set clock SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 46 of 1456

(4) Disconnect rear gate glass washer hose

from washer motor, then plug connection

with a suitable cap. (Wagon only)

(5) Remove the two bolts which hold washer

tank, then secure the tank away from work-

ing area.

B2M2023

(6) Disconnect spark plug cords from spark

plugs (#2 and #4 cylinders).

B2M2024

(7) Disconnect blow-by hose form rocker

cover (LH).

B2M2025

(8) Lift-up the vehicle.

(9) Remove under cover (LH).

(10) Place suitable container under the

vehicle.

(11) Remove rocker cover bolts, then

remove rocker cover (LH).

B2M2026

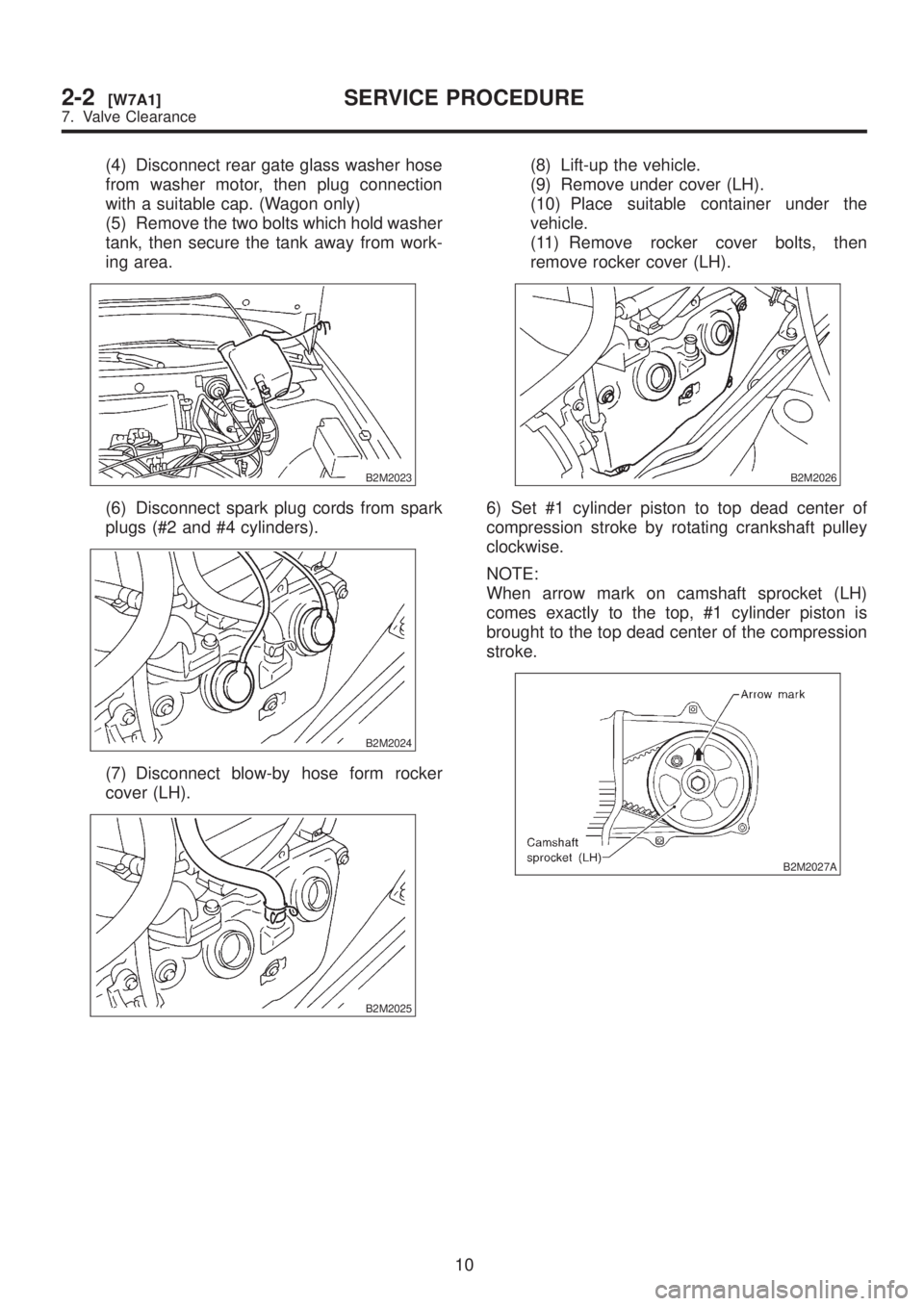

6) Set #1 cylinder piston to top dead center of

compression stroke by rotating crankshaft pulley

clockwise.

NOTE:

When arrow mark on camshaft sprocket (LH)

comes exactly to the top, #1 cylinder piston is

brought to the top dead center of the compression

stroke.

B2M2027A

10

2-2[W7A1]SERVICE PROCEDURE

7. Valve Clearance

Page 47 of 1456

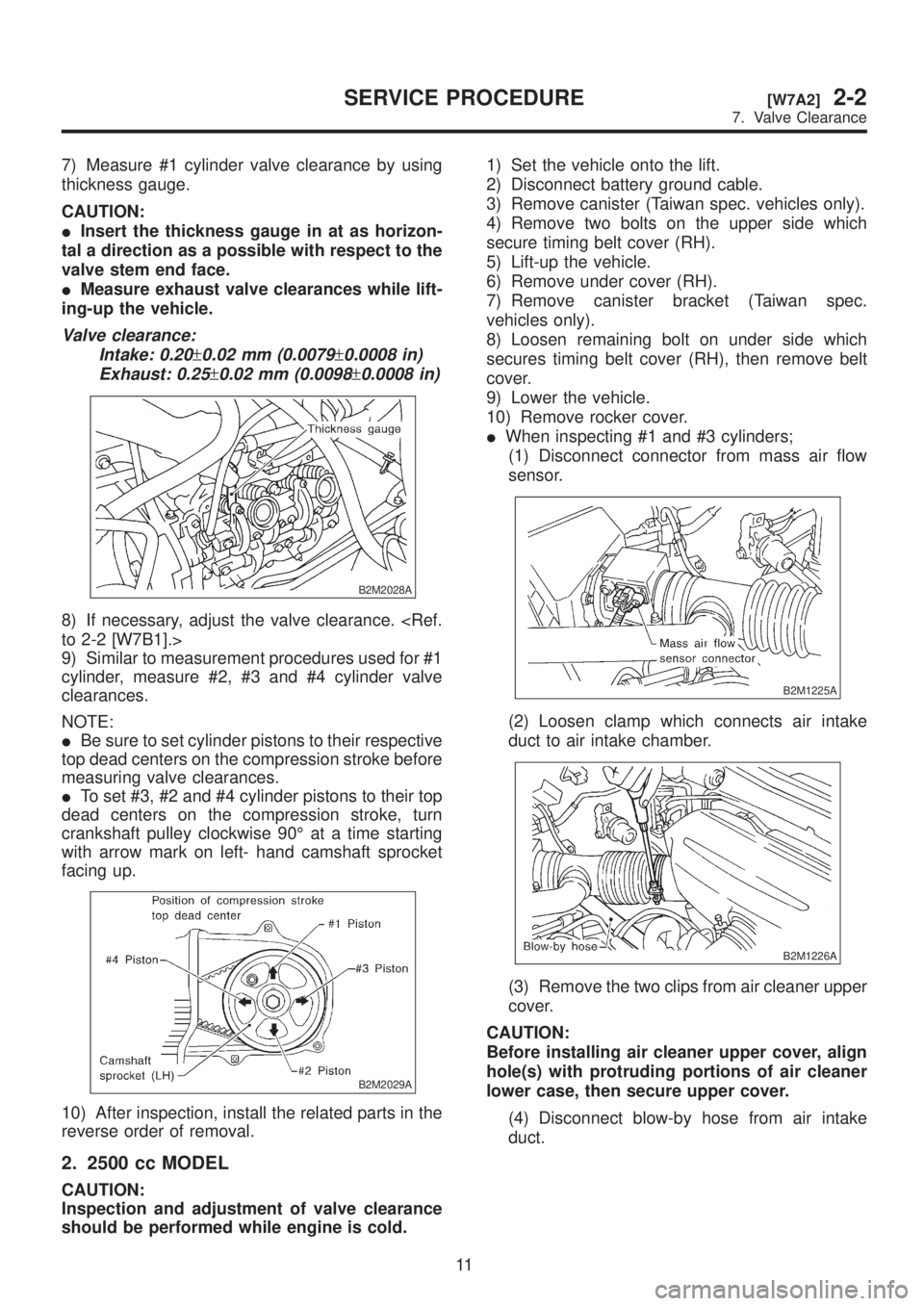

7) Measure #1 cylinder valve clearance by using

thickness gauge.

CAUTION:

IInsert the thickness gauge in at as horizon-

tal a direction as a possible with respect to the

valve stem end face.

IMeasure exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M2028A

8) If necessary, adjust the valve clearance.

9) Similar to measurement procedures used for #1

cylinder, measure #2, #3 and #4 cylinder valve

clearances.

NOTE:

IBe sure to set cylinder pistons to their respective

top dead centers on the compression stroke before

measuring valve clearances.

ITo set #3, #2 and #4 cylinder pistons to their top

dead centers on the compression stroke, turn

crankshaft pulley clockwise 90É at a time starting

with arrow mark on left- hand camshaft sprocket

facing up.

B2M2029A

10) After inspection, install the related parts in the

reverse order of removal.

2. 2500 cc MODEL

CAUTION:

Inspection and adjustment of valve clearance

should be performed while engine is cold.1) Set the vehicle onto the lift.

2) Disconnect battery ground cable.

3) Remove canister (Taiwan spec. vehicles only).

4) Remove two bolts on the upper side which

secure timing belt cover (RH).

5) Lift-up the vehicle.

6) Remove under cover (RH).

7) Remove canister bracket (Taiwan spec.

vehicles only).

8) Loosen remaining bolt on under side which

secures timing belt cover (RH), then remove belt

cover.

9) Lower the vehicle.

10) Remove rocker cover.

IWhen inspecting #1 and #3 cylinders;

(1) Disconnect connector from mass air flow

sensor.

B2M1225A

(2) Loosen clamp which connects air intake

duct to air intake chamber.

B2M1226A

(3) Remove the two clips from air cleaner upper

cover.

CAUTION:

Before installing air cleaner upper cover, align

hole(s) with protruding portions of air cleaner

lower case, then secure upper cover.

(4) Disconnect blow-by hose from air intake

duct.

11

[W7A2]2-2SERVICE PROCEDURE

7. Valve Clearance

Page 48 of 1456

(5) Remove air intake duct and air cleaner

upper cover as a unit.

B2M1227

(6) Remove air cleaner element.

(7) Remove air cleaner lower case.

S2M0179

(8) Disconnect spark plug cords from spark

plugs (#1 and #3 cylinders).

(9) Place suitable container under the vehicle.

(10) Disconnect PCV hose from rocker cover

(RH).

(11) Remove bolts, then remove rocker cover

(RH).

IWhen inspecting # 2 and #4 cylinders;

(1) Disconnect battery cables, and then

remove battery and battery carrier.

(2) Disconnect washer motor connectors.

(3) Disconnect washer hoses from washer

motors, then plug connections with suitable

caps.

(4) Remove washer tank.

(5) Disconnect spark plug cords from spark

plugs (#2 and #4 cylinders).

(6) Remove under cover (LH).

(7) Place suitable container under the vehicle.

(8) Disconnect PCV hose from rocker cover

(LH).

(9) Remove bolts, then remove rocker cover

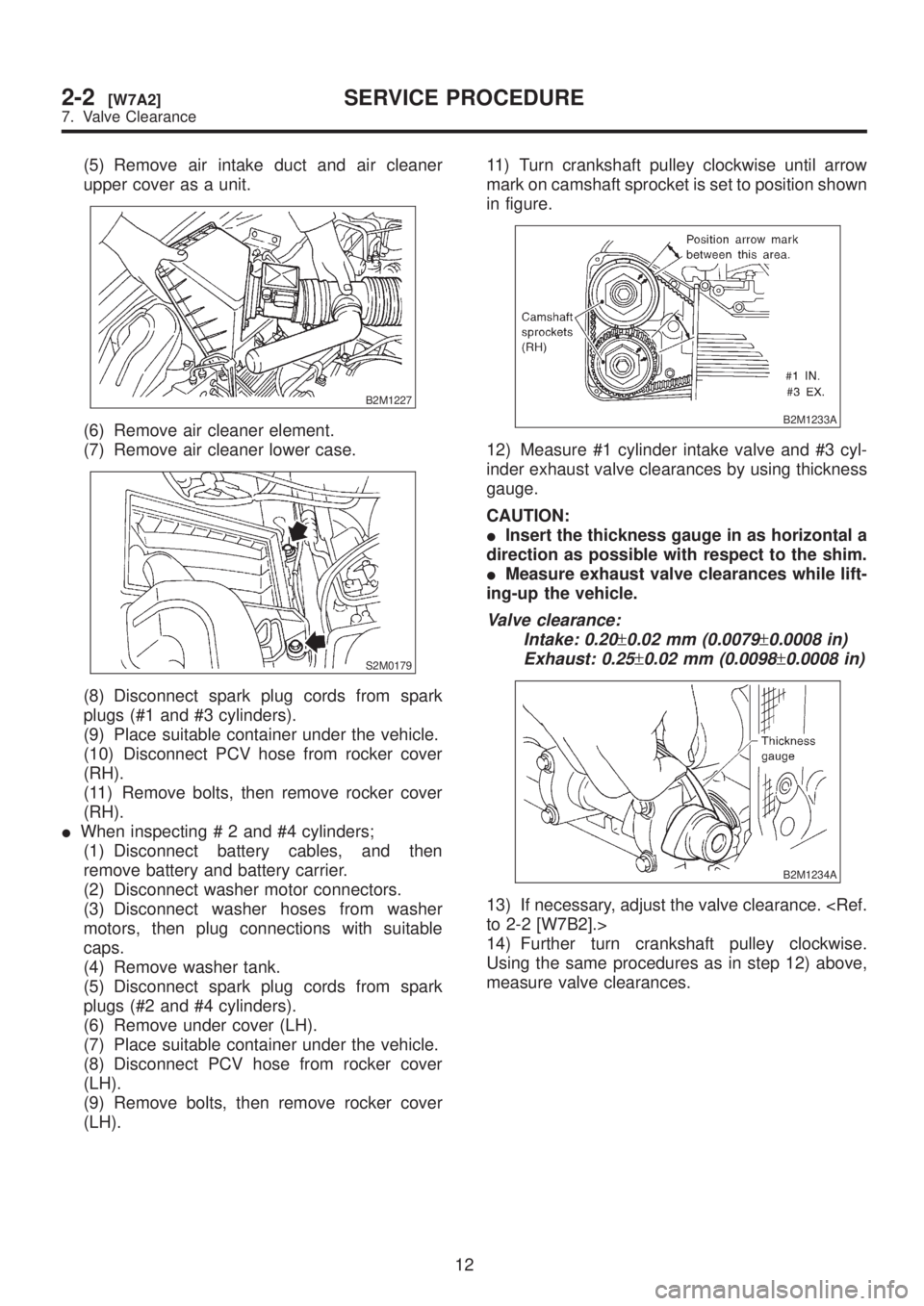

(LH).11) Turn crankshaft pulley clockwise until arrow

mark on camshaft sprocket is set to position shown

in figure.

B2M1233A

12) Measure #1 cylinder intake valve and #3 cyl-

inder exhaust valve clearances by using thickness

gauge.

CAUTION:

IInsert the thickness gauge in as horizontal a

direction as possible with respect to the shim.

IMeasure exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M1234A

13) If necessary, adjust the valve clearance.

14) Further turn crankshaft pulley clockwise.

Using the same procedures as in step 12) above,

measure valve clearances.

12

2-2[W7A2]SERVICE PROCEDURE

7. Valve Clearance

Page 49 of 1456

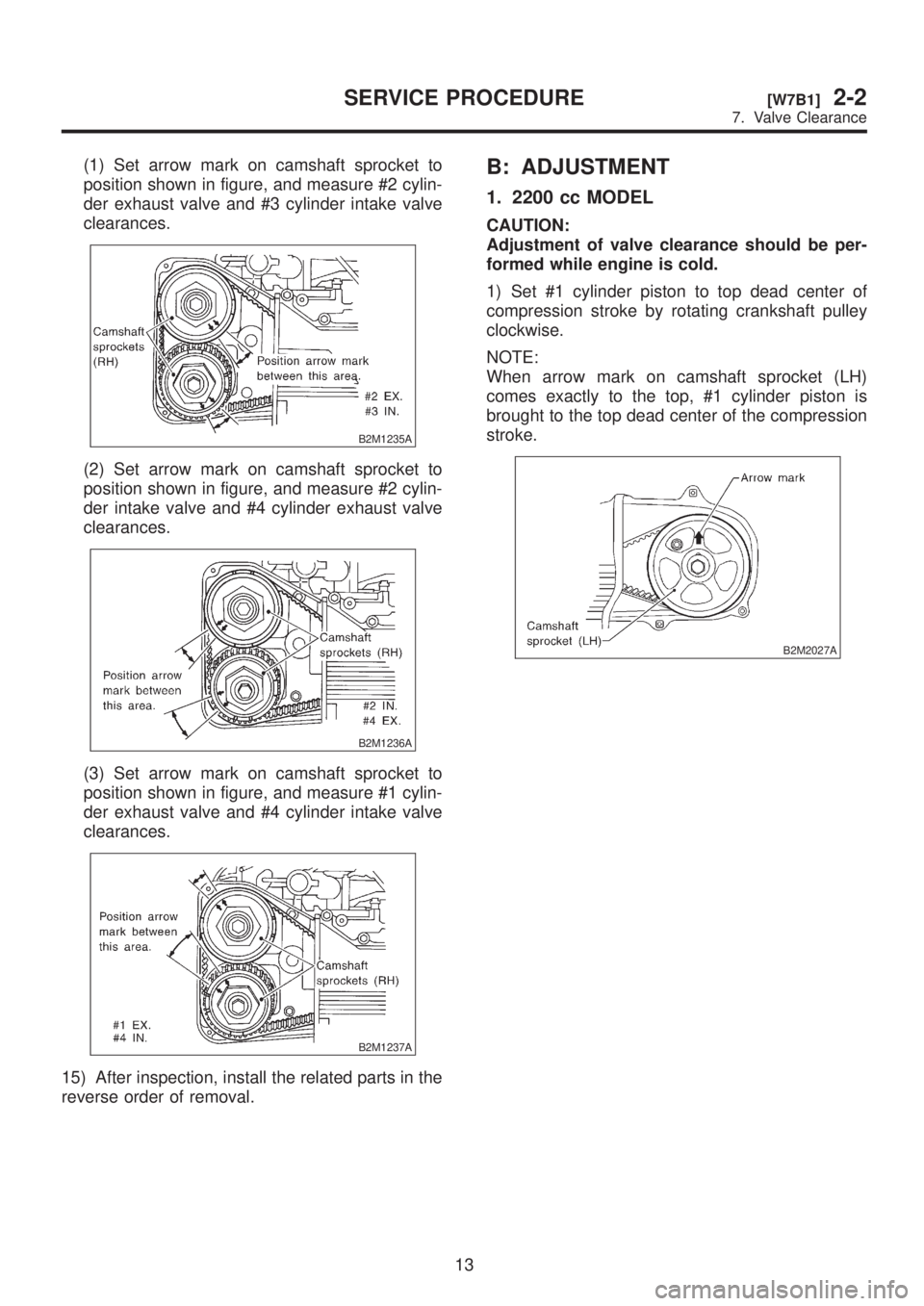

(1) Set arrow mark on camshaft sprocket to

position shown in figure, and measure #2 cylin-

der exhaust valve and #3 cylinder intake valve

clearances.

B2M1235A

(2) Set arrow mark on camshaft sprocket to

position shown in figure, and measure #2 cylin-

der intake valve and #4 cylinder exhaust valve

clearances.

B2M1236A

(3) Set arrow mark on camshaft sprocket to

position shown in figure, and measure #1 cylin-

der exhaust valve and #4 cylinder intake valve

clearances.

B2M1237A

15) After inspection, install the related parts in the

reverse order of removal.

B: ADJUSTMENT

1. 2200 cc MODEL

CAUTION:

Adjustment of valve clearance should be per-

formed while engine is cold.

1) Set #1 cylinder piston to top dead center of

compression stroke by rotating crankshaft pulley

clockwise.

NOTE:

When arrow mark on camshaft sprocket (LH)

comes exactly to the top, #1 cylinder piston is

brought to the top dead center of the compression

stroke.

B2M2027A

13

[W7B1]2-2SERVICE PROCEDURE

7. Valve Clearance

Page 50 of 1456

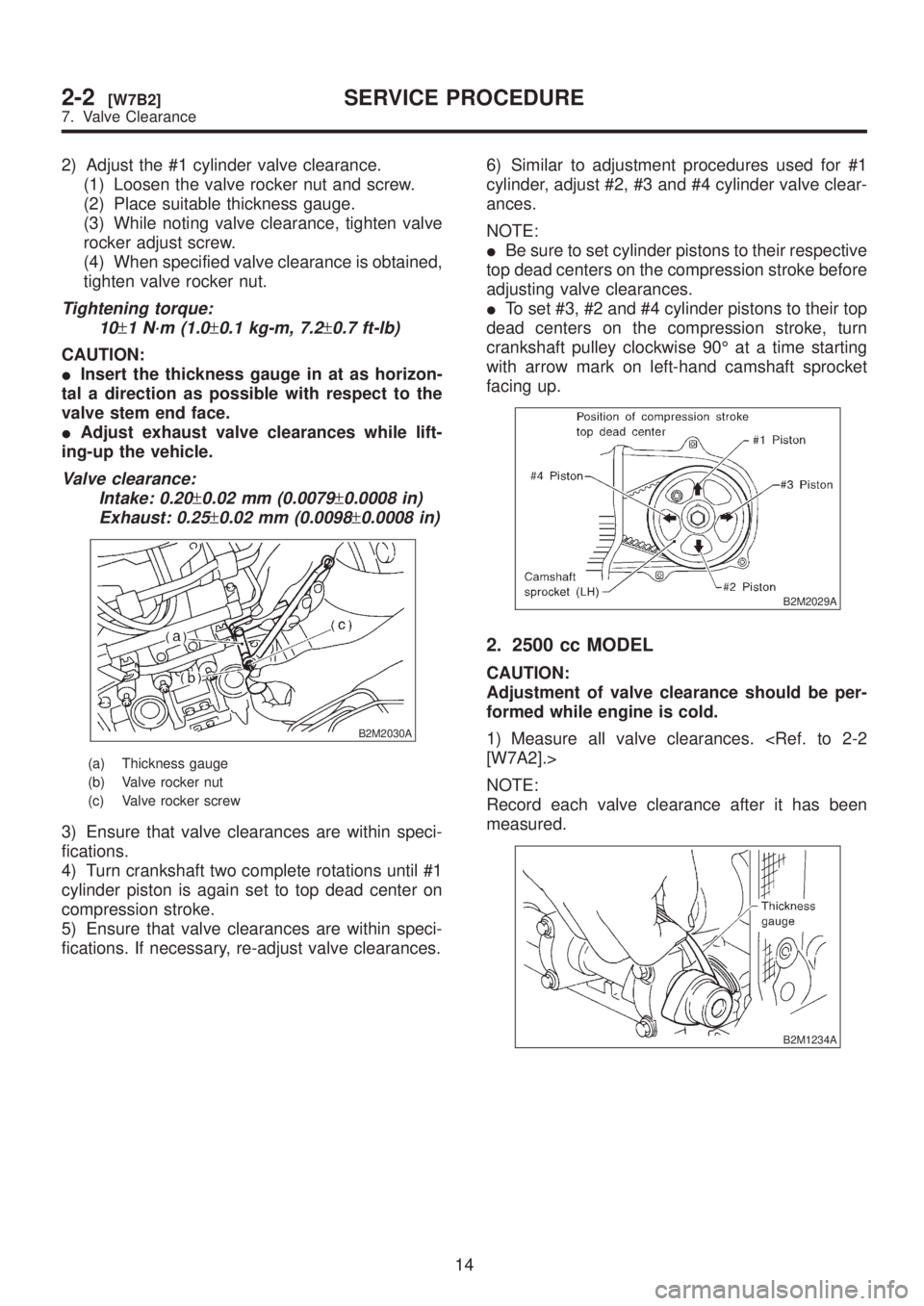

2) Adjust the #1 cylinder valve clearance.

(1) Loosen the valve rocker nut and screw.

(2) Place suitable thickness gauge.

(3) While noting valve clearance, tighten valve

rocker adjust screw.

(4) When specified valve clearance is obtained,

tighten valve rocker nut.

Tightening torque:

10

±1 N´m (1.0±0.1 kg-m, 7.2±0.7 ft-lb)

CAUTION:

IInsert the thickness gauge in at as horizon-

tal a direction as possible with respect to the

valve stem end face.

IAdjust exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M2030A

(a) Thickness gauge

(b) Valve rocker nut

(c) Valve rocker screw

3) Ensure that valve clearances are within speci-

fications.

4) Turn crankshaft two complete rotations until #1

cylinder piston is again set to top dead center on

compression stroke.

5) Ensure that valve clearances are within speci-

fications. If necessary, re-adjust valve clearances.6) Similar to adjustment procedures used for #1

cylinder, adjust #2, #3 and #4 cylinder valve clear-

ances.

NOTE:

IBe sure to set cylinder pistons to their respective

top dead centers on the compression stroke before

adjusting valve clearances.

ITo set #3, #2 and #4 cylinder pistons to their top

dead centers on the compression stroke, turn

crankshaft pulley clockwise 90É at a time starting

with arrow mark on left-hand camshaft sprocket

facing up.

B2M2029A

2. 2500 cc MODEL

CAUTION:

Adjustment of valve clearance should be per-

formed while engine is cold.

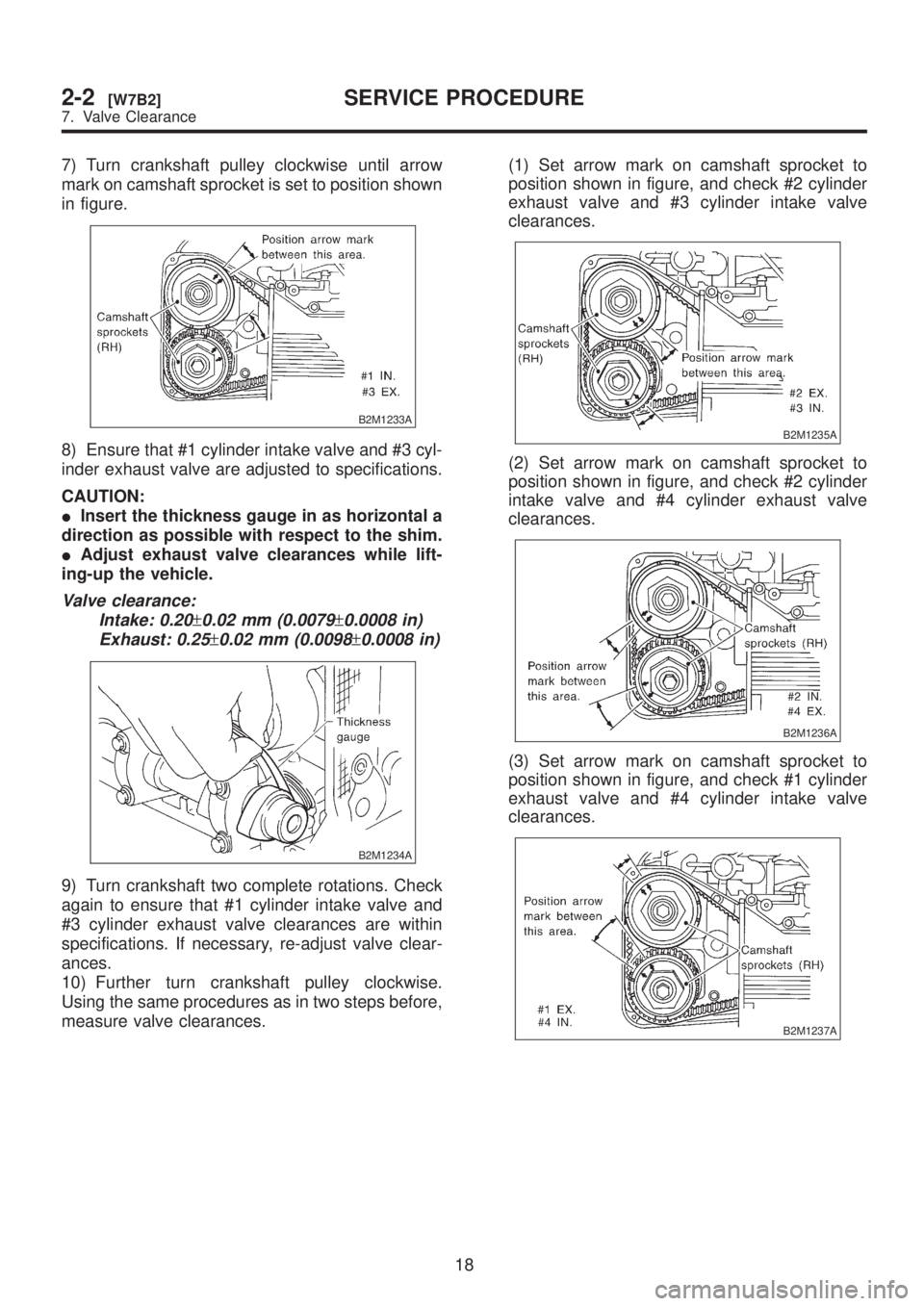

1) Measure all valve clearances.

NOTE:

Record each valve clearance after it has been

measured.

B2M1234A

14

2-2[W7B2]SERVICE PROCEDURE

7. Valve Clearance

Page 54 of 1456

7) Turn crankshaft pulley clockwise until arrow

mark on camshaft sprocket is set to position shown

in figure.

B2M1233A

8) Ensure that #1 cylinder intake valve and #3 cyl-

inder exhaust valve are adjusted to specifications.

CAUTION:

IInsert the thickness gauge in as horizontal a

direction as possible with respect to the shim.

IAdjust exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M1234A

9) Turn crankshaft two complete rotations. Check

again to ensure that #1 cylinder intake valve and

#3 cylinder exhaust valve clearances are within

specifications. If necessary, re-adjust valve clear-

ances.

10) Further turn crankshaft pulley clockwise.

Using the same procedures as in two steps before,

measure valve clearances.(1) Set arrow mark on camshaft sprocket to

position shown in figure, and check #2 cylinder

exhaust valve and #3 cylinder intake valve

clearances.

B2M1235A

(2) Set arrow mark on camshaft sprocket to

position shown in figure, and check #2 cylinder

intake valve and #4 cylinder exhaust valve

clearances.

B2M1236A

(3) Set arrow mark on camshaft sprocket to

position shown in figure, and check #1 cylinder

exhaust valve and #4 cylinder intake valve

clearances.

B2M1237A

18

2-2[W7B2]SERVICE PROCEDURE

7. Valve Clearance

Page 165 of 1456

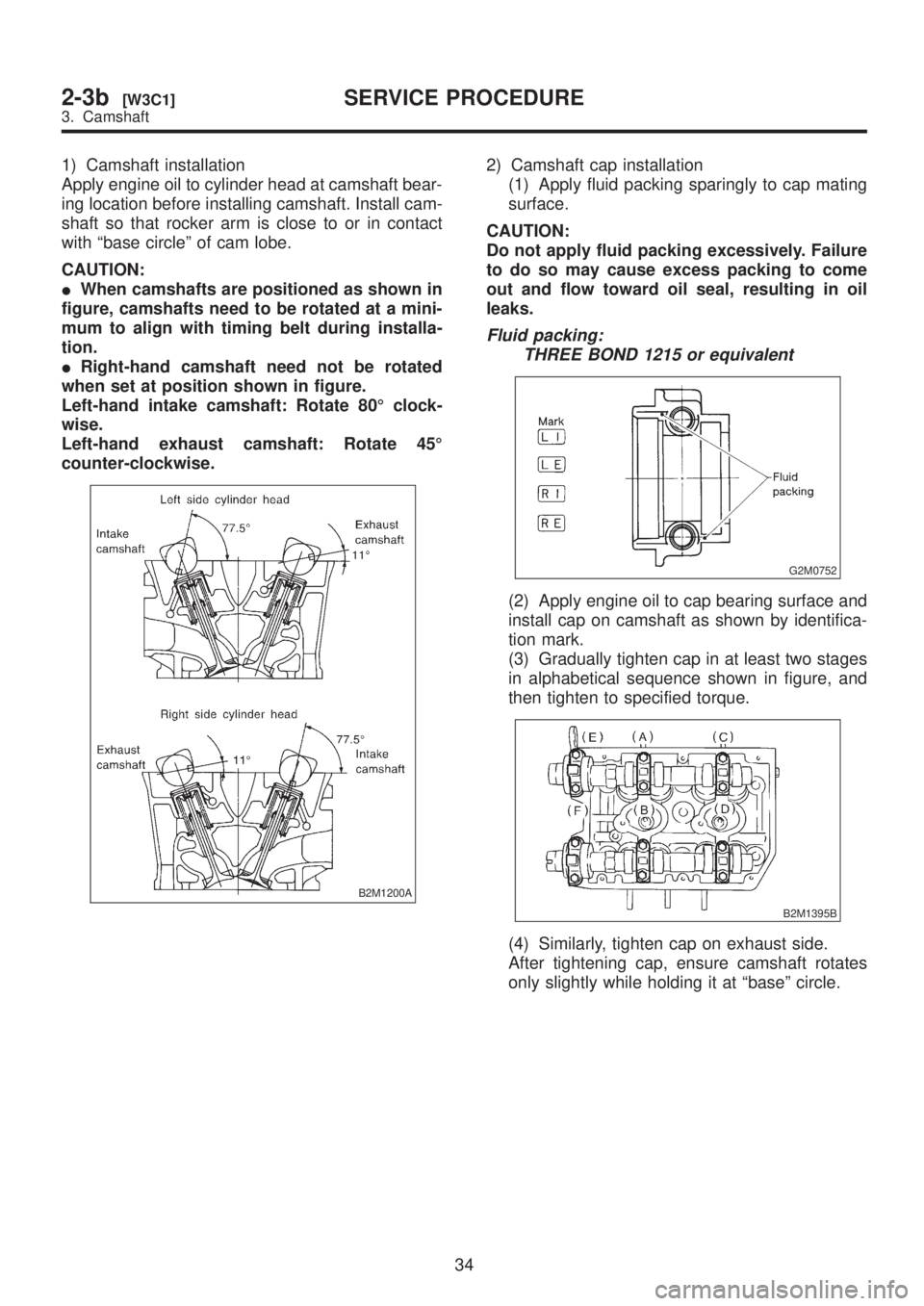

1) Camshaft installation

Apply engine oil to cylinder head at camshaft bear-

ing location before installing camshaft. Install cam-

shaft so that rocker arm is close to or in contact

with ªbase circleº of cam lobe.

CAUTION:

IWhen camshafts are positioned as shown in

figure, camshafts need to be rotated at a mini-

mum to align with timing belt during installa-

tion.

IRight-hand camshaft need not be rotated

when set at position shown in figure.

Left-hand intake camshaft: Rotate 80É clock-

wise.

Left-hand exhaust camshaft: Rotate 45É

counter-clockwise.

B2M1200A

2) Camshaft cap installation

(1) Apply fluid packing sparingly to cap mating

surface.

CAUTION:

Do not apply fluid packing excessively. Failure

to do so may cause excess packing to come

out and flow toward oil seal, resulting in oil

leaks.

Fluid packing:

THREE BOND 1215 or equivalent

G2M0752

(2) Apply engine oil to cap bearing surface and

install cap on camshaft as shown by identifica-

tion mark.

(3) Gradually tighten cap in at least two stages

in alphabetical sequence shown in figure, and

then tighten to specified torque.

B2M1395B

(4) Similarly, tighten cap on exhaust side.

After tightening cap, ensure camshaft rotates

only slightly while holding it at ªbaseº circle.

34

2-3b[W3C1]SERVICE PROCEDURE

3. Camshaft

Page 628 of 1456

15) Install rear sun gear.

NOTE:

Pay attention to the orientation of the rear sun

gear.

B3M1158A

16) Install thrust needle bearing to front planetary

carrier.

NOTE:

Pay attention to the orientation of the thrust needle

bearing.

B3M1174A

17) Install front planetary carrier to low clutch

drum.

B3M1157A

18) Install snap ring to low clutch drum.

B3M1156A

19) Install the needle bearing, and secure with the

snap ring.

B3M1164A

20) Install the one-way clutch, one-way clutch

inner race and plate, and secure with the snap ring.

NOTE:

Set the inner race. Make sure that the forward

clutch is free in the clockwise direction and locked

in the counterclockwise direction, as viewed from

the front of the vehicle.

B3M1175A

97

[W18C0]3-2SERVICE PROCEDURE

18. Low Clutch Drum and Planetary Gear

Page 711 of 1456

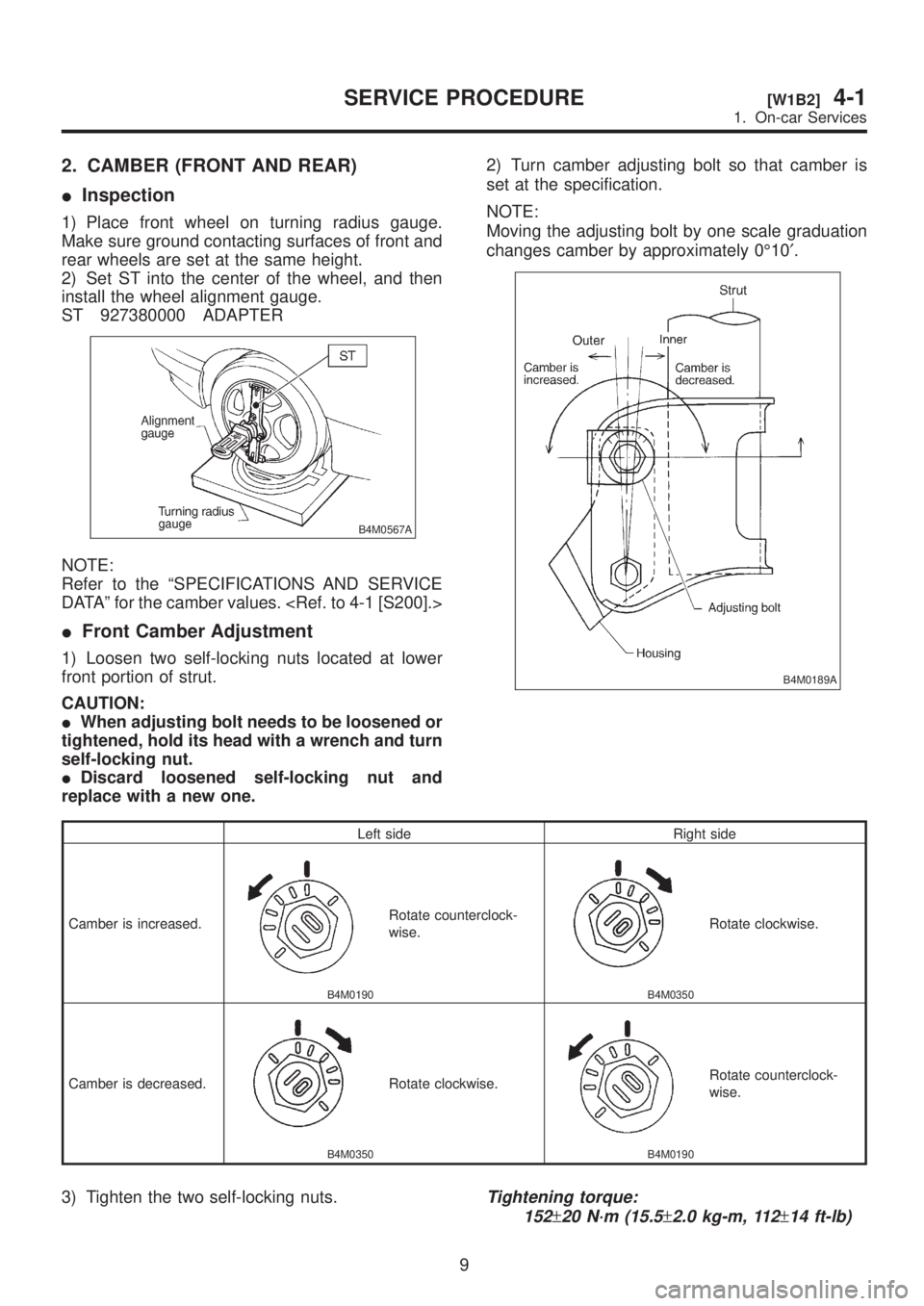

2. CAMBER (FRONT AND REAR)

IInspection

1) Place front wheel on turning radius gauge.

Make sure ground contacting surfaces of front and

rear wheels are set at the same height.

2) Set ST into the center of the wheel, and then

install the wheel alignment gauge.

ST 927380000 ADAPTER

B4M0567A

NOTE:

Refer to the ªSPECIFICATIONS AND SERVICE

DATAº for the camber values.

IFront Camber Adjustment

1) Loosen two self-locking nuts located at lower

front portion of strut.

CAUTION:

IWhen adjusting bolt needs to be loosened or

tightened, hold its head with a wrench and turn

self-locking nut.

IDiscard loosened self-locking nut and

replace with a new one.2) Turn camber adjusting bolt so that camber is

set at the specification.

NOTE:

Moving the adjusting bolt by one scale graduation

changes camber by approximately 0É10¢.

B4M0189A

Left side Right side

Camber is increased.

B4M0190

Rotate counterclock-

wise.

B4M0350

Rotate clockwise.

Camber is decreased.

B4M0350

Rotate clockwise.

B4M0190

Rotate counterclock-

wise.

3) Tighten the two self-locking nuts.Tightening torque:

152

±20 N´m (15.5±2.0 kg-m, 112±14 ft-lb)

9

[W1B2]4-1SERVICE PROCEDURE

1. On-car Services

Page 712 of 1456

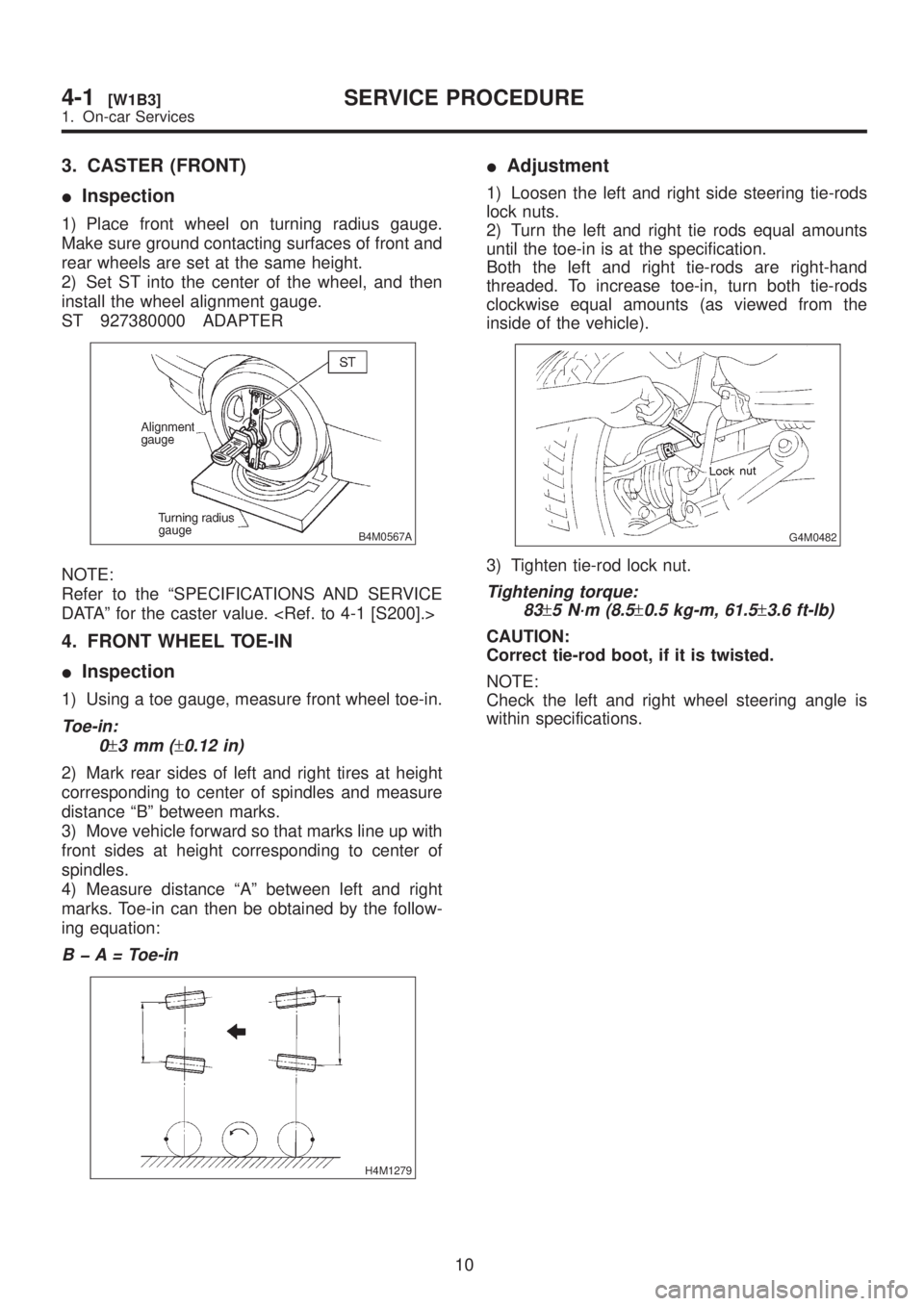

3. CASTER (FRONT)

IInspection

1) Place front wheel on turning radius gauge.

Make sure ground contacting surfaces of front and

rear wheels are set at the same height.

2) Set ST into the center of the wheel, and then

install the wheel alignment gauge.

ST 927380000 ADAPTER

B4M0567A

NOTE:

Refer to the ªSPECIFICATIONS AND SERVICE

DATAº for the caster value.

4. FRONT WHEEL TOE-IN

IInspection

1) Using a toe gauge, measure front wheel toe-in.

Toe-in:

0

±3mm(±0.12 in)

2) Mark rear sides of left and right tires at height

corresponding to center of spindles and measure

distance ªBº between marks.

3) Move vehicle forward so that marks line up with

front sides at height corresponding to center of

spindles.

4) Measure distance ªAº between left and right

marks. Toe-in can then be obtained by the follow-

ing equation:

B þ A = Toe-in

H4M1279

IAdjustment

1) Loosen the left and right side steering tie-rods

lock nuts.

2) Turn the left and right tie rods equal amounts

until the toe-in is at the specification.

Both the left and right tie-rods are right-hand

threaded. To increase toe-in, turn both tie-rods

clockwise equal amounts (as viewed from the

inside of the vehicle).

G4M0482

3) Tighten tie-rod lock nut.

Tightening torque:

83

±5 N´m (8.5±0.5 kg-m, 61.5±3.6 ft-lb)

CAUTION:

Correct tie-rod boot, if it is twisted.

NOTE:

Check the left and right wheel steering angle is

within specifications.

10

4-1[W1B3]SERVICE PROCEDURE

1. On-car Services