tyre SUZUKI ALTO 2014 User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2014, Model line: ALTO, Model: SUZUKI ALTO 2014Pages: 139, PDF Size: 2.22 MB

Page 86 of 139

8776G-74E

INSPECTION AND MAINTENANCE

9-4

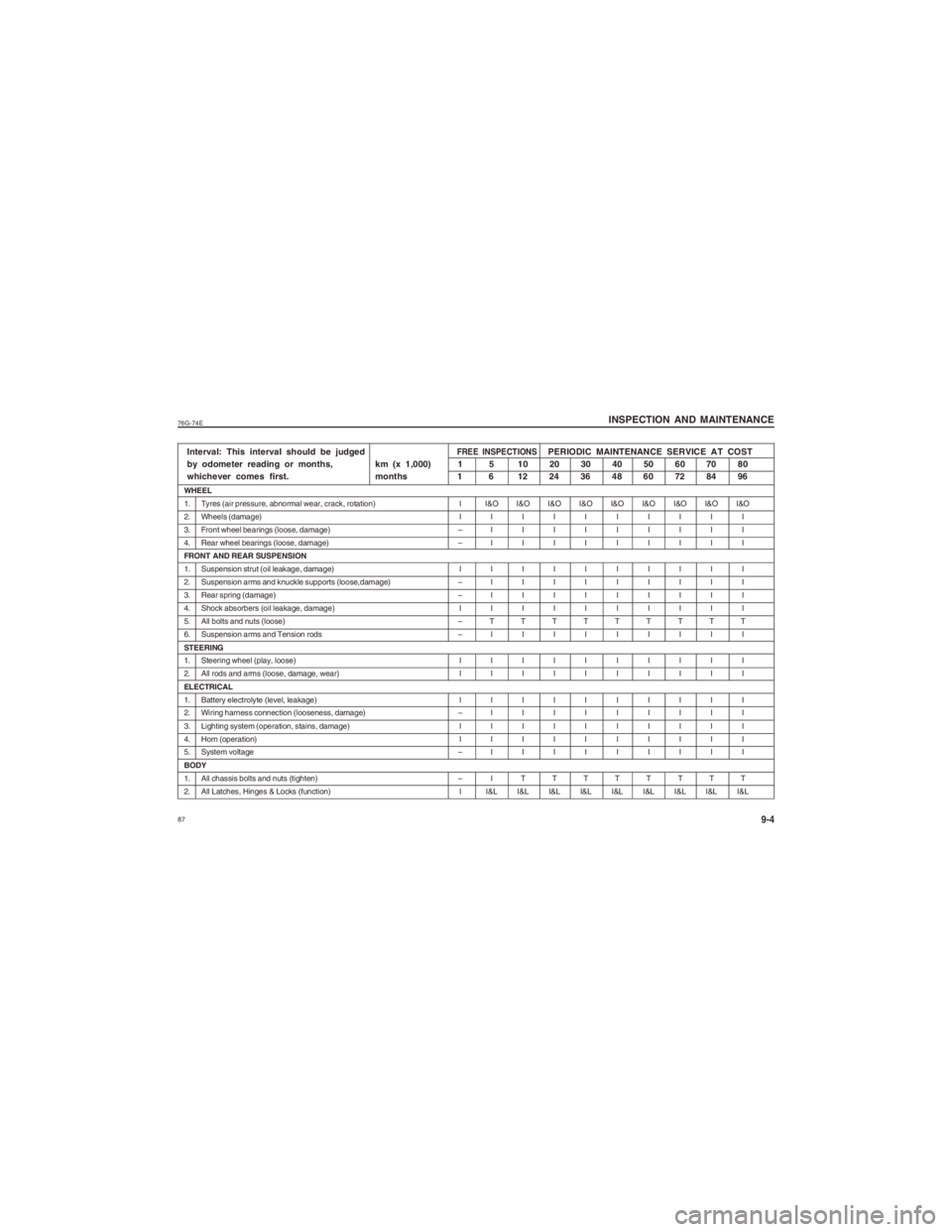

Interval: This interval should be judged

FREE INSPECTIONS

PERIODIC MAINTENANCE SERVICE AT COST

by odometer reading or months, km (x 1,000) 1 5 10 20 30 40 50 60 70 80

whichever comes first. months 1 6 12 24 36 48 60 72 84 96

WHEEL

1. Tyres (air pressure, abnormal wear, crack, rotation) I I&O I&O I&O I&O I&O I&O I&O I&O I&O

2. Wheels (damage) I I I I I I I I I I

3. Front wheel bearings (loose, damage) – I I I I I I I I I

4. Rear wheel bearings (loose, damage) – I I I I I I I I I

FRONT AND REAR SUSPENSION

1. Suspension strut (oil leakage, damage) I I I I I I I I I I

2. Suspension arms and knuckle supports (loose,damage) – I I I I I I I I I

3. Rear spring (damage) – I I I I I I I I I

4. Shock absorbers (oil leakage, damage) I I I I I I I I I I

5. All bolts and nuts (loose) – T T T T T T T T T

6. Suspension arms and Tension rods – I I I I I I I I I

STEERING

1. Steering wheel (play, loose) I I I I I I I I I I

2. All rods and arms (loose, damage, wear) I I I I I I I I I I

ELECTRICAL

1. Battery electrolyte (level, leakage) I I I I I I I I I I

2. Wiring harness connection (looseness, damage) – I I I I I I I I I

3. Lighting system (operation, stains, damage) I I I I I I I I I I

4. Horn (operation) I I I I I I I I I I

5. System voltage – I I I I I I I I I

BODY

1. All chassis bolts and nuts (tighten) – I T T T T T T T T

2. All Latches, Hinges & Locks (function) I I&L I&L I&L I&L I&L I&L I&L I&L I&L

Page 106 of 139

10776G-74E

9-24

INSPECTION AND MAINTENANCE

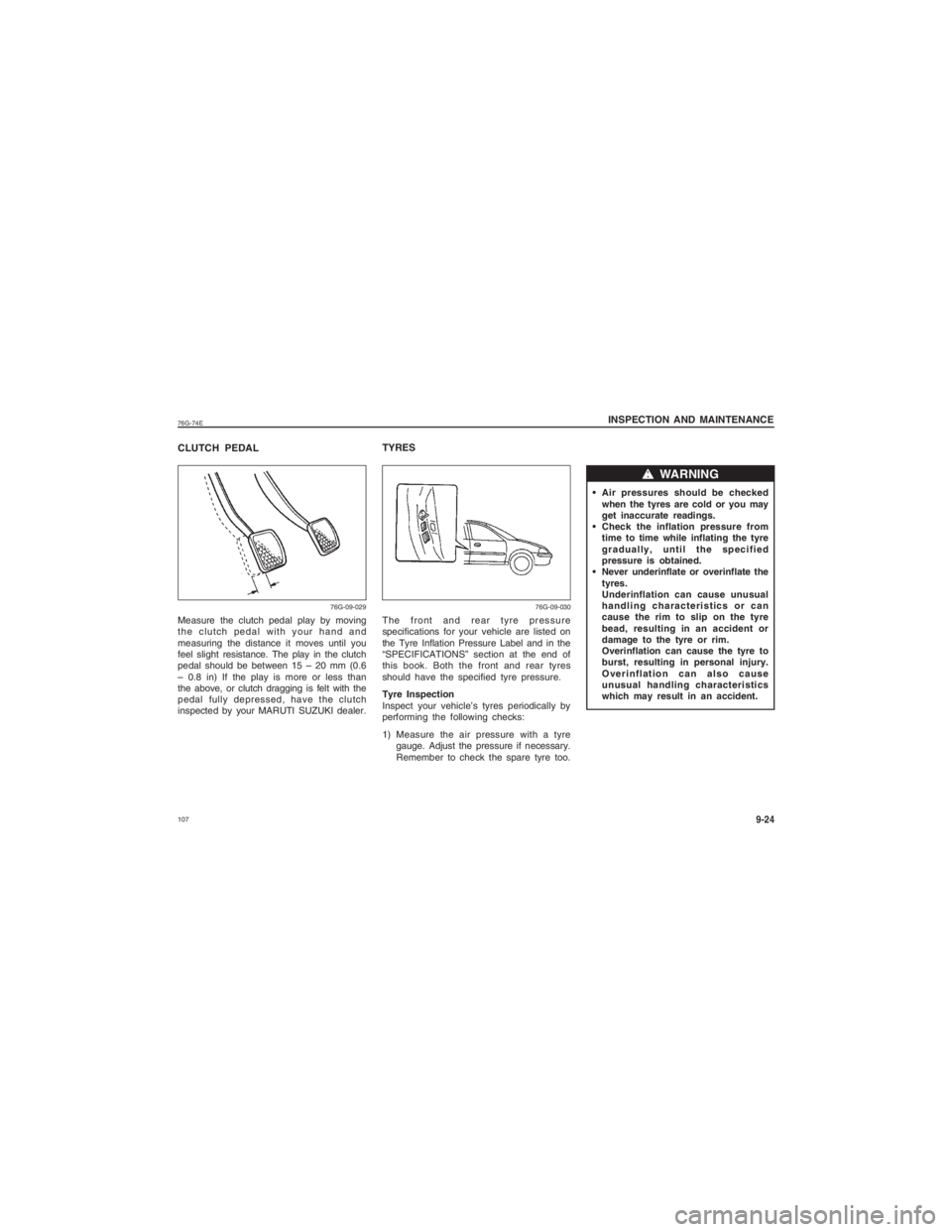

CLUTCH PEDAL

Measure the clutch pedal play by moving

the clutch pedal with your hand and

measuring the distance it moves until you

feel slight resistance. The play in the clutch

pedal should be between 15 – 20 mm (0.6

– 0.8 in) If the play is more or less than

the above, or clutch dragging is felt with the

pedal fully depressed, have the clutch

inspected by your MARUTI SUZUKI dealer.

76G-09-029

TYRESThe front and rear tyre pressure

specifications for your vehicle are listed on

the Tyre Inflation Pressure Label and in the

“SPECIFICATIONS” section at the end of

this book. Both the front and rear tyres

should have the specified tyre pressure.

Tyre Inspection

Inspect your vehicle’s tyres periodically by

performing the following checks:

1) Measure the air pressure with a tyre gauge. Adjust the pressure if necessary.

Remember to check the spare tyre too.

76G-09-030

Air pressures should be checkedwhen the tyres are cold or you may

get inaccurate readings.

Check the inflation pressure from time to time while inflating the tyre

gradually, until the specified

pressure is obtained.

Never underinflate or overinflate the tyres.

Underinflation can cause unusual

handling characteristics or can

cause the rim to slip on the tyre

bead, resulting in an accident or

damage to the tyre or rim.

Overinflation can cause the tyre to

burst, resulting in personal injury.

Overinflation can also cause

unusual handling characteristics

which may result in an accident.

ww ww

w WARNING

Page 107 of 139

108

76G-74E

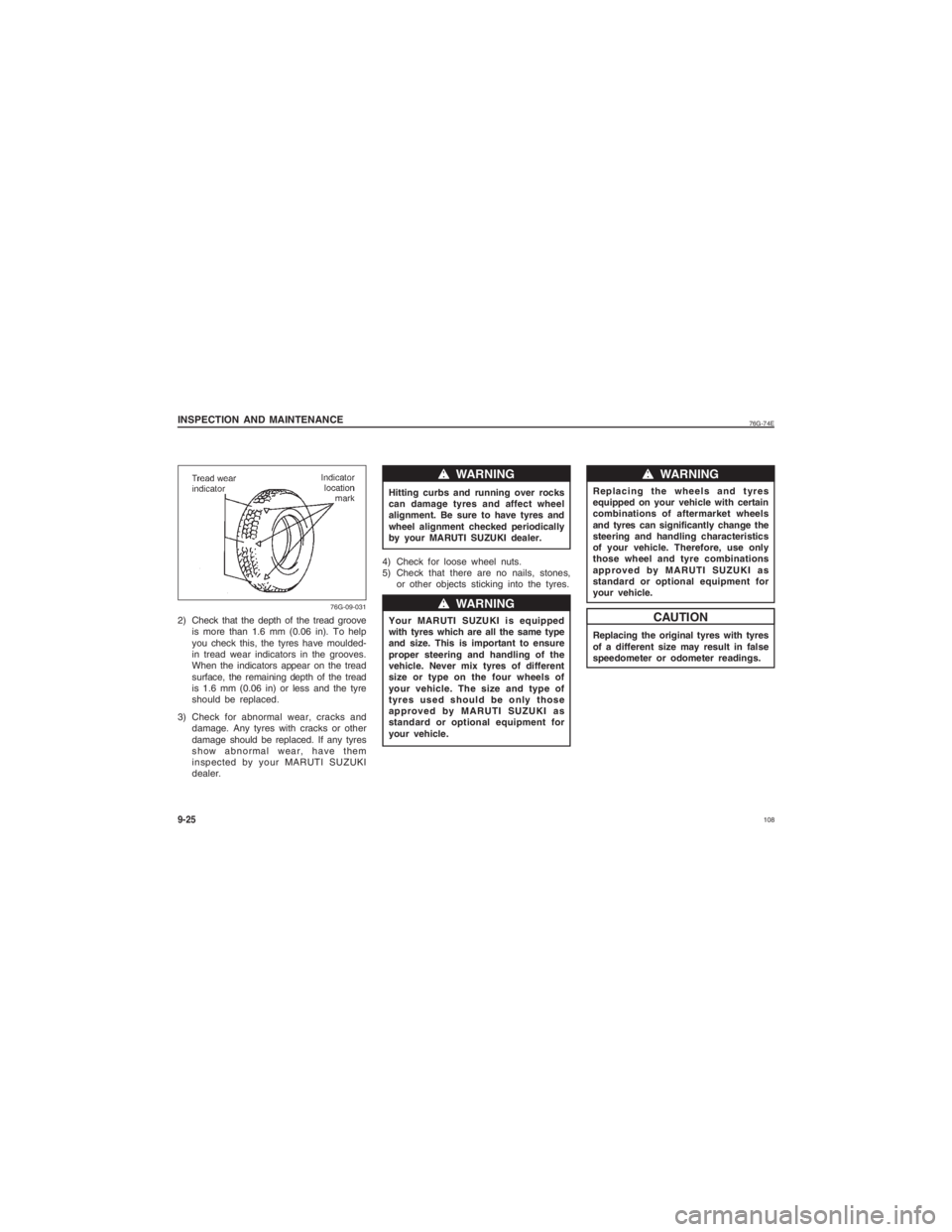

INSPECTION AND MAINTENANCE9-252) Check that the depth of the tread grooveis more than 1.6 mm (0.06 in). To help

you check this, the tyres have moulded-

in tread wear indicators in the grooves.

When the indicators appear on the tread

surface, the remaining depth of the tread

is 1.6 mm (0.06 in) or less and the tyre

should be replaced.

3) Check for abnormal wear, cracks and damage. Any tyres with cracks or other

damage should be replaced. If any tyres

show abnormal wear, have them

inspected by your MARUTI SUZUKI

dealer.

76G-09-031

Hitting curbs and running over rocks

can damage tyres and affect wheel

alignment. Be sure to have tyres and

wheel alignment checked periodically

by your MARUTI SUZUKI dealer.

4) Check for loose wheel nuts.

5) Check that there are no nails, stones, or other objects sticking into the tyres.

Your MARUTI SUZUKI is equipped

with tyres which are all the same type

and size. This is important to ensure

proper steering and handling of the

vehicle. Never mix tyres of different

size or type on the four wheels of

your vehicle. The size and type of

tyres used should be only those

approved by MARUTI SUZUKI as

standard or optional equipment for

your vehicle.

ww ww

w WARNINGww

ww

w WARNING

Replacing the wheels and tyres

equipped on your vehicle with certain

combinations of aftermarket wheels

and tyres can significantly change the

steering and handling characteristics

of your vehicle. Therefore, use only

those wheel and tyre combinations

approved by MARUTI SUZUKI as

standard or optional equipment for

your vehicle.

Replacing the original tyres with tyres

of a different size may result in false

speedometer or odometer readings.

ww ww

w WARNINGCAUTION

Page 108 of 139

10976G-74E

INSPECTION AND MAINTENANCE

9-26

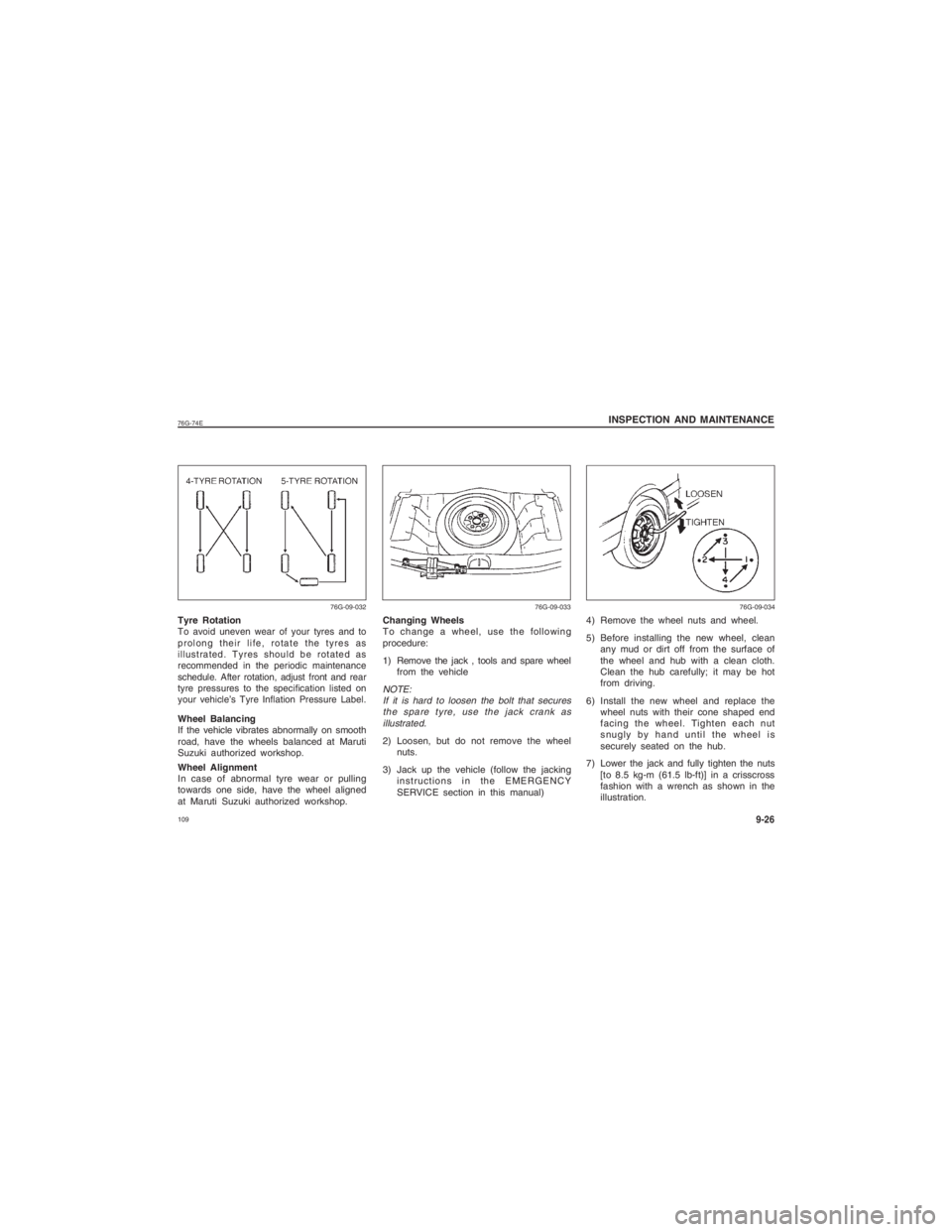

Tyre RotationTo avoid uneven wear of your tyres and to

prolong their life, rotate the tyres as

illustrated. Tyres should be rotated as

recommended in the periodic maintenance

schedule. After rotation, adjust front and rear

tyre pressures to the specification listed on

your vehicle’s Tyre Inflation Pressure Label.Wheel Balancing

If the vehicle vibrates abnormally on smooth

road, have the wheels balanced at Maruti

Suzuki authorized workshop.

Wheel Alignment

In case of abnormal tyre wear or pulling

towards one side, have the wheel aligned

at Maruti Suzuki authorized workshop.

76G-09-032

Changing Wheels

To change a wheel, use the following

procedure:

1) Remove the jack , tools and spare wheelfrom the vehicleNOTE:If it is hard to loosen the bolt that securesthe spare tyre, use the jack crank as

illustrated.2) Loosen, but do not remove the wheel nuts.

3) Jack up the vehicle (follow the jacking instructions in the EMERGENCY

SERVICE section in this manual)

76G-09-033

4) Remove the wheel nuts and wheel.

5) Before installing the new wheel, cleanany mud or dirt off from the surface of

the wheel and hub with a clean cloth.

Clean the hub carefully; it may be hot

from driving.

6) Install the new wheel and replace the wheel nuts with their cone shaped end

facing the wheel. Tighten each nut

snugly by hand until the wheel is

securely seated on the hub.

7) Lower the jack and fully tighten the nuts [to 8.5 kg-m (61.5 lb-ft)] in a crisscross

fashion with a wrench as shown in the

illustration.

76G-09-034

Page 109 of 139

110

76G-74E

INSPECTION AND MAINTENANCE9-27

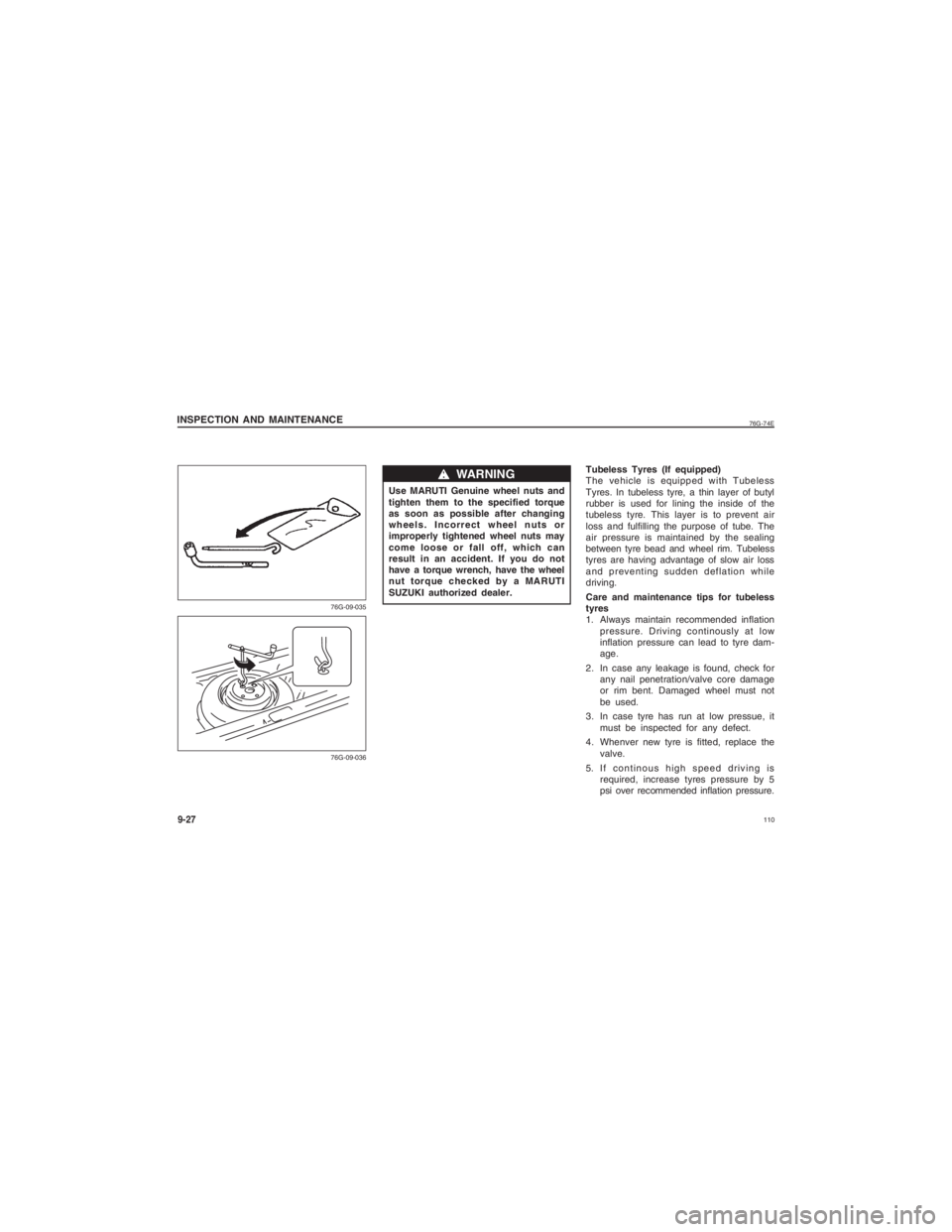

76G-09-035

76G-09-036

Use MARUTI Genuine wheel nuts and

tighten them to the specified torque

as soon as possible after changing

wheels. Incorrect wheel nuts or

improperly tightened wheel nuts may

come loose or fall off, which can

result in an accident. If you do not

have a torque wrench, have the wheel

nut torque checked by a MARUTI

SUZUKI authorized dealer.

ww ww

w WARNING

Tubeless Tyres (If equipped)

The vehicle is equipped with Tubeless

Tyres. In tubeless tyre, a thin layer of butyl

rubber is used for lining the inside of the

tubeless tyre. This layer is to prevent air

loss and fulfilling the purpose of tube. The

air pressure is maintained by the sealing

between tyre bead and wheel rim. Tubeless

tyres are having advantage of slow air loss

and preventing sudden deflation while

driving.

Care and maintenance tips for tubeless

tyres

1. Always maintain recommended inflation

pressure. Driving continously at low

inflation pressure can lead to tyre dam-

age.

2. In case any leakage is found, check for any nail penetration/valve core damage

or rim bent. Damaged wheel must not

be used.

3. In case tyre has run at low pressue, it must be inspected for any defect.

4. Whenver new tyre is fitted, replace the valve.

5. If continous high speed driving is required, increase tyres pressure by 5

psi over recommended inflation pressure.

Page 110 of 139

11176G-74E

INSPECTION AND MAINTENANCE

9-28

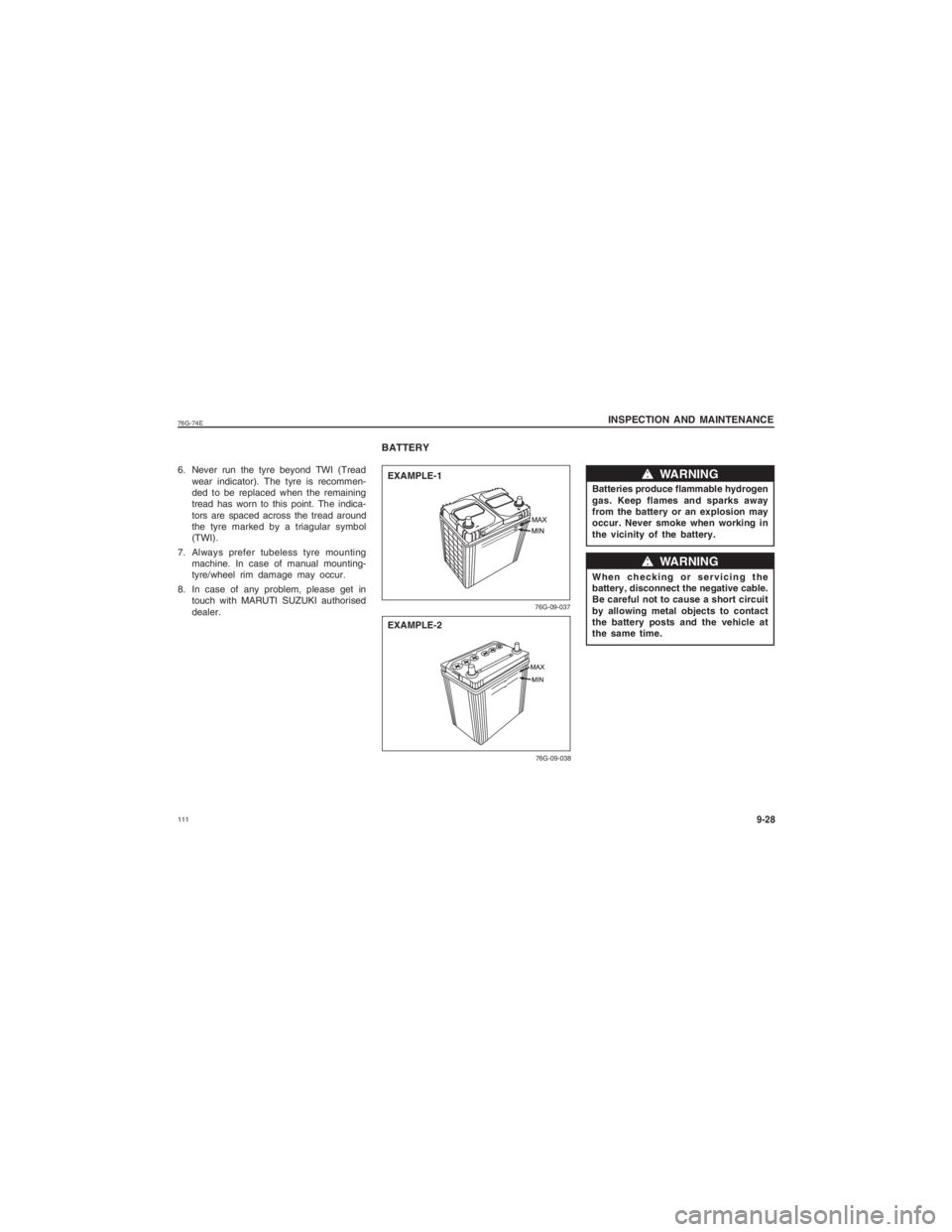

6. Never run the tyre beyond TWI (Treadwear indicator). The tyre is recommen-

ded to be replaced when the remaining

tread has worn to this point. The indica-

tors are spaced across the tread around

the tyre marked by a triagular symbol

(TWI).

7. Always prefer tubeless tyre mounting machine. In case of manual mounting-

tyre/wheel rim damage may occur.

8. In case of any problem, please get in touch with MARUTI SUZUKI authorised

dealer.

76G-09-037

76G-09-038

Batteries produce flammable hydrogen

gas. Keep flames and sparks away

from the battery or an explosion may

occur. Never smoke when working in

the vicinity of the battery.

When checking or servicing the

battery, disconnect the negative cable.

Be careful not to cause a short circuit

by allowing metal objects to contact

the battery posts and the vehicle at

the same time.

ww ww

w WARNINGww

ww

w WARNING

EXAMPLE-1

EXAMPLE-2BATTERY

Page 121 of 139

122

76G-74E

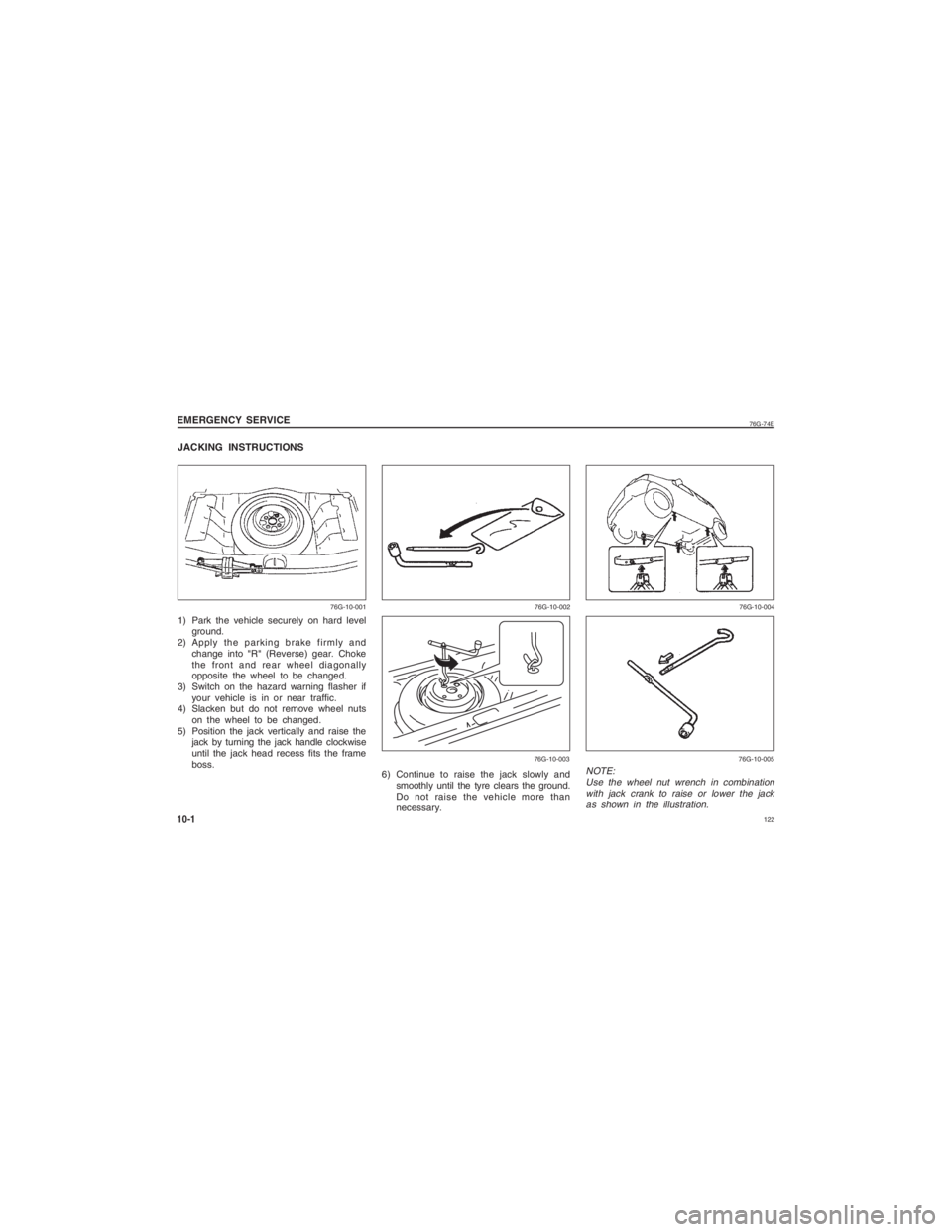

JACKING INSTRUCTIONS1) Park the vehicle securely on hard levelground.

2) Apply the parking brake firmly and

change into "R" (Reverse) gear. Choke

the front and rear wheel diagonally

opposite the wheel to be changed.

3) Switch on the hazard warning flasher if your vehicle is in or near traffic.

4) Slacken but do not remove wheel nuts

on the wheel to be changed.

5) Position the jack vertically and raise the jack by turning the jack handle clockwise

until the jack head recess fits the frame

boss.EMERGENCY SERVICE10-1

NOTE:

Use the wheel nut wrench in combinationwith jack crank to raise or lower the jack

as shown in the illustration.

76G-10-001 76G-10-002 76G-10-004

76G-10-003 76G-10-005

6) Continue to raise the jack slowly and

smoothly until the tyre clears the ground.

Do not raise the vehicle more than

necessary.

Page 135 of 139

136

76G-74E

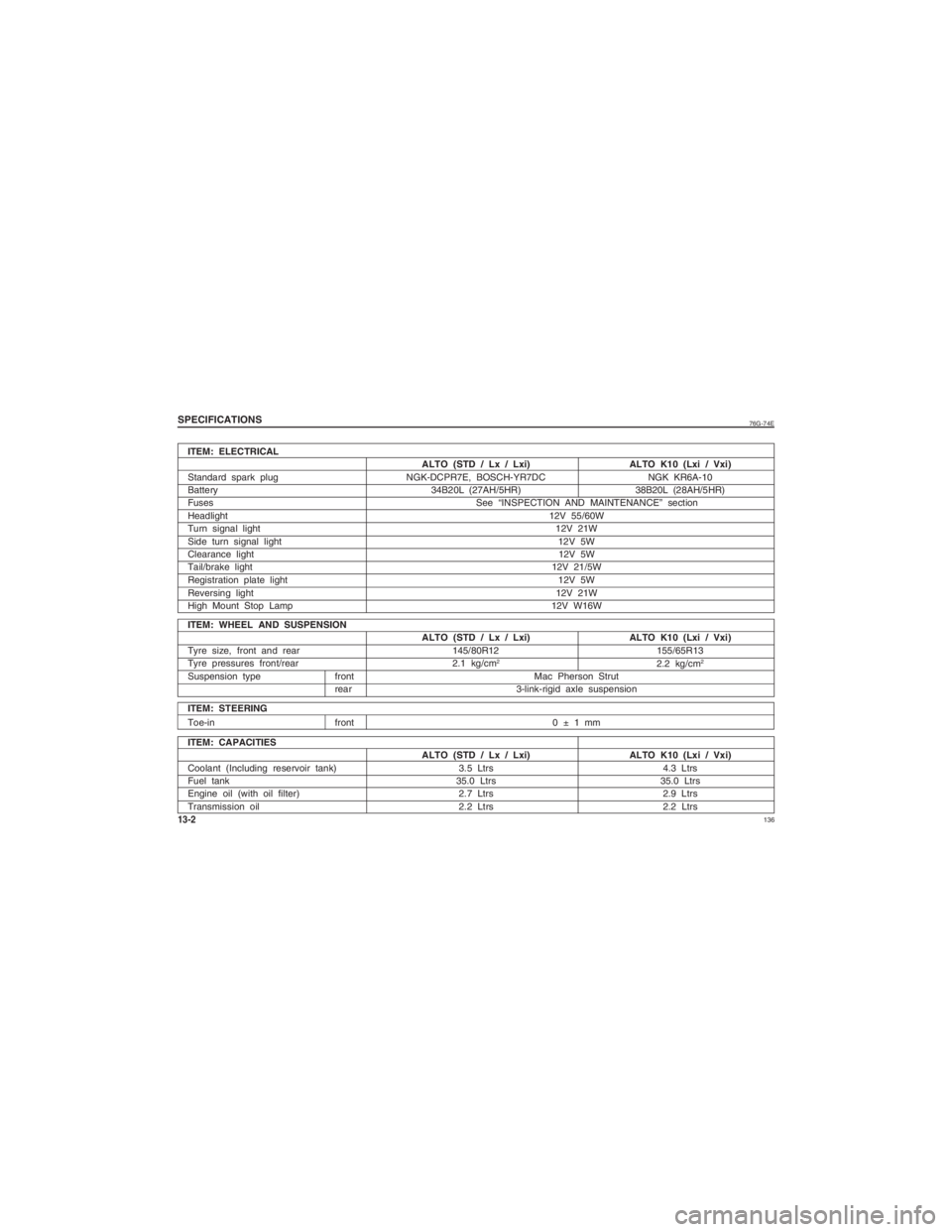

ITEM: ELECTRICALALTO (STD / Lx / Lxi) ALTO K10 (Lxi / Vxi)

Standard spark plug NGK-DCPR7E, BOSCH-YR7DC NGK KR6A-10

Battery 34B20L (27AH/5HR) 38B20L (28AH/5HR)

Fuses See “INSPECTION AND MAINTENANCE” section

Headlight 12V 55/60W

Turn signal light 12V 21W

Side turn signal light 12V 5W

Clearance light 12V 5W

Tail/brake light 12V 21/5W

Registration plate light 12V 5W

Reversing light 12V 21W

High Mount Stop Lamp 12V W16W

ITEM: WHEEL AND SUSPENSION ALTO (STD / Lx / Lxi) ALTO K10 (Lxi / Vxi)

Tyre size, front and rear 145/80R12 155/65R13

Tyre pressures front/rear 2.1 kg/cm

2

2.2 kg/cm

2

Suspension type front Mac Pherson Strut

rear 3-link-rigid axle suspension

ITEM: STEERING

Toe-in front 0 ± 1 mm

ITEM: CAPACITIES ALTO (STD / Lx / Lxi)ALTO K10 (Lxi / Vxi)

Coolant (Including reservoir tank) 3.5 Ltrs4.3 Ltrs

Fuel tank 35.0 Ltrs35.0 Ltrs

Engine oil (with oil filter) 2.7 Ltrs2.9 Ltrs

Transmission oil 2.2 Ltrs2.2 LtrsSPECIFICATIONS13-2