clock SUBARU LEGACY 1999 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 628 of 1456

15) Install rear sun gear.

NOTE:

Pay attention to the orientation of the rear sun

gear.

B3M1158A

16) Install thrust needle bearing to front planetary

carrier.

NOTE:

Pay attention to the orientation of the thrust needle

bearing.

B3M1174A

17) Install front planetary carrier to low clutch

drum.

B3M1157A

18) Install snap ring to low clutch drum.

B3M1156A

19) Install the needle bearing, and secure with the

snap ring.

B3M1164A

20) Install the one-way clutch, one-way clutch

inner race and plate, and secure with the snap ring.

NOTE:

Set the inner race. Make sure that the forward

clutch is free in the clockwise direction and locked

in the counterclockwise direction, as viewed from

the front of the vehicle.

B3M1175A

97

[W18C0]3-2SERVICE PROCEDURE

18. Low Clutch Drum and Planetary Gear

Page 711 of 1456

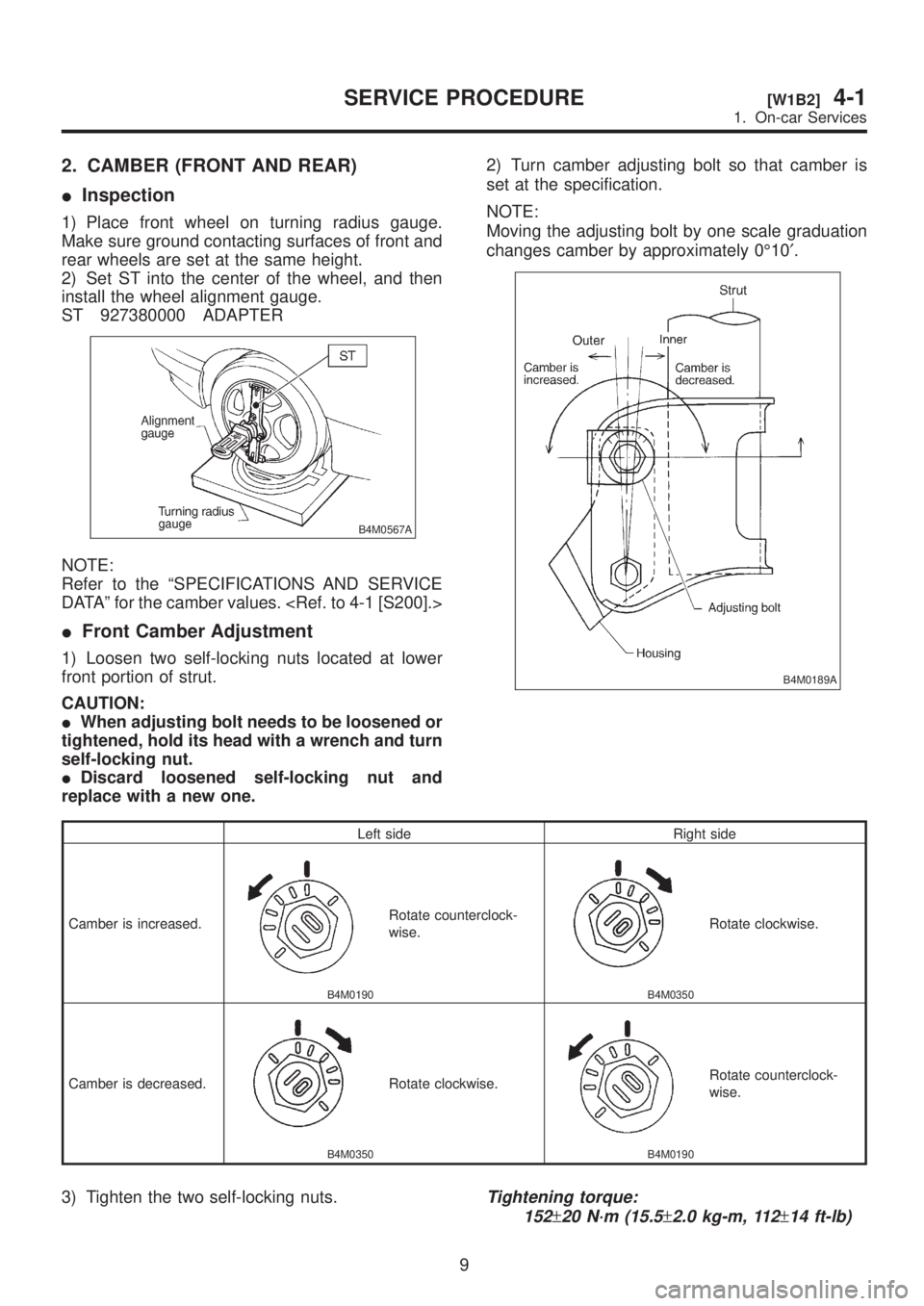

2. CAMBER (FRONT AND REAR)

IInspection

1) Place front wheel on turning radius gauge.

Make sure ground contacting surfaces of front and

rear wheels are set at the same height.

2) Set ST into the center of the wheel, and then

install the wheel alignment gauge.

ST 927380000 ADAPTER

B4M0567A

NOTE:

Refer to the ªSPECIFICATIONS AND SERVICE

DATAº for the camber values.

IFront Camber Adjustment

1) Loosen two self-locking nuts located at lower

front portion of strut.

CAUTION:

IWhen adjusting bolt needs to be loosened or

tightened, hold its head with a wrench and turn

self-locking nut.

IDiscard loosened self-locking nut and

replace with a new one.2) Turn camber adjusting bolt so that camber is

set at the specification.

NOTE:

Moving the adjusting bolt by one scale graduation

changes camber by approximately 0É10¢.

B4M0189A

Left side Right side

Camber is increased.

B4M0190

Rotate counterclock-

wise.

B4M0350

Rotate clockwise.

Camber is decreased.

B4M0350

Rotate clockwise.

B4M0190

Rotate counterclock-

wise.

3) Tighten the two self-locking nuts.Tightening torque:

152

±20 N´m (15.5±2.0 kg-m, 112±14 ft-lb)

9

[W1B2]4-1SERVICE PROCEDURE

1. On-car Services

Page 712 of 1456

3. CASTER (FRONT)

IInspection

1) Place front wheel on turning radius gauge.

Make sure ground contacting surfaces of front and

rear wheels are set at the same height.

2) Set ST into the center of the wheel, and then

install the wheel alignment gauge.

ST 927380000 ADAPTER

B4M0567A

NOTE:

Refer to the ªSPECIFICATIONS AND SERVICE

DATAº for the caster value.

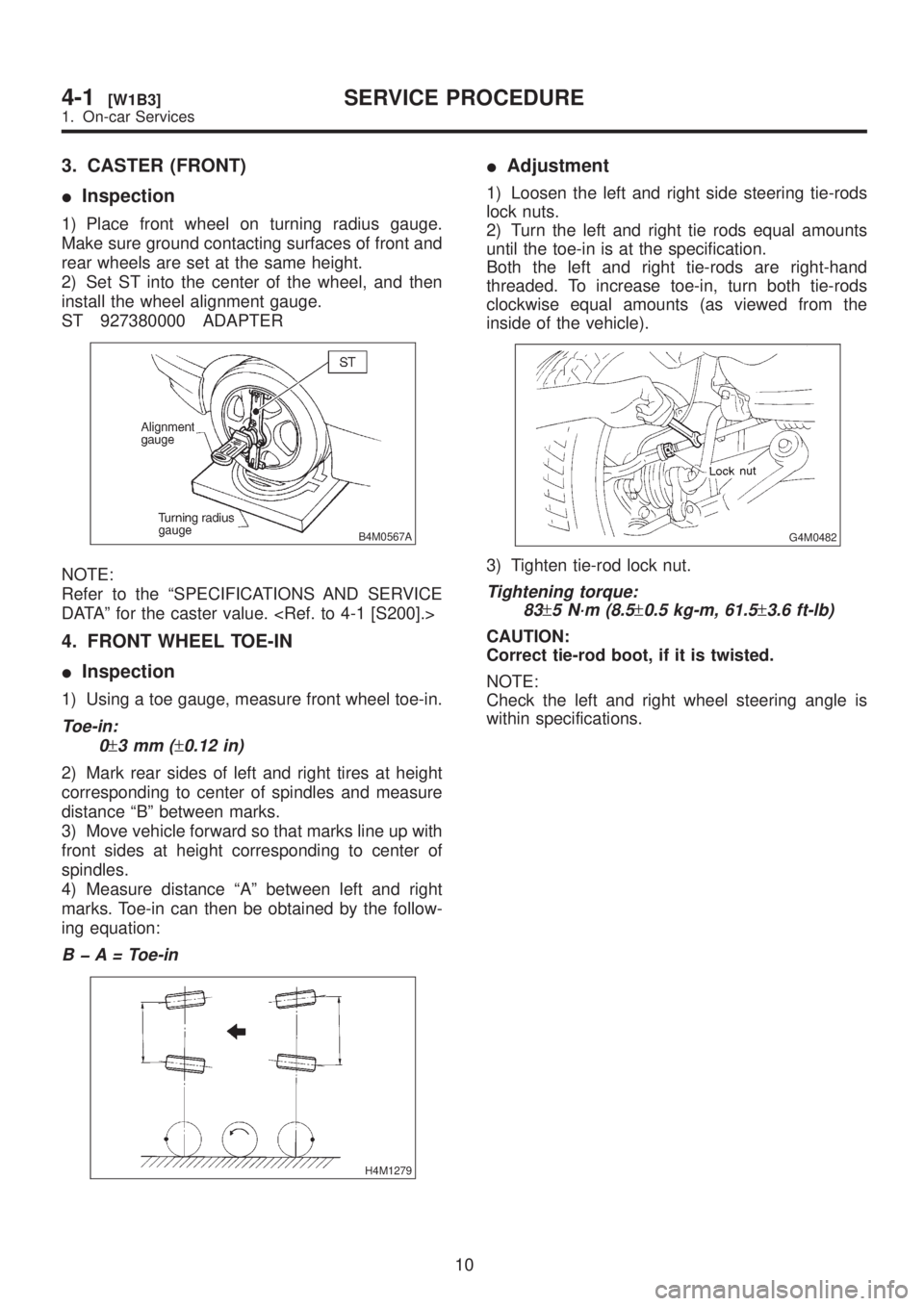

4. FRONT WHEEL TOE-IN

IInspection

1) Using a toe gauge, measure front wheel toe-in.

Toe-in:

0

±3mm(±0.12 in)

2) Mark rear sides of left and right tires at height

corresponding to center of spindles and measure

distance ªBº between marks.

3) Move vehicle forward so that marks line up with

front sides at height corresponding to center of

spindles.

4) Measure distance ªAº between left and right

marks. Toe-in can then be obtained by the follow-

ing equation:

B þ A = Toe-in

H4M1279

IAdjustment

1) Loosen the left and right side steering tie-rods

lock nuts.

2) Turn the left and right tie rods equal amounts

until the toe-in is at the specification.

Both the left and right tie-rods are right-hand

threaded. To increase toe-in, turn both tie-rods

clockwise equal amounts (as viewed from the

inside of the vehicle).

G4M0482

3) Tighten tie-rod lock nut.

Tightening torque:

83

±5 N´m (8.5±0.5 kg-m, 61.5±3.6 ft-lb)

CAUTION:

Correct tie-rod boot, if it is twisted.

NOTE:

Check the left and right wheel steering angle is

within specifications.

10

4-1[W1B3]SERVICE PROCEDURE

1. On-car Services

Page 713 of 1456

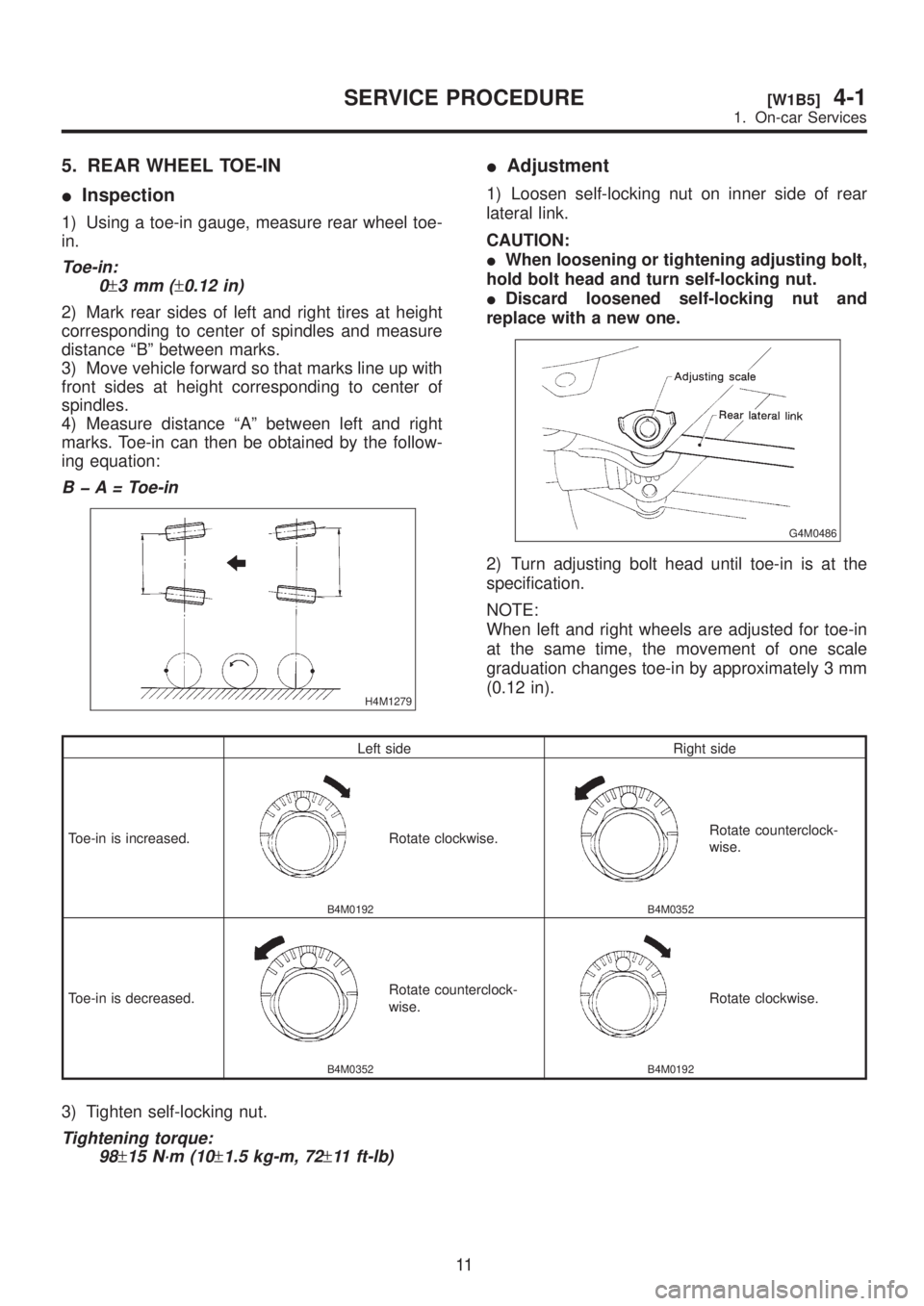

5. REAR WHEEL TOE-IN

IInspection

1) Using a toe-in gauge, measure rear wheel toe-

in.

Toe-in:

0

±3mm(±0.12 in)

2) Mark rear sides of left and right tires at height

corresponding to center of spindles and measure

distance ªBº between marks.

3) Move vehicle forward so that marks line up with

front sides at height corresponding to center of

spindles.

4) Measure distance ªAº between left and right

marks. Toe-in can then be obtained by the follow-

ing equation:

B þ A = Toe-in

H4M1279

IAdjustment

1) Loosen self-locking nut on inner side of rear

lateral link.

CAUTION:

IWhen loosening or tightening adjusting bolt,

hold bolt head and turn self-locking nut.

IDiscard loosened self-locking nut and

replace with a new one.

G4M0486

2) Turn adjusting bolt head until toe-in is at the

specification.

NOTE:

When left and right wheels are adjusted for toe-in

at the same time, the movement of one scale

graduation changes toe-in by approximately 3 mm

(0.12 in).

Left side Right side

Toe-in is increased.

B4M0192

Rotate clockwise.

B4M0352

Rotate counterclock-

wise.

Toe-in is decreased.

B4M0352

Rotate counterclock-

wise.

B4M0192

Rotate clockwise.

3) Tighten self-locking nut.

Tightening torque:

98

±15 N´m (10±1.5 kg-m, 72±11 ft-lb)

11

[W1B5]4-1SERVICE PROCEDURE

1. On-car Services

Page 793 of 1456

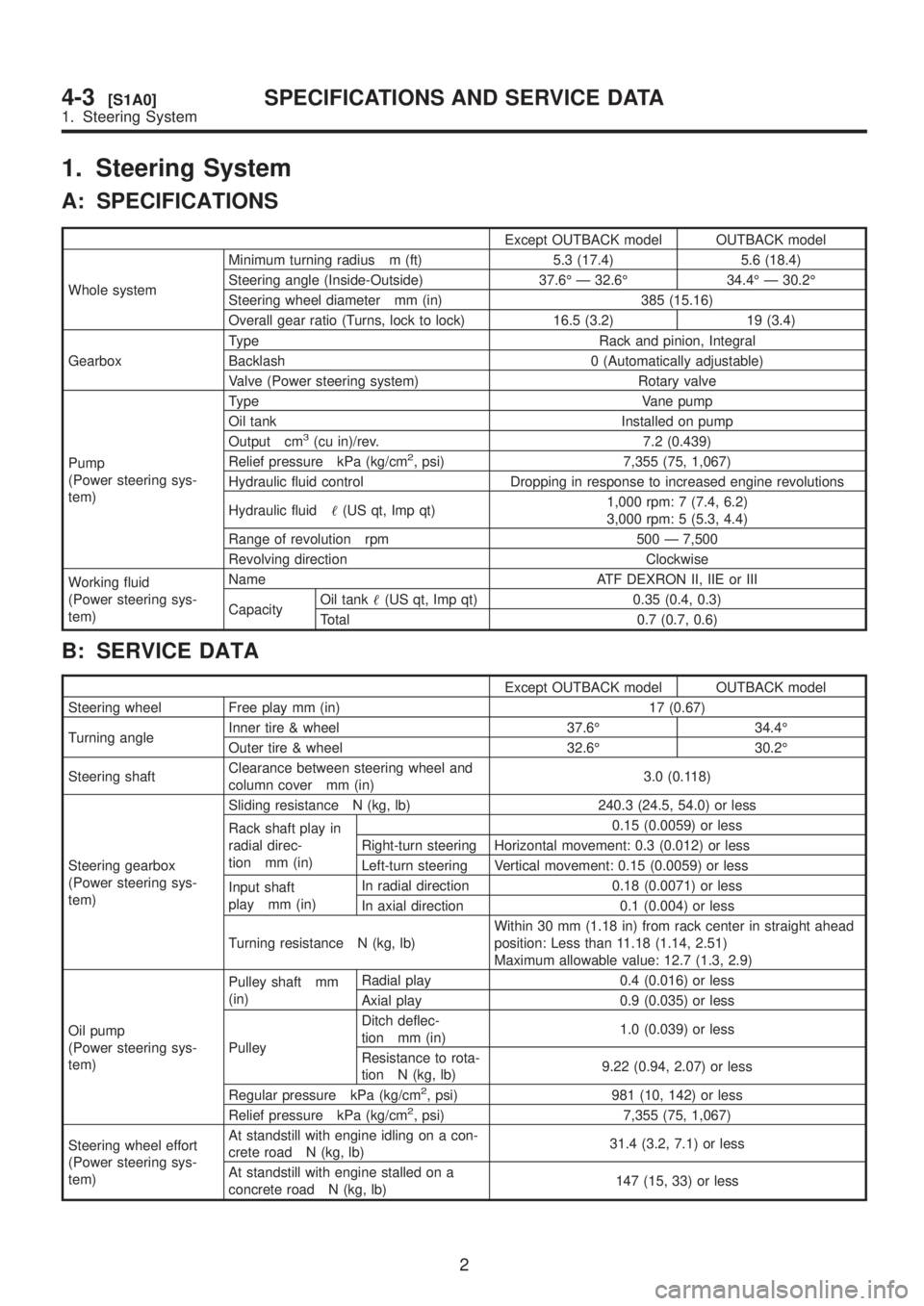

1. Steering System

A: SPECIFICATIONS

Except OUTBACK model OUTBACK model

Whole systemMinimum turning radius m (ft) 5.3 (17.4) 5.6 (18.4)

Steering angle (Inside-Outside) 37.6É Ð 32.6É 34.4É Ð 30.2É

Steering wheel diameter mm (in) 385 (15.16)

Overall gear ratio (Turns, lock to lock) 16.5 (3.2) 19 (3.4)

GearboxType Rack and pinion, Integral

Backlash 0 (Automatically adjustable)

Valve (Power steering system) Rotary valve

Pump

(Power steering sys-

tem)Type Vane pump

Oil tank Installed on pump

Output cm

3(cu in)/rev. 7.2 (0.439)

Relief pressure kPa (kg/cm2, psi) 7,355 (75, 1,067)

Hydraulic fluid control Dropping in response to increased engine revolutions

Hydraulic fluid(US qt, Imp qt)1,000 rpm: 7 (7.4, 6.2)

3,000 rpm: 5 (5.3, 4.4)

Range of revolution rpm 500 Ð 7,500

Revolving direction Clockwise

Working fluid

(Power steering sys-

tem)Name ATF DEXRON II, IIE or III

CapacityOil tank(US qt, Imp qt) 0.35 (0.4, 0.3)

Total 0.7 (0.7, 0.6)

B: SERVICE DATA

Except OUTBACK model OUTBACK model

Steering wheel Free play mm (in) 17 (0.67)

Turning angleInner tire & wheel 37.6É 34.4É

Outer tire & wheel 32.6É 30.2É

Steering shaftClearance between steering wheel and

column cover mm (in)3.0 (0.118)

Steering gearbox

(Power steering sys-

tem)Sliding resistance N (kg, lb) 240.3 (24.5, 54.0) or less

Rack shaft play in

radial direc-

tion mm (in)0.15 (0.0059) or less

Right-turn steering Horizontal movement: 0.3 (0.012) or less

Left-turn steering Vertical movement: 0.15 (0.0059) or less

Input shaft

play mm (in)In radial direction 0.18 (0.0071) or less

In axial direction 0.1 (0.004) or less

Turning resistance N (kg, lb)Within 30 mm (1.18 in) from rack center in straight ahead

position: Less than 11.18 (1.14, 2.51)

Maximum allowable value: 12.7 (1.3, 2.9)

Oil pump

(Power steering sys-

tem)Pulley shaft mm

(in)Radial play 0.4 (0.016) or less

Axial play 0.9 (0.035) or less

PulleyDitch deflec-

tion mm (in)1.0 (0.039) or less

Resistance to rota-

tion N (kg, lb)9.22 (0.94, 2.07) or less

Regular pressure kPa (kg/cm

2, psi) 981 (10, 142) or less

Relief pressure kPa (kg/cm2, psi) 7,355 (75, 1,067)

Steering wheel effort

(Power steering sys-

tem)At standstill with engine idling on a con-

crete road N (kg, lb)31.4 (3.2, 7.1) or less

At standstill with engine stalled on a

concrete road N (kg, lb)147 (15, 33) or less

2

4-3[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Steering System

Page 807 of 1456

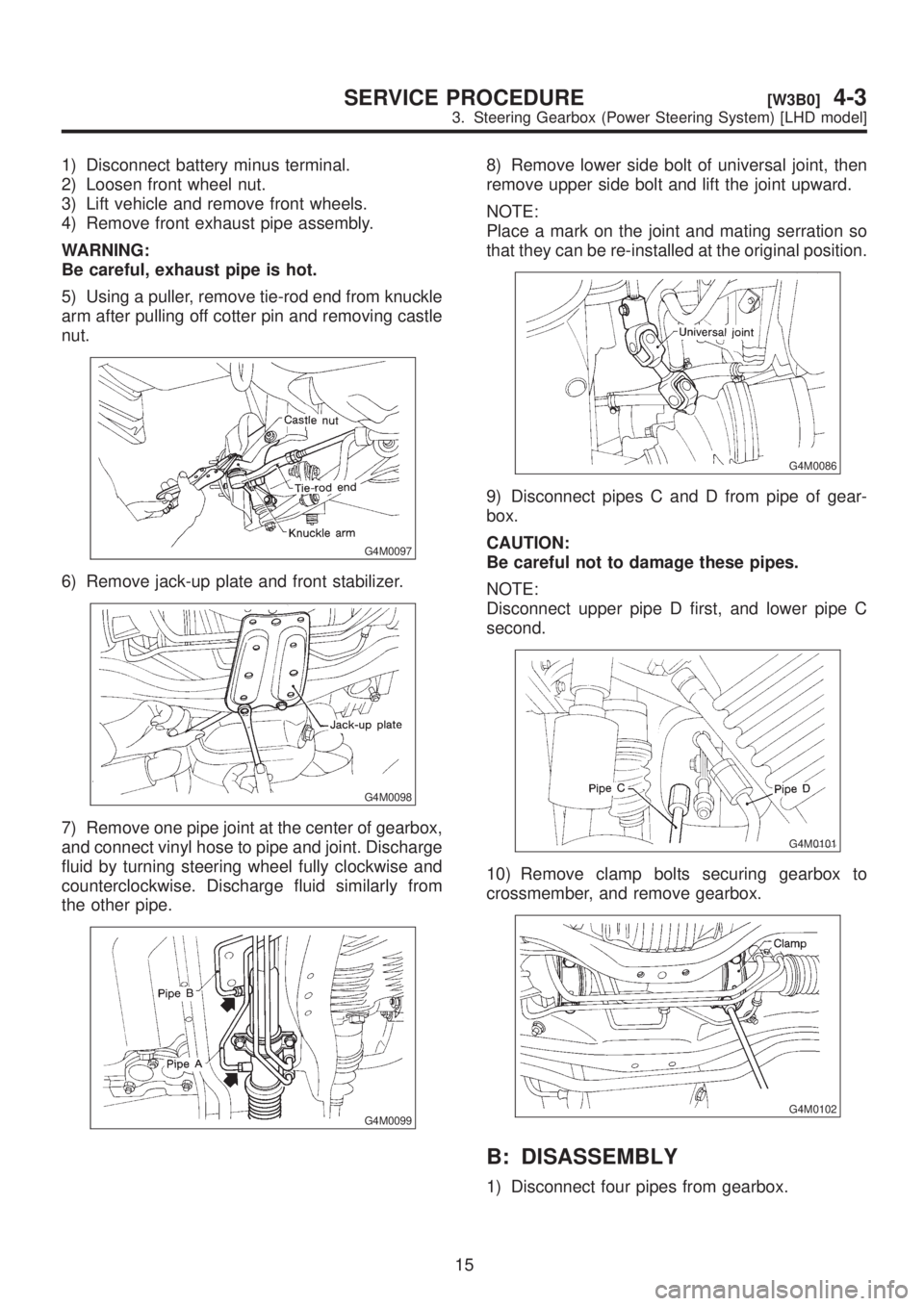

1) Disconnect battery minus terminal.

2) Loosen front wheel nut.

3) Lift vehicle and remove front wheels.

4) Remove front exhaust pipe assembly.

WARNING:

Be careful, exhaust pipe is hot.

5) Using a puller, remove tie-rod end from knuckle

arm after pulling off cotter pin and removing castle

nut.

G4M0097

6) Remove jack-up plate and front stabilizer.

G4M0098

7) Remove one pipe joint at the center of gearbox,

and connect vinyl hose to pipe and joint. Discharge

fluid by turning steering wheel fully clockwise and

counterclockwise. Discharge fluid similarly from

the other pipe.

G4M0099

8) Remove lower side bolt of universal joint, then

remove upper side bolt and lift the joint upward.

NOTE:

Place a mark on the joint and mating serration so

that they can be re-installed at the original position.

G4M0086

9) Disconnect pipes C and D from pipe of gear-

box.

CAUTION:

Be careful not to damage these pipes.

NOTE:

Disconnect upper pipe D first, and lower pipe C

second.

G4M0101

10) Remove clamp bolts securing gearbox to

crossmember, and remove gearbox.

G4M0102

B: DISASSEMBLY

1) Disconnect four pipes from gearbox.

15

[W3B0]4-3SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 844 of 1456

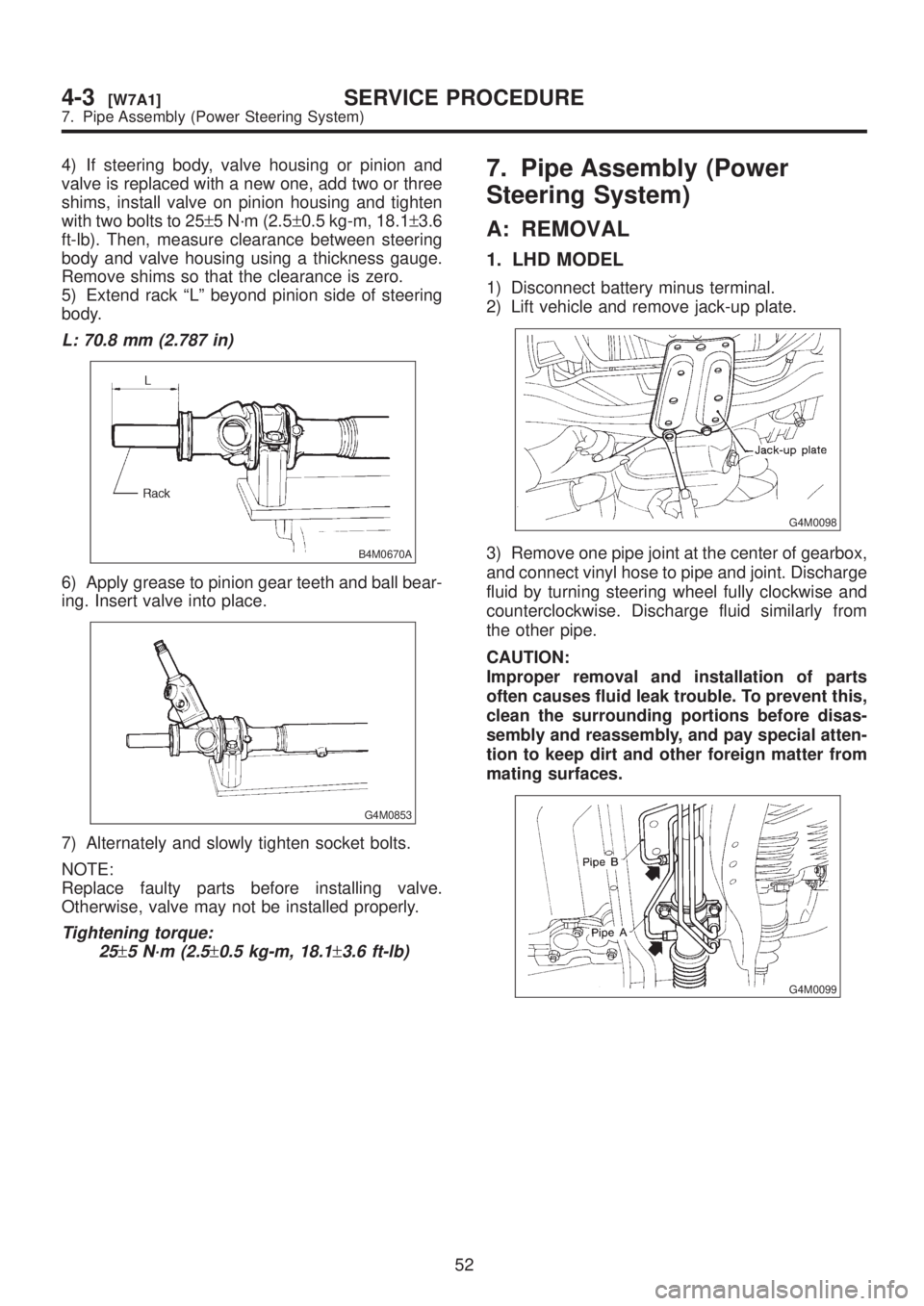

4) If steering body, valve housing or pinion and

valve is replaced with a new one, add two or three

shims, install valve on pinion housing and tighten

with two bolts to 25±5 N´m (2.5±0.5 kg-m, 18.1±3.6

ft-lb). Then, measure clearance between steering

body and valve housing using a thickness gauge.

Remove shims so that the clearance is zero.

5) Extend rack ªLº beyond pinion side of steering

body.

L: 70.8 mm (2.787 in)

B4M0670A

6) Apply grease to pinion gear teeth and ball bear-

ing. Insert valve into place.

G4M0853

7) Alternately and slowly tighten socket bolts.

NOTE:

Replace faulty parts before installing valve.

Otherwise, valve may not be installed properly.

Tightening torque:

25

±5 N´m (2.5±0.5 kg-m, 18.1±3.6 ft-lb)

7. Pipe Assembly (Power

Steering System)

A: REMOVAL

1. LHD MODEL

1) Disconnect battery minus terminal.

2) Lift vehicle and remove jack-up plate.

G4M0098

3) Remove one pipe joint at the center of gearbox,

and connect vinyl hose to pipe and joint. Discharge

fluid by turning steering wheel fully clockwise and

counterclockwise. Discharge fluid similarly from

the other pipe.

CAUTION:

Improper removal and installation of parts

often causes fluid leak trouble. To prevent this,

clean the surrounding portions before disas-

sembly and reassembly, and pay special atten-

tion to keep dirt and other foreign matter from

mating surfaces.

G4M0099

52

4-3[W7A1]SERVICE PROCEDURE

7. Pipe Assembly (Power Steering System)

Page 845 of 1456

4) If steering body, valve housing or pinion and

valve is replaced with a new one, add two or three

shims, install valve on pinion housing and tighten

with two bolts to 25±5 N´m (2.5±0.5 kg-m, 18.1±3.6

ft-lb). Then, measure clearance between steering

body and valve housing using a thickness gauge.

Remove shims so that the clearance is zero.

5) Extend rack ªLº beyond pinion side of steering

body.

L: 70.8 mm (2.787 in)

B4M0670A

6) Apply grease to pinion gear teeth and ball bear-

ing. Insert valve into place.

G4M0853

7) Alternately and slowly tighten socket bolts.

NOTE:

Replace faulty parts before installing valve.

Otherwise, valve may not be installed properly.

Tightening torque:

25

±5 N´m (2.5±0.5 kg-m, 18.1±3.6 ft-lb)

7. Pipe Assembly (Power

Steering System)

A: REMOVAL

1. LHD MODEL

1) Disconnect battery minus terminal.

2) Lift vehicle and remove jack-up plate.

G4M0098

3) Remove one pipe joint at the center of gearbox,

and connect vinyl hose to pipe and joint. Discharge

fluid by turning steering wheel fully clockwise and

counterclockwise. Discharge fluid similarly from

the other pipe.

CAUTION:

Improper removal and installation of parts

often causes fluid leak trouble. To prevent this,

clean the surrounding portions before disas-

sembly and reassembly, and pay special atten-

tion to keep dirt and other foreign matter from

mating surfaces.

G4M0099

52

4-3[W7A1]SERVICE PROCEDURE

7. Pipe Assembly (Power Steering System)

Page 847 of 1456

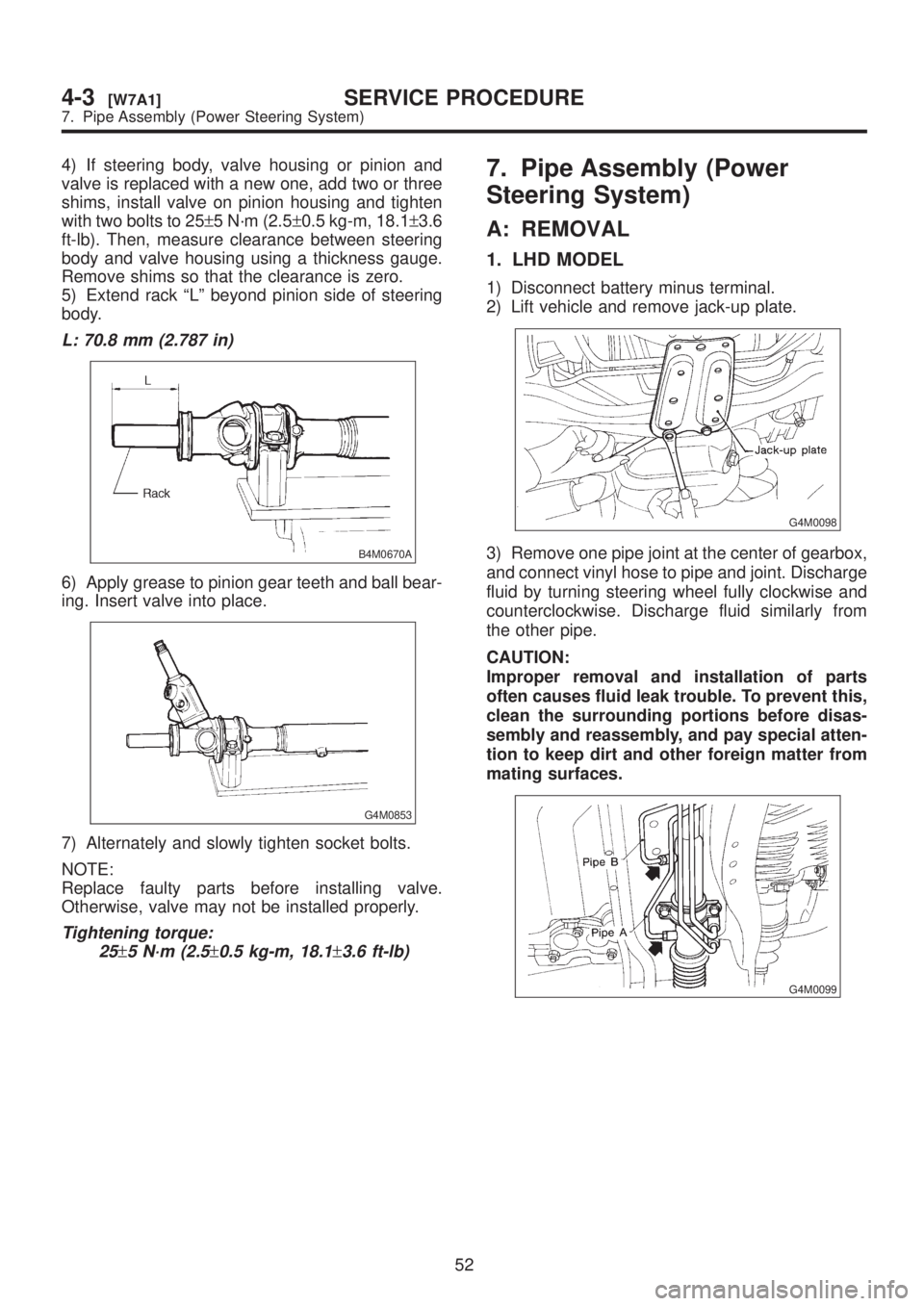

3) Remove one pipe joint at the center of gearbox,

and connect vinyl hose to pipe and joint. Discharge

fluid by turning steering wheel fully clockwise and

counterclockwise. Discharge fluid similarly from

the other pipe.

CAUTION:

Improper removal and installation of parts

often causes fluid leak trouble. To prevent this,

clean the surrounding portions before disas-

sembly and reassembly, and pay special atten-

tion to keep dirt and other foreign matter from

mating surfaces.

B4M0671A

4) Remove clamp E from pipes C and D.

B4M0672A

5) Remove flare nuts from control valve of gear-

box assembly, and then disconnect pipe C´D.

CAUTION:

IWhen disconnecting pipe C´D, use two

wrenches to prevent deformities.

IBe careful to keep pipe connections free

from foreign matter.6) Remove bolt A.

Disconnect pipe C from oil pump. Disconnect pipe

D from oil tank.

CAUTION:

IDo not allow fluid from the hose end to come

into contact with pulley belt.

ITo prevent foreign matter from entering the

hose and pipe, cover the open ends of them

with a clean cloth.

B4M1159A

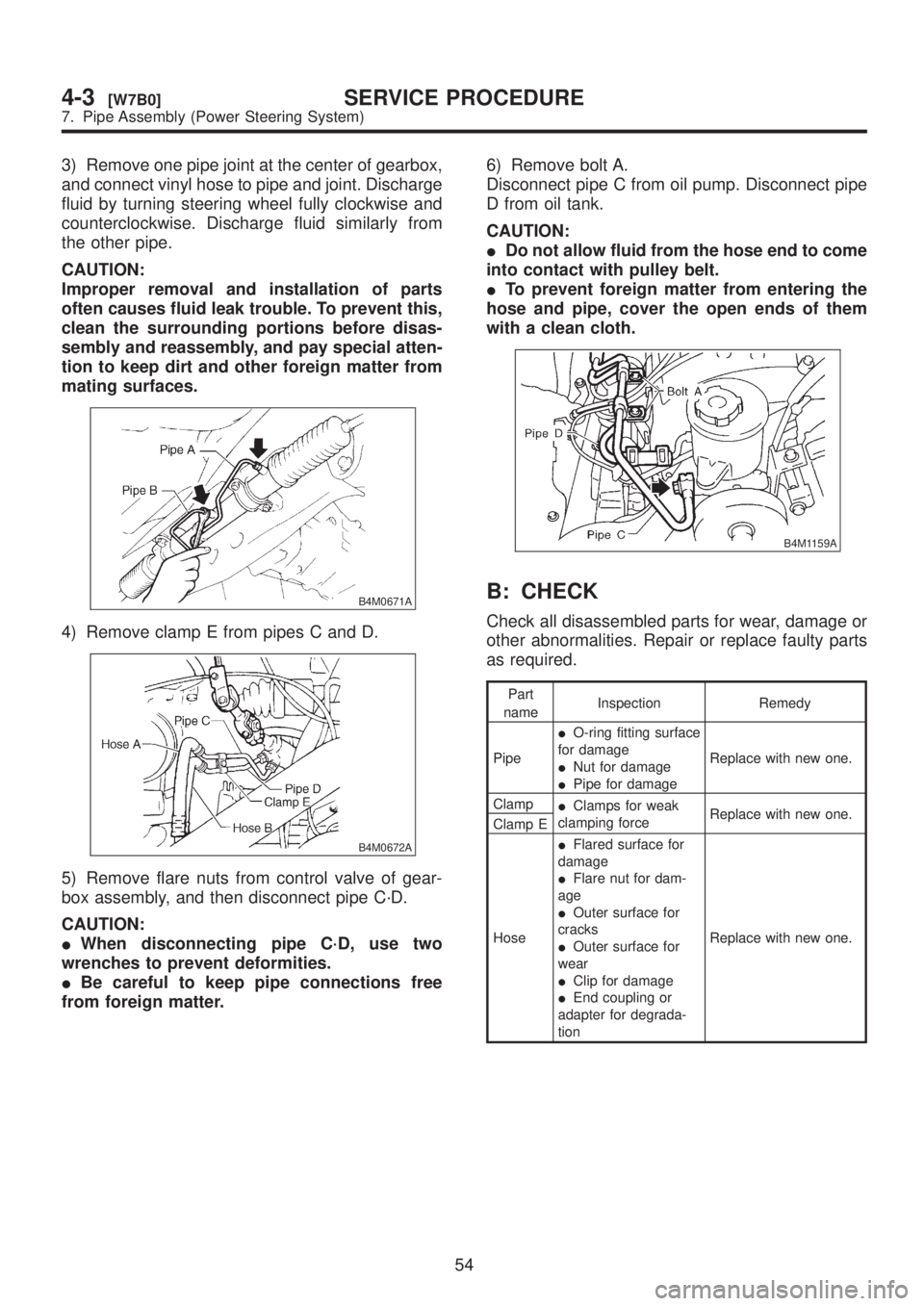

B: CHECK

Check all disassembled parts for wear, damage or

other abnormalities. Repair or replace faulty parts

as required.

Part

nameInspection Remedy

PipeIO-ring fitting surface

for damage

INut for damage

IPipe for damageReplace with new one.

Clamp

IClamps for weak

clamping forceReplace with new one.

Clamp E

HoseIFlared surface for

damage

IFlare nut for dam-

age

IOuter surface for

cracks

IOuter surface for

wear

IClip for damage

IEnd coupling or

adapter for degrada-

tionReplace with new one.

54

4-3[W7B0]SERVICE PROCEDURE

7. Pipe Assembly (Power Steering System)

Page 953 of 1456

B: REMOVAL

1. ACCELERATOR PEDAL

1) Disconnect ground cable from battery.

2) Disconnect accelerator cable from throttle body.

CAUTION:

Be careful not to kink accelerator cable.

3) Remove instrument panel lower cover from

instrument panel, and connector.

4) Disconnect accelerator cable from accelerator

pedal lever.

G4M0322

5) Working inside engine compartment, remove

casing cap out of the toe board by turning it clock-

wise.

G4M0335

6) Pull out the cable from the toe board hole.

7) Remove accelerator pedal connecting bolt from

accelerator pedal bracket.

G4M0321

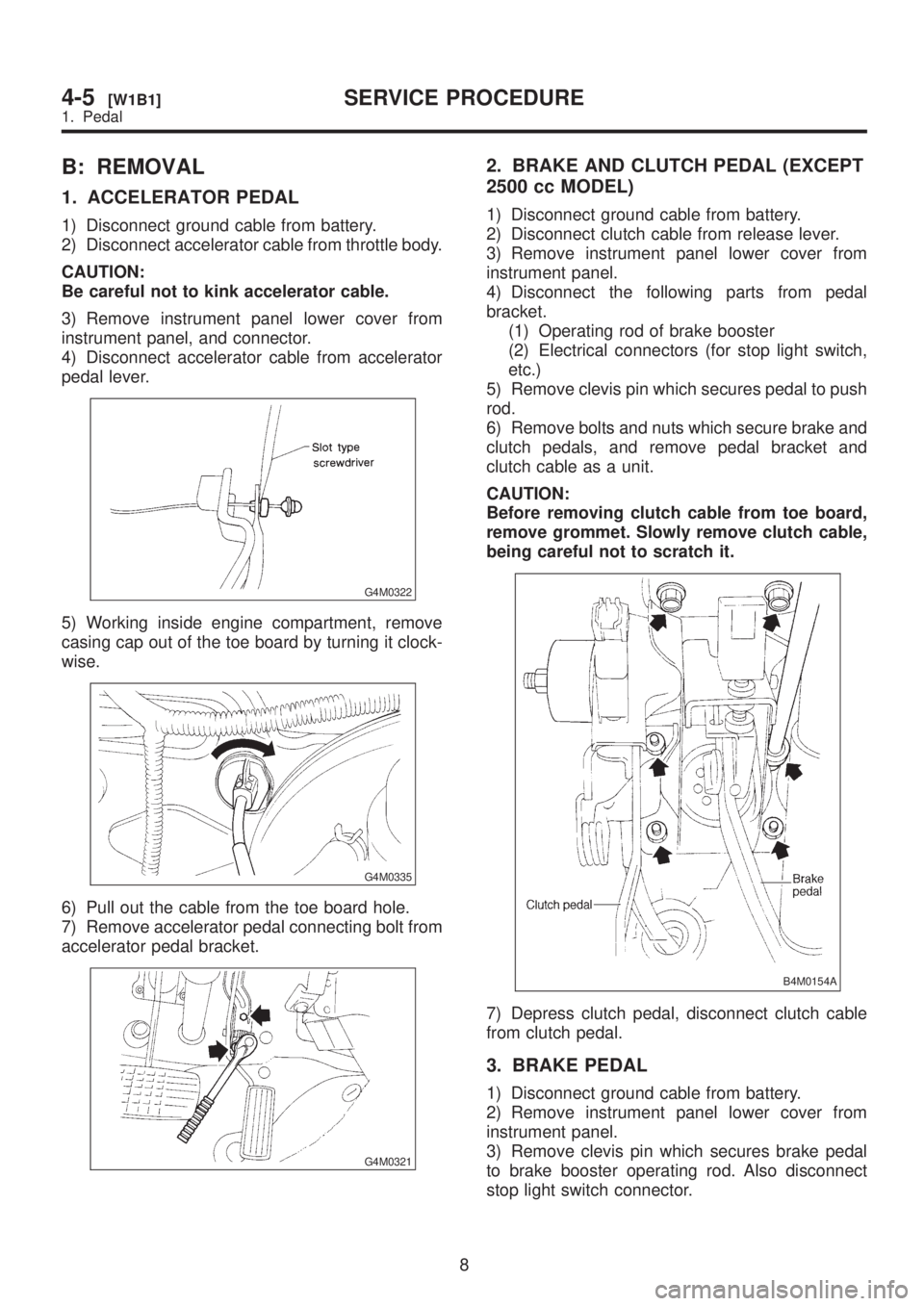

2. BRAKE AND CLUTCH PEDAL (EXCEPT

2500 cc MODEL)

1) Disconnect ground cable from battery.

2) Disconnect clutch cable from release lever.

3) Remove instrument panel lower cover from

instrument panel.

4) Disconnect the following parts from pedal

bracket.

(1) Operating rod of brake booster

(2) Electrical connectors (for stop light switch,

etc.)

5) Remove clevis pin which secures pedal to push

rod.

6) Remove bolts and nuts which secure brake and

clutch pedals, and remove pedal bracket and

clutch cable as a unit.

CAUTION:

Before removing clutch cable from toe board,

remove grommet. Slowly remove clutch cable,

being careful not to scratch it.

B4M0154A

7) Depress clutch pedal, disconnect clutch cable

from clutch pedal.

3. BRAKE PEDAL

1) Disconnect ground cable from battery.

2) Remove instrument panel lower cover from

instrument panel.

3) Remove clevis pin which secures brake pedal

to brake booster operating rod. Also disconnect

stop light switch connector.

8

4-5[W1B1]SERVICE PROCEDURE

1. Pedal