However, they do not

apply to deep tread, winter type

snow tires, space-saver or tempor-

ary use spare tires, tires with

nominal rim diameters of 12 inches

or less, or to some limited produc-

tion tires.

All passenger car tires must con-form to Federal Safety Require-

ments in addition to these grades.

&

Treadwear

The treadwear grade is a compara-

tive rating based on the wear rate of

the tire when tested under con-

trolled conditions on a specified

government test course.

For example, a tire graded 150

would wear one and one-half (1-

1/2) times as well on the govern-

ment course as a tire graded 100.

The relative performance of tires

depends upon the actual conditions

of their use, however, and may

depart significantly from the norm

due to variations in driving habits,

service practices and differences in

road characteristics and climate.

&Traction AA, A, B, C

The traction grades, from highest to

lowest, are AA, A, B and C. Those

grades represent the tire ’s ability to

stop on wet pavement as measured

under controlled conditions on spe- cified government test surfaces of

asphalt and concrete. A tire marked

C may have poor traction perfor-

mance.

WARNING

The traction grade assigned to

this tire is based on straight-

ahead braking traction tests,

and does not include accel-

eration, cornering, hydroplan-

ing, or peak traction charac-

teristics.

&

Temperature A, B, C

The temperature grades are A (the

highest), B, and C, representing the

tire ’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled con-

ditions on a specified indoor labora-

tory test wheel. Sustained high

temperature can cause the material

of the tire to degenerate and reduce

tire life, and excessive temperature

can lead to sudden tire failure. The

Consumer information and Reporting safety defects/Uniform tire quality grading standards

–CONTINUED –13-15

Page 587 of 594

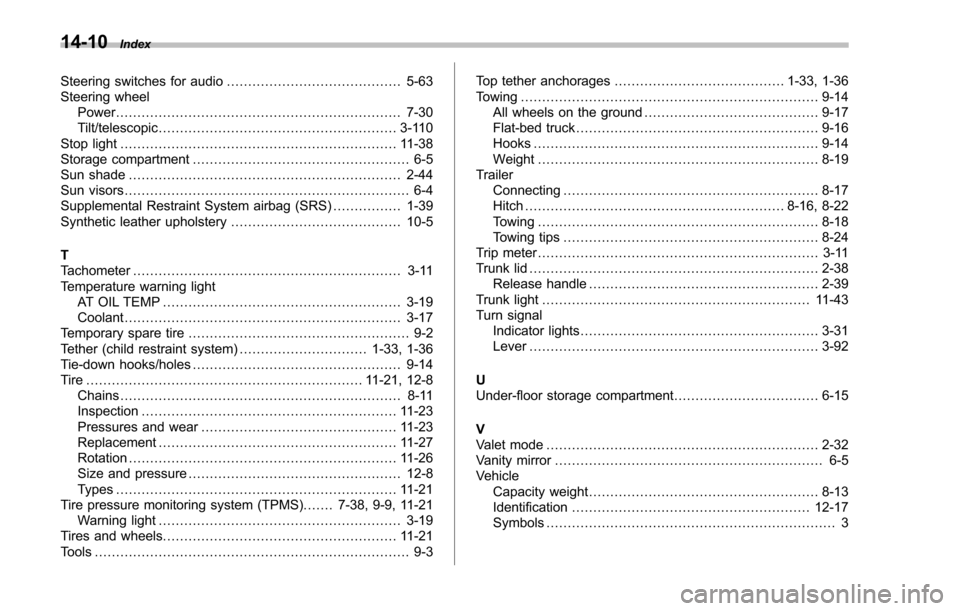

14-10Index

Steering switches for audio......................................... 5-63

Steering wheel Power ................................................................... 7-30

Tilt/telescopic ........................................................ 3-110

Stop light ................................................................. 11-38

Storage compartment ................................................... 6-5

Sun shade ................................................................ 2-44

Sun visors ................................................................... 6-4

Supplemental Restraint System airbag (SRS) ................ 1-39

Synthetic leather upholstery ........................................ 10-5

T

Tachometer ............................................................... 3-11

Temperature warning light AT OIL TEMP ........................................................ 3-19

Coolant ................................................................. 3-17

Temporary spare tire .................................................... 9-2

Tether (child restraint system) .............................. 1-33, 1-36

Tie-down hooks/holes ................................................. 9-14

Tire ................................................................. 11-21, 12-8 Chains .................................................................. 8-11

Inspection ............................................................ 11-23

Pressures and wear .............................................. 11-23

Replacement ........................................................ 11-27

Rotation ............................................................... 11-26

Size and pressure .................................................. 12-8

Types .................................................................. 11-21

Tire pressure monitoring system (TPMS). ...... 7-38, 9-9, 11-21

Warning light ......................................................... 3-19

Tires and wheels. ...................................................... 11-21

Tools ........................................................................\

.. 9-3 Top tether anchorages

........................................ 1-33, 1-36

Towing ...................................................................... 9-14

All wheels on the ground ......................................... 9-17

Flat-bed truck ......................................................... 9-16

Hooks ................................................................... 9-14

Weight .................................................................. 8-19

Trailer Connecting ............................................................ 8-17

Hitch ............................................................. 8-16, 8-22

Towing .................................................................. 8-18

Towing tips ............................................................ 8-24

Trip meter .................................................................. 3-11

Trunk lid .................................................................... 2-38

Release handle ...................................................... 2-39

Trunk light ............................................................... 11-43

Turn signal

Indicator lights ........................................................ 3-31

Lever .................................................................... 3-92

U

Under-floor storage compartment .................................. 6-15

V

Valet mode ................................................................ 2-32

Vanity mirror ............................................................... 6-5

Vehicle

Capacity weight ...................................................... 8-13

Identification ........................................................ 12-17

Symbols ....................................................................

3