run flat SUBARU LEGACY 2010 5.G User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2010, Model line: LEGACY, Model: SUBARU LEGACY 2010 5.GPages: 448, PDF Size: 7.36 MB

Page 319 of 448

WARNING

Never place a tire or tire changing

tools in the passenger compartment

after changing wheels. In a sudden

stop or collision, loose equipment

could strike occupants and cause

injury. Store the tire and all tools in

the proper place.

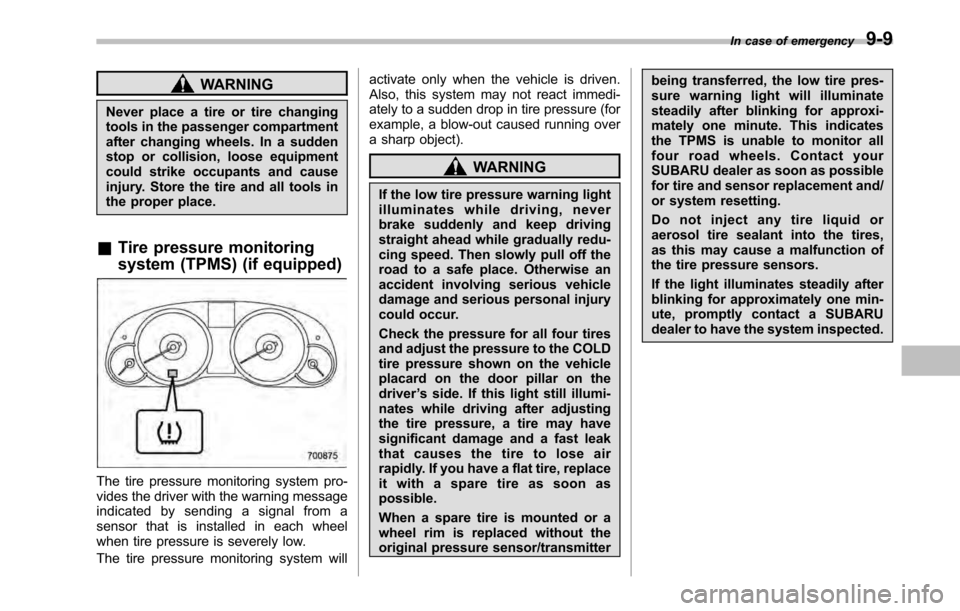

& Tire pressure monitoring

system (TPMS) (if equipped)

The tire pressure monitoring system pro-

vides the driver with the warning message

indicated by sending a signal from a

sensor that is installed in each wheel

when tire pressure is severely low.

The tire pressure monitoring system will activate only when the vehicle is driven.

Also, this system may not react immedi-

ately to a sudden drop in tire pressure (for

example, a blow-out caused running over

a sharp object).

WARNING

If the low tire pressure warning light

illuminates while driving, never

brake suddenly and keep driving

straight ahead while gradually redu-

cing speed. Then slowly pull off the

road to a safe place. Otherwise an

accident involving serious vehicle

damage and serious personal injury

could occur.

Check the pressure for all four tires

and adjust the pressure to the COLD

tire pressure shown on the vehicle

placard on the door pillar on thedriver ’s side. If this light still illumi-

nates while driving after adjusting

the tire pressure, a tire may have

significant damage and a fast leak

that causes the tire to lose air

rapidly. If you have a flat tire, replace

it with a spare tire as soon aspossible.

When a spare tire is mounted or a

wheel rim is replaced without the

original pressure sensor/transmitter being transferred, the low tire pres-

sure warning light will illuminate

steadily after blinking for approxi-

mately one minute. This indicates

the TPMS is unable to monitor all

four road wheels. Contact your

SUBARU dealer as soon as possible

for tire and sensor replacement and/

or system resetting.

Do not inject any tire liquid or

aerosol tire sealant into the tires,

as this may cause a malfunction of

the tire pressure sensors.

If the light illuminates steadily after

blinking for approximately one min-

ute, promptly contact a SUBARU

dealer to have the system inspected.

In case of emergency

9-9

Page 325 of 448

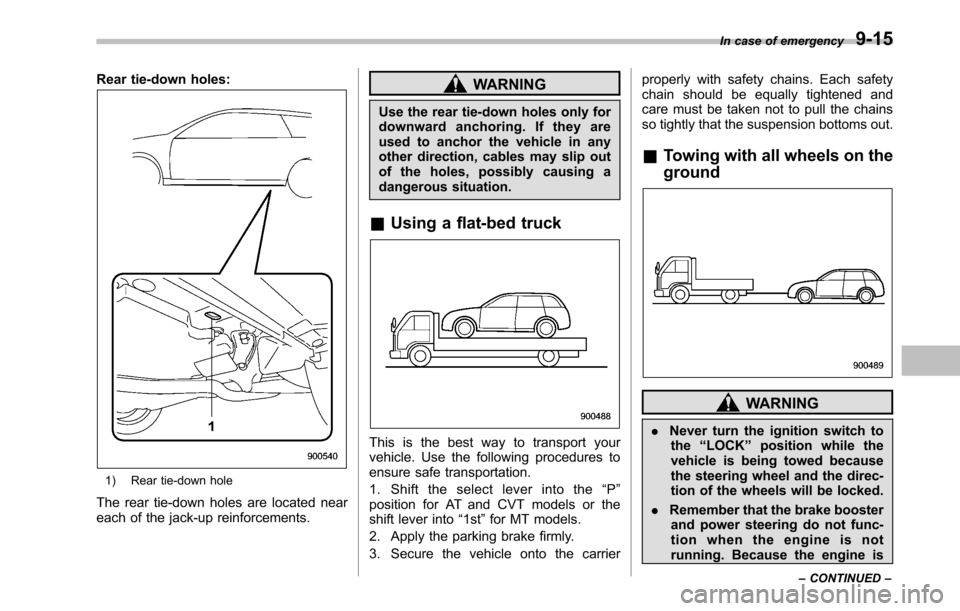

Rear tie-down holes:

1) Rear tie-down hole

The rear tie-down holes are located near

each of the jack-up reinforcements.

WARNING

Use the rear tie-down holes only for

downward anchoring. If they are

used to anchor the vehicle in any

other direction, cables may slip out

of the holes, possibly causing a

dangerous situation.

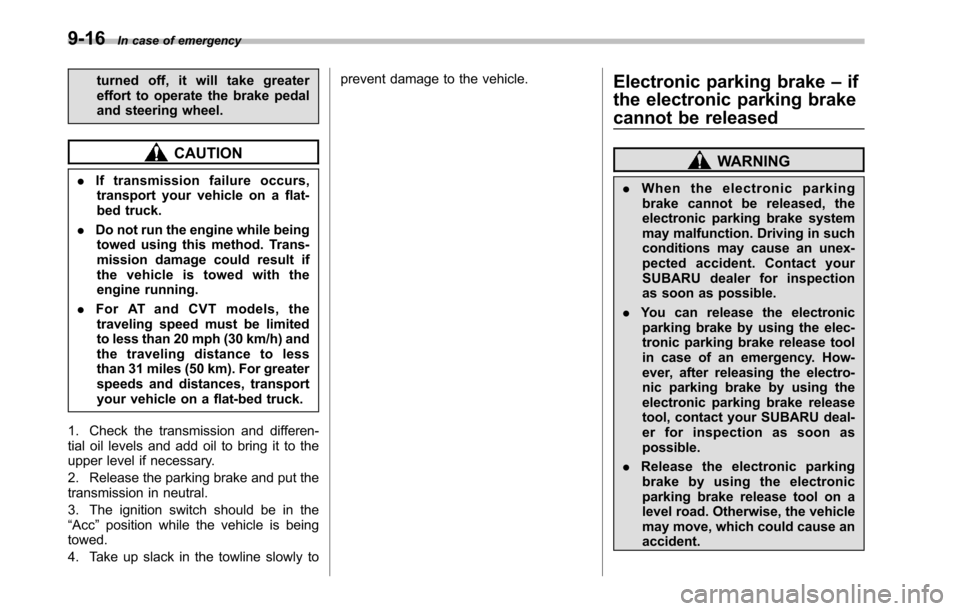

& Using a flat-bed truck

This is the best way to transport your

vehicle. Use the following procedures to

ensure safe transportation.

1. Shift the select lever into the “P ”

position for AT and CVT models or the

shift lever into “1st ”for MT models.

2. Apply the parking brake firmly.

3. Secure the vehicle onto the carrier properly with safety chains. Each safety

chain should be equally tightened and

care must be taken not to pull the chains

so tightly that the suspension bottoms out.

& Towing with all wheels on the ground

WARNING

. Never turn the ignition switch to

the “LOCK ”position while the

vehicle is being towed because

the steering wheel and the direc-

tion of the wheels will be locked.

. Remember that the brake booster

and power steering do not func-

tion when the engine is not

running. Because the engine is In case of emergency

9-15

– CONTINUED –

Page 326 of 448

9-16In case of emergency

turned off, it will take greater

effort to operate the brake pedal

and steering wheel.

CAUTION

. If transmission failure occurs,

transport your vehicle on a flat-

bed truck.

. Do not run the engine while being

towed using this method. Trans-

mission damage could result if

the vehicle is towed with the

engine running.

. For AT and CVT models, the

traveling speed must be limited

to less than 20 mph (30 km/h) and

the traveling distance to less

than 31 miles (50 km). For greater

speeds and distances, transport

your vehicle on a flat-bed truck.

1. Check the transmission and differen-

tial oil levels and add oil to bring it to the

upper level if necessary.

2. Release the parking brake and put the

transmission in neutral.

3. The ignition switch should be in the “ Acc ”position while the vehicle is being

towed.

4. Take up slack in the towline slowly to prevent damage to the vehicle.

Electronic parking brake–if

the electronic parking brake

cannot be releasedWARNING

. When the electronic parking

brake cannot be released, the

electronic parking brake system

may malfunction. Driving in such

conditions may cause an unex-

pected accident. Contact your

SUBARU dealer for inspection

as soon as possible.

. You can release the electronic

parking brake by using the elec-

tronic parking brake release tool

in case of an emergency. How-

ever, after releasing the electro-

nic parking brake by using the

electronic parking brake release

tool, contact your SUBARU deal-

er for inspection as soon aspossible.

. Release the electronic parking

brakebyusingtheelectronic

parking brake release tool on a

level road. Otherwise, the vehicle

may move, which could cause anaccident.

Page 329 of 448

Trunk lid (Legacy)–if the

trunk lid cannot be opened

The trunk lid can also be opened using the

key.

To open the trunk lid, insert the key into

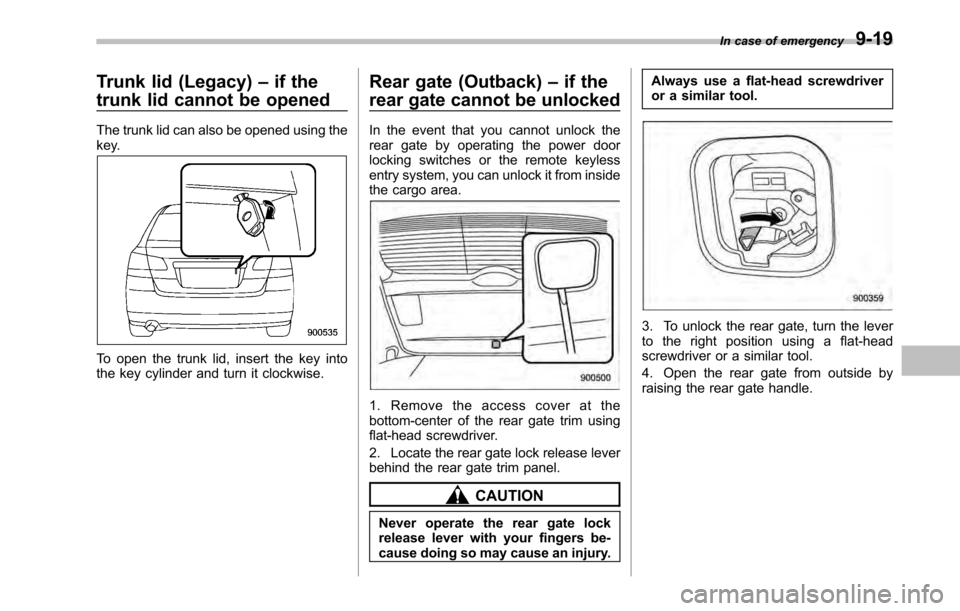

the key cylinder and turn it clockwise. Rear gate (Outback)

–if the

rear gate cannot be unlocked

In the event that you cannot unlock the

rear gate by operating the power door

locking switches or the remote keyless

entry system, you can unlock it from inside

the cargo area.

1. Remove the access cover at the

bottom-center of the rear gate trim using

flat-head screwdriver.

2. Locate the rear gate lock release lever

behind the rear gate trim panel.

CAUTION

Never operate the rear gate lock

release lever with your fingers be-

cause doing so may cause an injury. Always use a flat-head screwdriver

or a similar tool.

3. To unlock the rear gate, turn the lever

to the right position using a flat-head

screwdriver or a similar tool.

4. Open the rear gate from outside by

raising the rear gate handle.

In case of emergency

9-19

Page 341 of 448

&When checking or servicing

in the engine compartment

while the engine is running

WARNING

A running engine can be dangerous.

Keep your fingers, hands, clothing,

hair and tools away from the cooling

fan, belts and any other moving

engine parts. Removing rings,

watches and ties is advisable. Maintenance tips

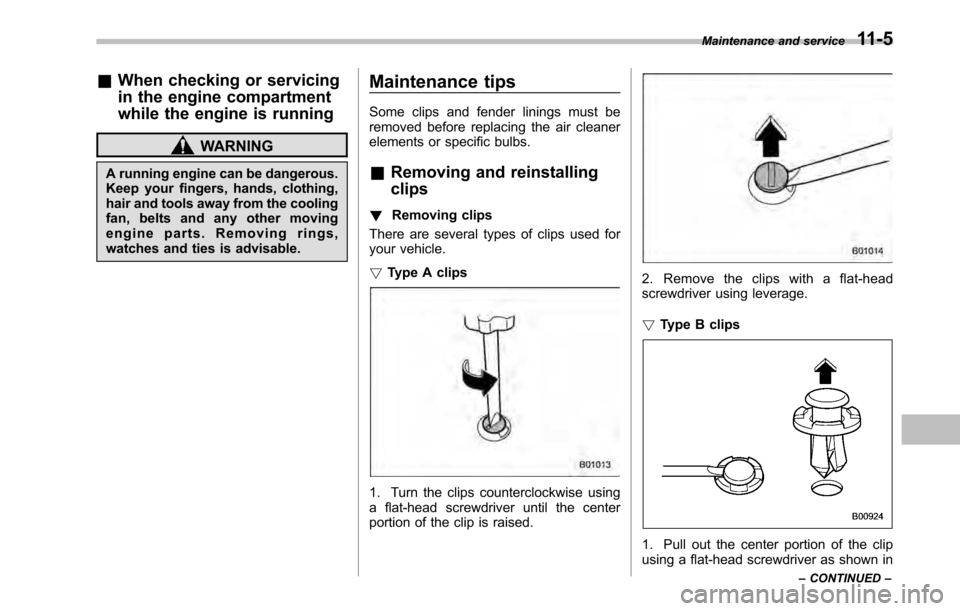

Some clips and fender linings must be

removed before replacing the air cleaner

elements or specific bulbs. &

Removing and reinstalling clips

! Removing clips

There are several types of clips used for

your vehicle. ! Type A clips

1. Turn the clips counterclockwise using

a flat-head screwdriver until the center

portion of the clip is raised.

2. Remove the clips with a flat-head

screwdriver using leverage. !Type B clips

1. Pull out the center portion of the clip

using a flat-head screwdriver as shown in Maintenance and service

11-5

– CONTINUED –

Page 371 of 448

Tires and wheels &Types of tires

You should be familiar with type of tires

present on your vehicle. ! All season tires

The factory-installed tires on your new

vehicle except 2.5 L turbo models are all

season tires.

All season tires are designed to provide

an adequate measure of traction, handling

and braking performance in year-round

driving including snowy and icy road

conditions. However all season tires do

not offer as much traction performance as

winter (snow) tires in heavy or loose snow

or on icy roads.

All season tires are identified by “ALL

SEASON ”and/or “M+S ”(Mud & Snow) on

the tire sidewall. ! Summer tires

The factory-installed tires on your new 2.5

L turbo models are summer tires. Summer

tires are high-speed capability tires best

suited for highway driving under dryconditions.

Summer tires are inadequate for driving

on slippery roads such as on snow-

covered or icy roads.

If you drive your vehicle on snow-covered or icy roads, we strongly recommend the

use of winter (snow) tires.

When installing winter tires, be sure to

replace all four tires. !

Winter (snow) tires

Winter tires are best suited for driving on

snow-covered and icy roads. However

winter tires do not perform as well as

summer tires and all season tires on roads

other than snow-covered and icy roads.

& Tire pressure monitoring

system (TPMS) (if equipped)

The tire pressure monitoring system pro-

vides the driver with a warning message

by sending a signal from a sensor that is

installed in each wheel when tire pressure

is severely low. The tire pressure monitor-

ing system will activate only when the

vehicle is driven. Also, this system may

not react immediately to a sudden drop in

tire pressure (for example, a blow-out

caused by running over a sharp object).

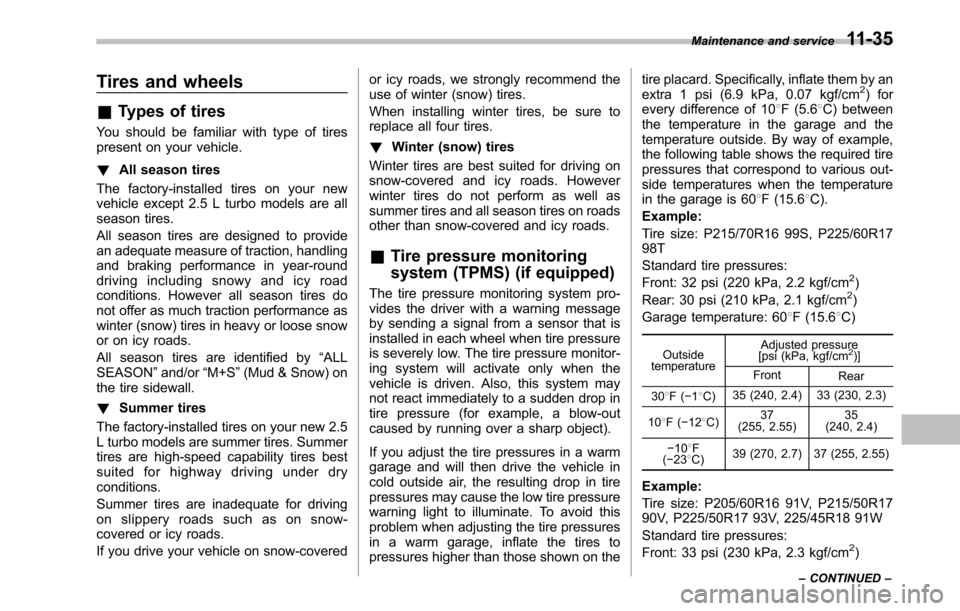

If you adjust the tire pressures in a warm

garage and will then drive the vehicle in

cold outside air, the resulting drop in tire

pressures may cause the low tire pressure

warning light to illuminate. To avoid this

problem when adjusting the tire pressures

in a warm garage, inflate the tires to

pressures higher than those shown on the tire placard. Specifically, inflate them by an

extra 1 psi (6.9 kPa, 0.07 kgf/cm2) for

every difference of 10 8F (5.6 8C) between

the temperature in the garage and the

temperature outside. By way of example,

the following table shows the required tire

pressures that correspond to various out-

side temperatures when the temperature

in the garage is 60 8F (15.6 8C).

Example:

Tire size: P215/70R16 99S, P225/60R17 98T

Standard tire pressures:

Front: 32 psi (220 kPa, 2.2 kgf/cm

2)

Rear: 30 psi (210 kPa, 2.1 kgf/cm2)

Garage temperature: 60 8F (15.6 8C)

Outside

temperature Adjusted pressure

[psi (kPa, kgf/cm

2)]

Front Rear

30 8F( �18C) 35 (240, 2.4) 33 (230, 2.3)

10 8F( �12 8C) 37

(255, 2.55) 35

(240, 2.4)

� 10 8F

( � 23 8C) 39 (270, 2.7)

37 (255, 2.55)

Example:

Tire size: P205/60R16 91V, P215/50R17

90V, P225/50R17 93V, 225/45R18 91W

Standard tire pressures:

Front: 33 psi (230 kPa, 2.3 kgf/cm

2)

Maintenance and service

11-35

– CONTINUED –

Page 378 of 448

11-42Maintenance and service

Aluminum wheels

Aluminum wheels can be scratched and

damaged easily. Handle them carefully to

maintain their appearance, performance,

and safety. .When any of the wheels is removed

and replaced for tire rotation or to change

a flat, always check the tightness of the

wheel nuts after driving approximately 600

miles (1,000 km). If any nut is loose,

tighten it to the specified torque. . Never apply oil to the threaded parts,

wheel nuts, or tapered surface of the wheel. . Never let the wheel rub against sharp

protrusions or curbs.. When wheel nuts, balance weights, or

the center cap is replaced, be sure to

replace them with genuine SUBARU parts

designed for aluminum wheels. Windshield washer fluid

CAUTION

Never use engine coolant as washer

fluid because it could cause paintdamage.

If you spray washer fluid on the windshield

but the windshield washer fluid warning

light illuminates or the supply of washer

fluid runs out, add washer fluid in the tank.

Remove the washer tank filler cap, then

add fluid until it reaches the “FULL ”mark

on the tank.

Use windshield washer fluid. If windshield

washer fluid is unavailable use clean

water.

Page 396 of 448

11-60Maintenance and service

& Door step light

1. Remove the lens by prying the edge of

the lens with a flat-head screwdriver.

2. Pull the bulb out of the socket.

3. Install a new bulb. 4. Reinstall the lens.

& Cargo area light (Outback)

1. Remove the lens by prying the edge of

the lens with a flat-head screwdriver.

2. Pull the bulb out of the socket.

3. Install a new bulb.

4. Reinstall the lens. &Trunk light (Legacy)

1. Push both sides of the light cover, and

then remove the cover by pulling it out.

2. Pull the bulb out of the socket.

3. Install a new bulb.

4. Reinstall the cover. &Other bulbs

Other bulbs may be difficult to replace.

We recommend that you have the bulbs

replaced by your SUBARU dealer if

necessary.

Page 419 of 448

sory weight, including heavy duty

brakes, ride levelers, roof rack,

heavy duty battery, and special trim. .Radial ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at substantially 90 degrees to

the centerline of the tread. . Recommended inflation pres-

sure

The cold inflation pressure recom-

mended by a vehicle manufacturer. . Reinforced tire

A tire designed to operate at higher

loads and at higher inflation pres-

sures than the corresponding stan-

dard tire. . Rim

A metal support for a tire or a tire

and tube assembly upon which the

tire beads are seated. . Rim diameter

Nominal diameter of the bead seat. . Rim size designation

Rim diameter and width. .

Rim type designation

The industry of manufacturer ’s des-

ignation for a rim by style or code. . Rim width

Nominal distance between rim flanges. . Section width

The linear distance between the

exteriors of the sidewalls of an

inflated tire, excluding elevations

due to labeling, decoration, or

protective bands. . Sidewall

That portion of a tire between the

tread and bead. . Sidewall separation

The parting of the rubber com-

pound from the cord material in

the sidewall. . Test rim

The rim on which a tire is fitted for

testing, and it may be any rim listed

as appropriate for use with that tire. . Tread

That portion of a tire that comes

into contact with the road. .

Tread rib

A tread section running circumfer-

entially around a tire. . Tread separation

Pulling away of the tread from the

tire carcass. . Treadwear indicators (TWI)

The projections within the principal

grooves designed to give a visual

indication of the degrees of wear of

the tread. . Vehicle capacity weight

The rated cargo and luggage load

plus 150 lbs (68 kg) times thevehicle ’s designated seating capa-

city. . Vehicle maximum load on the

tire

Load on an individual tire that is

determined by distributing to each

axle its share of the maximum

loaded vehicle weight and dividing

by two. . Vehicle normal load on the tire

Load on an individual tire that is

determined by distributing to each

axle its share of the curb weight,

Consumer information and Reporting safety defects

13-9

– CONTINUED –

Page 438 of 448

14-10Index

Sun visors ................................................................... 6-4

Supplemental Restraint System airbag (SRS) ................ 1-38

Synthetic leather upholstery ........................................ 10-5

T

Tachometer ................................................................. 3-7

Temperature warning light AT OIL TEMP ........................................................ 3-15

Coolant ................................................................. 3-13

Temporary spare tire .................................................... 9-2

Tether (child restraint system) .............................. 1-33, 1-35

Tie-down hooks ......................................................... 9-13

Tire ................................................................. 11-35, 12-5

Chains .................................................................. 8-11

Inspection ............................................................ 11-37

Pressures and wear .............................................. 11-37

Replacement ........................................................ 11-41

Rotation ............................................................... 11-40

Types .................................................................. 11-35

Tire pressure monitoring system (TPMS). ...... 7-32, 9-9, 11-35

Warning light ......................................................... 3-15

Tires and wheels. ...................................................... 11-35

Tools .......................................................................... 9-3

Top tether anchorages ........................................ 1-33, 1-35

Towing ...................................................................... 9-12

All wheels on the ground ........................................ 9-15

Flat-bed truck ........................................................ 9-15

Hooks ................................................................... 9-13

Weight.................................................................. 8-19

Trailer

Connecting ............................................................ 8-17 Hitch

............................................................. 8-16, 8-22

Towing .................................................................. 8-19

Towing tips ............................................................ 8-24

Trip meter ................................................................... 3-6

Trunk lid ............................................................ 2-24, 9-19

Release handle ...................................................... 2-25

Trunk light ............................................................... 11-60

Turn signal

Indicator lights ........................................................ 3-23

Lever .................................................................... 3-29

U

Under-floor storage compartment .................................. 6-18

V

Valet mode ................................................................ 2-18

Vanity mirror ...................................................... 6-5, 11-59

Light ................................................................... 11-59

Vehicle

Capacity weight ...................................................... 8-13

Identification ........................................................ 12-13

Symbols .................................................................... 3

Vehicle Dynamics Control OFF indicator light .......................................... 3-21, 7-31

OFF switch ............................................................ 7-31

Operation indicator light ................................... 3-21, 7-30

System .................................................................. 7-28

Warning light .................................................. 3-20, 7-29

Ventilator .................................................................... 4-2