diff SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1089 of 1456

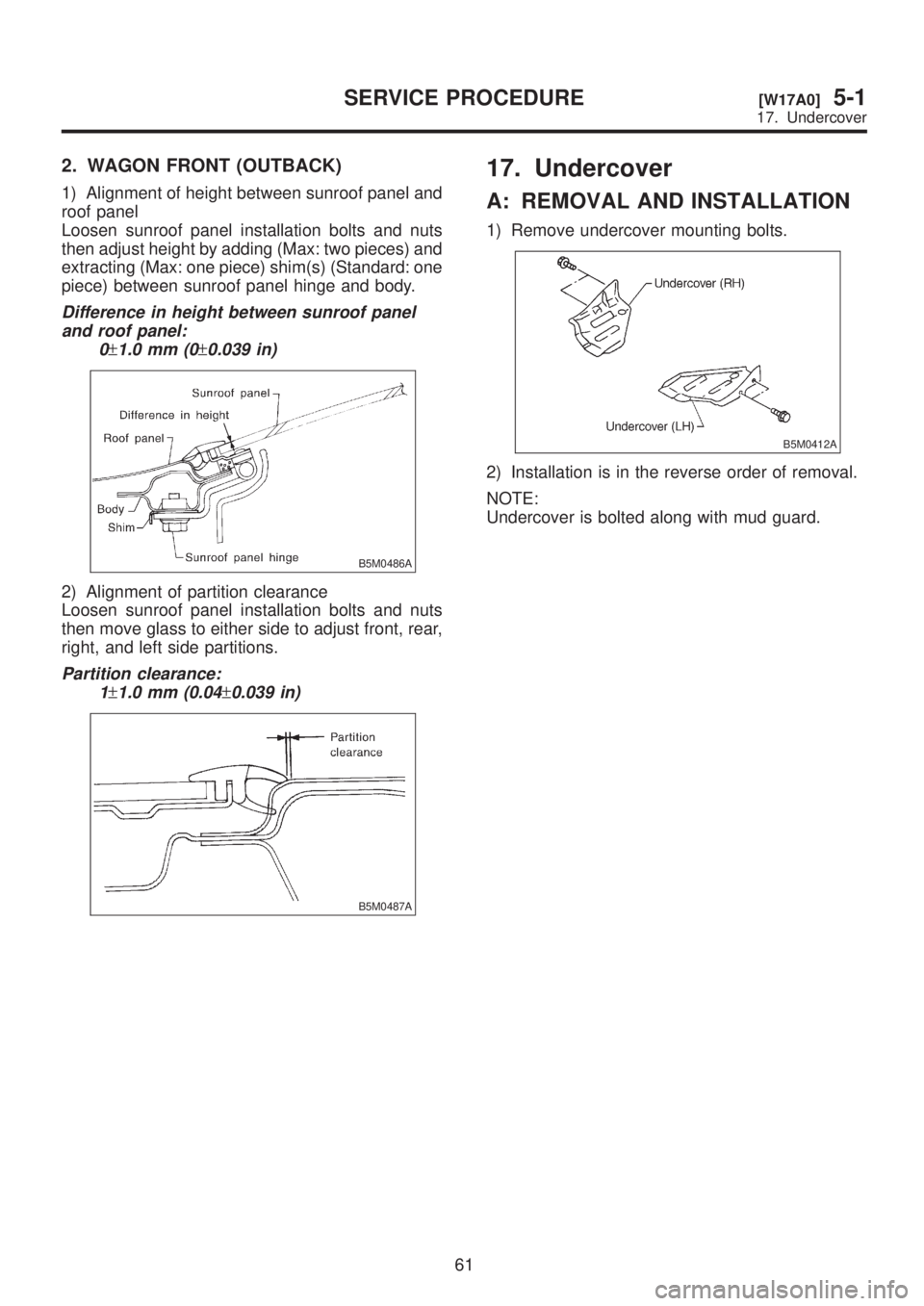

2. WAGON FRONT (OUTBACK)

1) Alignment of height between sunroof panel and

roof panel

Loosen sunroof panel installation bolts and nuts

then adjust height by adding (Max: two pieces) and

extracting (Max: one piece) shim(s) (Standard: one

piece) between sunroof panel hinge and body.

Difference in height between sunroof panel

and roof panel:

0

±1.0 mm (0±0.039 in)

B5M0486A

2) Alignment of partition clearance

Loosen sunroof panel installation bolts and nuts

then move glass to either side to adjust front, rear,

right, and left side partitions.

Partition clearance:

1

±1.0 mm (0.04±0.039 in)

B5M0487A

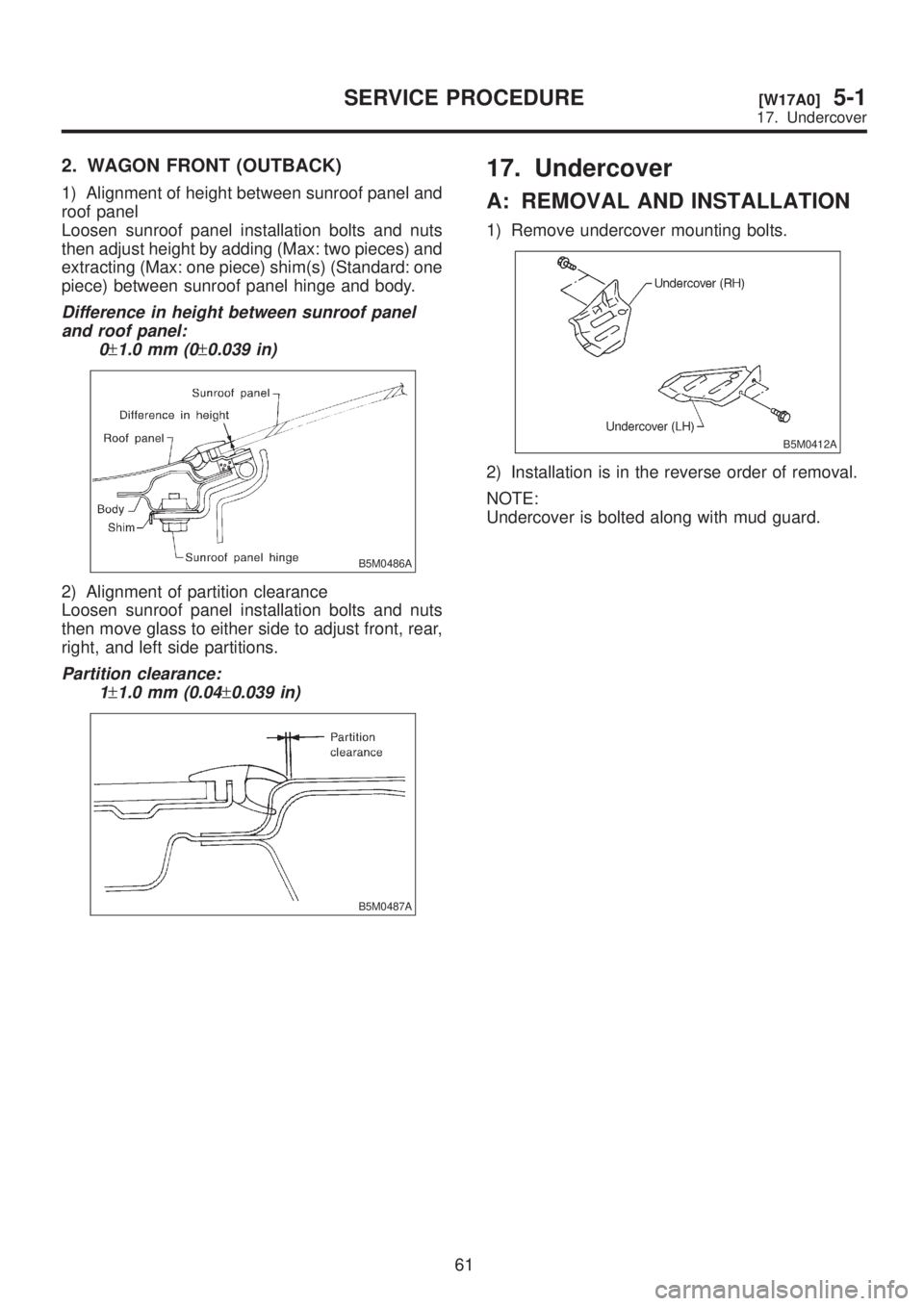

17. Undercover

A: REMOVAL AND INSTALLATION

1) Remove undercover mounting bolts.

B5M0412A

2) Installation is in the reverse order of removal.

NOTE:

Undercover is bolted along with mud guard.

61

[W17A0]5-1SERVICE PROCEDURE

17. Undercover

Page 1090 of 1456

2. WAGON FRONT (OUTBACK)

1) Alignment of height between sunroof panel and

roof panel

Loosen sunroof panel installation bolts and nuts

then adjust height by adding (Max: two pieces) and

extracting (Max: one piece) shim(s) (Standard: one

piece) between sunroof panel hinge and body.

Difference in height between sunroof panel

and roof panel:

0

±1.0 mm (0±0.039 in)

B5M0486A

2) Alignment of partition clearance

Loosen sunroof panel installation bolts and nuts

then move glass to either side to adjust front, rear,

right, and left side partitions.

Partition clearance:

1

±1.0 mm (0.04±0.039 in)

B5M0487A

17. Undercover

A: REMOVAL AND INSTALLATION

1) Remove undercover mounting bolts.

B5M0412A

2) Installation is in the reverse order of removal.

NOTE:

Undercover is bolted along with mud guard.

61

[W17A0]5-1SERVICE PROCEDURE

17. Undercover

Page 1123 of 1456

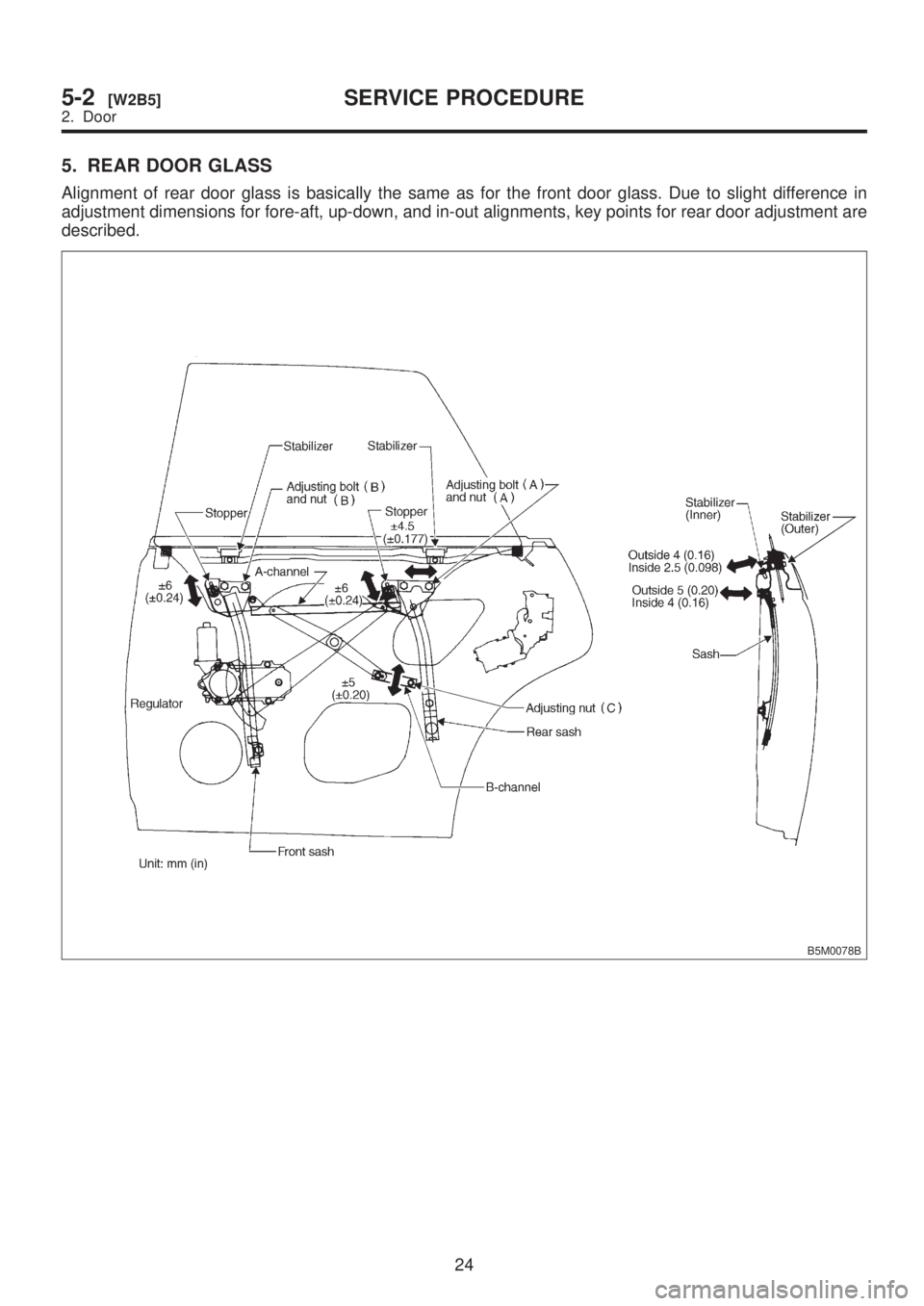

5. REAR DOOR GLASS

Alignment of rear door glass is basically the same as for the front door glass. Due to slight difference in

adjustment dimensions for fore-aft, up-down, and in-out alignments, key points for rear door adjustment are

described.

B5M0078B

24

5-2[W2B5]SERVICE PROCEDURE

2. Door

Page 1152 of 1456

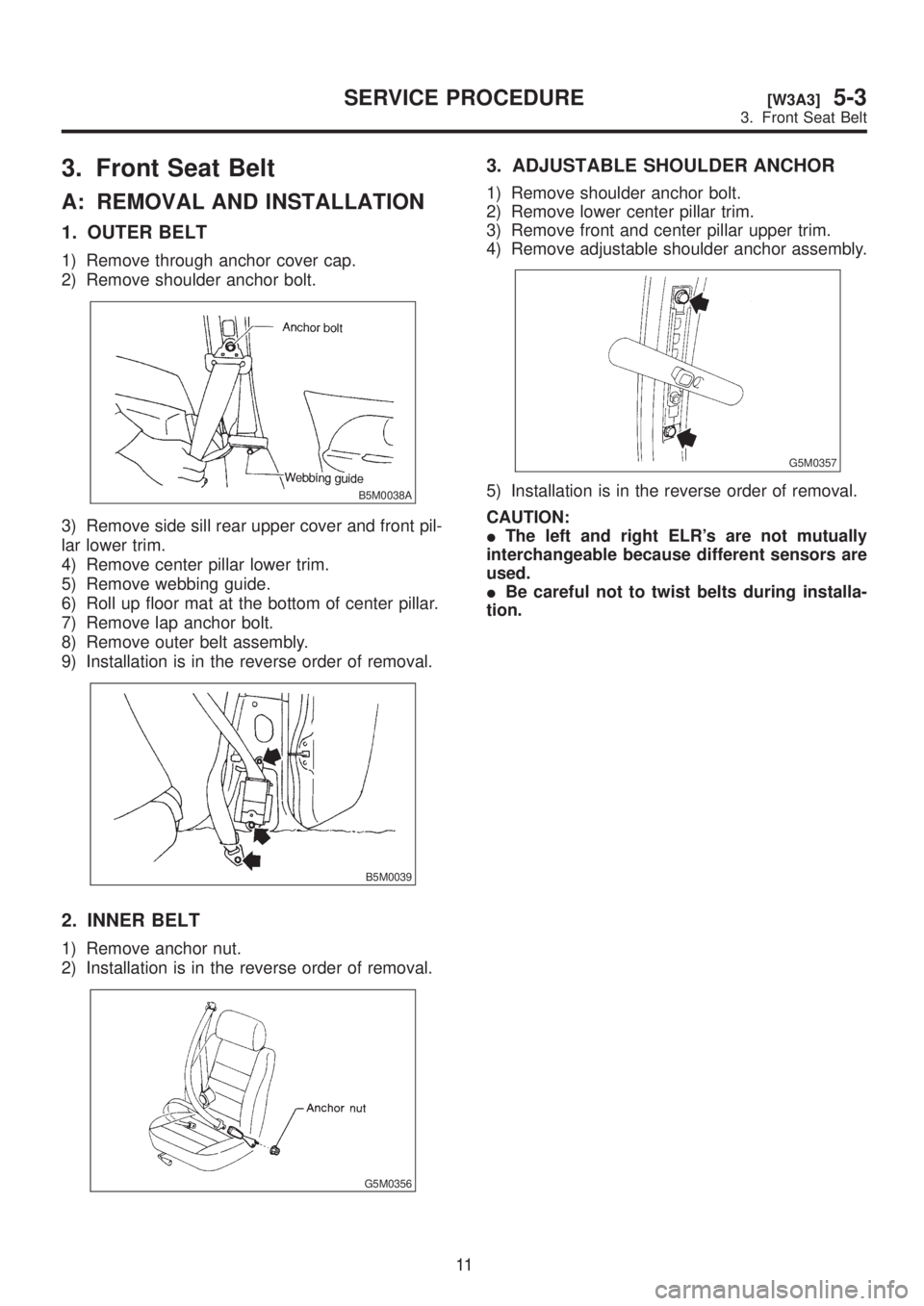

3. Front Seat Belt

A: REMOVAL AND INSTALLATION

1. OUTER BELT

1) Remove through anchor cover cap.

2) Remove shoulder anchor bolt.

B5M0038A

3) Remove side sill rear upper cover and front pil-

lar lower trim.

4) Remove center pillar lower trim.

5) Remove webbing guide.

6) Roll up floor mat at the bottom of center pillar.

7) Remove lap anchor bolt.

8) Remove outer belt assembly.

9) Installation is in the reverse order of removal.

B5M0039

2. INNER BELT

1) Remove anchor nut.

2) Installation is in the reverse order of removal.

G5M0356

3. ADJUSTABLE SHOULDER ANCHOR

1) Remove shoulder anchor bolt.

2) Remove lower center pillar trim.

3) Remove front and center pillar upper trim.

4) Remove adjustable shoulder anchor assembly.

G5M0357

5) Installation is in the reverse order of removal.

CAUTION:

IThe left and right ELR's are not mutually

interchangeable because different sensors are

used.

IBe careful not to twist belts during installa-

tion.

11

[W3A3]5-3SERVICE PROCEDURE

3. Front Seat Belt

Page 1156 of 1456

CAUTION:

IThe left and right ELR's are not mutually

interchangeable because different sensors are

used.

IBe careful not to twist belts during installa-

tion.

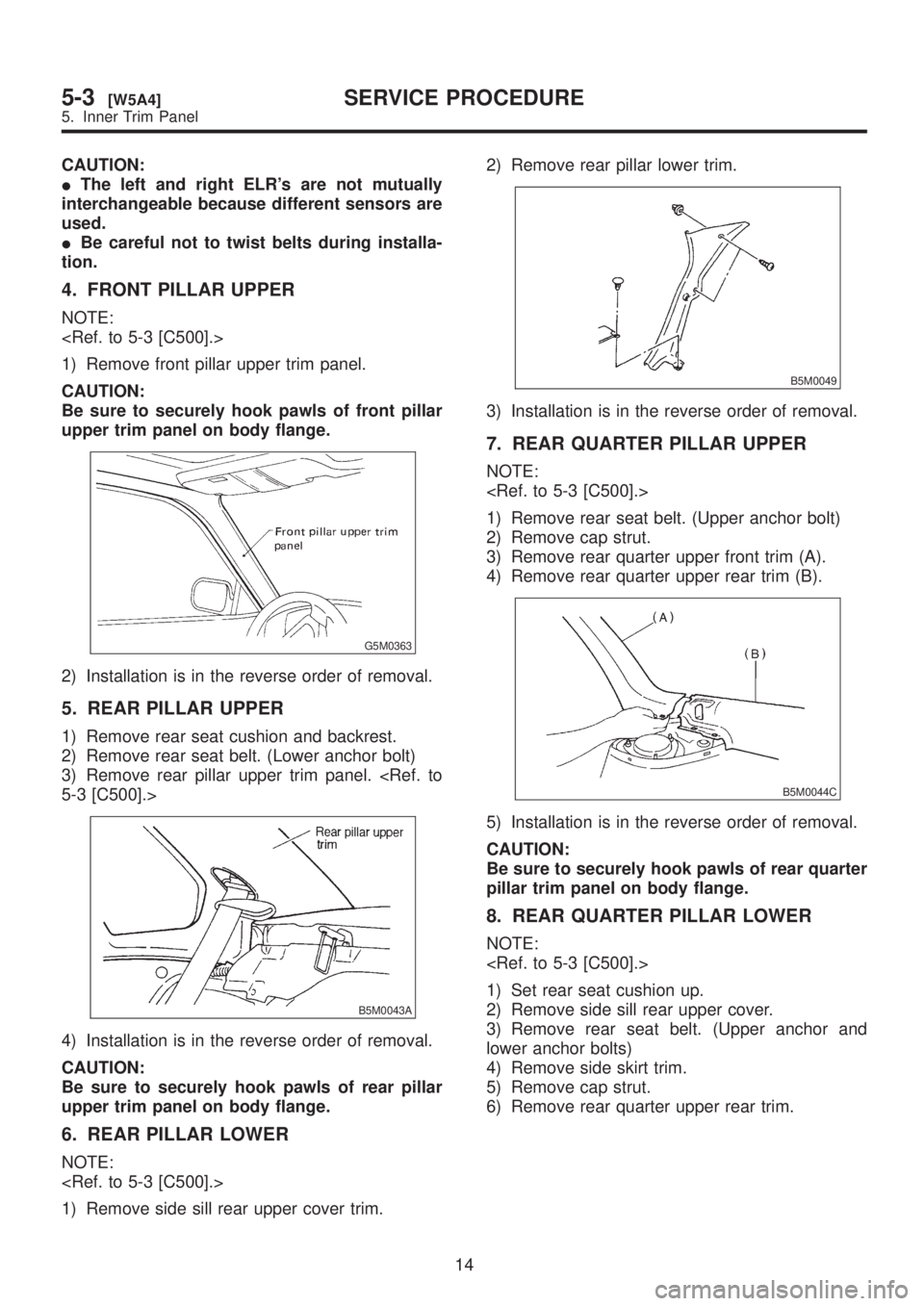

4. FRONT PILLAR UPPER

NOTE:

1) Remove front pillar upper trim panel.

CAUTION:

Be sure to securely hook pawls of front pillar

upper trim panel on body flange.

G5M0363

2) Installation is in the reverse order of removal.

5. REAR PILLAR UPPER

1) Remove rear seat cushion and backrest.

2) Remove rear seat belt. (Lower anchor bolt)

3) Remove rear pillar upper trim panel.

B5M0043A

4) Installation is in the reverse order of removal.

CAUTION:

Be sure to securely hook pawls of rear pillar

upper trim panel on body flange.

6. REAR PILLAR LOWER

NOTE:

1) Remove side sill rear upper cover trim.2) Remove rear pillar lower trim.

B5M0049

3) Installation is in the reverse order of removal.

7. REAR QUARTER PILLAR UPPER

NOTE:

1) Remove rear seat belt. (Upper anchor bolt)

2) Remove cap strut.

3) Remove rear quarter upper front trim (A).

4) Remove rear quarter upper rear trim (B).

B5M0044C

5) Installation is in the reverse order of removal.

CAUTION:

Be sure to securely hook pawls of rear quarter

pillar trim panel on body flange.

8. REAR QUARTER PILLAR LOWER

NOTE:

1) Set rear seat cushion up.

2) Remove side sill rear upper cover.

3) Remove rear seat belt. (Upper anchor and

lower anchor bolts)

4) Remove side skirt trim.

5) Remove cap strut.

6) Remove rear quarter upper rear trim.

14

5-3[W5A4]SERVICE PROCEDURE

5. Inner Trim Panel

Page 1211 of 1456

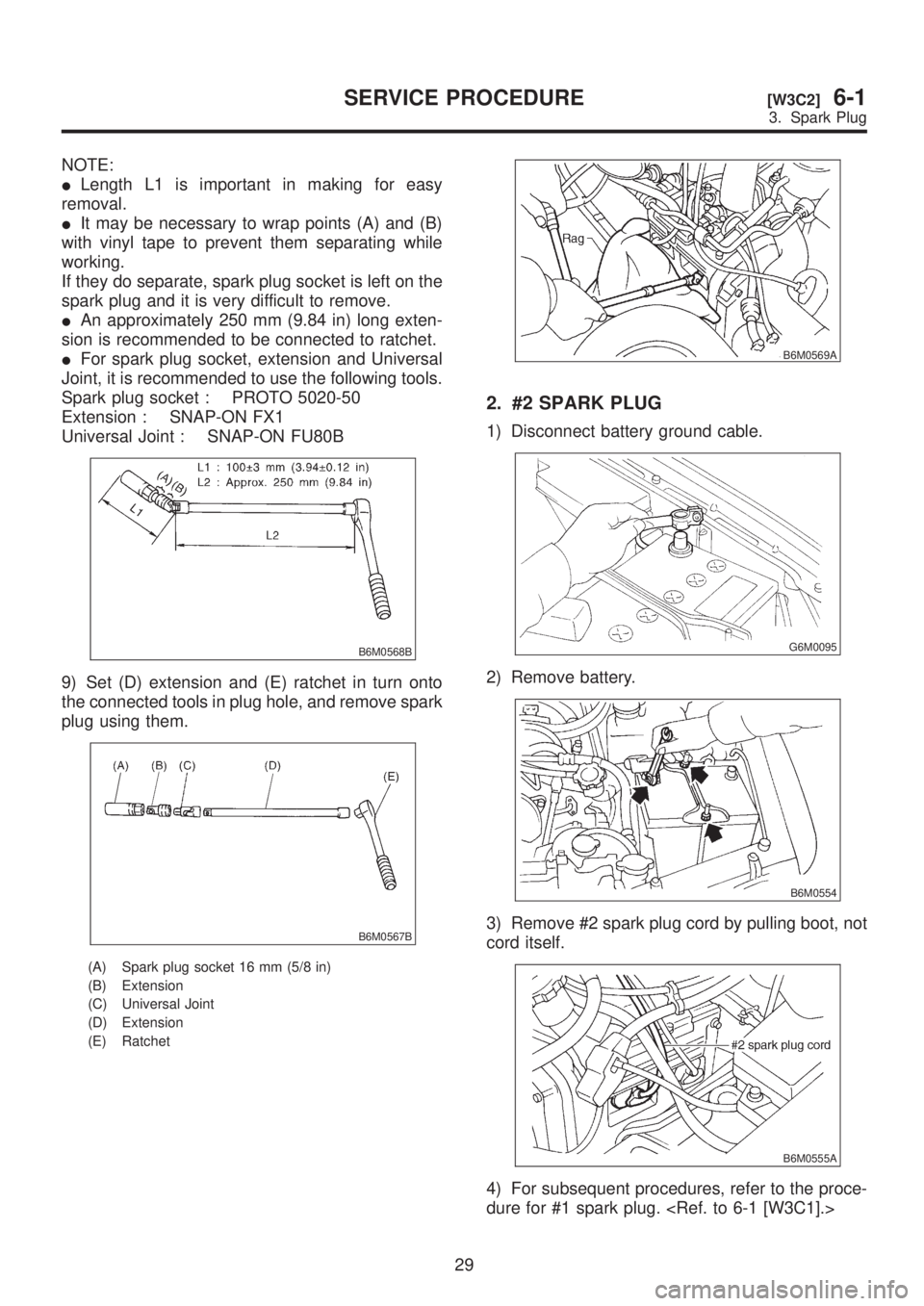

NOTE:

ILength L1 is important in making for easy

removal.

IIt may be necessary to wrap points (A) and (B)

with vinyl tape to prevent them separating while

working.

If they do separate, spark plug socket is left on the

spark plug and it is very difficult to remove.

IAn approximately 250 mm (9.84 in) long exten-

sion is recommended to be connected to ratchet.

IFor spark plug socket, extension and Universal

Joint, it is recommended to use the following tools.

Spark plug socket : PROTO 5020-50

Extension : SNAP-ON FX1

Universal Joint : SNAP-ON FU80B

B6M0568B

9) Set (D) extension and (E) ratchet in turn onto

the connected tools in plug hole, and remove spark

plug using them.

B6M0567B

(A) Spark plug socket 16 mm (5/8 in)

(B) Extension

(C) Universal Joint

(D) Extension

(E) Ratchet

B6M0569A

2. #2 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Remove battery.

B6M0554

3) Remove #2 spark plug cord by pulling boot, not

cord itself.

B6M0555A

4) For subsequent procedures, refer to the proce-

dure for #1 spark plug.

29

[W3C2]6-1SERVICE PROCEDURE

3. Spark Plug

Page 1214 of 1456

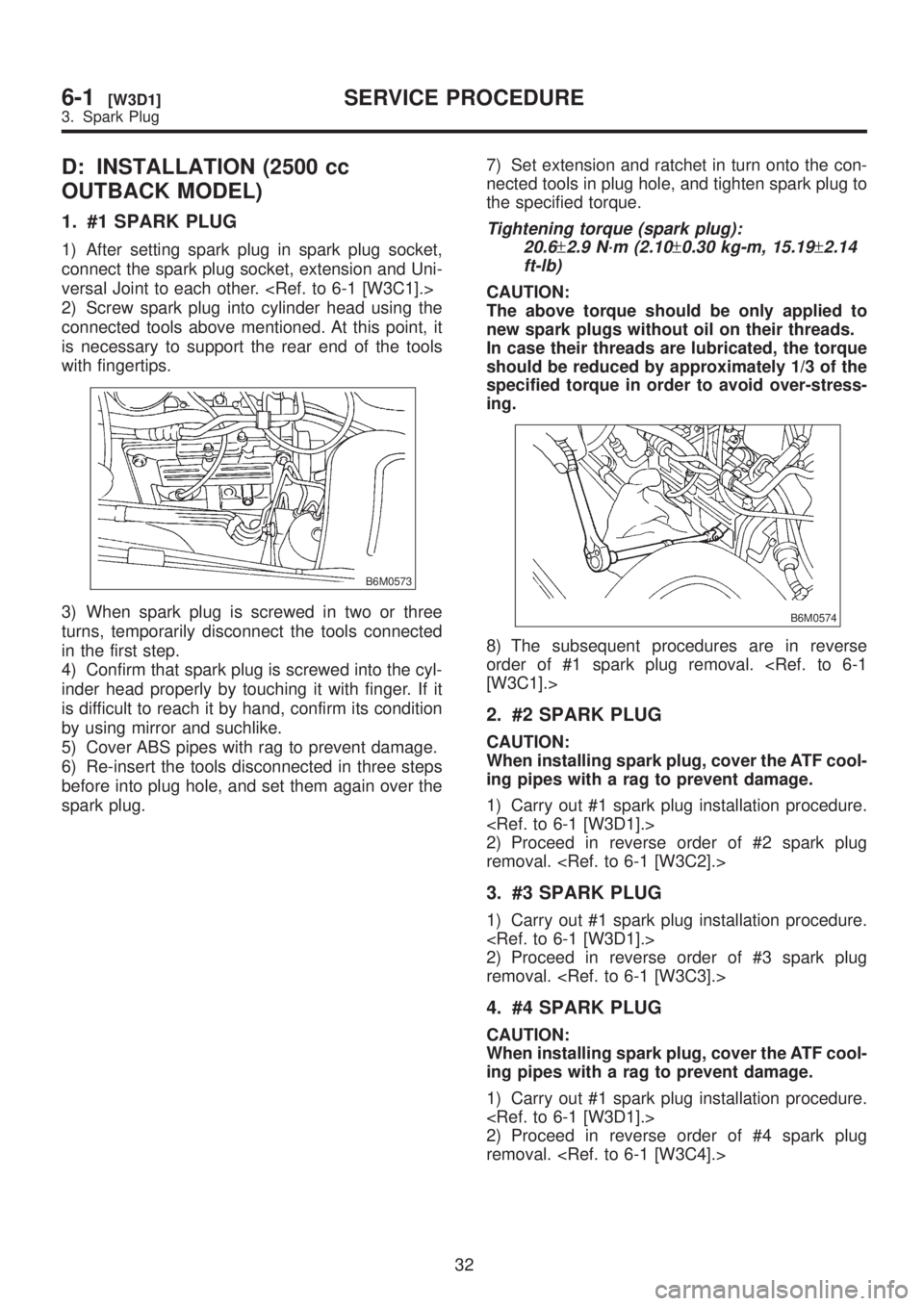

D: INSTALLATION (2500 cc

OUTBACK MODEL)

1. #1 SPARK PLUG

1) After setting spark plug in spark plug socket,

connect the spark plug socket, extension and Uni-

versal Joint to each other.

2) Screw spark plug into cylinder head using the

connected tools above mentioned. At this point, it

is necessary to support the rear end of the tools

with fingertips.

B6M0573

3) When spark plug is screwed in two or three

turns, temporarily disconnect the tools connected

in the first step.

4) Confirm that spark plug is screwed into the cyl-

inder head properly by touching it with finger. If it

is difficult to reach it by hand, confirm its condition

by using mirror and suchlike.

5) Cover ABS pipes with rag to prevent damage.

6) Re-insert the tools disconnected in three steps

before into plug hole, and set them again over the

spark plug.7) Set extension and ratchet in turn onto the con-

nected tools in plug hole, and tighten spark plug to

the specified torque.

Tightening torque (spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

CAUTION:

The above torque should be only applied to

new spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approximately 1/3 of the

specified torque in order to avoid over-stress-

ing.

B6M0574

8) The subsequent procedures are in reverse

order of #1 spark plug removal.

2. #2 SPARK PLUG

CAUTION:

When installing spark plug, cover the ATF cool-

ing pipes with a rag to prevent damage.

1) Carry out #1 spark plug installation procedure.

2) Proceed in reverse order of #2 spark plug

removal.

3. #3 SPARK PLUG

1) Carry out #1 spark plug installation procedure.

2) Proceed in reverse order of #3 spark plug

removal.

4. #4 SPARK PLUG

CAUTION:

When installing spark plug, cover the ATF cool-

ing pipes with a rag to prevent damage.

1) Carry out #1 spark plug installation procedure.

2) Proceed in reverse order of #4 spark plug

removal.

32

6-1[W3D1]SERVICE PROCEDURE

3. Spark Plug

Page 1281 of 1456

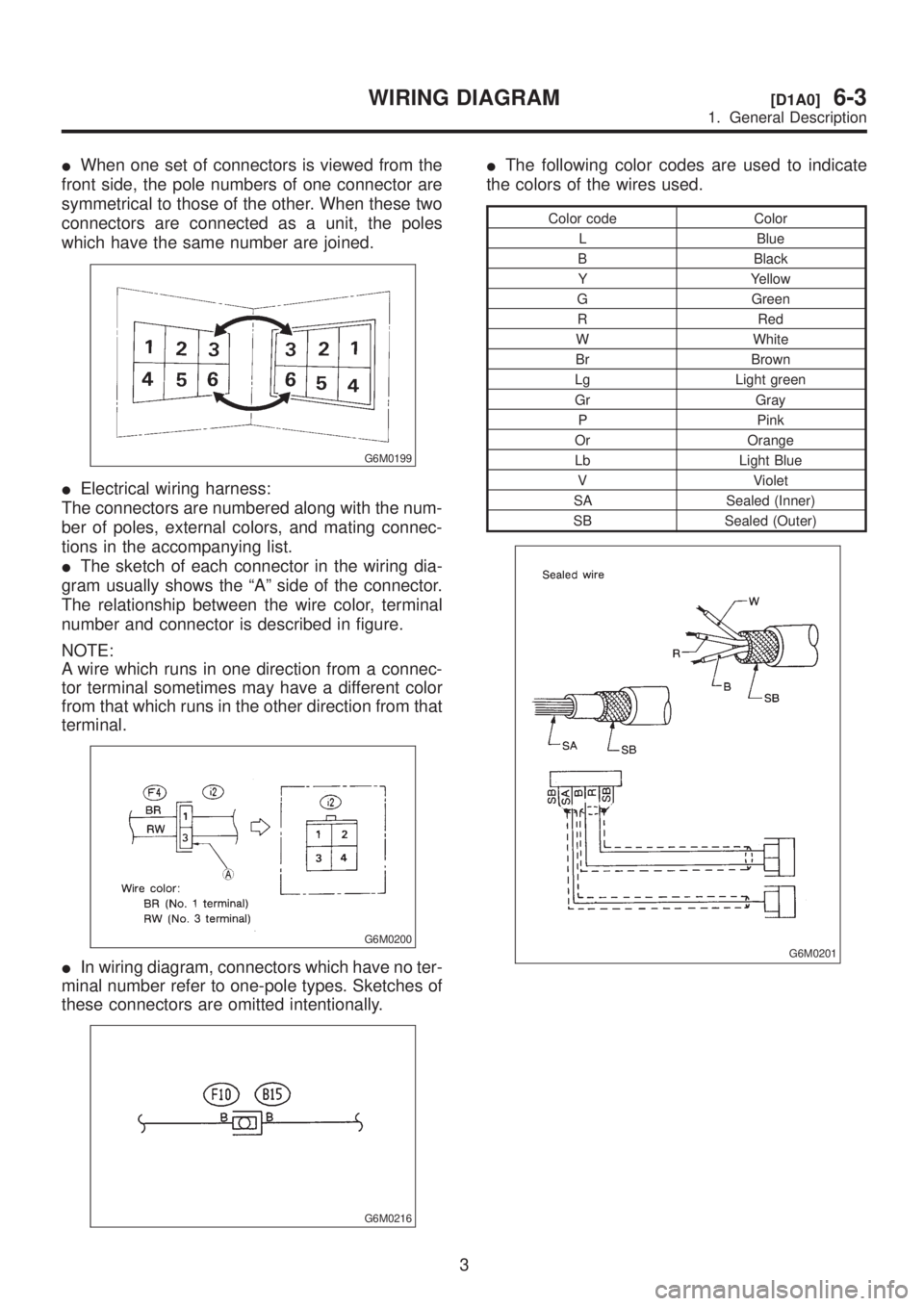

IWhen one set of connectors is viewed from the

front side, the pole numbers of one connector are

symmetrical to those of the other. When these two

connectors are connected as a unit, the poles

which have the same number are joined.

G6M0199

IElectrical wiring harness:

The connectors are numbered along with the num-

ber of poles, external colors, and mating connec-

tions in the accompanying list.

IThe sketch of each connector in the wiring dia-

gram usually shows the ªAº side of the connector.

The relationship between the wire color, terminal

number and connector is described in figure.

NOTE:

A wire which runs in one direction from a connec-

tor terminal sometimes may have a different color

from that which runs in the other direction from that

terminal.

G6M0200

IIn wiring diagram, connectors which have no ter-

minal number refer to one-pole types. Sketches of

these connectors are omitted intentionally.

G6M0216

IThe following color codes are used to indicate

the colors of the wires used.

Color code Color

L Blue

B Black

Y Yellow

G Green

R Red

W White

Br Brown

Lg Light green

Gr Gray

P Pink

Or Orange

Lb Light Blue

V Violet

SA Sealed (Inner)

SB Sealed (Outer)

G6M0201

3

[D1A0]6-3WIRING DIAGRAM

1. General Description

Page 1282 of 1456

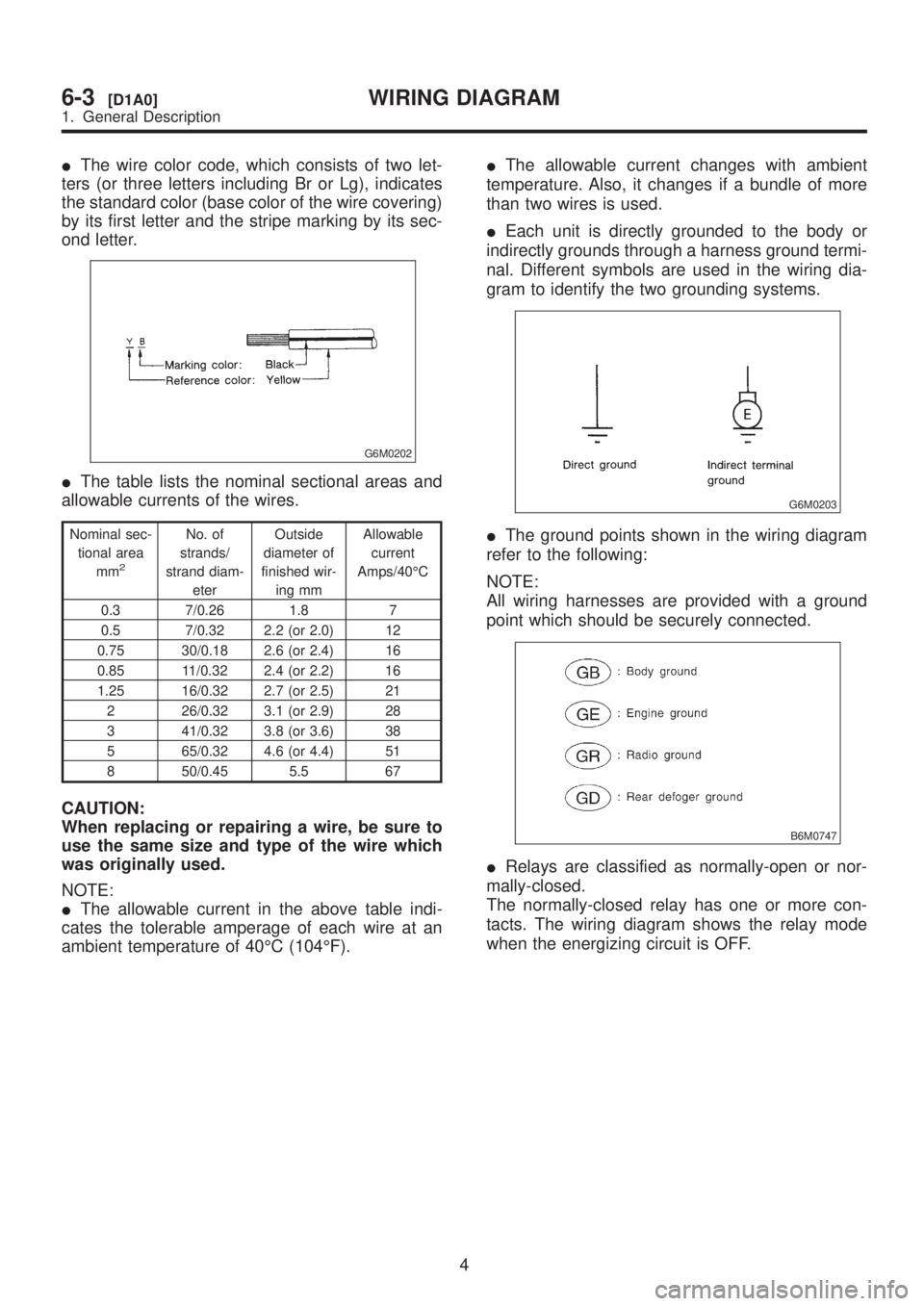

IThe wire color code, which consists of two let-

ters (or three letters including Br or Lg), indicates

the standard color (base color of the wire covering)

by its first letter and the stripe marking by its sec-

ond letter.

G6M0202

IThe table lists the nominal sectional areas and

allowable currents of the wires.

Nominal sec-

tional area

mm

2

No. of

strands/

strand diam-

eterOutside

diameter of

finished wir-

ing mmAllowable

current

Amps/40ÉC

0.3 7/0.26 1.8 7

0.5 7/0.32 2.2 (or 2.0) 12

0.75 30/0.18 2.6 (or 2.4) 16

0.85 11/0.32 2.4 (or 2.2) 16

1.25 16/0.32 2.7 (or 2.5) 21

2 26/0.32 3.1 (or 2.9) 28

3 41/0.32 3.8 (or 3.6) 38

5 65/0.32 4.6 (or 4.4) 51

8 50/0.45 5.5 67

CAUTION:

When replacing or repairing a wire, be sure to

use the same size and type of the wire which

was originally used.

NOTE:

IThe allowable current in the above table indi-

cates the tolerable amperage of each wire at an

ambient temperature of 40ÉC (104ÉF).IThe allowable current changes with ambient

temperature. Also, it changes if a bundle of more

than two wires is used.

IEach unit is directly grounded to the body or

indirectly grounds through a harness ground termi-

nal. Different symbols are used in the wiring dia-

gram to identify the two grounding systems.

G6M0203

IThe ground points shown in the wiring diagram

refer to the following:

NOTE:

All wiring harnesses are provided with a ground

point which should be securely connected.

B6M0747

IRelays are classified as normally-open or nor-

mally-closed.

The normally-closed relay has one or more con-

tacts. The wiring diagram shows the relay mode

when the energizing circuit is OFF.

4

6-3[D1A0]WIRING DIAGRAM

1. General Description