air condition SUZUKI ALTO 2014 User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2014, Model line: ALTO, Model: SUZUKI ALTO 2014Pages: 139, PDF Size: 2.22 MB

Page 85 of 139

86

76G-74E

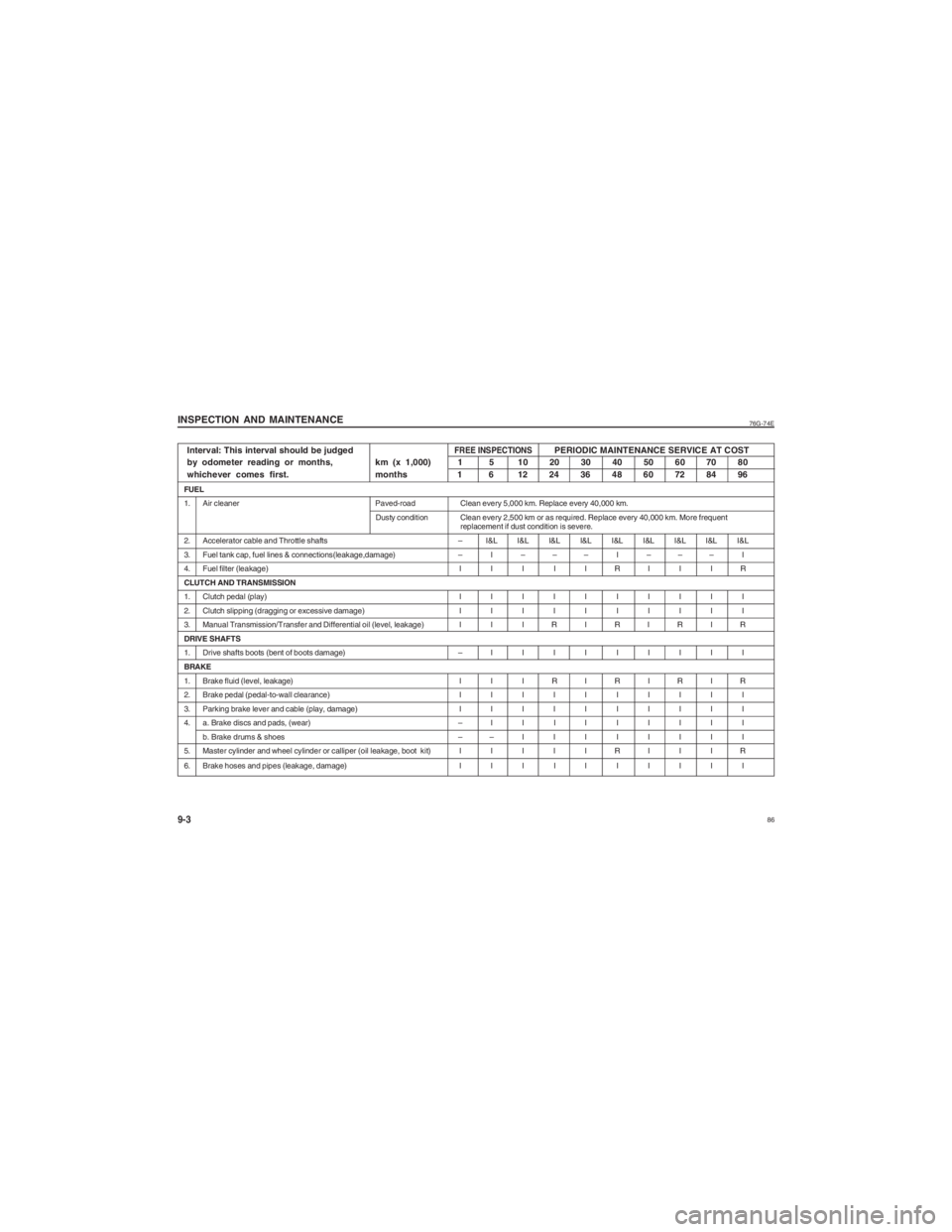

INSPECTION AND MAINTENANCE9-3Interval: This interval should be judged

FREE INSPECTIONS

PERIODIC MAINTENANCE SERVICE AT COST

by odometer reading or months, km (x 1,000) 1 5 10 20 30 40 50 60 70 80

whichever comes first. months 1 6 12 24 36 48 60 72 84 96

FUEL

1. Air cleaner Paved-roadClean every 5,000 km. Replace every 40,000 km.

Dusty condition Clean every 2,500 km or as required. Replace every 40,000 km. More frequ\

ent replacement if dust condition is severe.

2. Accelerator cable and Throttle shafts – I&L I&L I&L I&L I&L I&L I&L I&L I&L

3. Fuel tank cap, fuel lines & connections(leakage,damage) – I – – – I – – – I

4. Fuel filter (leakage) I I I I I R I I I R

CLUTCH AND TRANSMISSION

1. Clutch pedal (play) I I I I I I I I I I

2. Clutch slipping (dragging or excessive damage) I I I I I I I I I I

3. Manual Transmission/Transfer and Differential oil (level, leakage) I I I R I R I R I R

DRIVE SHAFTS

1. Drive shafts boots (bent of boots damage) – I I I I I I I I I

BRAKE

1. Brake fluid (level, leakage) I I I R I R I R I R

2. Brake pedal (pedal-to-wall clearance) I I I I I I I I I I

3. Parking brake lever and cable (play, damage) I I I I I I I I I I

4. a. Brake discs and pads, (wear) – I I I I I I I I I

b. Brake drums & shoes – – I I I I I I I I

5. Master cylinder and wheel cylinder or calliper (oil leakage, boot kit)\

I I I I I R I I I R

6. Brake hoses and pipes (leakage, damage) I I I I I I I I I I

Page 87 of 139

88

76G-74E

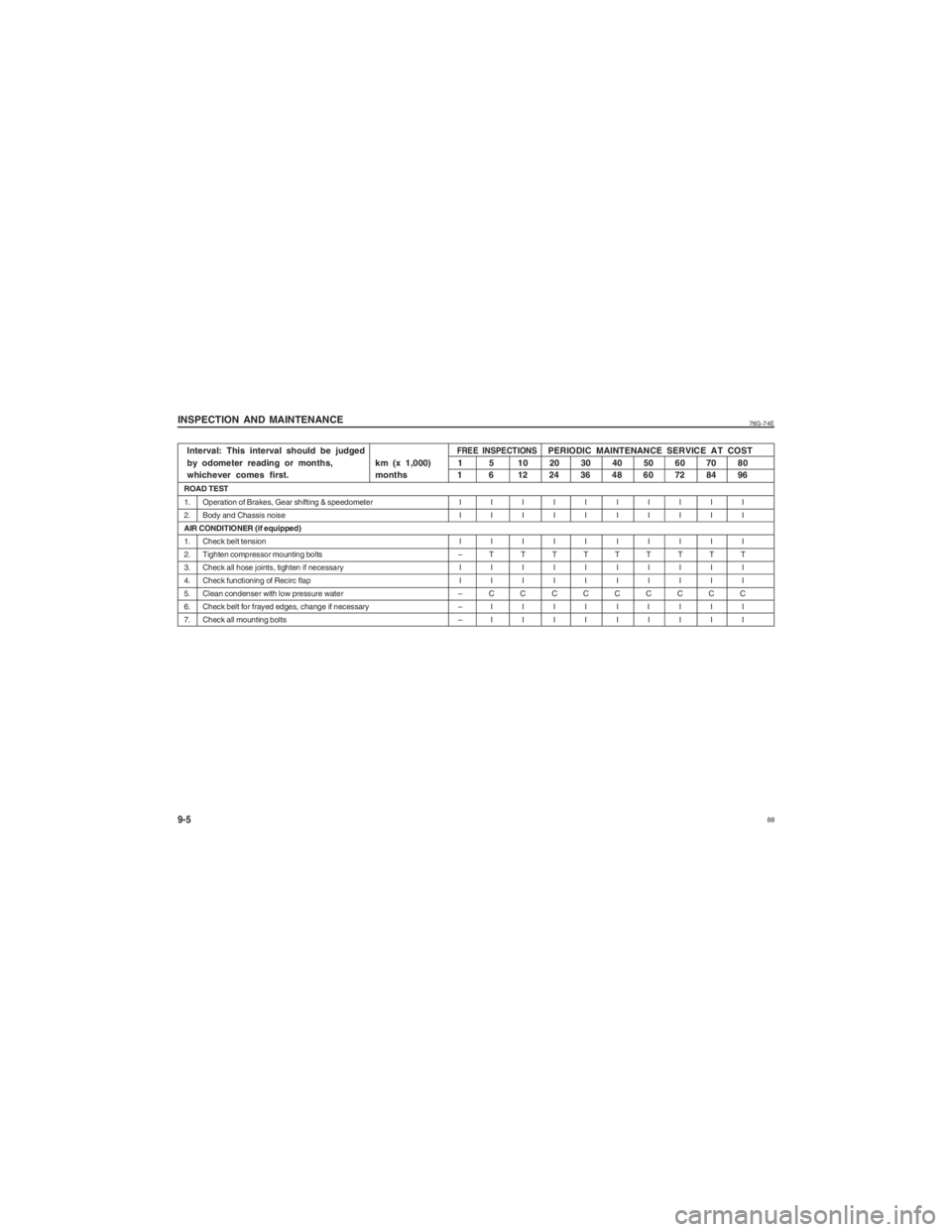

INSPECTION AND MAINTENANCE9-5Interval: This interval should be judged

FREE INSPECTIONS

PERIODIC MAINTENANCE SERVICE AT COST

by odometer reading or months, km (x 1,000) 1 5 10 20 30 40 50 60 70 80

whichever comes first. months 1 6 12 24 36 48 60 72 84 96

ROAD TEST

1. Operation of Brakes, Gear shifting & speedometer I I I I I I I I I I

2. Body and Chassis noise I I I I I I I I I I

AIR CONDITIONER (if equipped)

1. Check belt tension I I I I I I I I I I

2. Tighten compressor mounting bolts – T T T T T T T T T

3. Check all hose joints, tighten if necessary I I I I I I I I I I

4. Check functioning of Recirc flap I I I I I I I I I I

5. Clean condenser with low pressure water – C C C C C C C C C

6. Check belt for frayed edges, change if necessary – I I I I I I I I I

7. Check all mounting bolts – I I I I I I I I I

Page 92 of 139

9376G-74E

INSPECTION AND MAINTENANCE

9-10

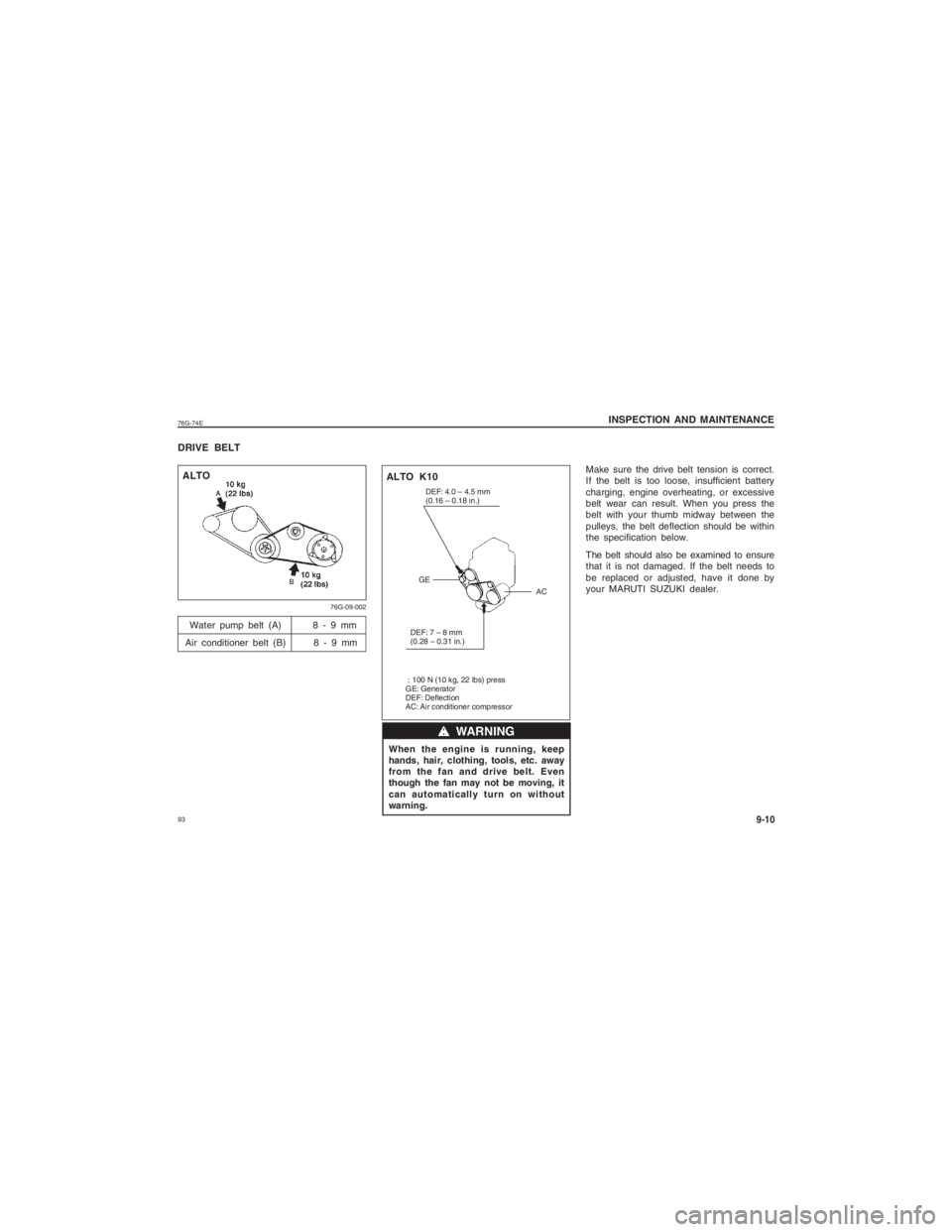

DRIVE BELT

When the engine is running, keep

hands, hair, clothing, tools, etc. away

from the fan and drive belt. Even

though the fan may not be moving, it

can automatically turn on without

warning.

Water pump belt (A) 8 - 9 mm

Air conditioner belt (B) 8 - 9 mm

ww ww

w WARNING

76G-09-002

Make sure the drive belt tension is correct.

If the belt is too loose, insufficient battery

charging, engine overheating, or excessive

belt wear can result. When you press the

belt with your thumb midway between the

pulleys, the belt deflection should be within

the specification below.

The belt should also be examined to ensure

that it is not damaged. If the belt needs to

be replaced or adjusted, have it done by

your MARUTI SUZUKI dealer.

DEF: 4.0 – 4.5 mm

(0.16 – 0.18 in.)

DEF: 7 – 8 mm

(0.28 – 0.31 in.)

: 100 N (10 kg, 22 lbs) press

GE: Generator

DEF: Deflection

AC: Air conditioner compressor GE

AC

ALTO K10

ALTO

Page 101 of 139

102

76G-74E

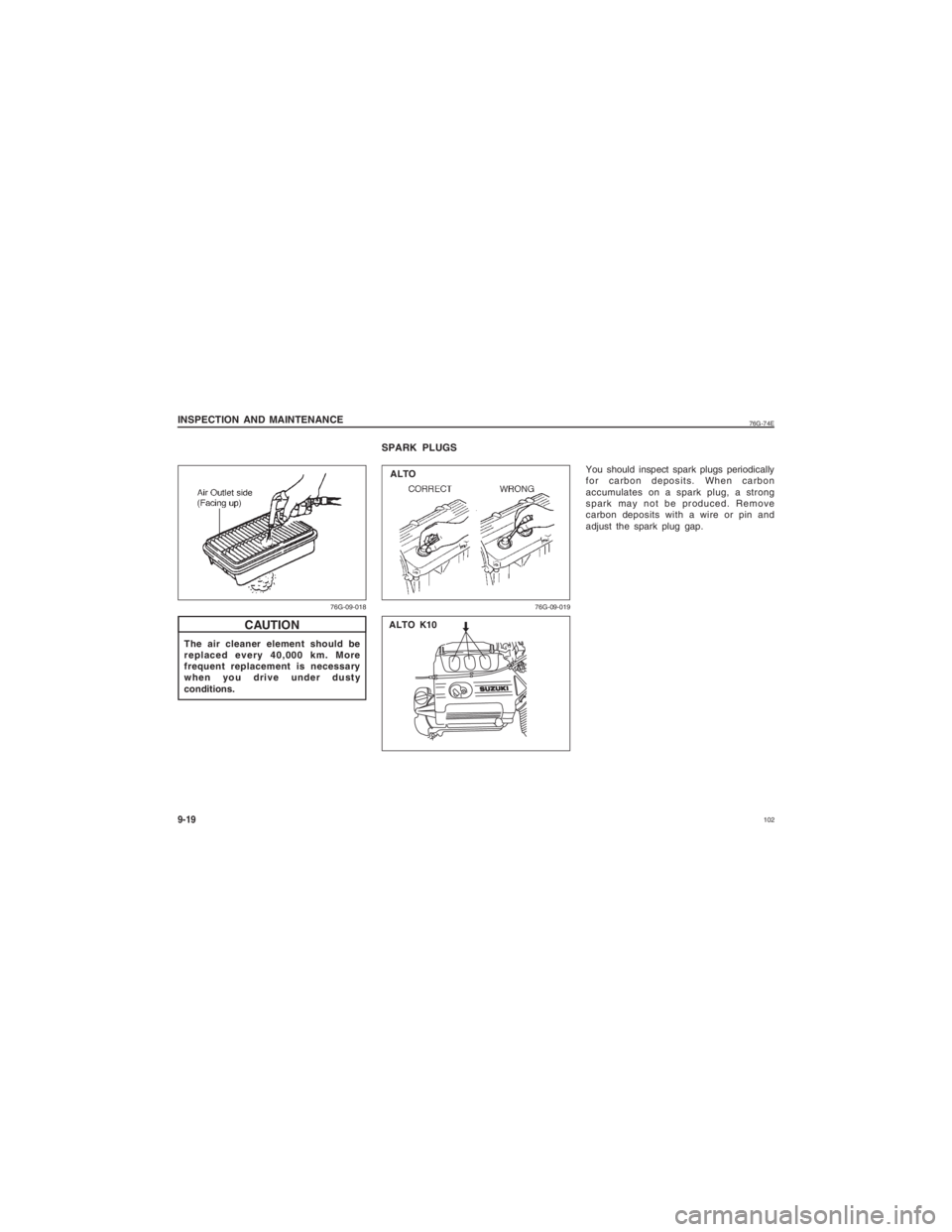

The air cleaner element should be

replaced every 40,000 km. More

frequent replacement is necessary

when you drive under dusty

conditions.

CAUTION

SPARK PLUGS

You should inspect spark plugs periodically

for carbon deposits. When carbon

accumulates on a spark plug, a strong

spark may not be produced. Remove

carbon deposits with a wire or pin and

adjust the spark plug gap.

76G-09-01876G-09-019

ALTO K10

INSPECTION AND MAINTENANCE9-19

ALTO

Page 111 of 139

112

76G-74E

INSPECTION AND MAINTENANCE9-29To avoid harm to yourself or damage

to your vehicle or battery, follow the

jump starting instructions in the

EMERGENCY SERVICE section of this

manual if it is necessary to jump start

your vehicle.

The level of the battery solution must be

kept between the “MAX” and the “MIN” level

lines at all times. If the level is found to be

below the “MIN” level line, add distilled

water to the “MAX” level line. You should

periodically check the battery, battery

terminals, and battery hold-down bracket for

corrosion. Remove corrosion using a stiff

brush and ammonia mixed with water, or

baking soda mixed with water. After

removing corrosion, rinse with clean water.

If your vehicle is not going to be driven for

a month or longer, disconnect the cable from

the negative terminal of the battery to help

prevent discharge.

ww ww

w WARNING

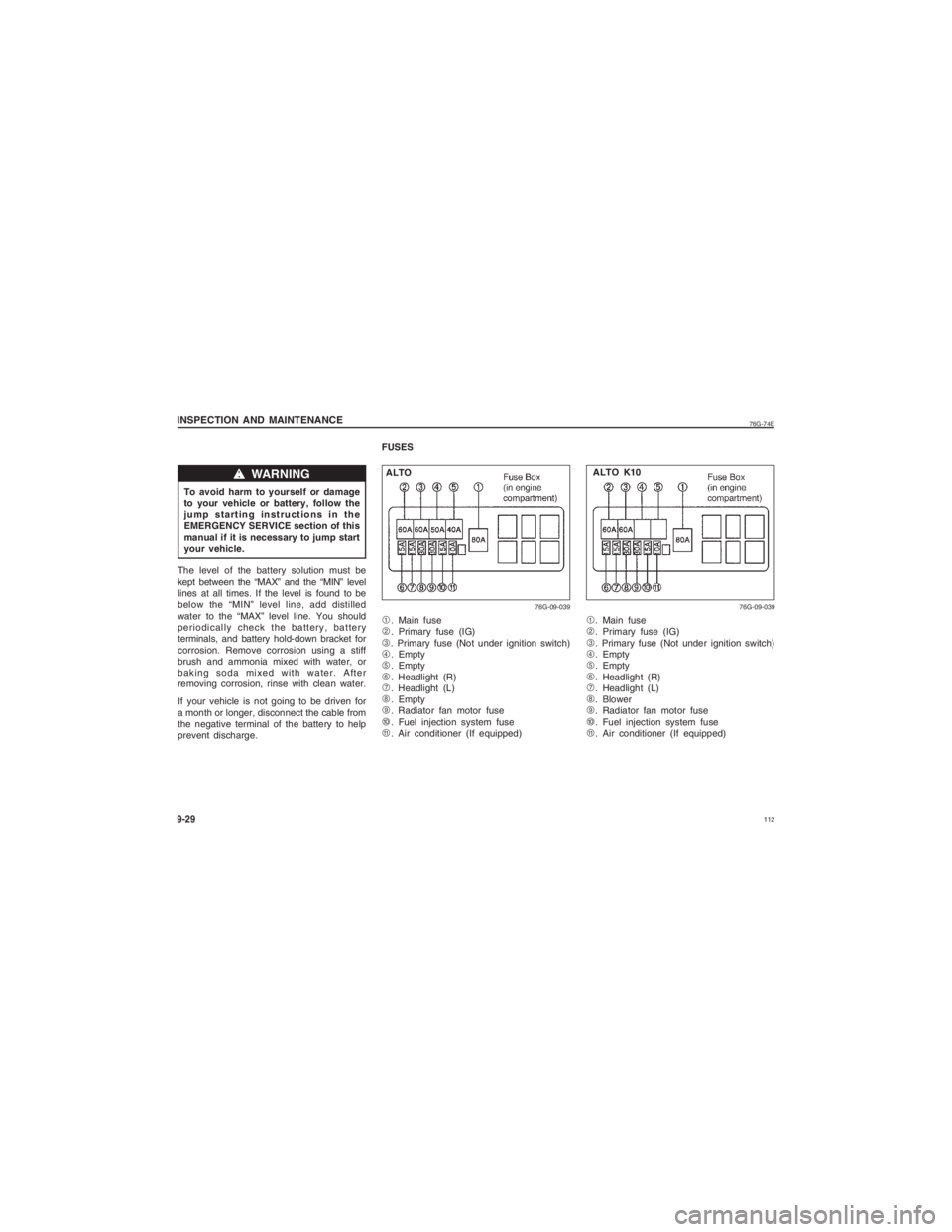

FUSES

1 . Main fuse

2 . Primary fuse (IG)

3 . Primary fuse (Not under ignition switch)

4 . Empty

5 . Empty

6 . Headlight (R)

7 . Headlight (L)

8 . Empty

9 . Radiator fan motor fuse

0 . Fuel injection system fuse

c . Air conditioner (If equipped)

76G-09-039

1. Main fuse

2 . Primary fuse (IG)

3 . Primary fuse (Not under ignition switch)

4 . Empty

5 . Empty

6 . Headlight (R)

7 . Headlight (L)

8 . Blower

9 . Radiator fan motor fuse

0 . Fuel injection system fuse

c . Air conditioner (If equipped)

76G-09-039

ALTO ALTO K10

Page 125 of 139

126

76G-74E

engine until these problems have been

corrected.

3) If you do not find a leak, carefully add coolant to the reservoir and then the

radiator, if necessary. (Refer to “ENGINE

COOLANT” in the “INSPECTION AND

MAINTENANCE” section.)

It is dangerous to remove the radiator

cap when the water temperature is

high, because scalding fluid and

steam may be blown out under

pressure. The cap should only be

taken off when the coolant

temperature has lowered.

To help prevent personal injury, keep

hands, tools and clothing away from

the engine cooling fan and air-

conditioner fan (if equipped). These

electric fans can automatically turn on

without warning.

EMERGENCY SERVICE10-5

ww ww

w WARNINGww

ww

w WARNING

1) Turn off the air conditioner, if equipped.

2) Take the vehicle to a safe place and

park.

3) Let the engine run at normal idle speed for a few minutes until engine coolant

temperature warning light goes off.

If you see or hear escaping steam,

stop the vehicle in a safe place and

immediately turn off the engine to let

it cool. Do not open the bonnet when

steam is present. When the steam can

no longer be seen or heard, open the

hood to see if the coolant is still

boiling. If it is, you must wait until it

stops boiling before you proceed.

If the engine coolant temperature warning

light does not goes off:

1) Turn off the engine and check that the water pump belt and pulleys are not

damaged or slipping. If any abnormality

is found, correct it.

2) Check the coolant level in the reservoir. If it is found to be lower than the “LOW”

line, look for leaks at the radiator, water

pump, and radiator and heater hoses. If

you locate any leaks that may have

caused the overheating, do not run the

ww ww

w WARNING

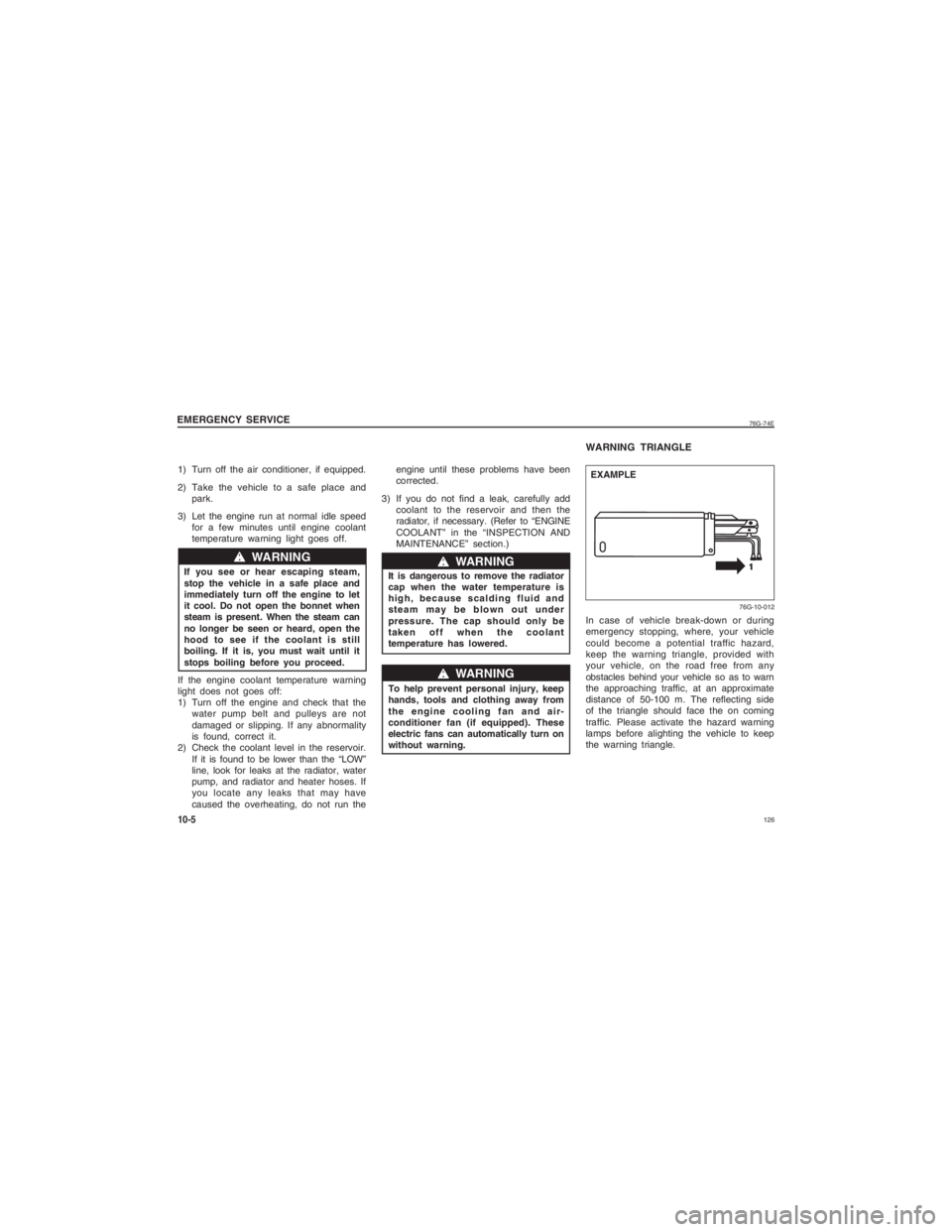

WARNING TRIANGLEIn case of vehicle break-down or during

emergency stopping, where, your vehicle

could become a potential traffic hazard,

keep the warning triangle, provided with

your vehicle, on the road free from any

obstacles behind your vehicle so as to warn

the approaching traffic, at an approximate

distance of 50-100 m. The reflecting side

of the triangle should face the on coming

traffic. Please activate the hazard warning

lamps before alighting the vehicle to keep

the warning triangle.

176G-10-012

EXAMPLE

Page 129 of 139

130

76G-74E

CORROSION PREVENTION

the vehicle which are not well ventilated

to permit quick drying.

This information illustrates the necessity of

keeping your vehicle (particularly the

underbody) as clean and dry as possible.

It is equally important to repair any damage

to the paint or protective coatings as soon

as possible.

How to Help Prevent Corrosion

Wash your vehicle frequently

The best way to preserve the finish on your

vehicle and to help avoid corrosion is to

keep it clean with frequent washing.

Wash your vehicle regularly during the

winter and immediately after the winter.

Keep your vehicle, particularly the

underside, as clean and dry as possible.

If you frequently drive on salted roads, your

vehicle should be washed at least once a

month during the winter. If you live near the

ocean, your vehicle should be washed at

least once a month throughout the year.

For washing instructions, refer to the

“VEHICLE CLEANING” section.

Remove foreign material deposits

Foreign material such as salts, chemicals,

road oil or tar, tree sap, bird droppings and

industrial fall-out may damage the finish of

your vehicle if it is left on painted surfaces.

Remove these types of deposits as quickly as possible. If these deposits are difficult to

wash off, an additional cleaner may be

required. Be sure that any cleaner you use

is not harmful to painted surfaces and is

specifically intended for your purposes.

Follow the manufacturer’s directions when

using these special cleaners.

Repair finish damage

Carefully examine your vehicle for damage

to the painted surfaces. Should you find any

chips or scratches in the paint, touch them

up immediately to prevent corrosion from

starting. If the chips or scratches have gone

through to the bare metal, have a qualified

body shop make the repair.

Keep Passenger and luggage

compartments clean.

Moisture, dirt or mud can accumulate under

the floor mats and may cause corrosion.

Occasionally, check under these mats to

ensure that this area is clean and dry. More

frequent checks are necessary if the vehicle

is used off road or in wet weather.

Certain cargos such as chemicals, fertilizers,

cleaners, salts, etc., are extremely corrosive

by nature. These products should be

transported in sealed containers. If a spill

or leak does occur, clean and dry the area

immediately.

It is important to take good care of your

vehicle to protect it from corrosion.

Listed below are instructions for how to

maintain your vehicle to prevent corrosion.

Please read and follow these instructions

carefully.

Important Information About Corrosion

Common causes of corrosion

1) Accumulation of road salt, dirt, moisture,

or chemicals in hard to reach areas of

the vehicle underbody or frame.

2) Chipping, scratches and any damage to treated or painted metal surfaces

resulting from minor accidents or

abrasion by stones and gravel.

Environmental conditions which

accelerate corrosion

1) Road salt, dust control chemicals, sea air or industrial pollution will all

accelerate the corrosion of metal.

2) High humidity will increase the rate of corrosion particularly when the

temperature range is just above the

freezing point.

3) Moisture in certain areas of a vehicle for an extended period of time may promote

corrosion even though other body

sections may be completely dry.

4) High temperatures will cause an

accelerated rate of corrosion to parts of

BODY WORK CARE11-1