weight SUBARU OUTBACK 2010 5.G Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2010, Model line: OUTBACK, Model: SUBARU OUTBACK 2010 5.GPages: 448, PDF Size: 7.36 MB

Page 304 of 448

8-20Driving tips

3.6 L models

Conditions Maximum total trailer weight

When towing a trailer without brakes. 1,000 lbs (453 kg)

When towing a trailer with brakes. 3,000 lbs (1,360 kg)

When towing a trailer on a long uphill grade

continuously for over 5 miles (8 km) with an

outside temperature of 104 8F (40 8C) or above. 1,500 lbs (680 kg)

All models other than 3.6 L models Model Conditions Maximum total trailer

weight

MT models When towing a trailer without brakes. 1,000 lbs (453 kg)

When towing a trailer with brakes. 2,700 lbs (1,224 kg)

CVT models When towing a trailer without brakes. 1,000 lbs (453 kg)

When towing a trailer with brakes. 2,700 lbs (1,224 kg)

When towing a trailer on a long uphill

grade continuously for over 5 miles (8

km) with an outside temperature of 1048F (40 8C) or above. 1,350 lbs (612 kg)!

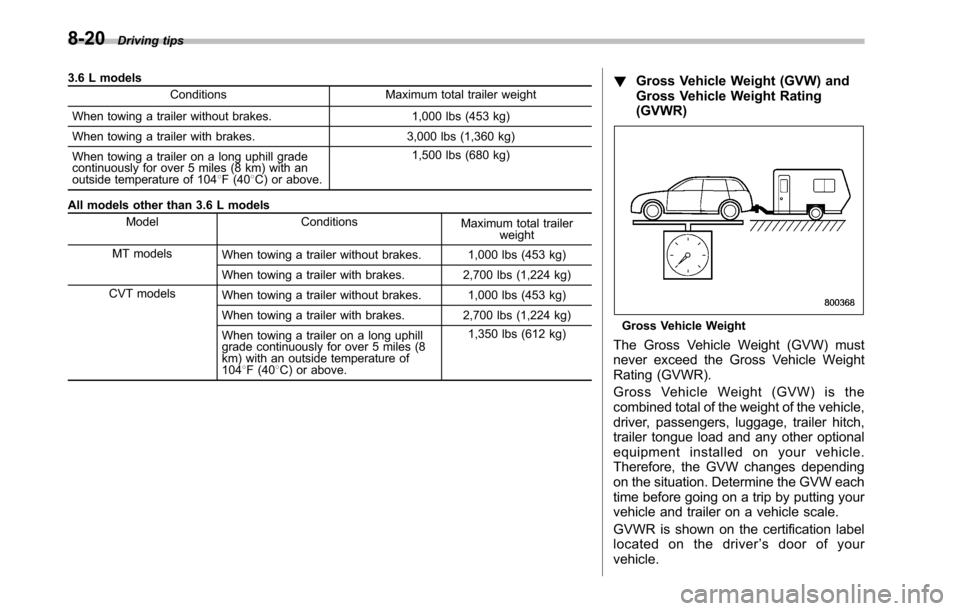

Gross Vehicle Weight (GVW) and

Gross Vehicle Weight Rating(GVWR)

Gross Vehicle Weight

The Gross Vehicle Weight (GVW) must

never exceed the Gross Vehicle Weight

Rating (GVWR).

Gross Vehicle Weight (GVW) is the

combined total of the weight of the vehicle,

driver, passengers, luggage, trailer hitch,

trailer tongue load and any other optional

equipment installed on your vehicle.

Therefore, the GVW changes depending

on the situation. Determine the GVW each

time before going on a trip by putting your

vehicle and trailer on a vehicle scale.

GVWR is shown on the certification label

located on the driver ’s door of your

vehicle.

Page 305 of 448

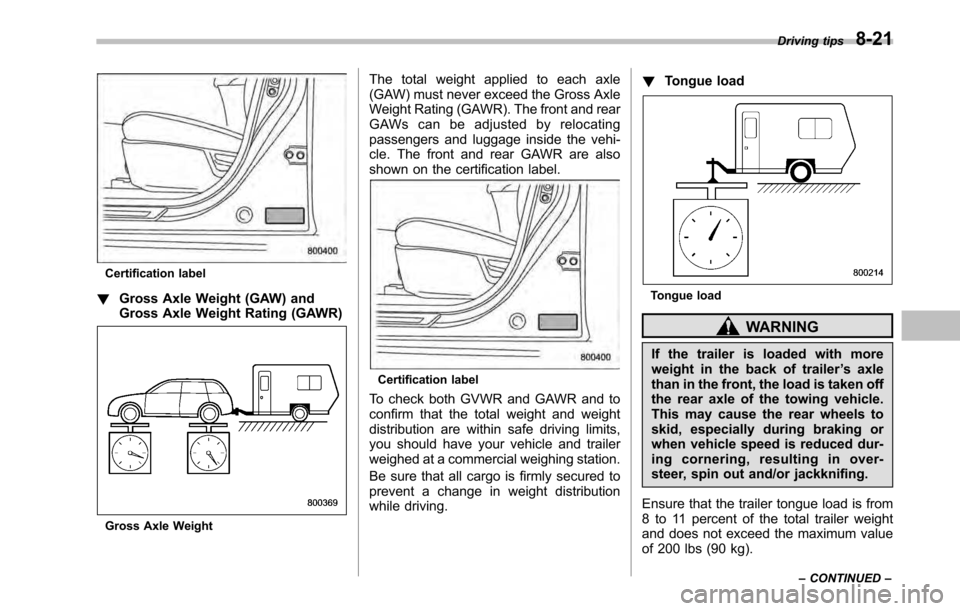

Certification label

! Gross Axle Weight (GAW) and

Gross Axle Weight Rating (GAWR)

Gross Axle Weight The total weight applied to each axle

(GAW) must never exceed the Gross Axle

Weight Rating (GAWR). The front and rear

GAWs can be adjusted by relocating

passengers and luggage inside the vehi-

cle. The front and rear GAWR are also

shown on the certification label.

Certification label

To check both GVWR and GAWR and to

confirm that the total weight and weight

distribution are within safe driving limits,

you should have your vehicle and trailer

weighed at a commercial weighing station.

Be sure that all cargo is firmly secured to

prevent a change in weight distribution

while driving. !

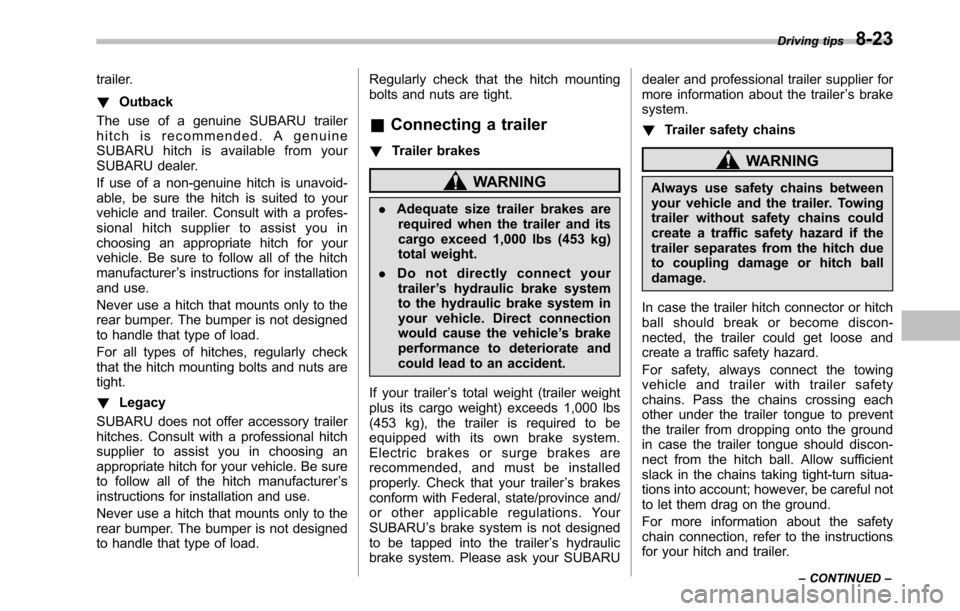

Tongue load

Tongue load

WARNING

If the trailer is loaded with more

weight in the back of trailer ’s axle

than in the front, the load is taken off

the rear axle of the towing vehicle.

This may cause the rear wheels to

skid, especially during braking or

when vehicle speed is reduced dur-

ing cornering, resulting in over-

steer, spin out and/or jackknifing.

Ensure that the trailer tongue load is from

8 to 11 percent of the total trailer weight

and does not exceed the maximum value

of 200 lbs (90 kg). Driving tips

8-21

– CONTINUED –

Page 306 of 448

8-22Driving tips

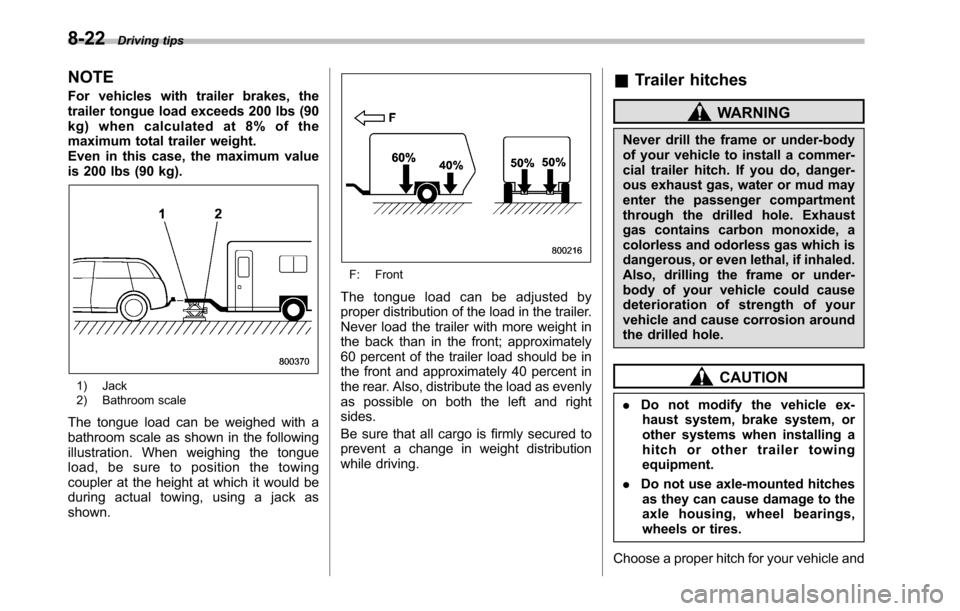

NOTE

For vehicles with trailer brakes, the

trailer tongue load exceeds 200 lbs (90

kg) when calculated at 8% of the

maximum total trailer weight.

Even in this case, the maximum value

is 200 lbs (90 kg).

1) Jack

2) Bathroom scale

The tongue load can be weighed with a

bathroom scale as shown in the following

illustration. When weighing the tongue

load, be sure to position the towing

coupler at the height at which it would be

during actual towing, using a jack asshown.

F: Front

The tongue load can be adjusted by

proper distribution of the load in the trailer.

Never load the trailer with more weight in

the back than in the front; approximately

60 percent of the trailer load should be in

the front and approximately 40 percent in

the rear. Also, distribute the load as evenly

as possible on both the left and rightsides.

Be sure that all cargo is firmly secured to

prevent a change in weight distribution

while driving. &

Trailer hitches

WARNING

Never drill the frame or under-body

of your vehicle to install a commer-

cial trailer hitch. If you do, danger-

ous exhaust gas, water or mud may

enter the passenger compartment

through the drilled hole. Exhaust

gas contains carbon monoxide, a

colorless and odorless gas which is

dangerous, or even lethal, if inhaled.

Also, drilling the frame or under-

body of your vehicle could cause

deterioration of strength of your

vehicle and cause corrosion around

the drilled hole.

CAUTION

. Do not modify the vehicle ex-

haust system, brake system, or

other systems when installing a

hitch or other trailer towingequipment.

. Do not use axle-mounted hitches

as they can cause damage to the

axle housing, wheel bearings,

wheels or tires.

Choose a proper hitch for your vehicle and

Page 307 of 448

trailer. !Outback

The use of a genuine SUBARU trailer

hitch is recommended. A genuine

SUBARU hitch is available from your

SUBARU dealer.

If use of a non-genuine hitch is unavoid-

able, be sure the hitch is suited to your

vehicle and trailer. Consult with a profes-

sional hitch supplier to assist you in

choosing an appropriate hitch for your

vehicle. Be sure to follow all of the hitchmanufacturer ’s instructions for installation

and use.

Never use a hitch that mounts only to the

rear bumper. The bumper is not designed

to handle that type of load.

For all types of hitches, regularly check

that the hitch mounting bolts and nuts aretight. ! Legacy

SUBARU does not offer accessory trailer

hitches. Consult with a professional hitch

supplier to assist you in choosing an

appropriate hitch for your vehicle. Be sure

to follow all of the hitch manufacturer ’s

instructions for installation and use.

Never use a hitch that mounts only to the

rear bumper. The bumper is not designed

to handle that type of load. Regularly check that the hitch mounting

bolts and nuts are tight.

& Connecting a trailer

! Trailer brakes

WARNING

. Adequate size trailer brakes are

required when the trailer and its

cargo exceed 1,000 lbs (453 kg)

total weight.

. Do not directly connect your

trailer ’s hydraulic brake system

to the hydraulic brake system in

your vehicle. Direct connection

would cause the vehicle ’s brake

performance to deteriorate and

could lead to an accident.

If your trailer ’s total weight (trailer weight

plus its cargo weight) exceeds 1,000 lbs

(453 kg), the trailer is required to be

equipped with its own brake system.

Electric brakes or surge brakes are

recommended, and must be installed

properly. Check that your trailer ’s brakes

conform with Federal, state/province and/

or other applicable regulations. YourSUBARU ’s brake system is not designed

to be tapped into the trailer ’s hydraulic

brake system. Please ask your SUBARU dealer and professional trailer supplier for

more information about the trailer

’s brake

system. ! Trailer safety chains

WARNING

Always use safety chains between

your vehicle and the trailer. Towing

trailer without safety chains could

create a traffic safety hazard if the

trailer separates from the hitch due

to coupling damage or hitch balldamage.

In case the trailer hitch connector or hitch

ball should break or become discon-

nected, the trailer could get loose and

create a traffic safety hazard.

For safety, always connect the towing

vehicle and trailer with trailer safety

chains. Pass the chains crossing each

other under the trailer tongue to prevent

the trailer from dropping onto the ground

in case the trailer tongue should discon-

nect from the hitch ball. Allow sufficient

slack in the chains taking tight-turn situa-

tions into account; however, be careful not

to let them drag on the ground.

For more information about the safety

chain connection, refer to the instructions

for your hitch and trailer. Driving tips

8-23

– CONTINUED –

Page 309 of 448

the rear, check the total trailer weight,

GVW, GAWs and tongue load again, then

confirm that the load and its distribution

are acceptable. .Check that the tire pressures are

correct.. Check that the vehicle and trailer are

connected properly. Confirm that

–the trailer tongue is connected

properly to the hitch ball. – the trailer lights connector is con-

nected properly and trailer ’s brake

lights illuminate when the vehicle ’s

brake pedal is pressed, and that the trailer ’s turn signal lights flash when

the vehicle ’s turn signal lever is oper-

ated. – the safety chains are connected

properly.– all cargo in the trailer is secured

safety in position.– the side mirrors provide a good

rearward field of view without a sig-

nificant blind spot.

. Sufficient time should be taken to learn

the “feel ”of the vehicle/trailer combination

before starting out on a trip. In an area free

of traffic, practice turning, stopping and

backing up. !

Driving with a trailer

. You should allow for considerably more

stopping distance when towing a trailer.

Avoid sudden braking because it may

result in skidding or jackknifing and loss ofcontrol. . Avoid abrupt starts and sudden accel-

erations. If your vehicle has a manual

transmission, always start out in first gear

and release the clutch at moderate enginerevolution. . Avoid uneven steering, sharp turns and

rapid lane changes.. Slow down before turning. Make a

longer than normal turning radius because

the trailer wheels will be closer than the

vehicle wheels to the inside of the turn. In

a tight turn, the trailer could hit yourvehicle. . Crosswinds will adversely affect the

handling of your vehicle and trailer, caus-

ing sway. Crosswinds can be due to

weather conditions or the passing of large

trucks or buses. If swaying occurs, firmly

grip the steering wheel and slow down

immediately but gradually. . When passing other vehicles, consid-

erable distance is required because of the

added weight and length caused by

attaching the trailer to your vehicle.

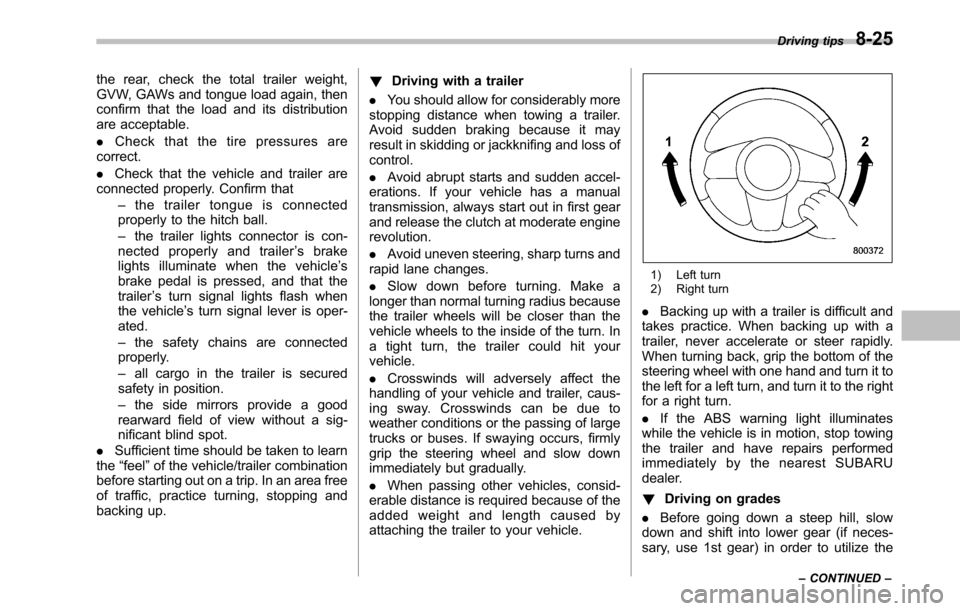

1) Left turn

2) Right turn

. Backing up with a trailer is difficult and

takes practice. When backing up with a

trailer, never accelerate or steer rapidly.

When turning back, grip the bottom of the

steering wheel with one hand and turn it to

the left for a left turn, and turn it to the right

for a right turn. . If the ABS warning light illuminates

while the vehicle is in motion, stop towing

the trailer and have repairs performed

immediately by the nearest SUBARU

dealer. ! Driving on grades

. Before going down a steep hill, slow

down and shift into lower gear (if neces-

sary, use 1st gear) in order to utilize the Driving tips

8-25

– CONTINUED –

Page 378 of 448

11-42Maintenance and service

Aluminum wheels

Aluminum wheels can be scratched and

damaged easily. Handle them carefully to

maintain their appearance, performance,

and safety. .When any of the wheels is removed

and replaced for tire rotation or to change

a flat, always check the tightness of the

wheel nuts after driving approximately 600

miles (1,000 km). If any nut is loose,

tighten it to the specified torque. . Never apply oil to the threaded parts,

wheel nuts, or tapered surface of the wheel. . Never let the wheel rub against sharp

protrusions or curbs.. When wheel nuts, balance weights, or

the center cap is replaced, be sure to

replace them with genuine SUBARU parts

designed for aluminum wheels. Windshield washer fluid

CAUTION

Never use engine coolant as washer

fluid because it could cause paintdamage.

If you spray washer fluid on the windshield

but the windshield washer fluid warning

light illuminates or the supply of washer

fluid runs out, add washer fluid in the tank.

Remove the washer tank filler cap, then

add fluid until it reaches the “FULL ”mark

on the tank.

Use windshield washer fluid. If windshield

washer fluid is unavailable use clean

water.

Page 414 of 448

13-4Consumer information and Reporting safety defects

!Maximum load rating

The load rating at the maximum

permissible weight load for this tire.

For example, “MAX. LOAD 615 kg

(1,356 LBS) @ 350 kpa (51 PSI)

MAX. PRESS. ”

WARNING

Maximum load rating applies

only to the tire, not to the

vehicle. Putting a load rated

tire on any vehicle does not

mean the vehicle can be

loaded up to the tire ’s rated

load.

! Construction type

Applicable construction of this tire.

For example, “TUBELESS STEEL

BELTED RADIAL ”

! Construction

The generic name of each cord

material used in the plies (both

sidewall and tread area) of this tire.

For example, “PLIES: TREAD 2 STEEL + 2 POLYESTER + 1

NYLON SIDEWALL 2 POLYE- STER

”

! Uniform Tire Quality Grading (UTQG)

For details, refer to “Uniform tire

quality grading standards ”F 13-15 .

Page 416 of 448

13-6Consumer information and Reporting safety defects

! Vehicle placard

The vehicle placard is affixed to the driver ’s side B-pillar.

Example:

U.S.-spec. models

Canada-spec. models

The vehicle placard shows original

tire size, recommended cold tire

inflation pressure on each tire at

maximum loaded vehicle weight,

seating capacity and loading infor-mation. ! Adverse safety consequences

of under-inflation

Driving at high speeds with exces-

sively low tire pressures can cause

the tires to flex severely and to

rapidly become hot. A sharp in-

crease in temperature could cause

tread separation, and failure of the

tire(s). Possible resulting loss of vehicle control could lead to anaccident.

! Measuring and adjusting air

pressure to achieve proper in- flation

Check and, if necessary, adjust the

pressure of each tire (including the

spare) at least once a month and

before any long journey. Check the

tire pressures when the tires are

cold. Use a pressure gauge to

adjust the tire pressures to the

specific values. Driving even a

short distance warms up the tires

and increases the tire pressures.

Also, the tire pressures are affected

by the outside temperature. It is

best to check tire pressure out-

doors before driving the vehicle.

When a tire becomes warm, the air

inside it expands, causing the tire

pressure to increase. Be careful not

to mistakenly release air from a

warm tire to reduce its pressure.

Page 417 of 448

&Glossary of tire terminology

. Accessory weight

The combined weight (in excess of

those standard items which may be

replaced) of automatic transmis-

sion, power steering, power brakes,

power windows, power seats, radio,

and heater, to the extent that these

items are available as factory-in-

stalled equipment (whether in-

stalled or not). . Bead

The part of the tire that is made of

steel wires, wrapped or reinforced

by ply cords and that is shaped to fit

the rim. . Bead separation

A breakdown of the bond between

components in the bead. . Bias ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at alternate angles substantially

less than 90 degrees to the center-

line of the tread. . Carcass

The tire structure, except tread and sidewall rubber which, when in-

flated, bears the load.

. Chunking

The breaking away of pieces of the

tread or sidewall. . Cold tire pressure

The pressure in a tire that has been

driven less than 1 mile or has been

standing for three hours or more. . Cord

The strands forming the plies in the tire. . Cord separation

The parting of cords from adjacent

rubber compounds. . Cracking

Any parting within the tread, side-

wall, or inner liner of the tire

extending to cord material. . Curb weight

The weight of a motor vehicle with

standard equipment including the

maximum capacity of fuel, oil and

coolant, and if so equipped, air

conditioning and additional weight

optional engine. .

Extra load tire

A tire designed to operate at higher

loads and higher inflation pressure

than the corresponding standardtire. . Groove

The space between two adjacent

tread ribs. . Innerliner

The layer(s) forming the inside sur-

face of a tubeless tire that contains

the inflating medium within the tire. . Innerliner separation

The parting of the innerliner from

cord material in the carcass. . Intended outboard sidewall

(1) The sidewall that contains a

whitewall, bears white lettering

or bears manufacturer, brand,

and/or model name molding that

is higher or deeper than the

same molding on the other side-

wall of the tire, or (2) The outward facing sidewall

of an asymmetrical tire that has

a particular side that must al-

ways face outward when mount-

Consumer information and Reporting safety defects

13-7

– CONTINUED –

Page 418 of 448

13-8Consumer information and Reporting safety defects

ing on a vehicle.

. Light truck (LT) tire

A tire designated by its manufac-

turer as primarily intended for use

on lightweight trucks or multipur-

pose passenger vehicles. . Load rating

The maximum load that a tire is

rated to carry for a given inflationpressure. . Maximum inflation pressure

The maximum cold inflation pres-

sure to which a tire may be inflated. . Maximum load rating

The load rating for a tire at the

maximum permissible inflation

pressure for that tire. . Maximum loaded vehicle weight

The sum of: (a) Curb weight

(b) Accessory weight

(c) Vehicle capacity weight

(d) Production options weight

. Maximum permissible inflation

pressure

The maximum cold inflation pres-

sure to which a tire may be inflated. .

Measuring rim

The rim on which a tire is fitted for

physical dimension requirements. . Normal occupant weight

150 lbs (68 kg) times the number of

occupants specified in the second

column of Table 1 that is appended

to the end of this section. . Occupant distribution

Distribution of occupants in a vehi-

cle as specified in the third column

of Table 1 that is appended to the

end of this section. . Open splice

Any parting at any junction of tread,

sidewall, or innerliner that extends

to cord material. . Outer diameter

The overall diameter of an inflated

new tire. . Overall width

The linear distance between the

exteriors of the sidewalls of an

inflated tire, including elevations

due to labeling, decorations, or

protective bands or ribs. .

Passenger car tire

A tire intended for use on passen-

ger cars, multipurpose passenger

vehicles, and trucks, that have a

gross vehicle weight rating (GVWR)

of 10,000 lbs (4,535 kg) or less. . Ply

A layer of rubber-coated parallel cords. . Ply separation

A parting of rubber compound

between adjacent plies. . Pneumatic tire

A mechanical device made of rub-

ber, chemicals, fabric and steel or

other materials, that, when

mounted on an automotive wheel,

provides the traction and contains

the gas or fluid that sustains theload. . Production options weight

The combined weight of those

installed regular production options

weighing over 5.1 lbs (2.3 kg) in

excess of those standard items

which they replace, not previously

considered in curb weight or acces-