door lock SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 733 of 1456

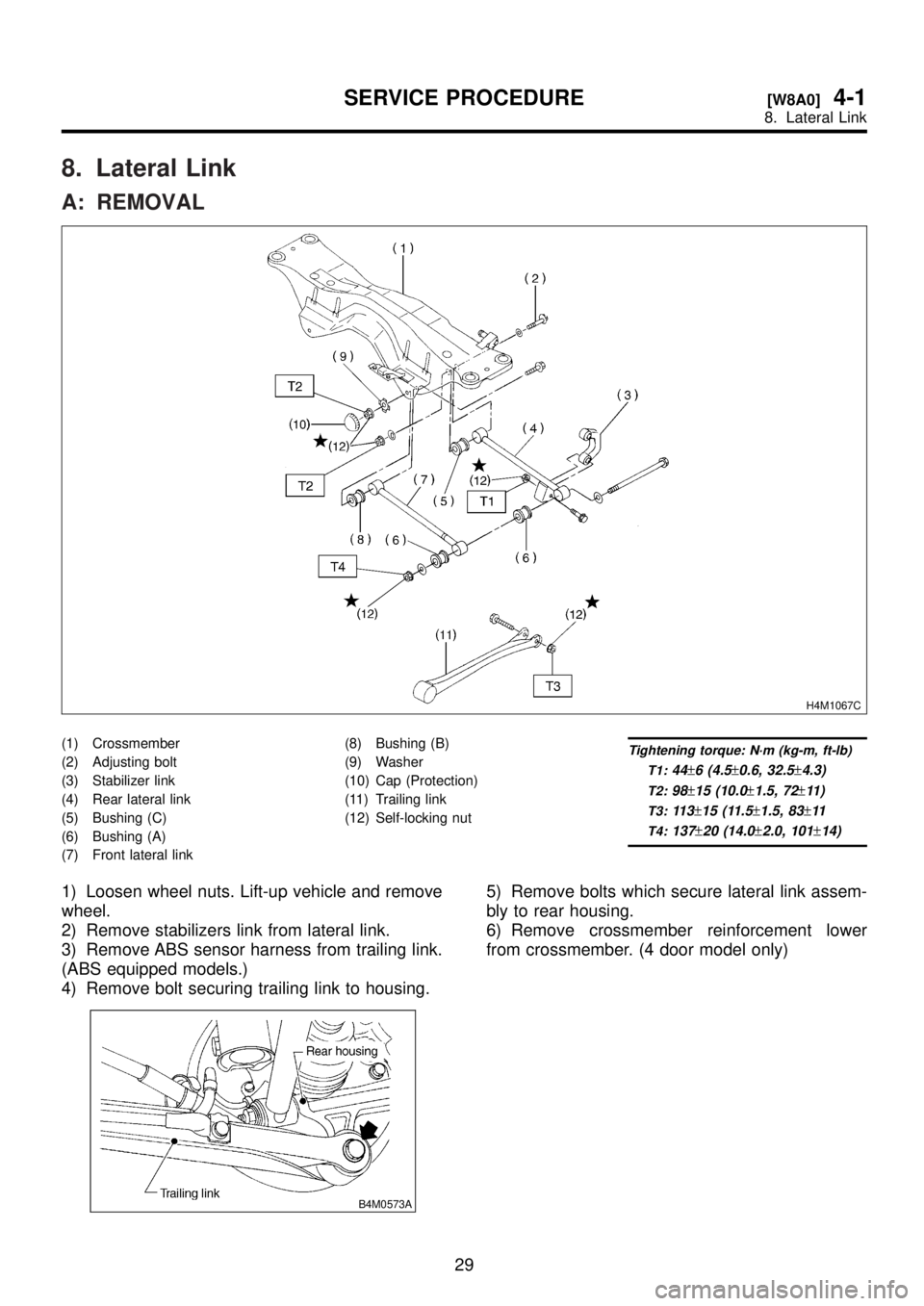

8. Lateral Link

A: REMOVAL

H4M1067C

(1) Crossmember

(2) Adjusting bolt

(3) Stabilizer link

(4) Rear lateral link

(5) Bushing (C)

(6) Bushing (A)

(7) Front lateral link(8) Bushing (B)

(9) Washer

(10) Cap (Protection)

(11) Trailing link

(12) Self-locking nutTightening torque: N´m (kg-m, ft-lb)

T1:

44±6 (4.5±0.6, 32.5±4.3)

T2:98±15 (10.0±1.5, 72±11 )

T3:11 3±15 (11.5±1.5, 83±11

T4:137±20 (14.0±2.0, 101±14)

1) Loosen wheel nuts. Lift-up vehicle and remove

wheel.

2) Remove stabilizers link from lateral link.

3) Remove ABS sensor harness from trailing link.

(ABS equipped models.)

4) Remove bolt securing trailing link to housing.

B4M0573A

5) Remove bolts which secure lateral link assem-

bly to rear housing.

6) Remove crossmember reinforcement lower

from crossmember. (4 door model only)

29

[W8A0]4-1SERVICE PROCEDURE

8. Lateral Link

Page 768 of 1456

3. Front and Rear Drive Shafts

A: REMOVAL

1. FRONT DRIVE SHAFT

1) Disconnect ground cable from battery.

2) Jack-up vehicle, support it with safety stands

(rigid racks), and remove front wheel cap and

wheels.

3) Unlock axle nut.

4) While depressing brake pedal, remove axle nut

using a socket wrench.

CAUTION:

Be sure to loosen and retighten axle nut after

removing wheel from vehicle. Failure to follow

this rule may damage wheel bearings.

5) Disconnect stabilizer link from transverse link.

6) Disconnect transverse link from housing.

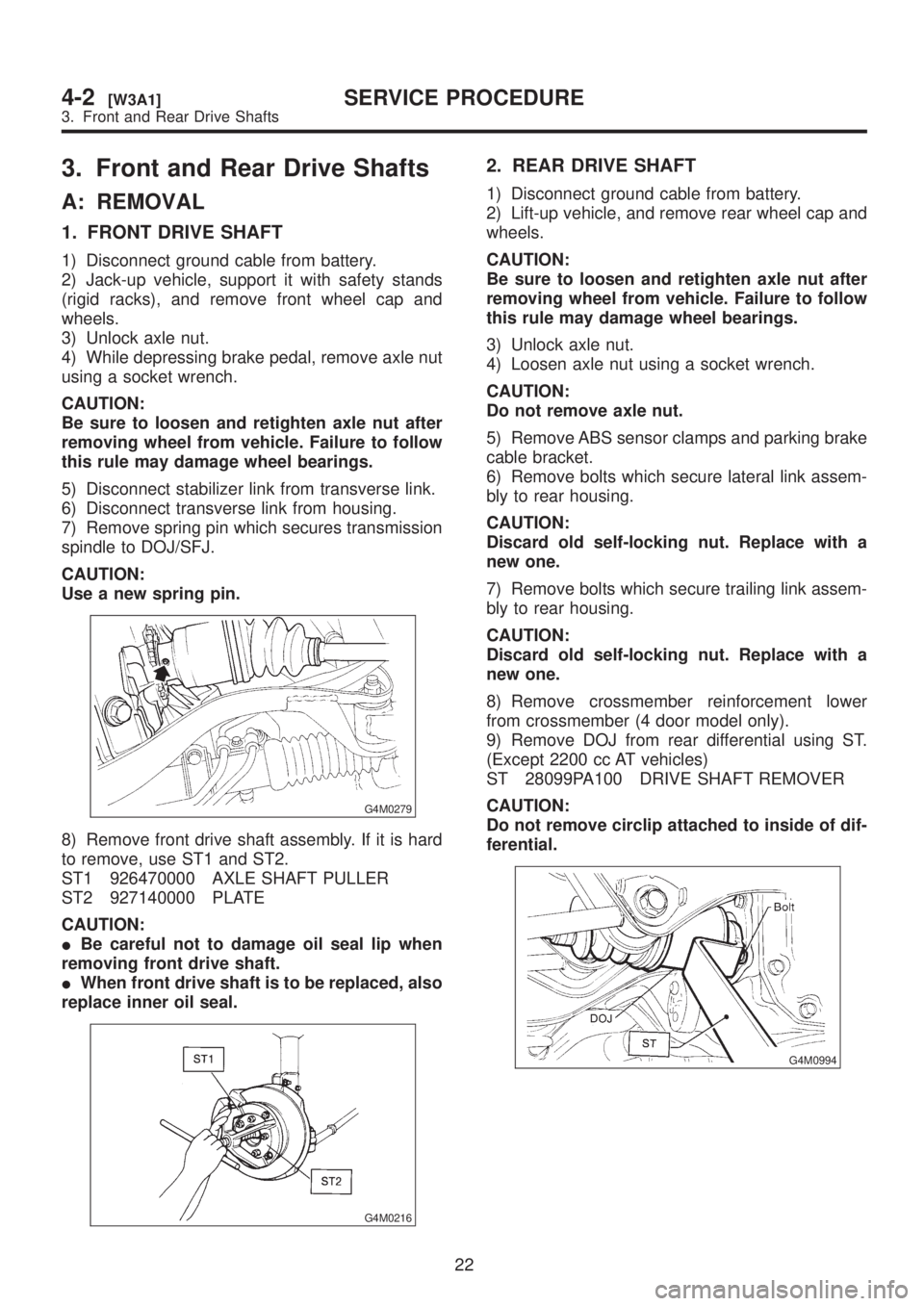

7) Remove spring pin which secures transmission

spindle to DOJ/SFJ.

CAUTION:

Use a new spring pin.

G4M0279

8) Remove front drive shaft assembly. If it is hard

to remove, use ST1 and ST2.

ST1 926470000 AXLE SHAFT PULLER

ST2 927140000 PLATE

CAUTION:

IBe careful not to damage oil seal lip when

removing front drive shaft.

IWhen front drive shaft is to be replaced, also

replace inner oil seal.

G4M0216

2. REAR DRIVE SHAFT

1) Disconnect ground cable from battery.

2) Lift-up vehicle, and remove rear wheel cap and

wheels.

CAUTION:

Be sure to loosen and retighten axle nut after

removing wheel from vehicle. Failure to follow

this rule may damage wheel bearings.

3) Unlock axle nut.

4) Loosen axle nut using a socket wrench.

CAUTION:

Do not remove axle nut.

5) Remove ABS sensor clamps and parking brake

cable bracket.

6) Remove bolts which secure lateral link assem-

bly to rear housing.

CAUTION:

Discard old self-locking nut. Replace with a

new one.

7) Remove bolts which secure trailing link assem-

bly to rear housing.

CAUTION:

Discard old self-locking nut. Replace with a

new one.

8) Remove crossmember reinforcement lower

from crossmember (4 door model only).

9) Remove DOJ from rear differential using ST.

(Except 2200 cc AT vehicles)

ST 28099PA100 DRIVE SHAFT REMOVER

CAUTION:

Do not remove circlip attached to inside of dif-

ferential.

G4M0994

22

4-2[W3A1]SERVICE PROCEDURE

3. Front and Rear Drive Shafts

Page 781 of 1456

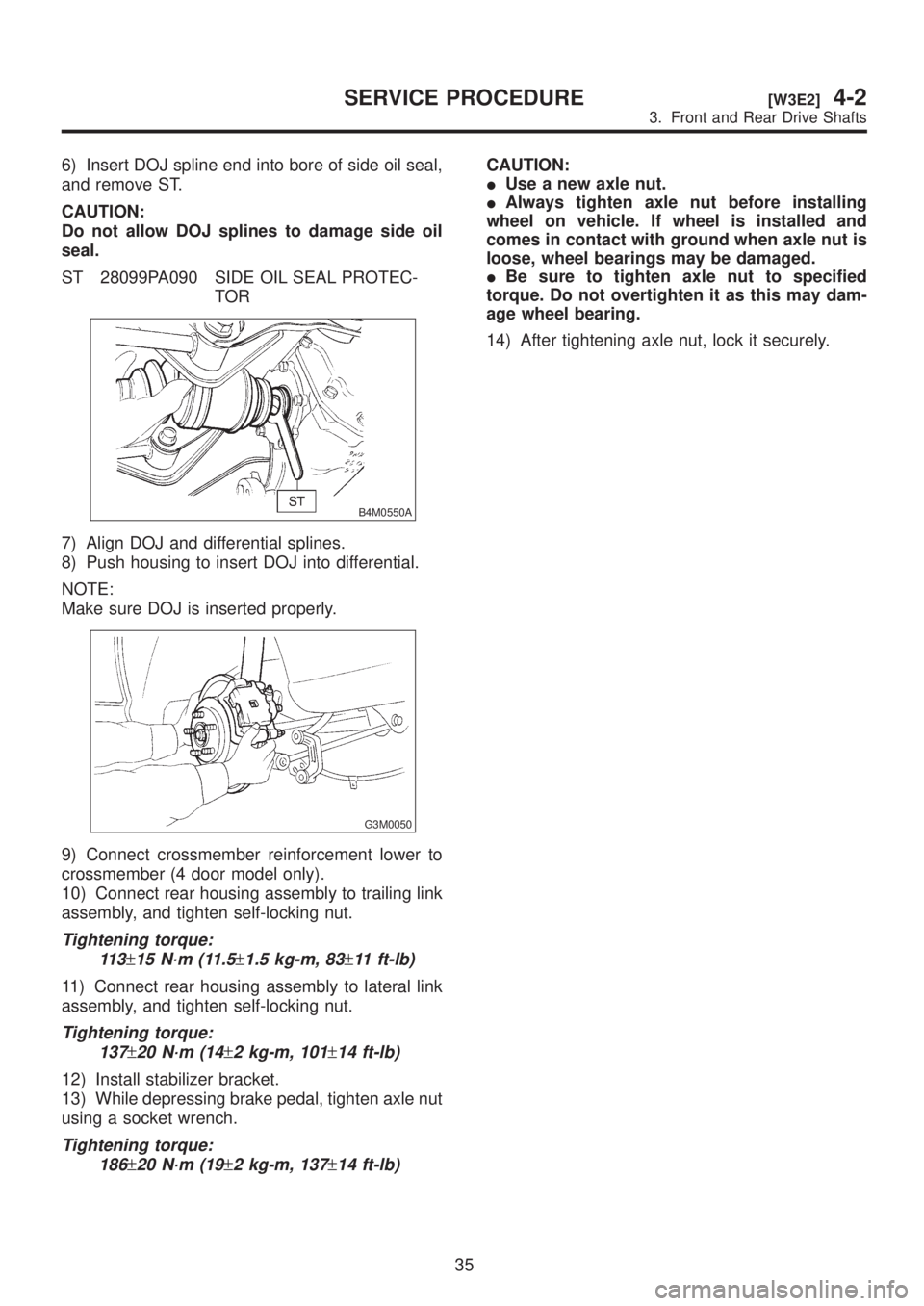

6) Insert DOJ spline end into bore of side oil seal,

and remove ST.

CAUTION:

Do not allow DOJ splines to damage side oil

seal.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

B4M0550A

7) Align DOJ and differential splines.

8) Push housing to insert DOJ into differential.

NOTE:

Make sure DOJ is inserted properly.

G3M0050

9) Connect crossmember reinforcement lower to

crossmember (4 door model only).

10) Connect rear housing assembly to trailing link

assembly, and tighten self-locking nut.

Tightening torque:

11 3

±15 N´m (11.5±1.5 kg-m, 83±11 ft-lb)

11) Connect rear housing assembly to lateral link

assembly, and tighten self-locking nut.

Tightening torque:

137

±20 N´m (14±2 kg-m, 101±14 ft-lb)

12) Install stabilizer bracket.

13) While depressing brake pedal, tighten axle nut

using a socket wrench.

Tightening torque:

186

±20 N´m (19±2 kg-m, 137±14 ft-lb)

CAUTION:

IUse a new axle nut.

IAlways tighten axle nut before installing

wheel on vehicle. If wheel is installed and

comes in contact with ground when axle nut is

loose, wheel bearings may be damaged.

IBe sure to tighten axle nut to specified

torque. Do not overtighten it as this may dam-

age wheel bearing.

14) After tightening axle nut, lock it securely.

35

[W3E2]4-2SERVICE PROCEDURE

3. Front and Rear Drive Shafts

Page 785 of 1456

assembly, and tighten self-locking nut.

9) Connect stabilizer link to lateral link.

10) Install crossmember reinforcement lower to

crossmember (4 door model only).

11) Install ABS sensor clamps and parking brake

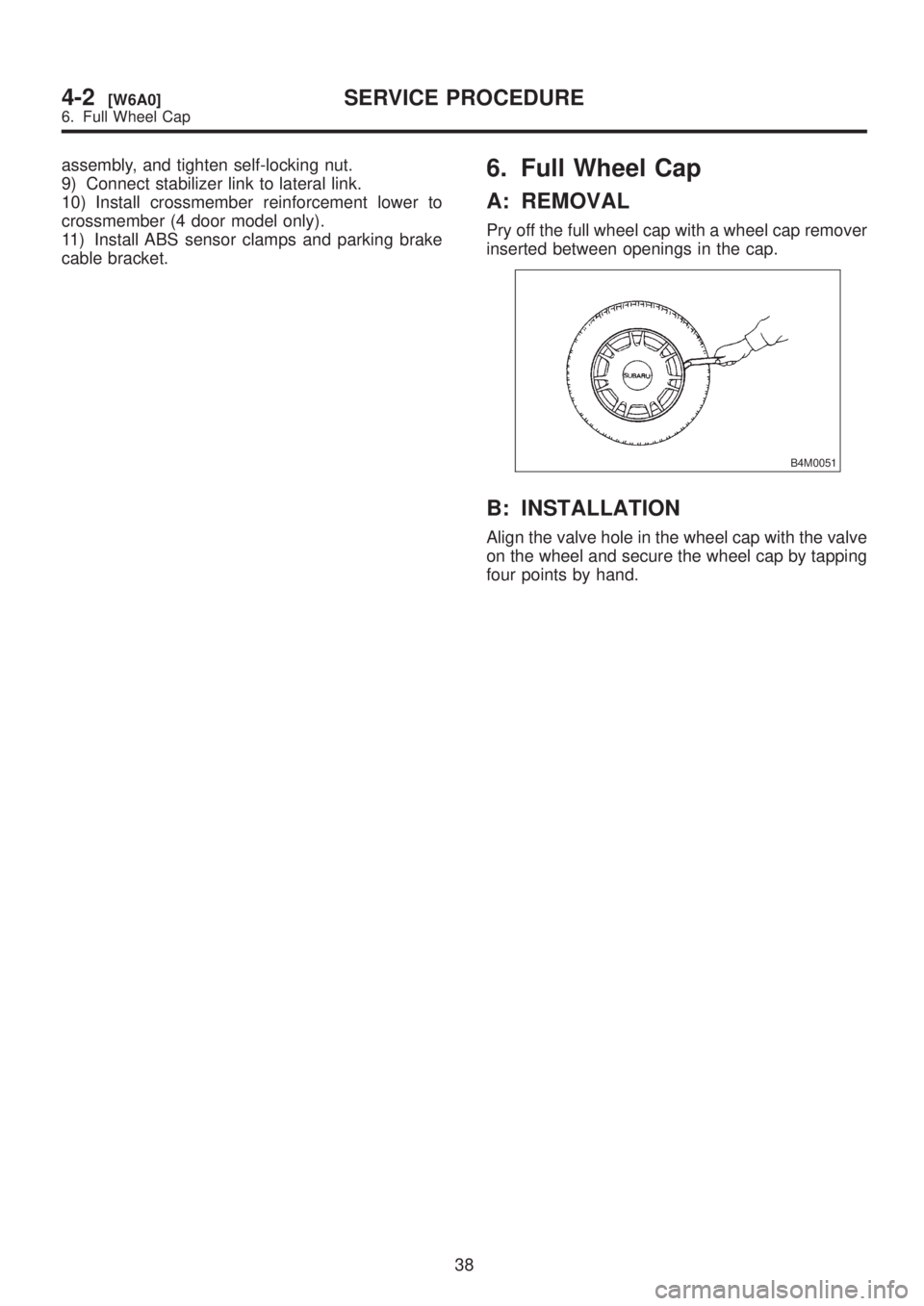

cable bracket.6. Full Wheel Cap

A: REMOVAL

Pry off the full wheel cap with a wheel cap remover

inserted between openings in the cap.

B4M0051

B: INSTALLATION

Align the valve hole in the wheel cap with the valve

on the wheel and secure the wheel cap by tapping

four points by hand.

38

4-2[W6A0]SERVICE PROCEDURE

6. Full Wheel Cap

Page 786 of 1456

assembly, and tighten self-locking nut.

9) Connect stabilizer link to lateral link.

10) Install crossmember reinforcement lower to

crossmember (4 door model only).

11) Install ABS sensor clamps and parking brake

cable bracket.6. Full Wheel Cap

A: REMOVAL

Pry off the full wheel cap with a wheel cap remover

inserted between openings in the cap.

B4M0051

B: INSTALLATION

Align the valve hole in the wheel cap with the valve

on the wheel and secure the wheel cap by tapping

four points by hand.

38

4-2[W6A0]SERVICE PROCEDURE

6. Full Wheel Cap

Page 1107 of 1456

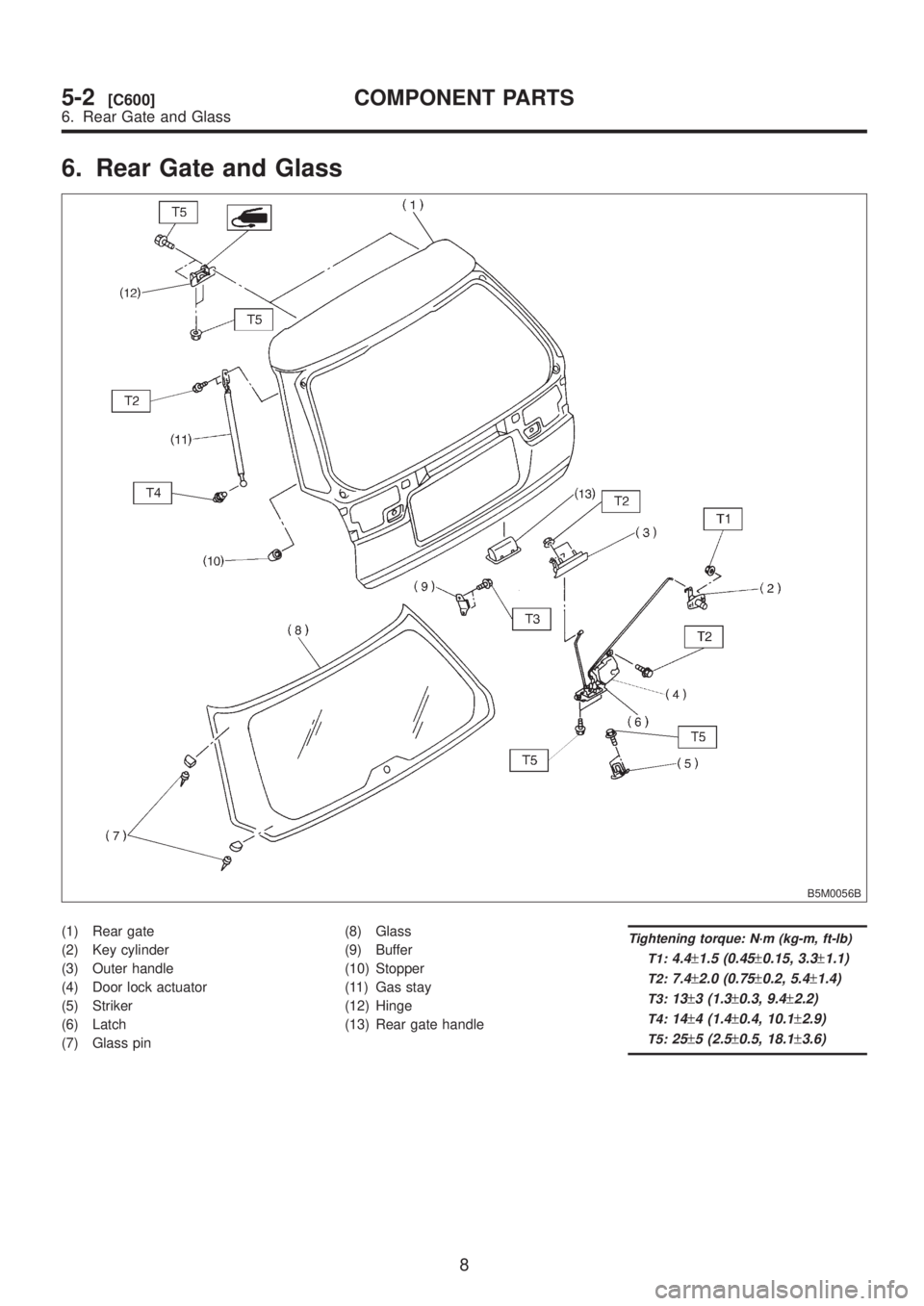

6. Rear Gate and Glass

B5M0056B

(1) Rear gate

(2) Key cylinder

(3) Outer handle

(4) Door lock actuator

(5) Striker

(6) Latch

(7) Glass pin(8) Glass

(9) Buffer

(10) Stopper

(11) Gas stay

(12) Hinge

(13) Rear gate handleTightening torque: N´m (kg-m, ft-lb)

T1:

4.4±1.5 (0.45±0.15, 3.3±1.1)

T2:7.4±2.0 (0.75±0.2, 5.4±1.4)

T3:13±3 (1.3±0.3, 9.4±2.2)

T4:14±4 (1.4±0.4, 10.1±2.9)

T5:25±5 (2.5±0.5, 18.1±3.6)

8

5-2[C600]COMPONENT PARTS

6. Rear Gate and Glass

Page 1108 of 1456

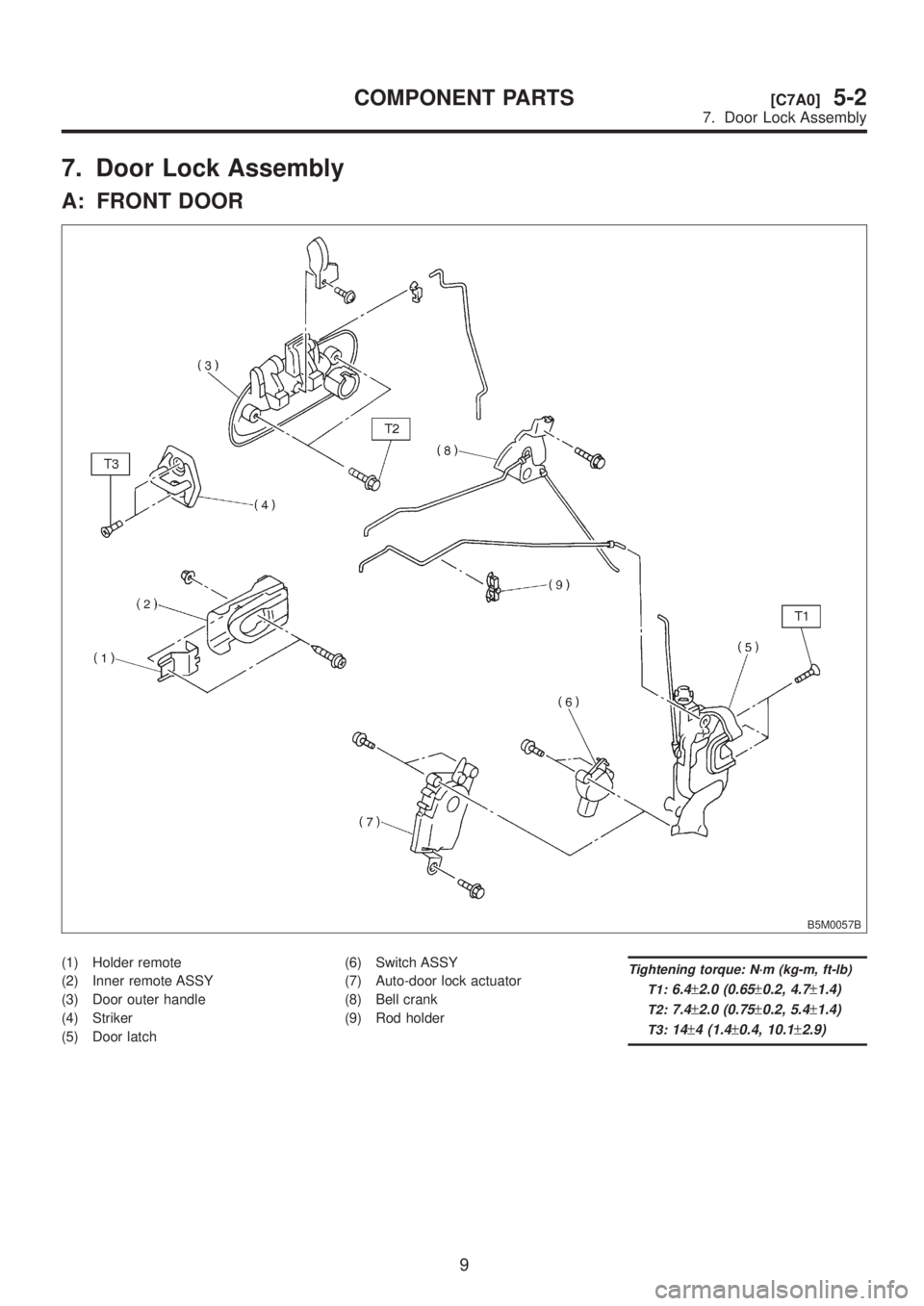

7. Door Lock Assembly

A: FRONT DOOR

B5M0057B

(1) Holder remote

(2) Inner remote ASSY

(3) Door outer handle

(4) Striker

(5) Door latch(6) Switch ASSY

(7) Auto-door lock actuator

(8) Bell crank

(9) Rod holderTightening torque: N´m (kg-m, ft-lb)

T1:

6.4±2.0 (0.65±0.2, 4.7±1.4)

T2:7.4±2.0 (0.75±0.2, 5.4±1.4)

T3:14±4 (1.4±0.4, 10.1±2.9)

9

[C7A0]5-2COMPONENT PARTS

7. Door Lock Assembly

Page 1109 of 1456

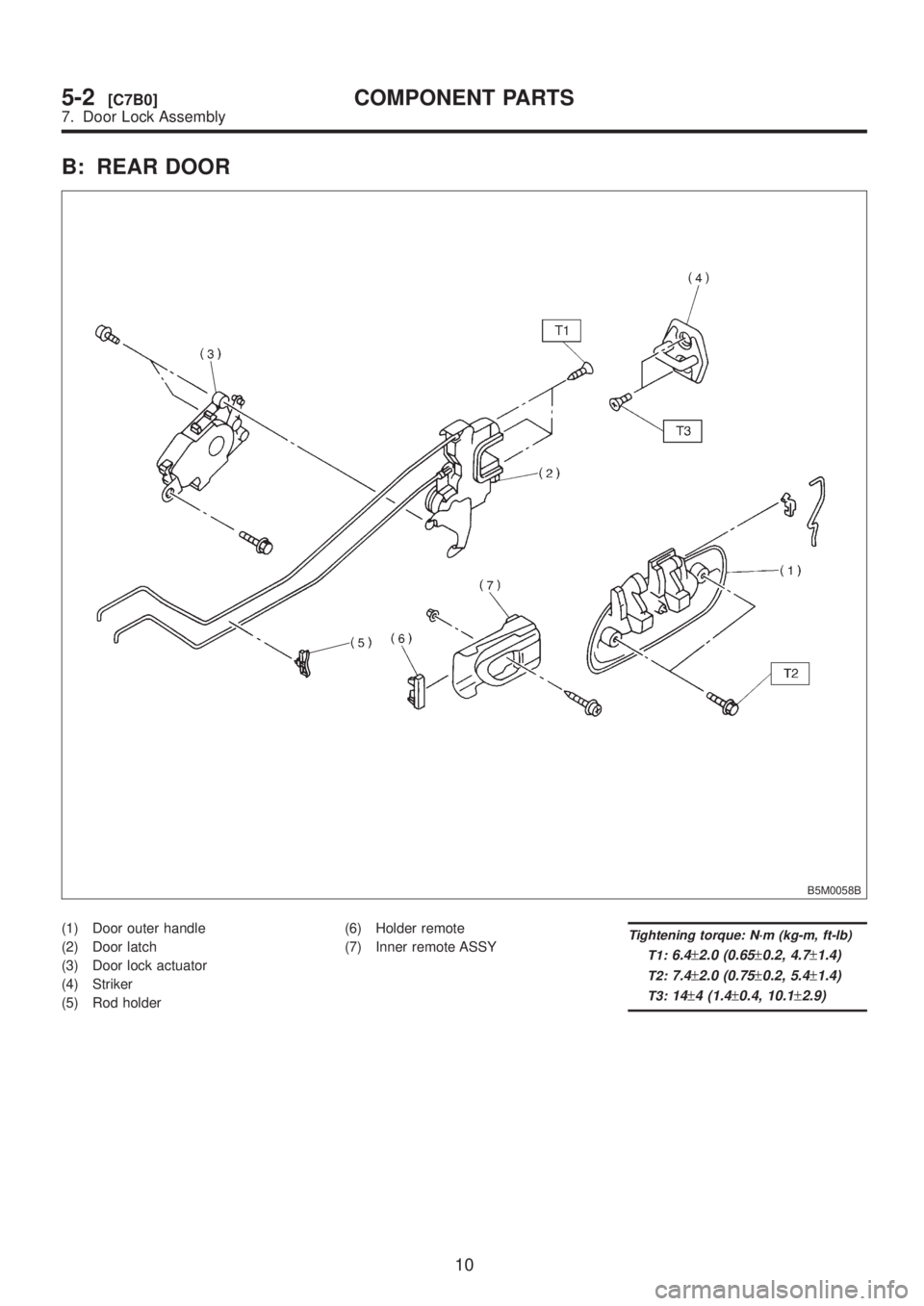

B: REAR DOOR

B5M0058B

(1) Door outer handle

(2) Door latch

(3) Door lock actuator

(4) Striker

(5) Rod holder(6) Holder remote

(7) Inner remote ASSYTightening torque: N´m (kg-m, ft-lb)

T1:

6.4±2.0 (0.65±0.2, 4.7±1.4)

T2:7.4±2.0 (0.75±0.2, 5.4±1.4)

T3:14±4 (1.4±0.4, 10.1±2.9)

10

5-2[C7B0]COMPONENT PARTS

7. Door Lock Assembly

Page 1113 of 1456

2. Door

A: REMOVAL AND INSTALLATION

1. DOOR ASSEMBLY

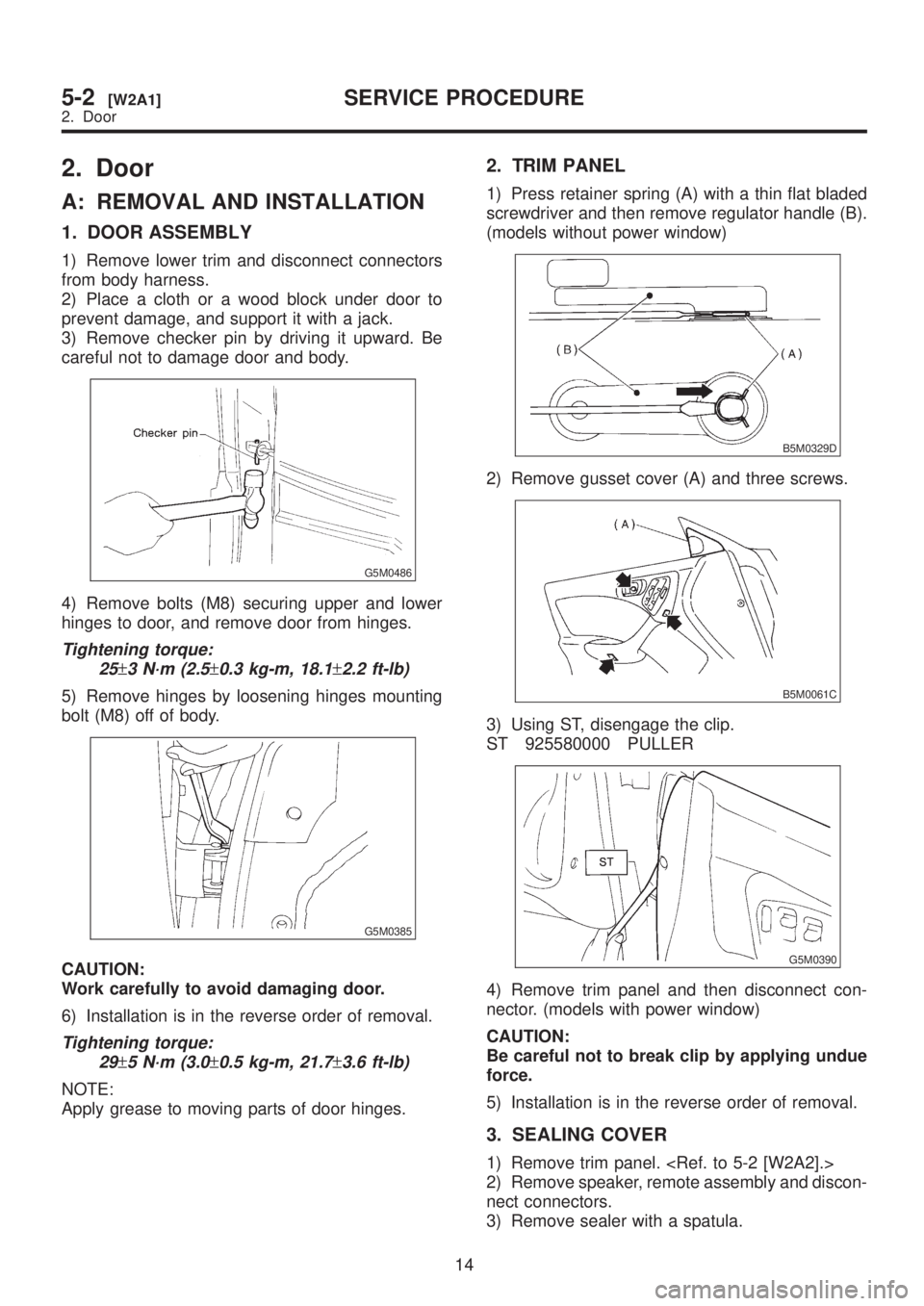

1) Remove lower trim and disconnect connectors

from body harness.

2) Place a cloth or a wood block under door to

prevent damage, and support it with a jack.

3) Remove checker pin by driving it upward. Be

careful not to damage door and body.

G5M0486

4) Remove bolts (M8) securing upper and lower

hinges to door, and remove door from hinges.

Tightening torque:

25

±3 N´m (2.5±0.3 kg-m, 18.1±2.2 ft-lb)

5) Remove hinges by loosening hinges mounting

bolt (M8) off of body.

G5M0385

CAUTION:

Work carefully to avoid damaging door.

6) Installation is in the reverse order of removal.

Tightening torque:

29

±5 N´m (3.0±0.5 kg-m, 21.7±3.6 ft-lb)

NOTE:

Apply grease to moving parts of door hinges.

2. TRIM PANEL

1) Press retainer spring (A) with a thin flat bladed

screwdriver and then remove regulator handle (B).

(models without power window)

B5M0329D

2) Remove gusset cover (A) and three screws.

B5M0061C

3) Using ST, disengage the clip.

ST 925580000 PULLER

G5M0390

4) Remove trim panel and then disconnect con-

nector. (models with power window)

CAUTION:

Be careful not to break clip by applying undue

force.

5) Installation is in the reverse order of removal.

3. SEALING COVER

1) Remove trim panel.

2) Remove speaker, remote assembly and discon-

nect connectors.

3) Remove sealer with a spatula.

14

5-2[W2A1]SERVICE PROCEDURE

2. Door

Page 1115 of 1456

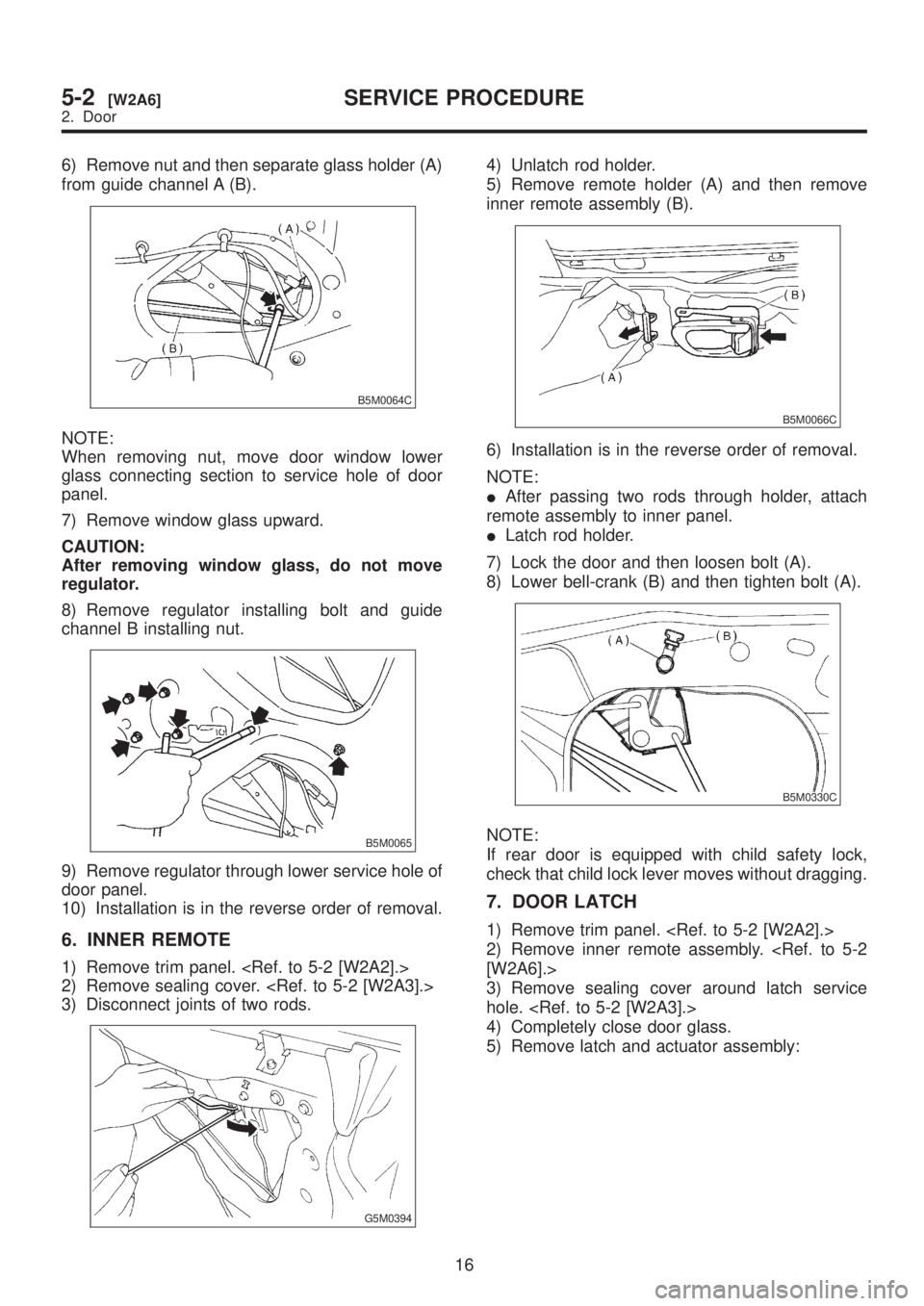

6) Remove nut and then separate glass holder (A)

from guide channel A (B).

B5M0064C

NOTE:

When removing nut, move door window lower

glass connecting section to service hole of door

panel.

7) Remove window glass upward.

CAUTION:

After removing window glass, do not move

regulator.

8) Remove regulator installing bolt and guide

channel B installing nut.

B5M0065

9) Remove regulator through lower service hole of

door panel.

10) Installation is in the reverse order of removal.

6. INNER REMOTE

1) Remove trim panel.

2) Remove sealing cover.

3) Disconnect joints of two rods.

G5M0394

4) Unlatch rod holder.

5) Remove remote holder (A) and then remove

inner remote assembly (B).

B5M0066C

6) Installation is in the reverse order of removal.

NOTE:

IAfter passing two rods through holder, attach

remote assembly to inner panel.

ILatch rod holder.

7) Lock the door and then loosen bolt (A).

8) Lower bell-crank (B) and then tighten bolt (A).

B5M0330C

NOTE:

If rear door is equipped with child safety lock,

check that child lock lever moves without dragging.

7. DOOR LATCH

1) Remove trim panel.

2) Remove inner remote assembly.

3) Remove sealing cover around latch service

hole.

4) Completely close door glass.

5) Remove latch and actuator assembly:

16

5-2[W2A6]SERVICE PROCEDURE

2. Door