ECU SUBARU TRIBECA 2013 1.G Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2013, Model line: TRIBECA, Model: SUBARU TRIBECA 2013 1.GPages: 420, PDF Size: 12.74 MB

Page 304 of 420

vehicle’s turn signal lever is operated.

– the safety chains are connected

properly. – all cargo in the trailer is secured

safely in position.– the side mirrors provide a good

rearward field of view without a sig-

nificant blind spot.

. Sufficient time should be taken to learn

the “feel ”of the vehicle/trailer combination

before starting out on a trip. In an area free

of traffic, practice turning, stopping and

backing up. ! Driving with a trailer

. You should allow for considerably more

stopping distance when towing a trailer.

Avoid sudden braking because it may

result in skidding or jackknifing and loss ofcontrol. . Avoid uneven steering, sharp turns and

rapid lane changes.. Slow down before turning. Make a

longer than normal turning radius because

the trailer wheels will be closer than the

vehicle wheels to the inside of the turn. In

a tight turn, the trailer could hit yourvehicle. . Crosswinds will adversely affect the

handling of your vehicle and trailer, caus-

ing sway. Crosswinds can be due to

weather conditions or the passing of large trucks or buses. If swaying occurs, firmly

grip the steering wheel and slow down

immediately but gradually. .

When passing other vehicles, consid-

erable distance is required because of the

added weight and length caused by

attaching the trailer to your vehicle.

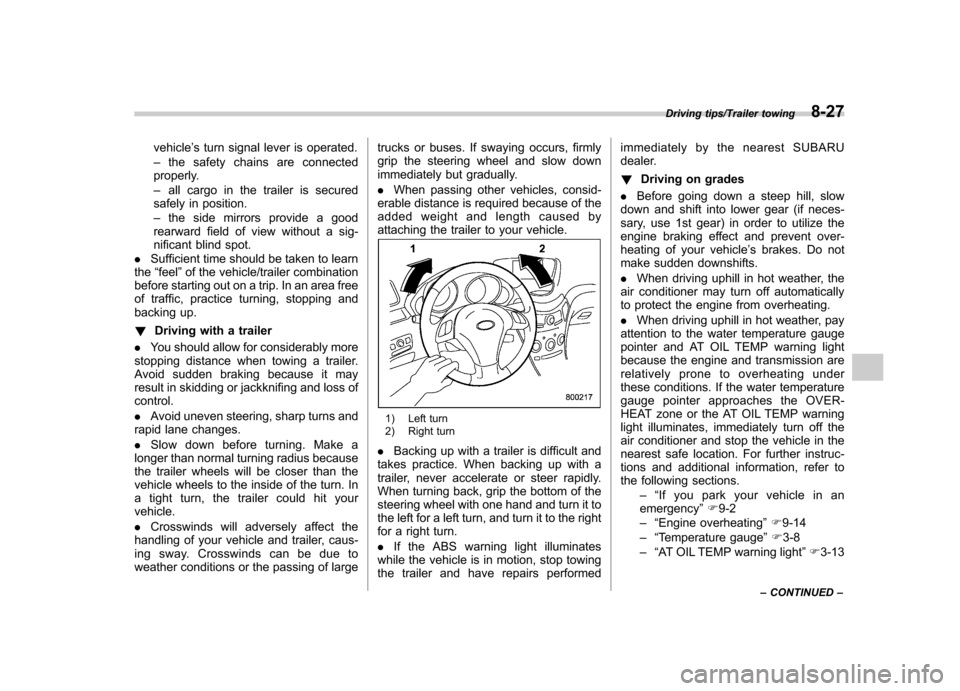

1) Left turn

2) Right turn

. Backing up with a trailer is difficult and

takes practice. When backing up with a

trailer, never accelerate or steer rapidly.

When turning back, grip the bottom of the

steering wheel with one hand and turn it to

the left for a left turn, and turn it to the right

for a right turn. . If the ABS warning light illuminates

while the vehicle is in motion, stop towing

the trailer and have repairs performed immediately by the nearest SUBARU

dealer. !

Driving on grades

. Before going down a steep hill, slow

down and shift into lower gear (if neces-

sary, use 1st gear) in order to utilize the

engine braking effect and prevent over-

heating of your vehicle ’s brakes. Do not

make sudden downshifts. . When driving uphill in hot weather, the

air conditioner may turn off automatically

to protect the engine from overheating. . When driving uphill in hot weather, pay

attention to the water temperature gauge

pointer and AT OIL TEMP warning light

because the engine and transmission are

relatively prone to overheating under

these conditions. If the water temperature

gauge pointer approaches the OVER-

HEAT zone or the AT OIL TEMP warning

light illuminates, immediately turn off the

air conditioner and stop the vehicle in the

nearest safe location. For further instruc-

tions and additional information, refer to

the following sections.

–“If you park your vehicle in an

emergency ”F 9-2

–“ Engine overheating ”F 9-14

–“ Temperature gauge ”F 3-8

–“ AT OIL TEMP warning light ”F 3-13

Driving tips/Trailer towing8-27

– CONTINUED –

Page 310 of 420

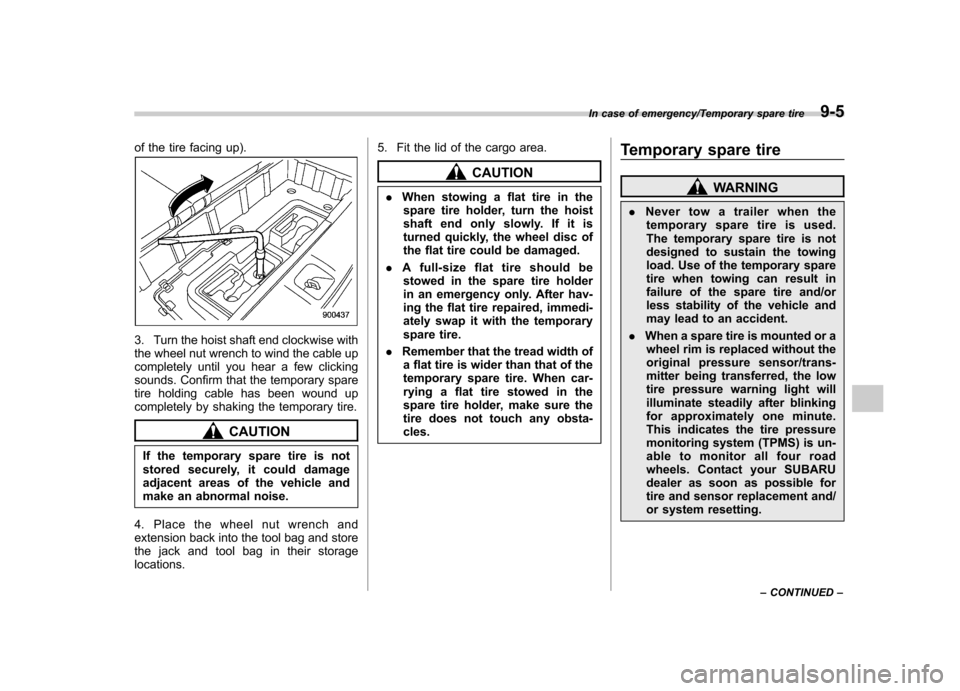

of the tire facing up).

3. Turn the hoist shaft end clockwise with

the wheel nut wrench to wind the cable up

completely until you hear a few clicking

sounds. Confirm that the temporary spare

tire holding cable has been wound up

completely by shaking the temporary tire.

CAUTION

If the temporary spare tire is not

stored securely, it could damage

adjacent areas of the vehicle and

make an abnormal noise.

4. Place the wheel nut wrench and

extension back into the tool bag and store

the jack and tool bag in their storagelocations. 5. Fit the lid of the cargo area.

CAUTION

. When stowing a flat tire in the

spare tire holder, turn the hoist

shaft end only slowly. If it is

turned quickly, the wheel disc of

the flat tire could be damaged.

. A full-size flat tire should be

stowed in the spare tire holder

in an emergency only. After hav-

ing the flat tire repaired, immedi-

ately swap it with the temporary

spare tire.

. Remember that the tread width of

a flat tire is wider than that of the

temporary spare tire. When car-

rying a flat tire stowed in the

spare tire holder, make sure the

tire does not touch any obsta-cles. Temporary spare tire

WARNING

. Never tow a trailer when the

temporary spare tire is used.

The temporary spare tire is not

designed to sustain the towing

load. Use of the temporary spare

tire when towing can result in

failure of the spare tire and/or

less stability of the vehicle and

may lead to an accident.

. When a spare tire is mounted or a

wheel rim is replaced without the

original pressure sensor/trans-

mitter being transferred, the low

tire pressure warning light will

illuminate steadily after blinking

for approximately one minute.

This indicates the tire pressure

monitoring system (TPMS) is un-

able to monitor all four road

wheels. Contact your SUBARU

dealer as soon as possible for

tire and sensor replacement and/

or system resetting.

In case of emergency/Temporary spare tire9-5

– CONTINUED –

Page 312 of 420

.Always turn off the engine before

raising the flat tire off the ground

using the jack. Never swing or

push the vehicle supported with

the jack. The jack can come out

of the jacking point due to a jolt

and this can result in a severeaccident.

1. Park on a hard, level surface, when-

ever possible, then stop the engine.

2. Set the parking brake securely and

shift in the “P ”(Park) position.

3. Turn on the hazard warning flasher

and have everyone get out of the vehicle.

4. Put wheel blocks at the front and rear

of the tire diagonally opposite the flat tire.

1) Jack handle

2) Jack

3) Spare tire

5. Take out the jack and jack handle.

The jack and jack handle are stored under

the floor of the cargo area.

6. Remove the spare tire.

Refer to “Spare tire ”F 9-2 for its location,

instructions and precautions.

Carefully read “Temporary spare tire ”F 9-

5 and strictly follow the instructions.

NOTE

Make sure the jack is well lubricated

before using it.Chrome plated wheels

7. Insert the tip (wrapped in vinyl tape or

a cloth) of a flat-head screwdriver into the

slot between the wheel and cap. Use it to

remove the cap. (Only vehicle equipped

with chrome plated wheels)

In case of emergency/Flat tires9-7

– CONTINUED –

Page 314 of 420

WARNING

Do not use oil or grease on the

wheel studs or nuts when the spare

tire is installed. This could cause the

nuts to become loose and lead to anaccident.

15. Turn the jack handle counterclockwise

to lower the vehicle.

CAUTION

There are 2 types of wheel nut

wrenches that apply to differentlengths.

For models with silver-colored alu-

minum wheels, the 10.8-inch (275

mm) wheel nut wrench is equipped

as a maintenance tool. And for

models with optional chrome-fin-

ished wheels, the 13.2-inch (335

mm) wheel nut wrench is equipped

as well. Confirm the equipped wheel

nut wrench type when you replace a

tire. If the wheel nut wrench is the

different type, it cannot be tightened

to the specified torque.

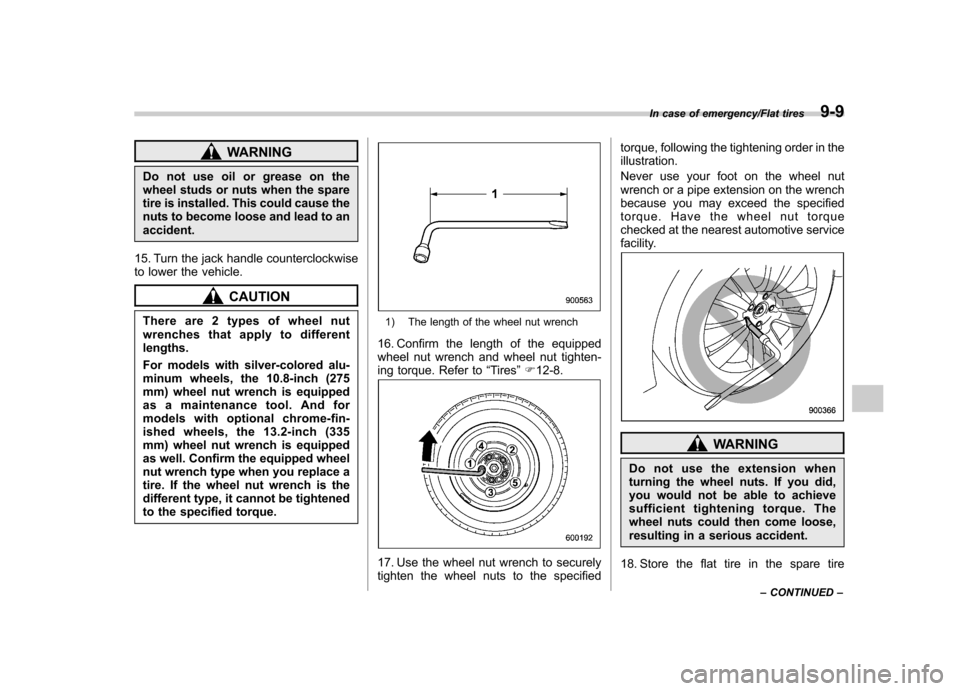

1) The length of the wheel nut wrench

16. Confirm the length of the equipped

wheel nut wrench and wheel nut tighten-

ing torque. Refer to “Tires ”F 12-8.

17. Use the wheel nut wrench to securely

tighten the wheel nuts to the specified torque, following the tightening order in theillustration.

Never use your foot on the wheel nut

wrench or a pipe extension on the wrench

because you may exceed the specified

torque. Have the wheel nut torque

checked at the nearest automotive service

facility.

WARNING

Do not use the extension when

turning the wheel nuts. If you did,

you would not be able to achieve

sufficient tightening torque. The

wheel nuts could then come loose,

resulting in a serious accident.

18. Store the flat tire in the spare tire

In case of emergency/Flat tires9-9

– CONTINUED –

Page 320 of 420

&Towing and tie-down hooks

The towing hooks should be used only in

an emergency (e.g., to free a stuck vehicle

from mud, sand or snow).

CAUTION

. Use only the specified towing

hooks and tie-down hooks. Never

use suspension parts or other

parts of the body for towing or

tie-down purposes.

. Never use the tie-down hook

closest to the muffler under the

vehicle for towing purposes.

. To prevent deformation to the

bumper and the towing hook, do

not apply excessive lateral load

to the towing hooks.

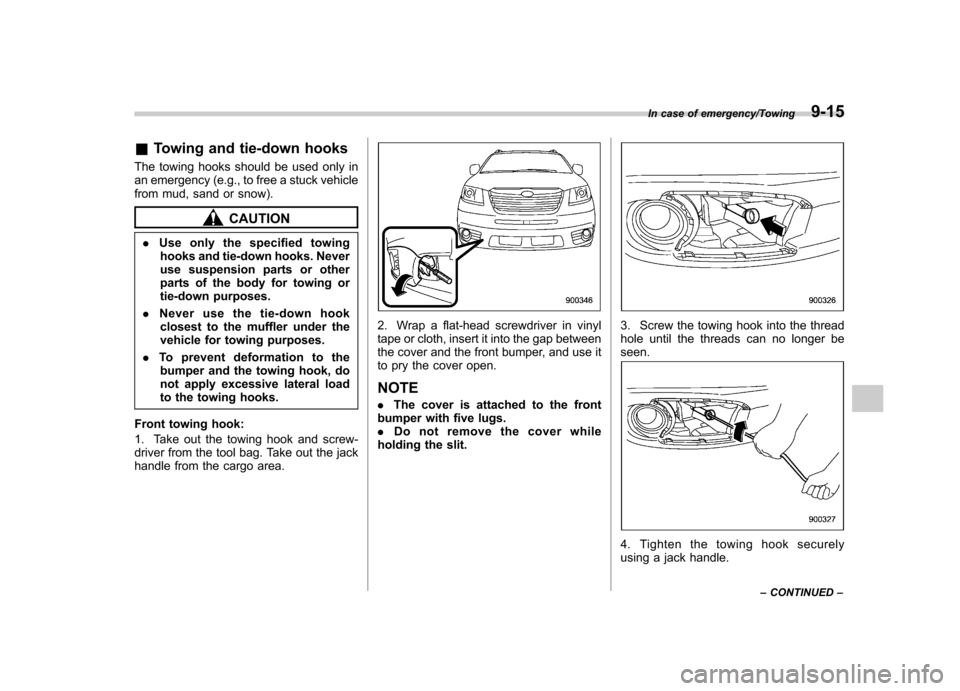

Front towing hook:

1. Take out the towing hook and screw-

driver from the tool bag. Take out the jack

handle from the cargo area.

2. Wrap a flat-head screwdriver in vinyl

tape or cloth, insert it into the gap between

the cover and the front bumper, and use it

to pry the cover open. NOTE . The cover is attached to the front

bumper with five lugs. . Do not remove the cover while

holding the slit.3. Screw the towing hook into the thread

hole until the threads can no longer beseen.

4. Tighten the towing hook securely

using a jack handle.

In case of emergency/Towing9-15

– CONTINUED –

Page 321 of 420

9-16In case of emergency/Towing

After towing, remove the towing hook from

the vehicle and stow it in the tool bag.

Fit the towing hook cover on the bumper.

WARNING

. Do not use the towing hook

except when towing your vehicle.

. Be sure to remove the towing

hook after towing. Leaving the

towing hook mounted on the

vehicle could interfere with prop-

er operation of the SRS airbag

system in a frontal collision.

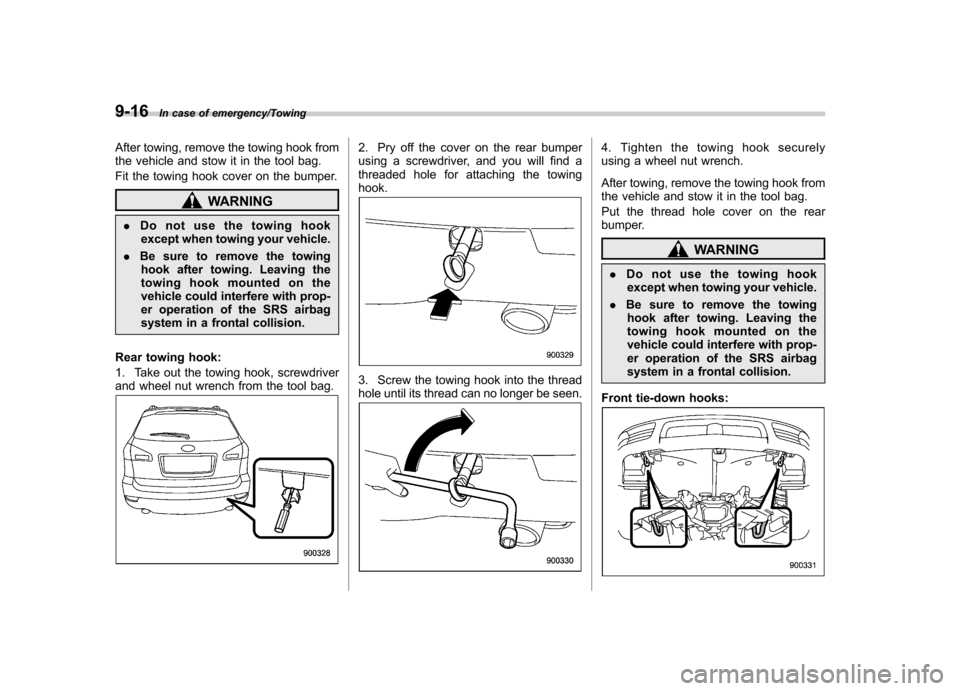

Rear towing hook:

1. Take out the towing hook, screwdriver

and wheel nut wrench from the tool bag.

2. Pry off the cover on the rear bumper

using a screwdriver, and you will find a

threaded hole for attaching the towinghook.

3. Screw the towing hook into the thread

hole until its thread can no longer be seen.

4. Tighten the towing hook securely

using a wheel nut wrench.

After towing, remove the towing hook from

the vehicle and stow it in the tool bag.

Put the thread hole cover on the rear

bumper.

WARNING

. Do not use the towing hook

except when towing your vehicle.

. Be sure to remove the towing

hook after towing. Leaving the

towing hook mounted on the

vehicle could interfere with prop-

er operation of the SRS airbag

system in a frontal collision.

Front tie-down hooks:

Page 322 of 420

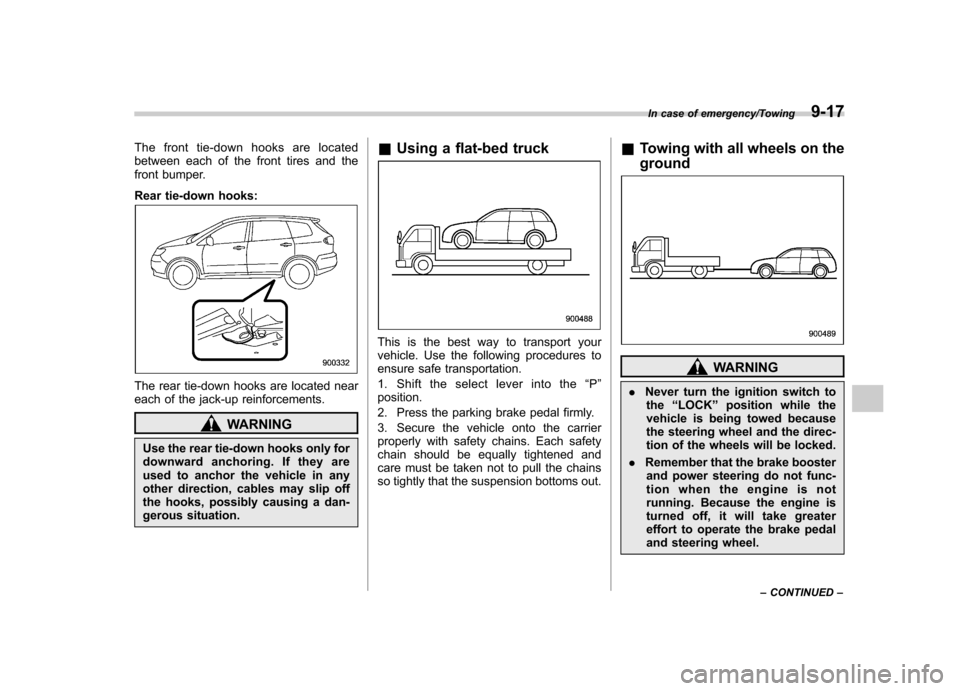

The front tie-down hooks are located

between each of the front tires and the

front bumper.

Rear tie-down hooks:

The rear tie-down hooks are located near

each of the jack-up reinforcements.

WARNING

Use the rear tie-down hooks only for

downward anchoring. If they are

used to anchor the vehicle in any

other direction, cables may slip off

the hooks, possibly causing a dan-

gerous situation. &

Using a flat-bed truck

This is the best way to transport your

vehicle. Use the following procedures to

ensure safe transportation.

1. Shift the select lever into the “P ”

position.

2. Press the parking brake pedal firmly.

3. Secure the vehicle onto the carrier

properly with safety chains. Each safety

chain should be equally tightened and

care must be taken not to pull the chains

so tightly that the suspension bottoms out. &

Towing with all wheels on the ground

WARNING

. Never turn the ignition switch to

the “LOCK ”position while the

vehicle is being towed because

the steering wheel and the direc-

tion of the wheels will be locked.

. Remember that the brake booster

and power steering do not func-

tion when the engine is not

running. Because the engine is

turned off, it will take greater

effort to operate the brake pedal

and steering wheel.

In case of emergency/Towing9-17

– CONTINUED –

Page 336 of 420

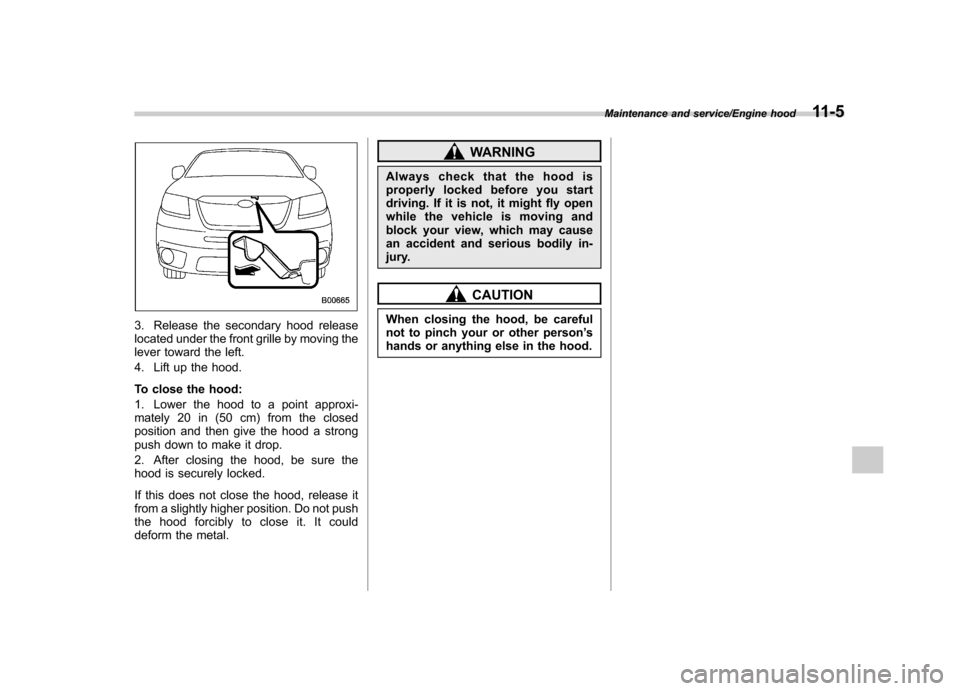

3. Release the secondary hood release

located under the front grille by moving the

lever toward the left.

4. Lift up the hood.

To close the hood:

1. Lower the hood to a point approxi-

mately 20 in (50 cm) from the closed

position and then give the hood a strong

push down to make it drop.

2. After closing the hood, be sure the

hood is securely locked.

If this does not close the hood, release it

from a slightly higher position. Do not push

the hood forcibly to close it. It could

deform the metal.

WARNING

Always check that the hood is

properly locked before you start

driving. If it is not, it might fly open

while the vehicle is moving and

block your view, which may cause

an accident and serious bodily in-

jury.

CAUTION

When closing the hood, be careful

not to pinch your or other person ’s

hands or anything else in the hood.

Maintenance and service/Engine hood11-5

Page 339 of 420

11-8Maintenance and service/Engine oil

.Be careful not to spill engine oil

when adding it. If oil touches the

exhaust pipe, it may cause a bad

smell, smoke, and/or a fire. If

engine oil gets on the exhaust

pipe, be sure to wipe it off.

If you check the oil level just after stopping

the engine, wait a few minutes for the oil to

drain back into the oil pan before checking

the level.

To prevent overfilling the engine oil, do not

add any additional oil above the full level

when the engine is cold. & Changing the oil and oil filter

CAUTION

. If you change your own oil, be

sure to drain all the oil from the

filter before disposal.

. Do not dispose of used engine oil

by placing it in the trash, or by

pouring it onto the ground, into

sewers, or into any body of water.

Check with your local govern-

ment office for the proper dis-

posal options available to you.

Change the oil and oil filter according to

the maintenance schedule in the “War- ranty and Maintenance Booklet

”.

The engine oil and oil filter must be

changed more frequently than listed in

the maintenance schedule when driving

on dusty roads, when short trips are

frequently made, or when driving in

extremely cold weather.

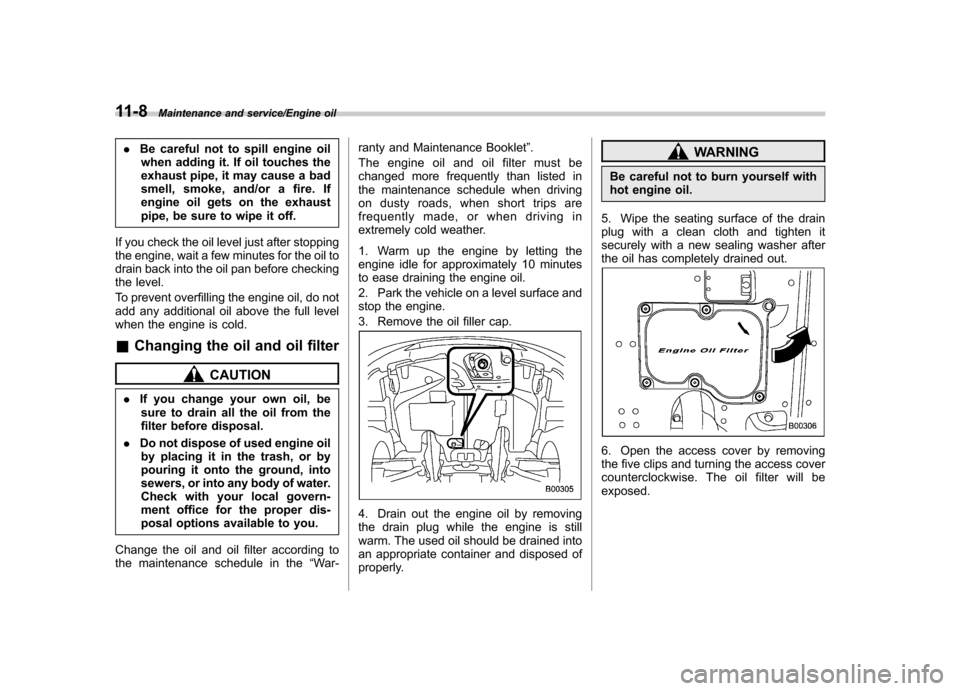

1. Warm up the engine by letting the

engine idle for approximately 10 minutes

to ease draining the engine oil.

2. Park the vehicle on a level surface and

stop the engine.

3. Remove the oil filler cap.

4. Drain out the engine oil by removing

the drain plug while the engine is still

warm. The used oil should be drained into

an appropriate container and disposed of

properly.

WARNING

Be careful not to burn yourself with

hot engine oil.

5. Wipe the seating surface of the drain

plug with a clean cloth and tighten it

securely with a new sealing washer after

the oil has completely drained out.

6. Open the access cover by removing

the five clips and turning the access cover

counterclockwise. The oil filter will beexposed.

Page 363 of 420

11-32Maintenance and service/Replacement of wiper blades

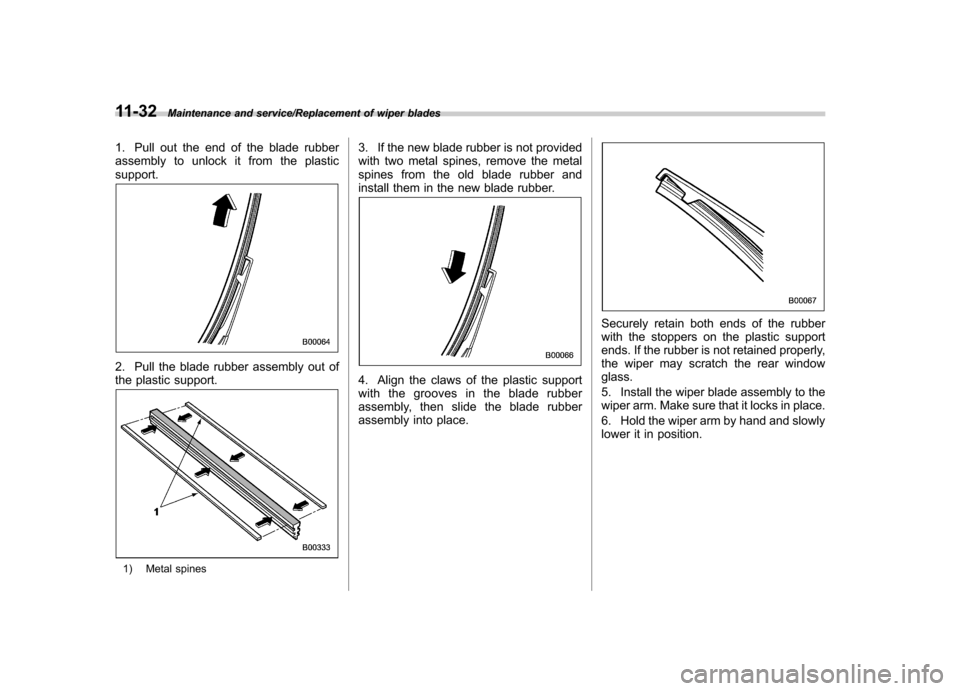

1. Pull out the end of the blade rubber

assembly to unlock it from the plasticsupport.

2. Pull the blade rubber assembly out of

the plastic support.

1) Metal spines3. If the new blade rubber is not provided

with two metal spines, remove the metal

spines from the old blade rubber and

install them in the new blade rubber.

4. Align the claws of the plastic support

with the grooves in the blade rubber

assembly, then slide the blade rubber

assembly into place.

Securely retain both ends of the rubber

with the stoppers on the plastic support

ends. If the rubber is not retained properly,

the wiper may scratch the rear windowglass.

5. Install the wiper blade assembly to the

wiper arm. Make sure that it locks in place.

6. Hold the wiper arm by hand and slowly

lower it in position.