coolant SUBARU IMPREZA WRX 2006 2.G User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2006, Model line: IMPREZA WRX, Model: SUBARU IMPREZA WRX 2006 2.GPages: 365, PDF Size: 7.09 MB

Page 286 of 365

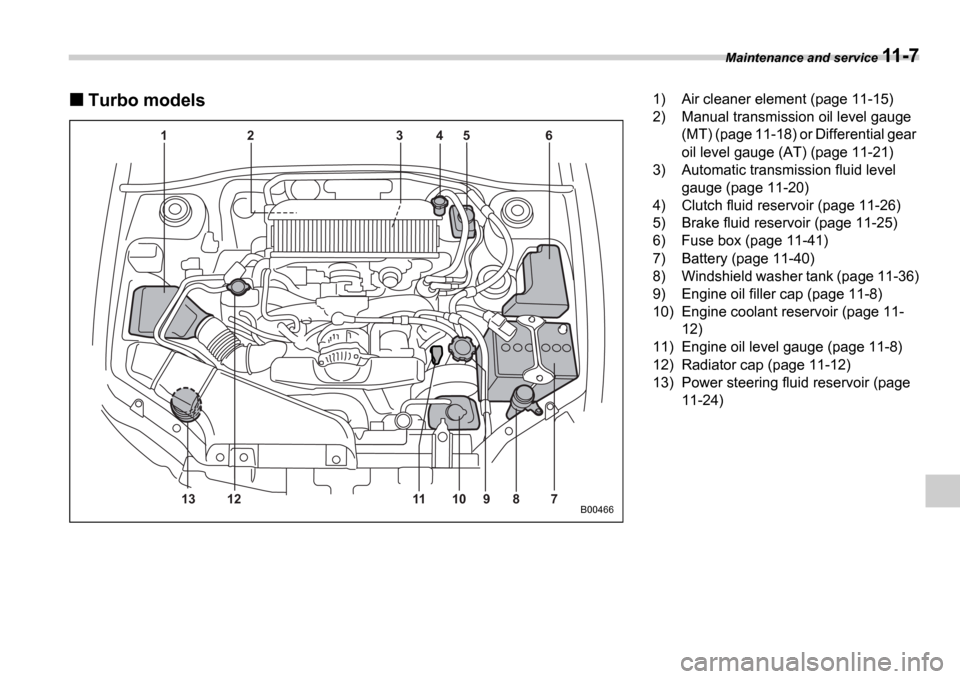

Maintenance and service 11-7

Turbo models

1 2 3 4 5 6

7

8

9

10

11

12

13

B00466

1) Air cleaner element (page 11-15)

2) Manual transmission oil level gauge

(MT) (page 11-18) or Differential gear

oil level gauge (AT) (page 11-21)

3) Automatic transmission fluid level gauge (page 11-20)

4) Clutch fluid reservoir (page 11-26)

5) Brake fluid reservoir (page 11-25)

6) Fuse box (page 11-41)

7) Battery (page 11-40)

8) Windshield washer tank (page 11-36)

9) Engine oil filler cap (page 11-8)

10) Engine coolant reservoir (page 11- 12)

11) Engine oil level gauge (page 11-8)

12) Radiator cap (page 11-12)

13) Power steering fluid reservoir (page

11-24)

Page 291 of 365

11-12 Maintenance and service

Cooling system

Cooling fan, hose and con-

nections

Your vehicle employs an electric cooling

fan which is thermostatically controlled to

operate when the engine coolant reaches

a specific temperature.

If the radiator cooling fan does not operate

even when the engine coolant tempera-

ture gauge exceeds the normal operating

range, the cooling fan circuit may be de-

fective. Check the fuse and replace it if

necessary. If the fuse is not blown, have

the cooling system checked by your

SUBARU dealer.

If frequent addition of coolant is neces-

sary, there may be a leak in the engine

cooling system. It is recommended that

the cooling system and connections be

checked for leaks, damage, or looseness.

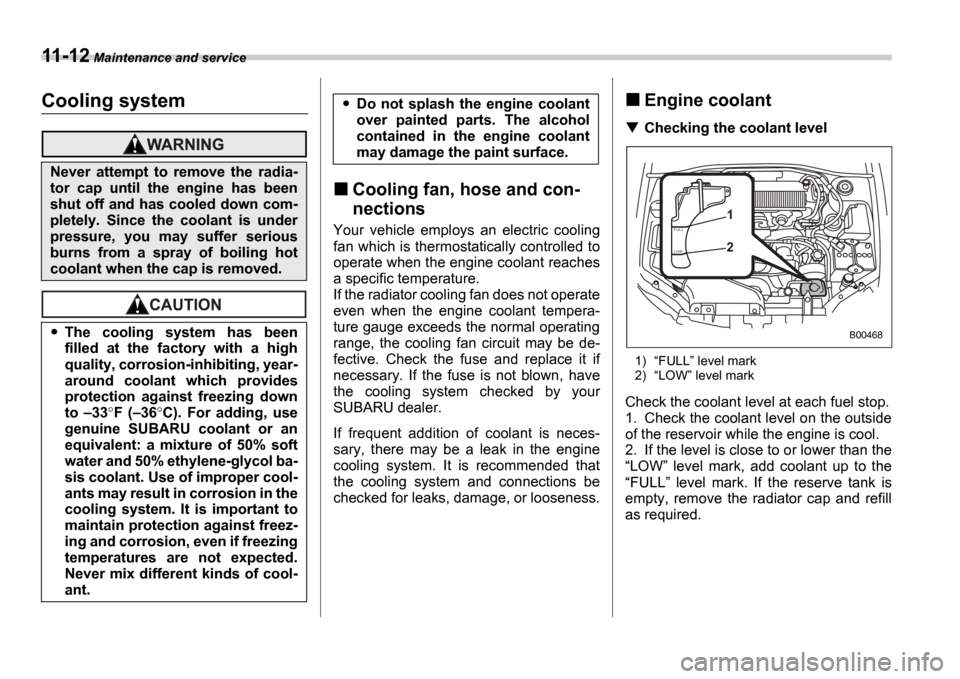

Engine coolant

Checking the coolant level

1)FULL level mark

2) LOW level mark

Check the coolant level at each fuel stop.

1. Check the coolant level on the outside

of the reservoir while the engine is cool.

2. If the level is close to or lower than the LOW level mark, add coolant up to the

FULL level mark. If the reserve tank is

empty, remove the radiator cap and refill

as required.

Never attempt to remove the radia-

tor cap until the engine has been

shut off and has cooled down com-

pletely. Since the coolant is under

pressure, you may suffer serious

burns from a spray of boiling hot

coolant when the cap is removed.

The cooling system has been

filled at the factory with a high

quality, corrosion-inhibiting, year-

around coolant which provides

protection against freezing down

to 33 F ( 36 C). For adding, use

genuine SUBARU coolant or an

equivalent: a mixture of 50% soft

water and 50% ethylene-glycol ba-

sis coolant. Use of improper cool-

ants may result in corrosion in the

cooling system. It is important to

maintain protection against freez-

ing and corrosion, even if freezing

temperatures are not expected.

Never mix different kinds of cool-

ant.

Do not splash the engine coolant

over painted parts. The alcohol

contained in the engine coolant

may damage the paint surface.

F U L L

L OW1 2

B00468

Page 292 of 365

Maintenance and service 11-13

CONTINUED

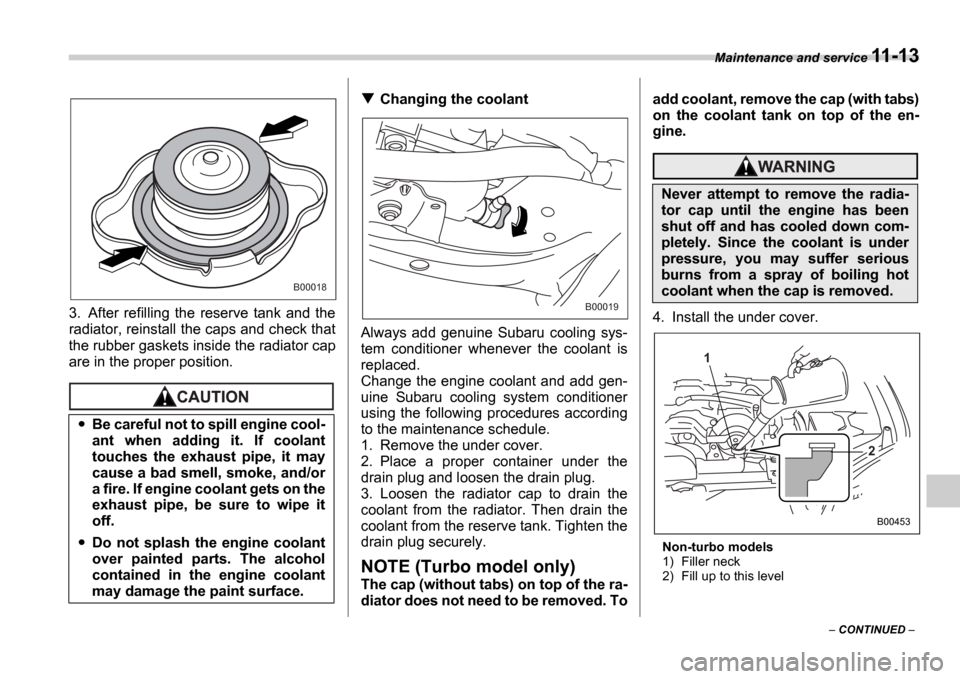

3. After refilling the reserve tank and the

radiator, reinstall the caps and check that

the rubber gaskets inside the radiator cap

are in the proper position.

Changing the coolant

Always add genuine Subaru cooling sys-

tem conditioner whenever the coolant is

replaced.

Change the engine coolant and add gen-

uine Subaru cooling system conditioner

using the following procedures according

to the maintenance schedule.

1. Remove the under cover.

2. Place a proper container under the

drain plug and loosen the drain plug.

3. Loosen the radiator cap to drain the

coolant from the radiator. Then drain the

coolant from the reserve tank. Tighten the

drain plug securely.

NOTE (Turbo model only)

The cap (without tabs) on top of the ra-

diator does not need to be removed. To add coolant, remove the cap (with tabs)

on the coolant tank on top of the en-

gine.

4. Install the under cover.

Non-turbo models

1) Filler neck

2) Fill up to this level

Be careful not to spill engine cool-

ant when adding it. If coolant

touches the exhaust pipe, it may

cause a bad smell, smoke, and/or

a fire. If engine coolant gets on the

exhaust pipe, be sure to wipe it

off.

Do not splash the engine coolant

over painted parts. The alcohol

contained in the engine coolant

may damage the paint surface.

B00018

B00019

Never attempt to remove the radia-

tor cap until the engine has been

shut off and has cooled down com-

pletely. Since the coolant is under

pressure, you may suffer serious

burns from a spray of boiling hot

coolant when the cap is removed.

1

2

B00453

Page 293 of 365

11-14 Maintenance and service

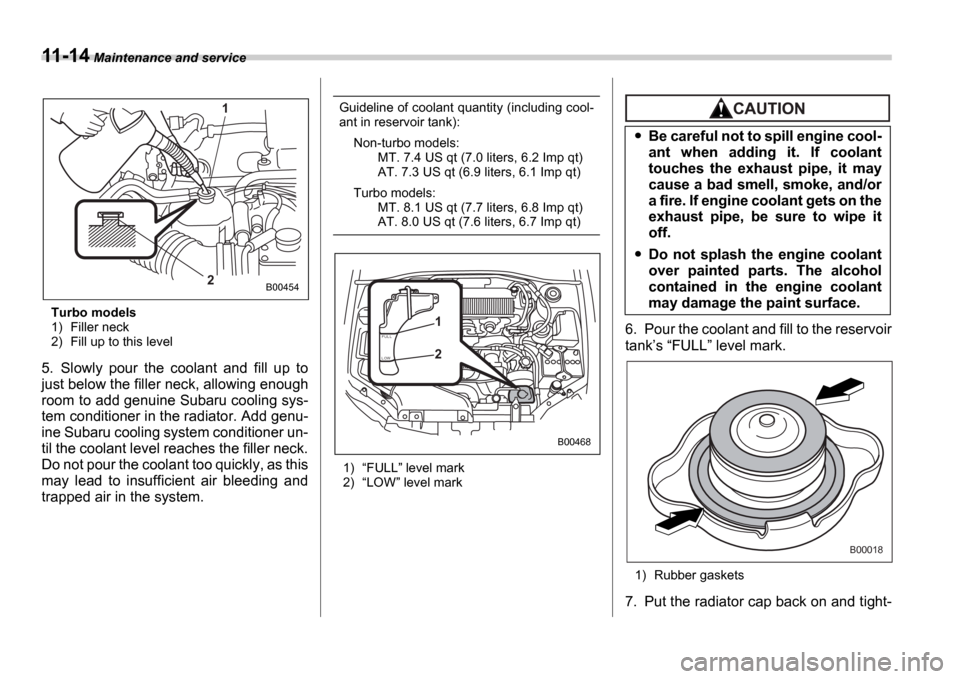

Turbo models

1) Filler neck

2) Fill up to this level

5. Slowly pour the coolant and fill up to

just below the filler neck, allowing enough

room to add genuine Subaru cooling sys-

tem conditioner in the radiator. Add genu-

ine Subaru cooling system conditioner un-

til the coolant level reaches the filler neck.

Do not pour the coolant too quickly, as this

may lead to insufficient air bleeding and

trapped air in the system.

Guideline of coolant quantity (including cool-

ant in reservoir tank):

Non-turbo models: MT. 7.4 US qt (7.0 liters, 6.2 Imp qt)

AT. 7.3 US qt (6.9 liters, 6.1 Imp qt)

Turbo models: MT. 8.1 US qt (7.7 liters, 6.8 Imp qt)

AT. 8.0 US qt (7.6 liters, 6.7 Imp qt)

1) FULL level mark

2) LOW level mark

6. Pour the coolant and fill to the reservoir

tank s FULL level mark.

1) Rubber gaskets

7. Put the radiator cap back on and tight-

1

2

B00454

F U L L

L OW1 2

B00468

Be careful not to spill engine cool-

ant when adding it. If coolant

touches the exhaust pipe, it may

cause a bad smell, smoke, and/or

a fire. If engine coolant gets on the

exhaust pipe, be sure to wipe it

off.

Do not splash the engine coolant

over painted parts. The alcohol

contained in the engine coolant

may damage the paint surface.

B00018

Page 294 of 365

Maintenance and service 11-15

CONTINUED

en firmly. At this time, make sure that the

rubber gasket in the radiator cap is cor-

rectly in place.

8. Start and run the engine for more than

five minutes at 2,000 to 3,000 rpm.

9. Stop the engine and wait until the cool-

ant cools down (122 to 140

F [50 to

60 C]). If there is any loss of coolant, add

coolant to the radiator s filler neck and to

the reserve tank s FULL level.

10.Put the radiator cap and reservoir cap

back on and tighten firmly.

Air cleaner element

The air cleaner element functions as a fil-

ter screen. When the element is perforat-

ed or removed, engine wear will be exces-

sive and engine life shortened.

The air cleaner element is a viscous type.

It is unnecessary to clean or wash the ele-

ment.

Replacing the air cleaner ele-

ment

Replace the air cleaner element according

to the maintenance schedule in the War-

ranty and Maintenance Booklet . Under

extremely dusty conditions, replace it

more frequently. It is recommended that

you always use genuine SUBARU parts.

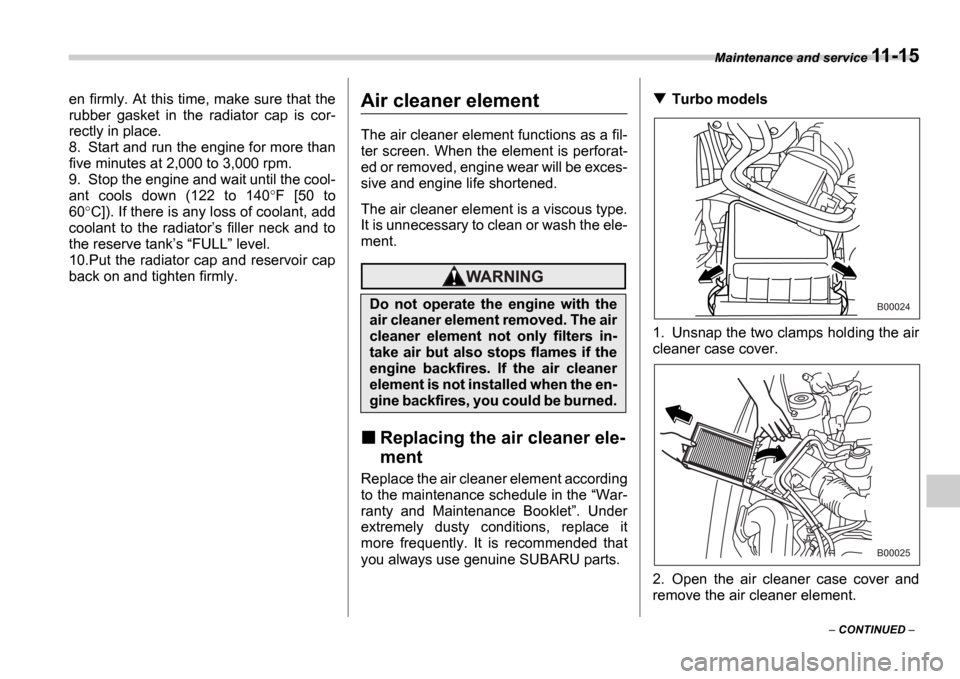

Turbo models

1. Unsnap the two clamps holding the air

cleaner case cover.

2. Open the air cleaner case cover and

remove the air cleaner element.

Do not operate the engine with the

air cleaner element removed. The air

cleaner element not only filters in-

take air but also stops flames if the

engine backfires. If the air cleaner

element is not installed when the en-

gine backfires, you could be burned.B00024

B00025

Page 315 of 365

11-36 Maintenance and service

Windshield washer fluid

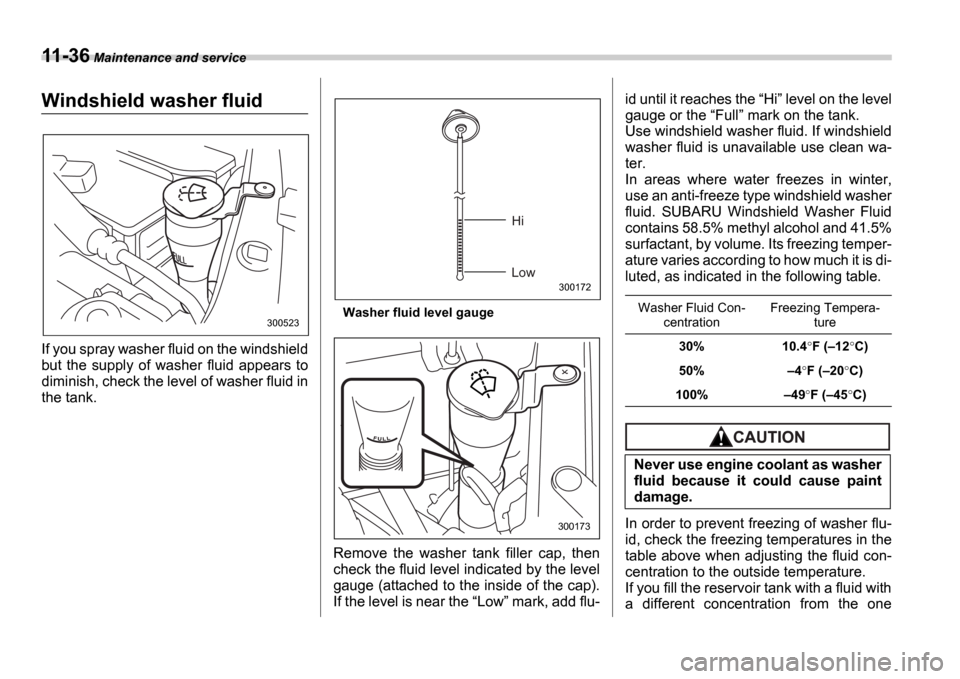

If you spray washer fluid on the windshield

but the supply of washer fluid appears to

diminish, check the level of washer fluid in

the tank.

Washer fluid level gauge

Remove the washer tank filler cap, then

check the fluid level indicated by the level

gauge (attached to the inside of the cap).

If the level is near the Low mark, add flu- id until it reaches the

Hi level on the level

gauge or the Full mark on the tank.

Use windshield washer fluid. If windshield

washer fluid is unavailable use clean wa-

ter.

In areas where water freezes in winter,

use an anti-freeze type windshield washer

fluid. SUBARU Windshield Washer Fluid

contains 58.5% methyl alcohol and 41.5%

surfactant, by volume. Its freezing temper-

ature varies according to how much it is di-

luted, as indicated in the following table.

In order to prevent freezing of washer flu-

id, check the freezing temperatures in the

table above when adjusting the fluid con-

centration to the outside temperature.

If you fill the reservoir tank with a fluid with

a different concentration from the one

300523

Hi

Low

300172

300173

Washer Fluid Con- centration Freezing Tempera-

ture

30% 10.4 F ( 12 C)

50% 4F ( 20 C)

100% 49 F ( 45 C)

Never use engine coolant as washer

fluid because it could cause paint

damage.

Page 335 of 365

12-4 Specifications

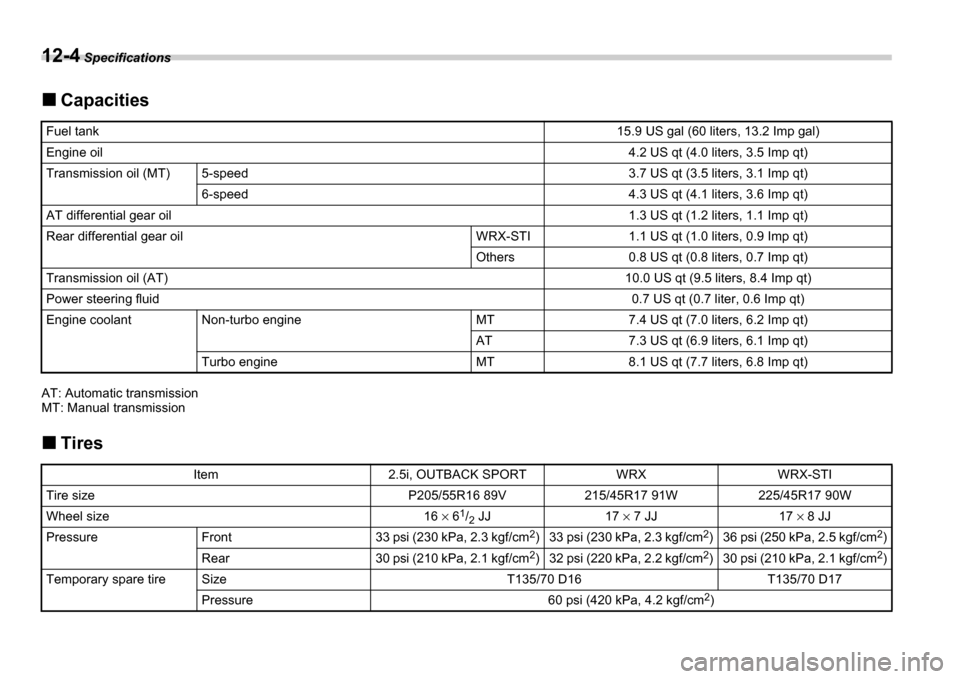

Capacities

AT: Automatic transmission

MT: Manual transmission

Tires

Fuel tank15.9 US gal (60 liters, 13.2 Imp gal)

Engine oil4.2 US qt (4.0 liters, 3.5 Imp qt)

Transmission oil (MT)5-speed3.7 US qt (3.5 liters, 3.1 Imp qt)

6-speed4.3 US qt (4.1 liters, 3.6 Imp qt)

AT differential gear oil1.3 US qt (1.2 liters, 1.1 Imp qt)

Rear differential gear oilWRX-STI1.1 US qt (1.0 liters, 0.9 Imp qt)

Others0.8 US qt (0.8 liters, 0.7 Imp qt)

Transmission oil (AT)10.0 US qt (9.5 liters, 8.4 Imp qt)

Power steering fluid0.7 US qt (0.7 liter, 0.6 Imp qt)

Engine coolantNon-turbo engineMT7.4 US qt (7.0 liters, 6.2 Imp qt)

AT7.3 US qt (6.9 liters, 6.1 Imp qt)

Turbo engineMT8.1 US qt (7.7 liters, 6.8 Imp qt)

Item2.5i, OUTBACK SPORTWRXWRX-STI

Tire sizeP205/55R16 89V215/45R17 91W225/45R17 90W

Wheel size16 6 1

/2 JJ17

7 JJ17 8 JJ

PressureFront33 psi (230 kPa, 2.3 kgf/cm 2

)33 psi (230 kPa, 2.3 kgf/cm 2

)36 psi (250 kPa, 2.5 kgf/cm 2

)

Rear30 psi (210 kPa, 2.1 kgf/cm 2

)32 psi (220 kPa, 2.2 kgf/cm 2

)30 psi (210 kPa, 2.1 kgf/cm 2

)

Temporary spare tireSizeT135/70 D16T135/70 D17

Pressure60 psi (420 kPa, 4.2 kgf/cm 2

)

Page 348 of 365

Consumer information and Reporting safety defects 13-7

CONTINUED

asymmetrical tire that has a particu-

lar side that must always face out-

ward when mounting on a vehicle.

Accessory weight

The combined weight (in excess of

those standard items which may be

replaced) of floor mats, leather seats

and cross bars to the extent that these

items are available as factory-in-

stalled equipment (whether installed

or not).

Curb weight

The weight of a motor vehicle with

standard equipment including the

maximum capacity of fuel, oil, and

coolant and air conditioning.

Maximum loaded vehicle weight

The sum of curb weight, accessory

weight, vehicle capacity weight and

production options weight.

Normal occupant weight

150 lbs (68 kg) times the number of

occupants (3 occupants).

Occupant distribution

Distribution of occupants in a vehicle,

2 in front, 1 in rear seat.

Production options weight

The combined weight of those in-

stalled regular production options weighing over 5.1 lbs (2.3 kg) in ex-

cess of those standards items which

they replace, not previously consid-

ered in curb weight or accessory

weight.

Vehicle capacity weight

The total weight of cargo, luggage

and occupants that can be added to

the vehicle.

Vehicle maximum load on a tire

Load on an individual tire that is deter-

mined by distributing to each axle its

share of the maximum loaded vehicle

weight and dividing by two.

Vehicle normal load on a tire

Load on an individual tire that is deter-

mined by distributing to each axle its

share of the curb weight, accessory

weight, and normal occupant weight

and dividing by two.

Tire care maintenance and

safety practices

Check on a daily basis that the tires

are free from serious damage, nails,

and stones. At the same time, check

the tires for abnormal wear.

Inspect the tire tread regularly and

replace the tires before their tread wear indicators become visible. When

a tire

s tread wear indicator becomes

visible, the tire is worn beyond the ac-

ceptable limit and must be replaced

immediately. With a tire in this condi-

tion, driving at even low speeds in wet

weather can cause the vehicle to hy-

droplane. Possible resulting loss of

vehicle control can lead to an acci-

dent.

To maximize the life of each tire and

ensure that the tires wear uniformly, it

is best to rotate the tires every 7,500

miles (12,500 km). Rotating the tires

involves switching the front and rear

tires on the right-hand side of the ve-

hicle and similarly switching the front

and rear tires on the left-hand side of

the vehicle. (Each tire must be kept on

its original side of the vehicle.) Re-

place any damaged or unevenly worn

tire at the time of rotation. After tire ro-

tation, adjust the tire pressures and

make sure the wheel nuts are correct-

ly tightened. A tightening torque spec-

ification and a tightening sequence

specification for the wheel nuts can be

found Flat tires section in chapter 9.

Page 359 of 365

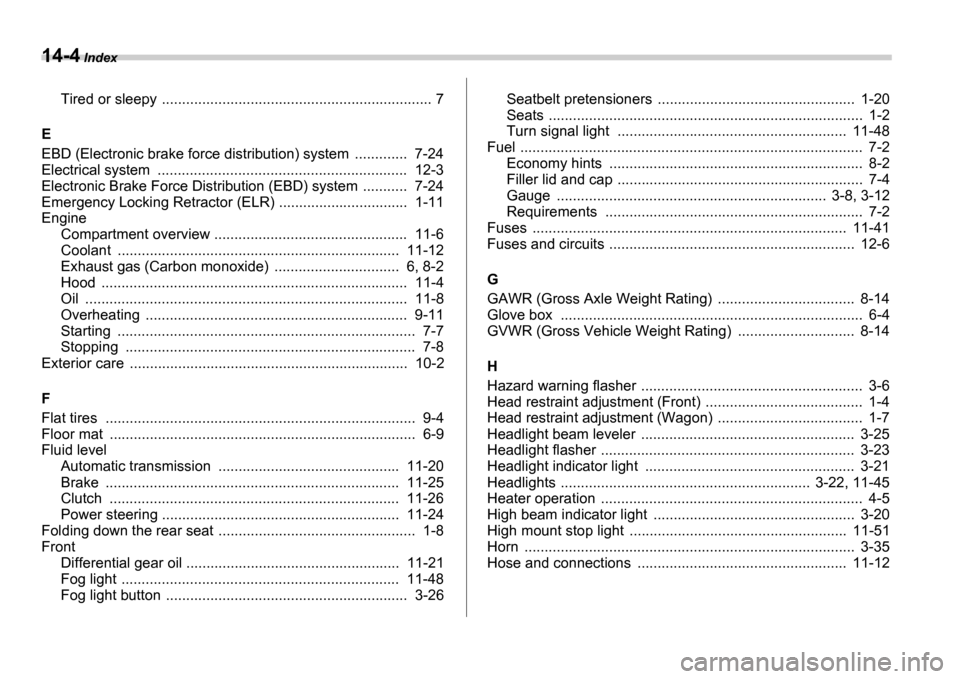

14-4 Index

Tired or sleepy .................................... ............................... 7

E

EBD (Electronic brake force distribution) system ........ ..... 7-24

Electrical system ..................................... ......................... 12-3

Electronic Brake Force Distribution (EBD) system ......... .. 7-24

Emergency Locking Retractor (ELR) .................... ............ 1-11

Engine Compartment overview ................................ ................ 11-6

Coolant ........................................... ........................... 11-12

Exhaust gas (Carbon monoxide) ....................... ........ 6, 8-2

Hood .............................................. .............................. 11-4

Oil ............................................... ................................. 11-8

Overheating ........................................ ......................... 9-11

Starting .......................................... ................................ 7-7

Stopping .......................................... .............................. 7-8

Exterior care ....................................... .............................. 10-2

F

Flat tires ......................................... .................................... 9-4

Floor mat ......................................... ................................... 6-9

Fluid level

Automatic transmission ............................... .............. 11-20

Brake .............................................. ........................... 11-25

Clutch ............................................. ........................... 11-26

Power steering ..................................... ...................... 11-24

Folding down the rear seat ......................... ........................ 1-8

Front

Differential gear oil ............................. ........................ 11-21

Fog light ......................................... ............................ 11-48

Fog light button .................................. .......................... 3-26Seatbelt pretensioners ..............................

................... 1-20

Seats .............................................. ................................ 1-2

Turn signal light .................................. ....................... 11-48

Fuel .............................................. ....................................... 7-2

Economy hints ........................................ ....................... 8-2

Filler lid and cap ................................. ............................ 7-4

Gauge ............................................. ...................... 3-8, 3-12

Requirements ...................................... .......................... 7-2

Fuses .............................................. ................................ 11-41

Fuses and circuits ..................................... ........................ 12-6

G

GAWR (Gross Axle Weight Rating) ..................... ............. 8-14

Glove box ........................................... ................................ 6-4

GVWR (Gross Vehicle Weight Rating) ................... .......... 8-14

H

Hazard warning flasher ............................. .......................... 3-6

Head restraint adjustment (Front) ................... .................... 1-4

Head restraint adjustment (Wagon) .................. .................. 1-7

Headlight beam leveler ............................ ......................... 3-25

Headlight flasher .................................. ............................. 3-23

Headlight indicator light .......................... .......................... 3-21

Headlights ......................................... ..................... 3-22, 11-45

Heater operation .................................. ............................... 4-5

High beam indicator light .......................... ........................ 3-20

High mount stop light .............................. ........................ 11-51

Horn .............................................. .................................... 3-35

Hose and connections .................................. .................. 11-12