maintenance SUBARU TRIBECA 2008 Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2008, Model line: TRIBECA, Model: SUBARU TRIBECA 2008Pages: 409, PDF Size: 5.75 MB

Page 349 of 409

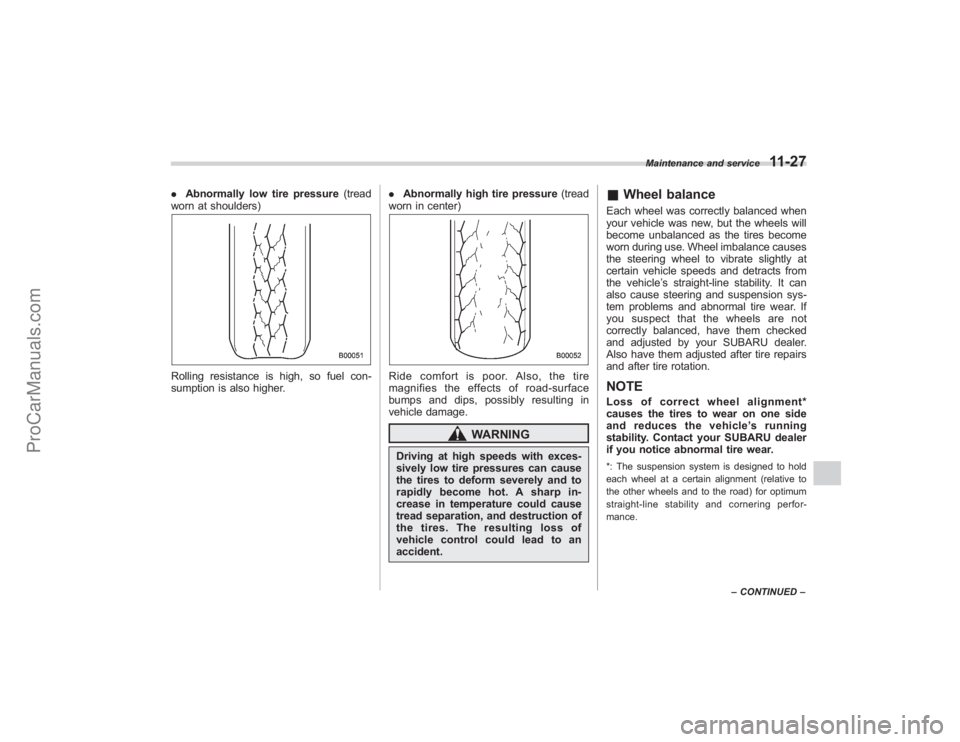

.Abnormally low tire pressure (tread

worn at shoulders)Rolling resistance is high, so fuel con-

sumption is also higher. .

Abnormally high tire pressure (tread

worn in center)

Ride comfort is poor. Also, the tire

magnifies the effects of road-surface

bumps and dips, possibly resulting in

vehicle damage.

WARNING

Driving at high speeds with exces-

sively low tire pressures can cause

the tires to deform severely and to

rapidly become hot. A sharp in-

crease in temperature could cause

tread separation, and destruction of

the tires. The resulting loss of

vehicle control could lead to an

accident.

& Wheel balanceEach wheel was correctly balanced when

your vehicle was new, but the wheels will

become unbalanced as the tires become

worn during use. Wheel imbalance causes

the steering wheel to vibrate slightly at

certain vehicle speeds and detracts from

the vehicle ’s straight-line stability. It can

also cause steering and suspension sys-

tem problems and abnormal tire wear. If

you suspect that the wheels are not

correctly balanced, have them checked

and adjusted by your SUBARU dealer.

Also have them adjusted after tire repairs

and after tire rotation.NOTELoss of correct wheel alignment*

causes the tires to wear on one side

and reduces the vehicle ’s running

stability. Contact your SUBARU dealer

if you notice abnormal tire wear.*: The suspension system is designed to hold

each wheel at a certain alignment (relative to

the other wheels and to the road) for optimum

straight-line stability and cornering perfor-

mance. Maintenance and service

11-27

–

CONTINUED –

ProCarManuals.com

Page 350 of 409

11-28

Maintenance and service

&Wear indicators1) New tread

2) Worn tread

3) Tread wear indicatorEach tire incorporates a tread wear

indicator, which becomes visible when

the depth of the tread grooves decreases

to 0.071 in (1.8 mm). A tire must be

replaced when the tread wear indicator

appears as a solid band across the tread.

WARNING

When a tire ’s tread wear indicator

becomes visible, the tire is worn

beyond the acceptable limit and

must be replaced immediately. With

a tire in this condition, driving at

high speeds in wet weather can cause the vehicle to hydroplane.

The resulting loss of vehicle control

can lead to an accident.

NOTEFor safety, inspect the tire tread reg-

ularly and replace the tires before their

tread wear indicators become visible.&

Tire rotation direction markExample of tire rotation direction mark

1) FrontIf the tire has the rotation direction

specification, the tire rotation direction

mark is placed on its sidewall.

When you install a tire that has the tire

rotation direction mark, install the tire with the direction mark facing forward.

&

Tire rotationVehicles equipped with 4 non-unidirec-

tional tires

1) Front

ProCarManuals.com

Page 351 of 409

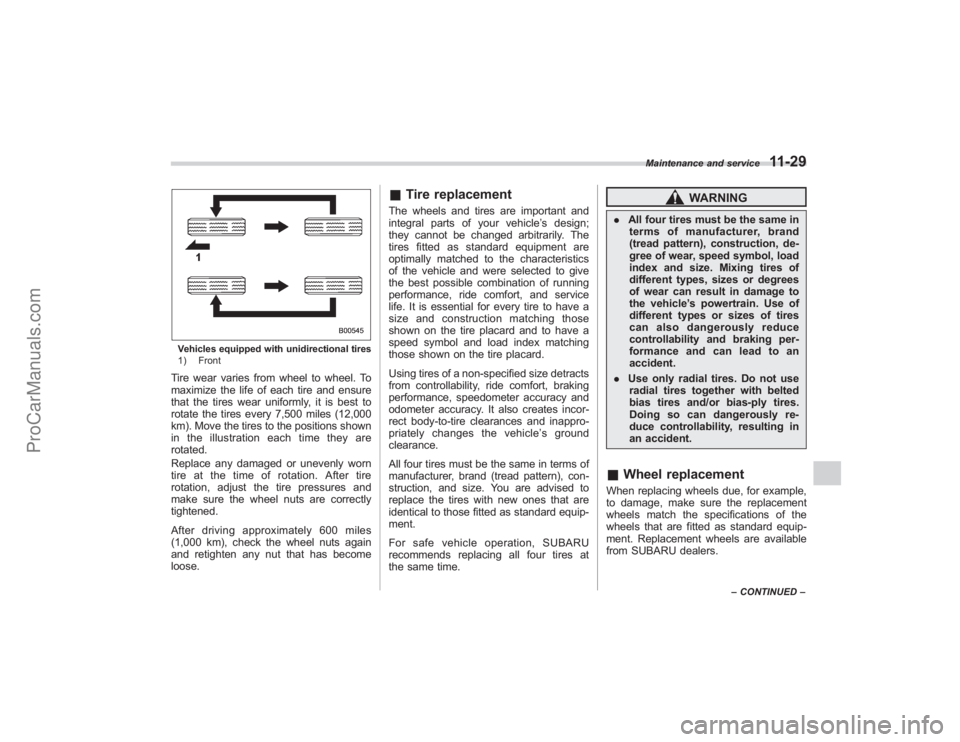

Vehicles equipped with unidirectional tires

1) FrontTire wear varies from wheel to wheel. To

maximize the life of each tire and ensure

that the tires wear uniformly, it is best to

rotate the tires every 7,500 miles (12,000

km). Move the tires to the positions shown

in the illustration each time they are

rotated.

Replace any damaged or unevenly worn

tire at the time of rotation. After tire

rotation, adjust the tire pressures and

make sure the wheel nuts are correctly

tightened.

After driving approximately 600 miles

(1,000 km), check the wheel nuts again

and retighten any nut that has become

loose.

&Tire replacementThe wheels and tires are important and

integral parts of your vehicle ’s design;

they cannot be changed arbitrarily. The

tires fitted as standard equipment are

optimally matched to the characteristics

of the vehicle and were selected to give

the best possible combination of running

performance, ride comfort, and service

life. It is essential for every tire to have a

size and construction matching those

shown on the tire placard and to have a

speed symbol and load index matching

those shown on the tire placard.

Using tires of a non-specified size detracts

from controllability, ride comfort, braking

performance, speedometer accuracy and

odometer accuracy. It also creates incor-

rect body-to-tire clearances and inappro-

priately changes the vehicle ’s ground

clearance.

All four tires must be the same in terms of

manufacturer, brand (tread pattern), con-

struction, and size. You are advised to

replace the tires with new ones that are

identical to those fitted as standard equip-

ment.

For safe vehicle operation, SUBARU

recommends replacing all four tires at

the same time.

WARNING

. All four tires must be the same in

terms of manufacturer, brand

(tread pattern), construction, de-

gree of wear, speed symbol, load

index and size. Mixing tires of

different types, sizes or degrees

of wear can result in damage to

the vehicle ’s powertrain. Use of

different types or sizes of tires

can also dangerously reduce

controllability and braking per-

formance and can lead to an

accident.

. Use only radial tires. Do not use

radial tires together with belted

bias tires and/or bias-ply tires.

Doing so can dangerously re-

duce controllability, resulting in

an accident.& Wheel replacementWhen replacing wheels due, for example,

to damage, make sure the replacement

wheels match the specifications of the

wheels that are fitted as standard equip-

ment. Replacement wheels are available

from SUBARU dealers.

Maintenance and service

11-29

–CONTINUED –

ProCarManuals.com

Page 352 of 409

11-30

Maintenance and service

WARNING

Use only those wheels that are

specified for your vehicle. Wheels

not meeting specifications could

interfere with brake caliper opera-

tion and may cause the tires to rub

against the wheel well housing dur-

ing turns. The resulting loss of

vehicle control could lead to an

accident.

Aluminum wheels.Aluminum wheels can be scratched

and damaged easily. Handle them care-

fully to maintain their appearance, perfor-

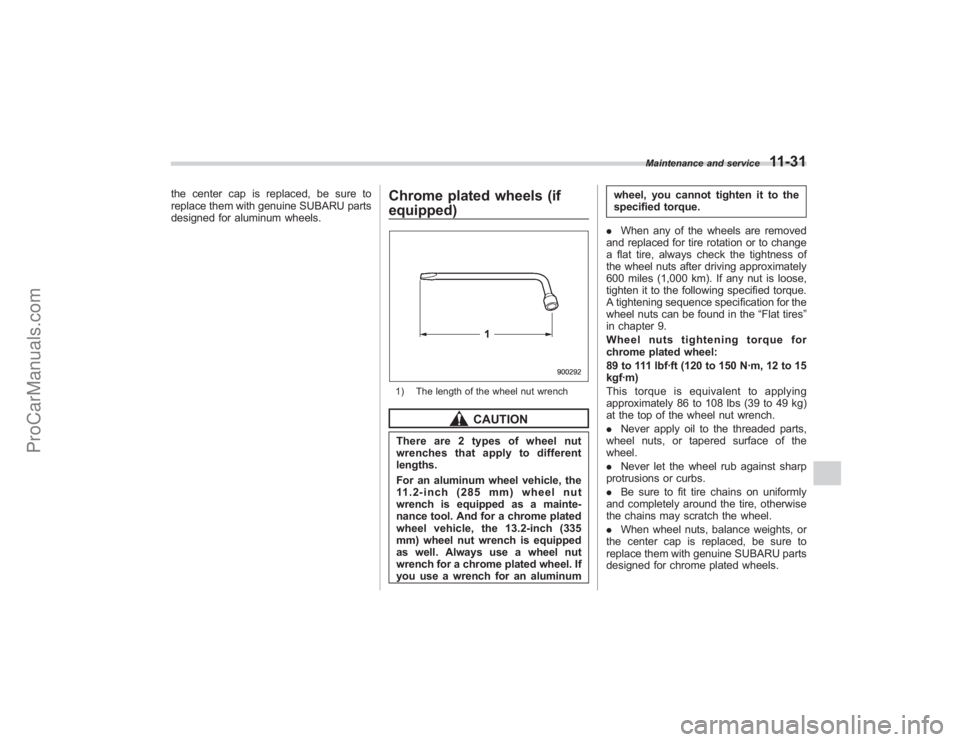

mance, and safety.1) The length of the wheel nut wrench

CAUTION

There are 2 types of wheel nut

wrenches that apply to different

lengths.

For an aluminum wheel vehicle, the

11.2-inch (285 mm) wheel nut

wrench is equipped as a mainte-

nance tool. And for a chrome plated

wheel vehicle, the 13.2-inch (335

mm) wheel nut wrench is equipped as well. Always use a wheel nut

wrench for an aluminum wheel. If

youuseawrenchforachrome

plated wheel, you cannot tighten it

to the specified torque.

. When any of the wheels are removed

and replaced for tire rotation or to change

a flat tire, always check the tightness of

the wheel nuts after driving approximately

600 miles (1,000 km). If any nut is loose,

tighten it to the following specified torque.

A tightening sequence specification for the

wheel nuts can be found in the “Flat tires”

in chapter 9.

Wheel nuts tightening torque for alu-

minum wheel:

74 to 89 lbf·ft (100 to 120 N·m, 10 to 12

kgf·m)

This torque is equivalent to applying

approximately 88 to 110 lbs (40 to 50 kg)

at the top of the wheel nut wrench.

. Never apply oil to the threaded parts,

wheel nuts, or tapered surface of the

wheel.

. Never let the wheel rub against sharp

protrusions or curbs.

. Be sure to fit tire chains on uniformly

and completely around the tire, otherwise

the chains may scratch the wheel.

. When wheel nuts, balance weights, or

ProCarManuals.com

Page 353 of 409

the center cap is replaced, be sure to

replace them with genuine SUBARU parts

designed for aluminum wheels.

Chrome plated wheels (if

equipped)1) The length of the wheel nut wrench

CAUTION

There are 2 types of wheel nut

wrenches that apply to different

lengths.

For an aluminum wheel vehicle, the

11.2-inch (285 mm) wheel nut

wrench is equipped as a mainte-

nance tool. And for a chrome plated

wheel vehicle, the 13.2-inch (335

mm) wheel nut wrench is equipped

as well. Always use a wheel nut

wrench for a chrome plated wheel. If

you use a wrench for an aluminumwheel, you cannot tighten it to the

specified torque.

. When any of the wheels are removed

and replaced for tire rotation or to change

a flat tire, always check the tightness of

the wheel nuts after driving approximately

600 miles (1,000 km). If any nut is loose,

tighten it to the following specified torque.

A tightening sequence specification for the

wheel nuts can be found in the “Flat tires”

in chapter 9.

Wheel nuts tightening torque for

chrome plated wheel:

89 to 111 lbf·ft (120 to 150 N·m, 12 to 15

kgf·m)

This torque is equivalent to applying

approximately 86 to 108 lbs (39 to 49 kg)

at the top of the wheel nut wrench.

. Never apply oil to the threaded parts,

wheel nuts, or tapered surface of the

wheel.

. Never let the wheel rub against sharp

protrusions or curbs.

. Be sure to fit tire chains on uniformly

and completely around the tire, otherwise

the chains may scratch the wheel.

. When wheel nuts, balance weights, or

the center cap is replaced, be sure to

replace them with genuine SUBARU parts

designed for chrome plated wheels.

Maintenance and service

11-31

ProCarManuals.com

Page 354 of 409

11-32

Maintenance and service

Windshield washer fluid

CAUTION

Never use engine coolant as washer

fluid because it could cause paint

damage.If you spray washer fluid on the windshield

but the windshield washer fluid warning

light comes on or the supply of washer

fluid drops, check the level of washer fluid

in the tank.

Washer fluid level gaugeRemove the washer tank filler cap, then

check the fluid level indicated by the level

gauge (attached to the inside of the cap).

If the level is near the“Low”mark, add

fluid until it reaches the “Hi”level on the level gauge.

After adding fluid, make sure the wind-

shield washer fluid warning light has gone

out.

Use windshield washer fluid. If windshield

washer fluid is unavailable use clean

water.

In areas where water freezes in winter,

use an anti-freeze type windshield washer

fluid. SUBARU Windshield Washer Fluid

contains 58.5% methyl alcohol and 41.5%

surfactant, by volume. Its freezing tem-

perature varies according to how much it

is diluted, as indicated in the following

table.

Washer Fluid

Concentration Freezing

Temperature

30% 10.48F( −12 8C)

50% −48F( −20 8C)

100% −498F( −45 8C)

CAUTION

Never use engine coolant as washer

fluid because it could cause paint

damage.

In order to prevent freezing of washer

fluid, check the freezing temperatures in

the table above when adjusting the fluid

ProCarManuals.com

Page 355 of 409

concentration to the outside temperature.

If you fill the reservoir tank with a fluid with

a different concentration from the one

used previously, purge the old fluid from

the piping between the reservoir tank and

washer nozzles by operating the washer

for a certain period of time. Otherwise, if

the concentration of the fluid remaining in

thepipingistoolowfortheoutside

temperature, it may freeze and block the

nozzles.

CAUTION

Adjust the washer fluid concentra-

tion appropriately for the outside

temperature. If the concentration is

inappropriate, sprayed washer fluid

may freeze on the windshield and

obstruct your view, and the fluid

may freeze in the reservoir tank.

Replacement of wiper bladesGrease, wax, insects, or other materials

on the windshield or the wiper blade

results in jerky wiper operation and streak-

ing on the glass. If you cannot remove the

streaks after operating the windshield

washer or if the wiper operation is jerky,

clean the outer surface of the windshield

(or rear window) and the wiper blades

using a sponge or soft cloth with a neutral

detergent or mild-abrasive cleaner. After

cleaning, rinse the windshield and wiper

blades with clean water. The windshield is

clean if beads do not form when you rinse

the windshield with water.

CAUTION

.Do not clean the wiper blades

with gasoline or a solvent, such

as paint thinner or benzine. This

will cause deterioration of the

wiper blades.

. Whenyouwishtoraisethe

passenger-side wiper arm, first

raise the driver-side wiper arm.

Otherwise, the passenger-side

wiper assembly and driver-side

wiper assembly will touch each

other, possibly resulting in

scratches. .

Return the passenger-side wiper

arm to its original position before

returning the driver-side wiper

arm to its original position.

Otherwise, the passenger-side

wiper assembly and driver-side

wiper assembly will touch each

other, possibly resulting in

scratches.

If you cannot eliminate the streaking even

after following this method, replace the

wiper blades using the following proce-

dures. Be sure to use genuine SUBARU

wiper blade rubbers as replacements.

& Windshield wiper blade as-

sembly1. Raise the windshield wiper arm on the

driver ’s side.

2. Next, raise the windshield wiper arm

on the passenger ’s side.

Maintenance and service

11-33

– CONTINUED –

ProCarManuals.com

Page 356 of 409

11-34

Maintenance and service

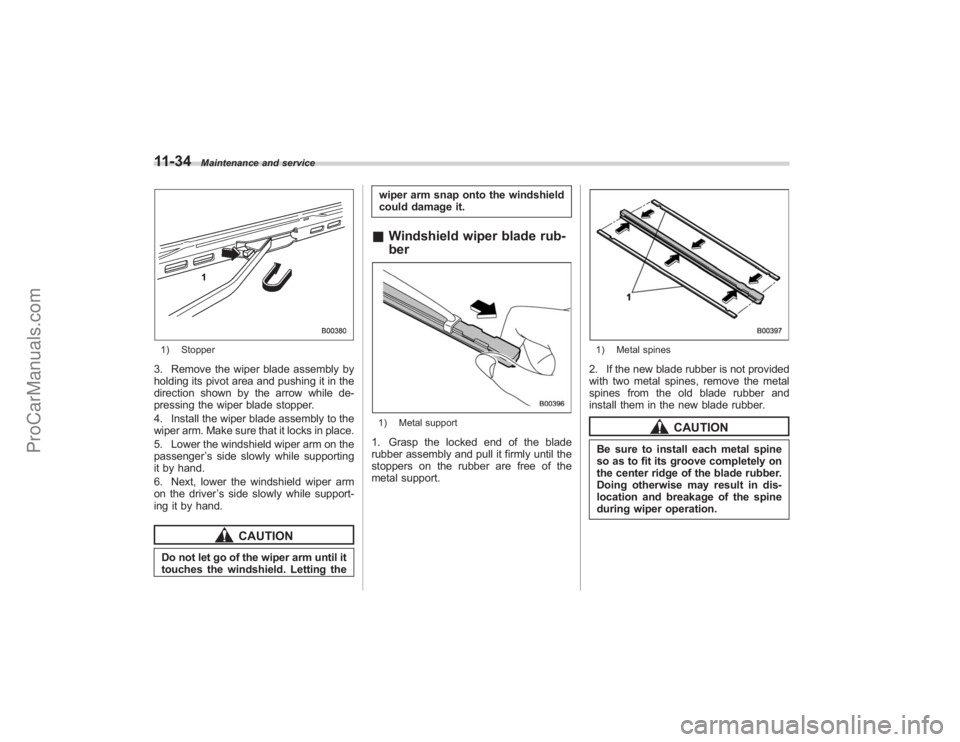

1) Stopper3. Remove the wiper blade assembly by

holding its pivot area and pushing it in the

direction shown by the arrow while de-

pressing the wiper blade stopper.

4. Install the wiper blade assembly to the

wiper arm. Make sure that it locks in place.

5. Lower the windshield wiper arm on the

passenger’s side slowly while supporting

it by hand.

6. Next, lower the windshield wiper arm

on the driver ’s side slowly while support-

ing it by hand.

CAUTION

Do not let go of the wiper arm until it

touches the windshield. Letting the wiper arm snap onto the windshield

could damage it.

&

Windshield wiper blade rub-

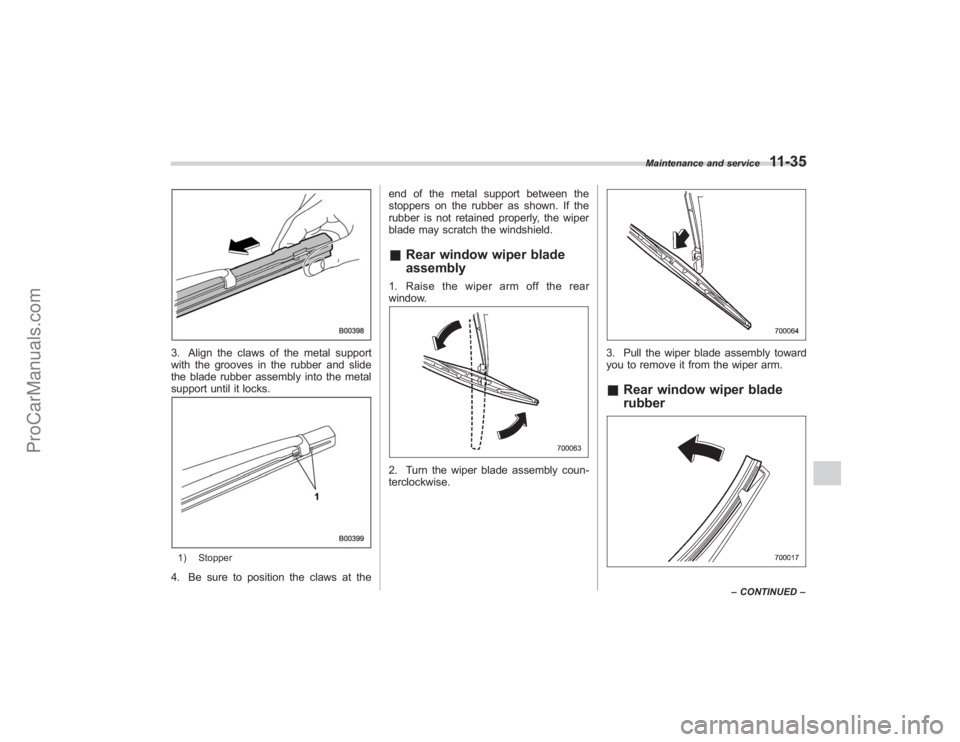

ber1) Metal support1. Grasp the locked end of the blade

rubber assembly and pull it firmly until the

stoppers on the rubber are free of the

metal support.

1) Metal spines2. If the new blade rubber is not provided

with two metal spines, remove the metal

spines from the old blade rubber and

install them in the new blade rubber.

CAUTION

Be sure to install each metal spine

so as to fit its groove completely on

the center ridge of the blade rubber.

Doing otherwise may result in dis-

location and breakage of the spine

during wiper operation.

ProCarManuals.com

Page 357 of 409

3. Align the claws of the metal support

with the grooves in the rubber and slide

the blade rubber assembly into the metal

support until it locks.1) Stopper4. Be sure to position the claws at theend of the metal support between the

stoppers on the rubber as shown. If the

rubber is not retained properly, the wiper

blade may scratch the windshield.

&

Rear window wiper blade

assembly1. Raise the wiper arm off the rear

window.2. Turn the wiper blade assembly coun-

terclockwise.

3. Pull the wiper blade assembly toward

you to remove it from the wiper arm.&Rear window wiper blade

rubber

Maintenance and service

11-35

–CONTINUED –

ProCarManuals.com

Page 358 of 409

11-36

Maintenance and service

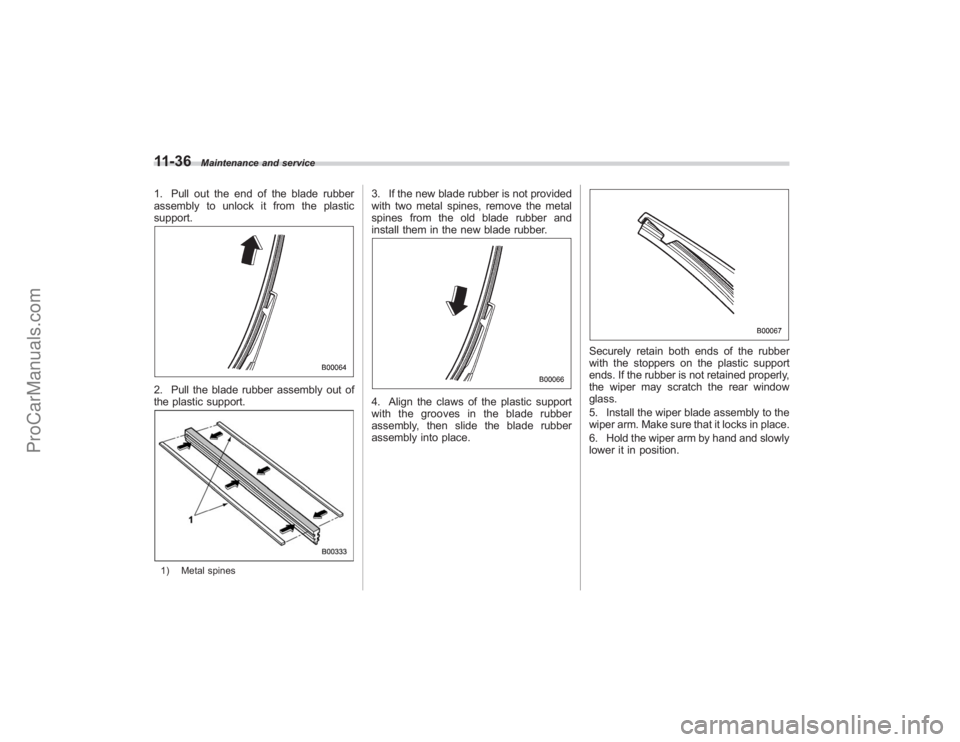

1. Pull out the end of the blade rubber

assembly to unlock it from the plastic

support.2. Pull the blade rubber assembly out of

the plastic support.1) Metal spines

3. If the new blade rubber is not provided

with two metal spines, remove the metal

spines from the old blade rubber and

install them in the new blade rubber.4. Align the claws of the plastic support

with the grooves in the blade rubber

assembly, then slide the blade rubber

assembly into place.

Securely retain both ends of the rubber

with the stoppers on the plastic support

ends. If the rubber is not retained properly,

the wiper may scratch the rear window

glass.

5. Install the wiper blade assembly to the

wiper arm. Make sure that it locks in place.

6. Hold the wiper arm by hand and slowly

lower it in position.

ProCarManuals.com