brake SUBARU OUTBACK 2010 5.G Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2010, Model line: OUTBACK, Model: SUBARU OUTBACK 2010 5.GPages: 448, PDF Size: 7.36 MB

Page 328 of 448

9-18In case of emergency

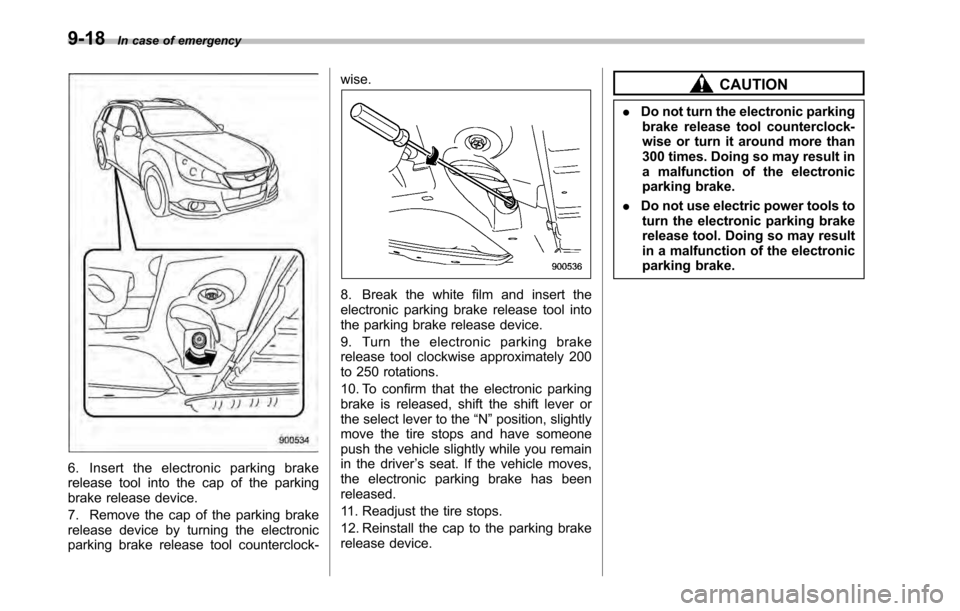

6. Insert the electronic parking brake

release tool into the cap of the parking

brake release device.

7. Remove the cap of the parking brake

release device by turning the electronic

parking brake release tool counterclock- wise.

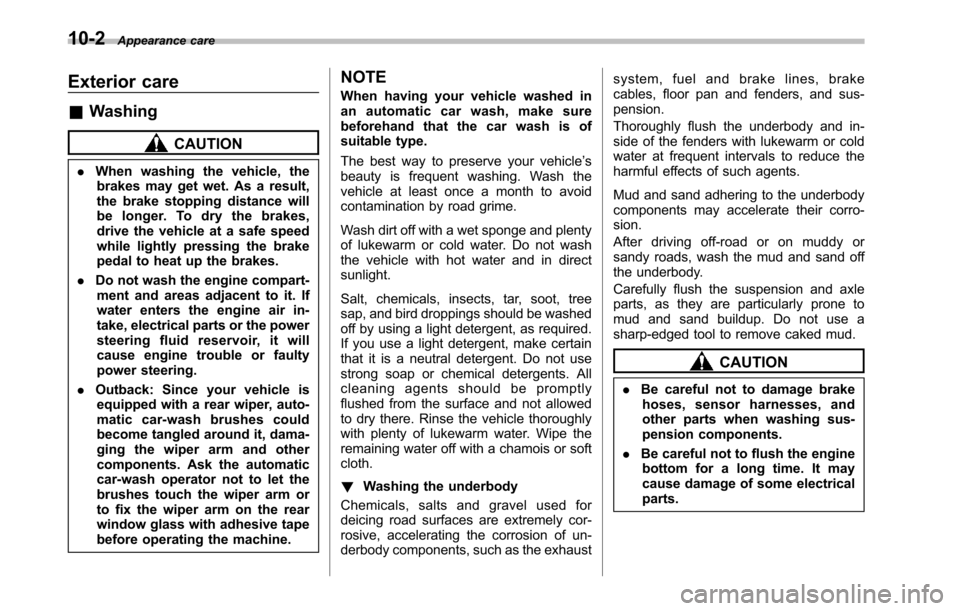

8. Break the white film and insert the

electronic parking brake release tool into

the parking brake release device.

9. Turn the electronic parking brake

release tool clockwise approximately 200

to 250 rotations.

10. To confirm that the electronic parking

brake is released, shift the shift lever or

the select lever to the

“N ”position, slightly

move the tire stops and have someone

push the vehicle slightly while you remain

in the driver ’s seat. If the vehicle moves,

the electronic parking brake has beenreleased.

11. Readjust the tire stops.

12. Reinstall the cap to the parking brake

release device.

CAUTION

. Do not turn the electronic parking

brake release tool counterclock-

wise or turn it around more than

300 times. Doing so may result in

a malfunction of the electronic

parking brake.

. Do not use electric power tools to

turn the electronic parking brake

release tool. Doing so may result

in a malfunction of the electronic

parking brake.

Page 332 of 448

10-2Appearance care

Exterior care &Washing

CAUTION

. When washing the vehicle, the

brakes may get wet. As a result,

the brake stopping distance will

be longer. To dry the brakes,

drive the vehicle at a safe speed

while lightly pressing the brake

pedal to heat up the brakes.

. Do not wash the engine compart-

ment and areas adjacent to it. If

water enters the engine air in-

take, electrical parts or the power

steering fluid reservoir, it will

cause engine trouble or faulty

power steering.

. Outback: Since your vehicle is

equipped with a rear wiper, auto-

matic car-wash brushes could

become tangled around it, dama-

ging the wiper arm and other

components. Ask the automatic

car-wash operator not to let the

brushes touch the wiper arm or

to fix the wiper arm on the rear

window glass with adhesive tape

before operating the machine. NOTE

When having your vehicle washed in

an automatic car wash, make sure

beforehand that the car wash is of

suitable type.

The best way to preserve your vehicle

’s

beauty is frequent washing. Wash the

vehicle at least once a month to avoid

contamination by road grime.

Wash dirt off with a wet sponge and plenty

of lukewarm or cold water. Do not wash

the vehicle with hot water and in direct sunlight.

Salt, chemicals, insects, tar, soot, tree

sap, and bird droppings should be washed

off by using a light detergent, as required.

If you use a light detergent, make certain

that it is a neutral detergent. Do not use

strong soap or chemical detergents. All

cleaning agents should be promptly

flushed from the surface and not allowed

to dry there. Rinse the vehicle thoroughly

with plenty of lukewarm water. Wipe the

remaining water off with a chamois or softcloth. ! Washing the underbody

Chemicals, salts and gravel used for

deicing road surfaces are extremely cor-

rosive, accelerating the corrosion of un-

derbody components, such as the exhaust system, fuel and brake lines, brake

cables, floor pan and fenders, and sus-pension.

Thoroughly flush the underbody and in-

side of the fenders with lukewarm or cold

water at frequent intervals to reduce the

harmful effects of such agents.

Mud and sand adhering to the underbody

components may accelerate their corro-sion.

After driving off-road or on muddy or

sandy roads, wash the mud and sand off

the underbody.

Carefully flush the suspension and axle

parts, as they are particularly prone to

mud and sand buildup. Do not use a

sharp-edged tool to remove caked mud.

CAUTION

. Be careful not to damage brake

hoses, sensor harnesses, and

other parts when washing sus-

pension components.

. Be careful not to flush the engine

bottom for a long time. It may

cause damage of some electricalparts.

Page 334 of 448

10-4Appearance care

Corrosion protection

Your SUBARU has been designed and

built to resist corrosion. Special materials

and protective finishes have been used on

most parts of the vehicle to help maintain

fine appearance, strength, and reliableoperation. &Most common causes of corrosion

The most common causes of corrosion are:

1. The accumulation of moisture retain-

ing dirt and debris in body panel sections,

cavities, and other areas.

2. Damage to paint and other protective

coatings caused by gravel and stone

chips or minor accidents.

Corrosion is accelerated on the vehicle when:

1. It is exposed to road salt or dust

control chemicals, or used in coastal

areas where there is more salt in the air,

or in areas where there is considerable

industrial pollution.

2. It is driven in areas of high humidity,

especially when temperatures range just

above freezing.

3. Dampness in certain parts of the

vehicle remains for a long time, even though other parts of the vehicle may be

dry.

4. High temperatures will cause corro-

sion to parts of the vehicle which cannot

dry quickly due to lack of proper ventila-tion.

& To help prevent corrosion

Wash the vehicle regularly to prevent

corrosion of the body and suspension

components. Also, wash the vehicle

promptly after driving on any of the

following surfaces. . roads that have been salted to prevent

them from freezing in winter. mud, sand, or gravel

. coastal roads

After the winter has ended, it is recom-

mended that the underbody be given a

very thorough washing.

Before the beginning of winter, check the

condition of underbody components, such

as the exhaust system, fuel and brake

lines, brake cables, suspension, steering

system, floor pan, and fenders. If any of

them are found to be rusted, they should

be given an appropriate rust prevention

treatment or should be replaced. Contact

your SUBARU dealer to perform this kind

of maintenance and treatment if you need assistance.

Repair chips and scratches in the paint as

soon as you find them.

Check the interior of the vehicle for water

and dirt accumulation under the floor mats

because that could cause corrosion.

Occasionally check under the mats to

make sure the area is dry.

Keep your garage dry. Do not park your

vehicle in a damp, poorly ventilated

garage. In such a garage, corrosion can

be caused by dampness. If you wash the

vehicle in the garage or put the vehicle

into the garage when wet or covered with

snow, that can cause dampness.

If your vehicle is operated in cold weather

and/or in areas where road salts and other

corrosive materials are used, the door

hinges and locks, trunk lid lock, and hood

latch should be inspected and lubricated

periodically.

Page 337 of 448

Maintenance schedule....................................... 11-3

Maintenance precautions ................................... 11-3

Before checking or servicing in the engine compartment .................................................... 11-4

When checking or servicing in the engine compartment (2.5 L non-turbo models) .. ........... 11-4

When checking or servicing in the engine compartment while the engine is running .......... 11-5

Maintenance tips ................................................ 11-5

Removing and reinstalling clips .......................... 11-5

Removing air intake duct .................................... 11-7

Pulling off the fender lining ................................ 11-7

Engine hood ....................................................... 11-7

Engine compartment overview .......................... 11-9

2.5 L non-turbo models ...................................... 11-9

2.5 L turbo models ........................................... 11-10

3.6 L models .................................................... 11-11

Engine oil .......................................................... 11-12

Checking the oil level ....................................... 11-12

Changing the oil and oil filter ............................ 11-14

Recommended grade and viscosity .................. 11-16

Recommended grade and viscosity under severe driving conditions .......................................... 11-17

Cooling system ................................................ 11-17

Cooling fan, hose and connections ................... 11-17

Engine coolant ................................................. 11-18

Air cleaner element .......................................... 11-20

Replacing the air cleaner element ..................... 11-21

Spark plugs ...................................................... 11-22

Recommended spark plugs .............................. 11-22 Drive belts

........................................................ 11-23

Manual transmission oil .................................. 11-23

Checking the oil level ...................................... 11-23

Recommended grade and viscosity .................. 11-24

Automatic transmission fluid .......................... 11-24

Checking the fluid level .................................... 11-24

Recommended fluid ......................................... 11-25

Continuously variable transmission fluid ...... 11-26

Front differential gear oil (AT and CVT models) .......................................................... 11-26

Checking the oil level ...................................... 11-26

Recommended grade and viscosity .................. 11-27

Rear differential gear oil .................................. 11-27

Checking the gear oil level ............................... 11-27

Recommended grade and viscosity .................. 11-28

Power steering fluid ........................................ 11-29

Checking the fluid level .................................... 11-29

Recommended fluid ......................................... 11-30

Brake fluid ........................................................ 11-30

Checking the fluid level .................................... 11-30

Recommended brake fluid ............................... 11-31

Clutch fluid (MT models) ................................. 11-31

Checking the fluid level .................................... 11-31

Recommended clutch fluid ............................... 11-32

Brake booster .................................................. 11-32

Brake pedal ...................................................... 11-33

Checking the brake pedal free play .................. 11-33

Checking the brake pedal reserve distance....... 11-33 Maintenance and service

11

Page 338 of 448

Maintenance and serviceClutch pedal (MT models) ................................ 11-33

Checking the clutch function ............................ 11-33

Checking the clutch pedal free play .................. 11-34

Replacement of brake pad and lining ............. 11-34

Breaking-in of new brake pads and linings ........ 11-34

Tires and wheels .............................................. 11-35

Types of tires ................................................... 11-35

Tire pressure monitoring system (TPMS) (if equipped) ................................................... 11-35

Tire inspection ................................................. 11-37

Tire pressures and wear ................................... 11-37

Wheel balance .................................................. 11-39

Wear indicators ................................................ 11-39

Tire rotation direction mark .............................. 11-40

Tire rotation ..................................................... 11-40

Tire replacement .............................................. 11-41

Wheel replacement ........................................... 11-41

Aluminum wheels ............................................. 11-42

Windshield washer fluid .................................. 11-42

Replacement of wiper blades .......................... 11-43

Windshield wiper blade assembly ..................... 11-44

Windshield wiper blade rubber ......................... 11-44 Rear window wiper blade assembly

(Outback) ...................................................... 11-45

Rear window wiper blade rubber (Outback) ...... 11-46

Battery .............................................................. 11-47

Fuses ................................................................ 11-48

Main fuse .......................................................... 11-50

Installation of accessories .............................. 11-50

Replacing bulbs ............................................... 11-50

Headlight ......................................................... 11-50

Front turn signal light ...................................... 11-53

Front position light .......................................... 11-53

Front fog light (if equipped) .............................. 11-53

Rear combination lights ................................... 11-54

Tail/Back-up light (Outback) ............................. 11-56

License plate light ........................................... 11-57

Dome light ....................................................... 11-58

Map light ......................................................... 11-59

Vanity mirror light ............................................ 11-59

Door step light ................................................. 11-60

Cargo area light (Outback) ............................... 11-60

Trunk light (Legacy) ......................................... 11-60

Other bulbs ..................................................... 11-60

Page 340 of 448

11-4Maintenance and service

guard against getting oil or fluids

in your eyes. If something does

get in your eyes, thoroughly

wash them out with clean water.

. Do not tamper with the wiring of

the SRS airbag system or seat-

belt pretensioner system, or at-

tempt to take its connectors

apart, as that may activate the

system or it can render it inop-

erative. NEVER use a circuit

tester for these wiring. If your

SRS airbag or seatbelt preten-

sioner needs service, consult

your nearest SUBARU dealer. &

Before checking or servicing

in the engine compartment

WARNING

. Always stop the engine and set

the parking brake firmly to pre-

vent the vehicle from moving.

. Always let the engine cool down.

Engine parts become very hot

when the engine is running and

remain hot for some time after

the engine is stopped.

. Do not spill engine oil, engine

coolant, brake fluid or any other

fluid on hot engine components.

This may cause a fire.

. Always remove the key from the

ignition switch. When the ignition

switch is in the “ON ”position,

thecoolingfanmayoperate

suddenly even when the engine

is stopped.

. Before performing any servicing

on a vehicle equipped with a

remote engine start system tem-

porarily place that system in the

service mode to prevent it from

unexpectedly starting the engine. &

When checking or servicing

in the engine compartment

(2.5 L non-turbo models)

CAUTION

Do not contact the belt cover while

checking the components in the

engine compartment. Doing so may

cause your hand to slip off the belt

cover and result in an unexpected

injury.

Page 345 of 448

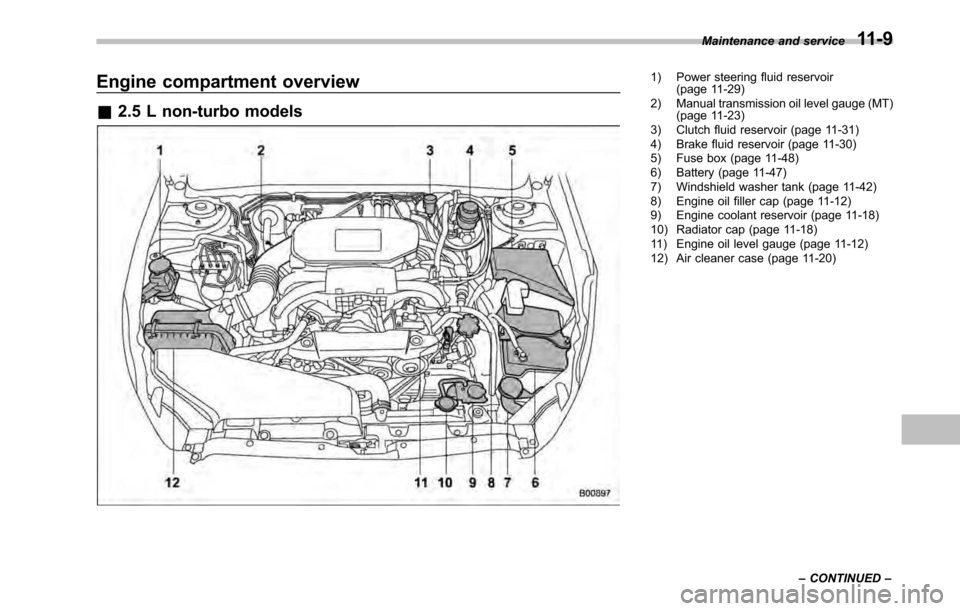

Engine compartment overview &2.5 L non-turbo models1) Power steering fluid reservoir

(page 11-29)

2) Manual transmission oil level gauge (MT) (page 11-23)

3) Clutch fluid reservoir (page 11-31)

4) Brake fluid reservoir (page 11-30)

5) Fuse box (page 11-48)

6) Battery (page 11-47)

7) Windshield washer tank (page 11-42)

8) Engine oil filler cap (page 11-12)

9) Engine coolant reservoir (page 11-18)

10) Radiator cap (page 11-18)

11) Engine oil level gauge (page 11-12)

12) Air cleaner case (page 11-20) Maintenance and service

11-9

– CONTINUED –

Page 346 of 448

11-10Maintenance and service

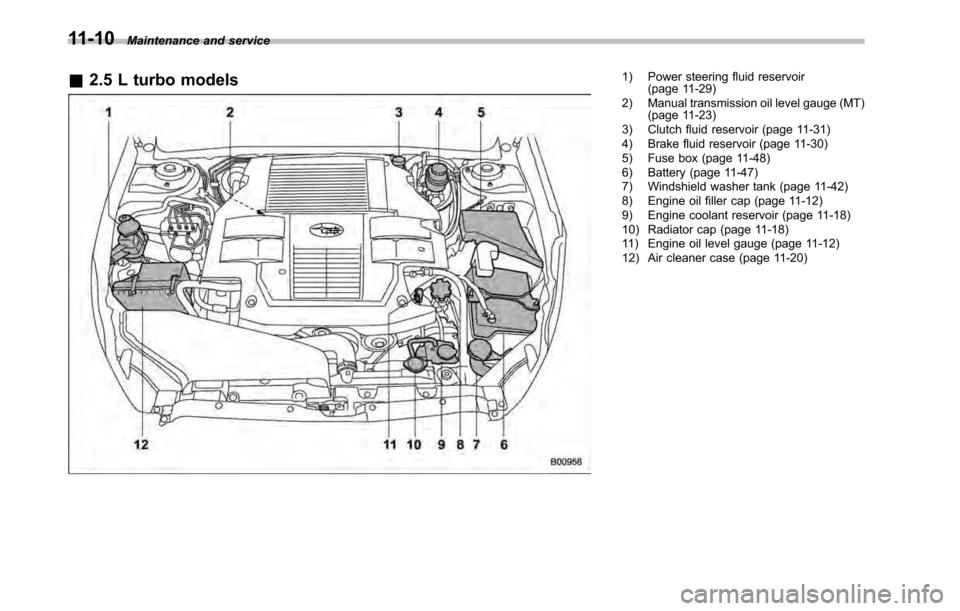

& 2.5 L turbo models

1) Power steering fluid reservoir

(page 11-29)

2) Manual transmission oil level gauge (MT) (page 11-23)

3) Clutch fluid reservoir (page 11-31)

4) Brake fluid reservoir (page 11-30)

5) Fuse box (page 11-48)

6) Battery (page 11-47)

7) Windshield washer tank (page 11-42)

8) Engine oil filler cap (page 11-12)

9) Engine coolant reservoir (page 11-18)

10) Radiator cap (page 11-18)

11) Engine oil level gauge (page 11-12)

12) Air cleaner case (page 11-20)

Page 347 of 448

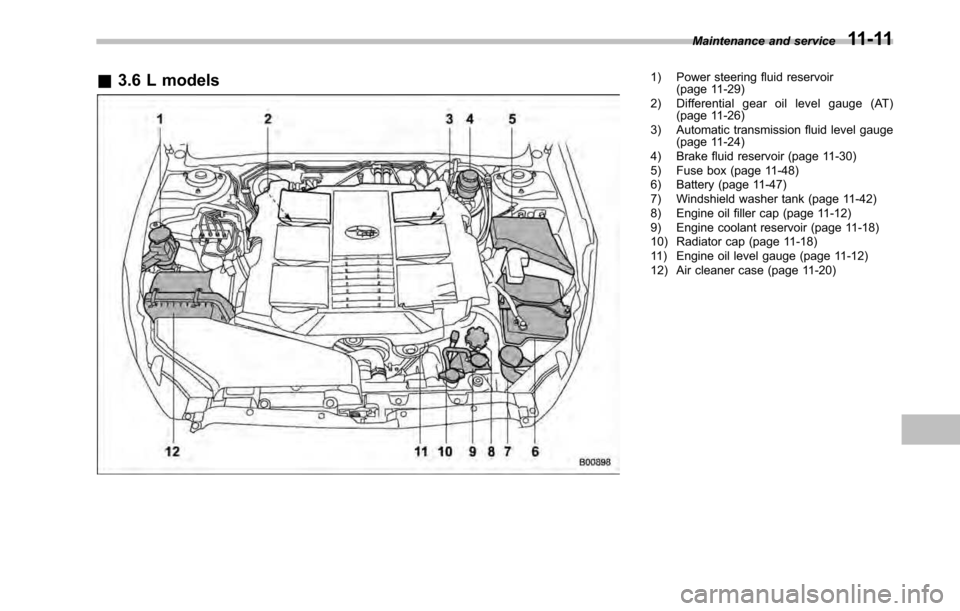

&3.6 L models1) Power steering fluid reservoir

(page 11-29)

2) Differential gear oil level gauge (AT) (page 11-26)

3) Automatic transmission fluid level gauge (page 11-24)

4) Brake fluid reservoir (page 11-30)

5) Fuse box (page 11-48)

6) Battery (page 11-47)

7) Windshield washer tank (page 11-42)

8) Engine oil filler cap (page 11-12)

9) Engine coolant reservoir (page 11-18)

10) Radiator cap (page 11-18)

11) Engine oil level gauge (page 11-12)

12) Air cleaner case (page 11-20) Maintenance and service

11-11

Page 360 of 448

11-24Maintenance and service

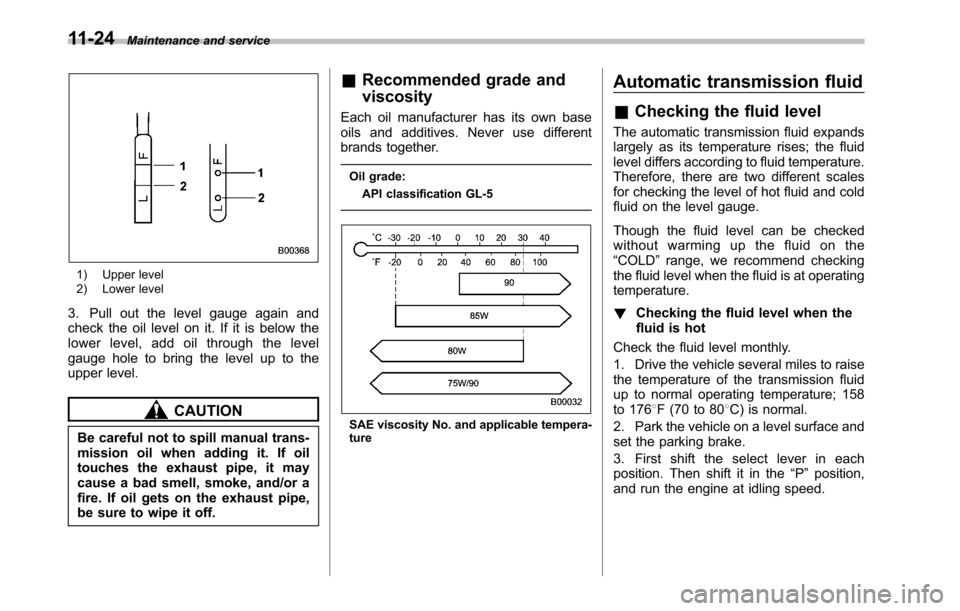

1) Upper level

2) Lower level

3. Pull out the level gauge again and

check the oil level on it. If it is below the

lower level, add oil through the level

gauge hole to bring the level up to the

upper level.

CAUTION

Be careful not to spill manual trans-

mission oil when adding it. If oil

touches the exhaust pipe, it may

cause a bad smell, smoke, and/or a

fire. If oil gets on the exhaust pipe,

be sure to wipe it off. &

Recommended grade and viscosity

Each oil manufacturer has its own base

oils and additives. Never use different

brands together.

Oil grade: API classification GL-5SAE viscosity No. and applicable tempera- ture Automatic transmission fluid &

Checking the fluid level

The automatic transmission fluid expands

largely as its temperature rises; the fluid

level differs according to fluid temperature.

Therefore, there are two different scales

for checking the level of hot fluid and cold

fluid on the level gauge.

Though the fluid level can be checked

without warming up the fluid on the“ COLD ”range, we recommend checking

the fluid level when the fluid is at operatingtemperature. ! Checking the fluid level when the

fluid is hot

Check the fluid level monthly.

1. Drive the vehicle several miles to raise

the temperature of the transmission fluid

up to normal operating temperature; 158

to 176 8F (70 to 80 8C) is normal.

2. Park the vehicle on a level surface and

set the parking brake.

3. First shift the select lever in each

position. Then shift it in the “P ” position,

and run the engine at idling speed.