ECU SUZUKI ERTIGA 2013 1.G Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2013, Model line: ERTIGA, Model: SUZUKI ERTIGA 2013 1.GPages: 207, PDF Size: 5.14 MB

Page 144 of 207

Downloaded from www.Manualslib.com manuals search engine 6-1VEHICLE LOADING AND TOWING

60MK0-14E

Vehicle LoadingYour vehicle was designed for specific

weight capacities. The weight capacities of

your vehicle are indicated by the Gross

Vehicle Weight Rating (GVWR) and the

Gross Axle Weight Rating (GAWR, front

and rear). The GVWR and GAWR (front

and rear) are listed in the “SPECIFICA-

TIONS” section.

GVWR – Maximum permissible overall

weight of the fully loaded vehicle (including

all the occupants, accessories and cargo

plus the trailer nose weight if towing a

trailer).

GAWR – (Front and Rear) Maximum per-

missible weight on an individual axle.

Actual weight of the loaded vehicle and

actual loads at the front and rear axles can

only be determined by weighing the vehi-

cle. Compare these weights to the GVWR

and GAWR (front and rear). If the gross

vehicle weight or the load on either axle

exceeds these ratings, you must remove

enough weight to bring the load down to

the rated capacity.

Trailer TowingYour SUZUKI was originally designed to

carry people and a normal amount of

cargo, not to tow a trailer. SUZUKI does

not recommend you use your vehicle to

tow a trailer. Towing a trailer can adversely

affect handling, durability, and fuel econ-

omy.

WARNING

Never overload your vehicle. The

gross vehicle weight (sum of the

weights of the vehicle, all the occu-

pants, accessories, cargo plus trailer

nose weight if towing a trailer) must

never exceed the Gross Vehicle

Weight Rating (GVWR). In addition,

never distribute a load so that the

weight on either the front or rear axle

exceeds the Gross Axle Weight Rat-

ing (GAWR).

WARNING

Always distribute cargo evenly. To

avoid personal injury or damage to

your vehicle, always secure cargo to

prevent it from shifting if the vehicle

moves suddenly. Place heavier

objects on the floor and as far for-

ward in the cargo area as possible.

Never pile cargo higher than the top

of the seat backs.

Page 158 of 207

Downloaded from www.Manualslib.com manuals search engine 7-13INSPECTION AND MAINTENANCE

60MK0-14E

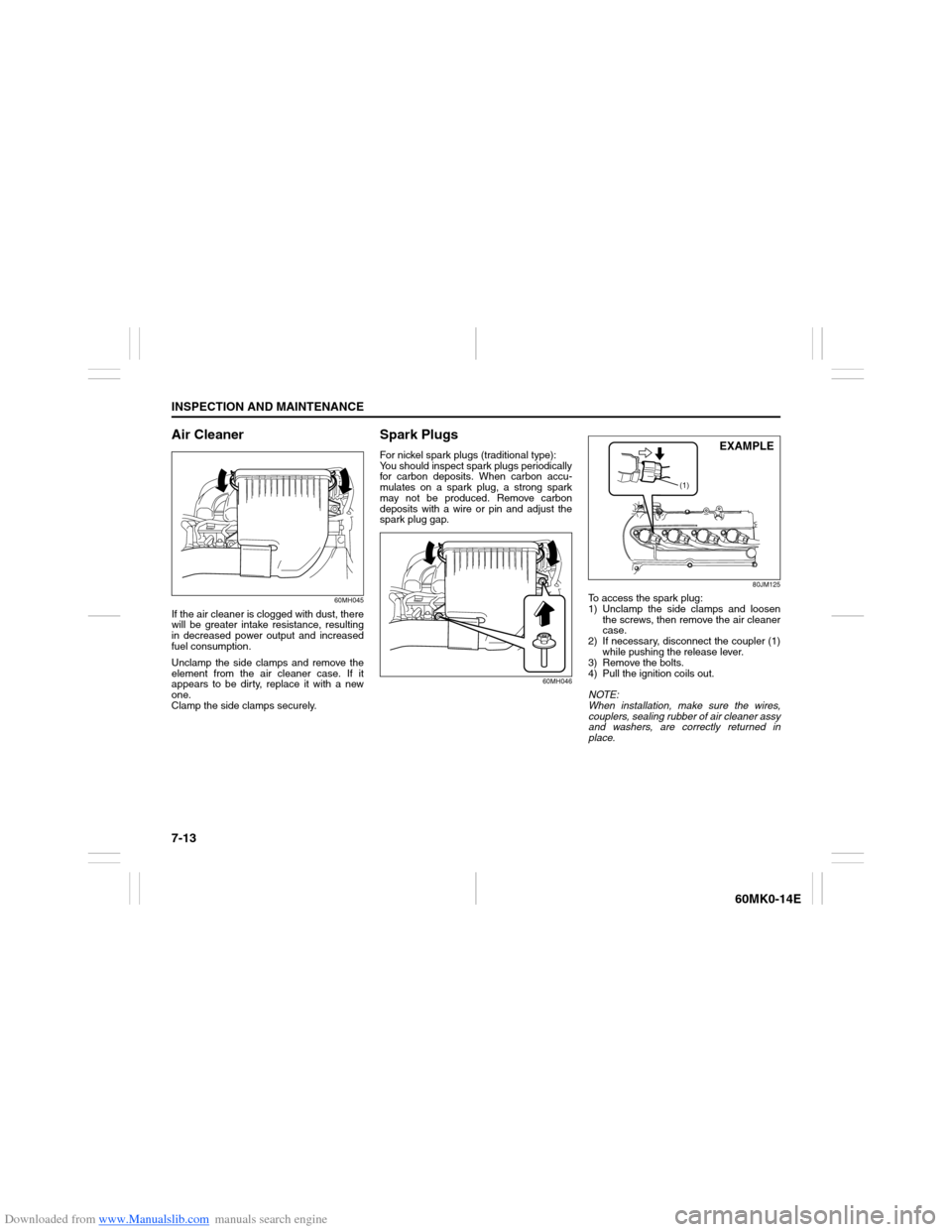

Air Cleaner

60MH045

If the air cleaner is clogged with dust, there

will be greater intake resistance, resulting

in decreased power output and increased

fuel consumption.

Unclamp the side clamps and remove the

element from the air cleaner case. If it

appears to be dirty, replace it with a new

one.

Clamp the side clamps securely.

Spark PlugsFor nickel spark plugs (traditional type):

You should inspect spark plugs periodically

for carbon deposits. When carbon accu-

mulates on a spark plug, a strong spark

may not be produced. Remove carbon

deposits with a wire or pin and adjust the

spark plug gap.

60MH04680JM125

To access the spark plug:

1) Unclamp the side clamps and loosen

the screws, then remove the air cleaner

case.

2) If necessary, disconnect the coupler (1)

while pushing the release lever.

3) Remove the bolts.

4) Pull the ignition coils out.

NOTE:

When installation, make sure the wires,

couplers, sealing rubber of air cleaner assy

and washers, are correctly returned in

place.

(1)

EXAMPLE

Page 162 of 207

Downloaded from www.Manualslib.com manuals search engine 7-17INSPECTION AND MAINTENANCE

60MK0-14E

68LM707

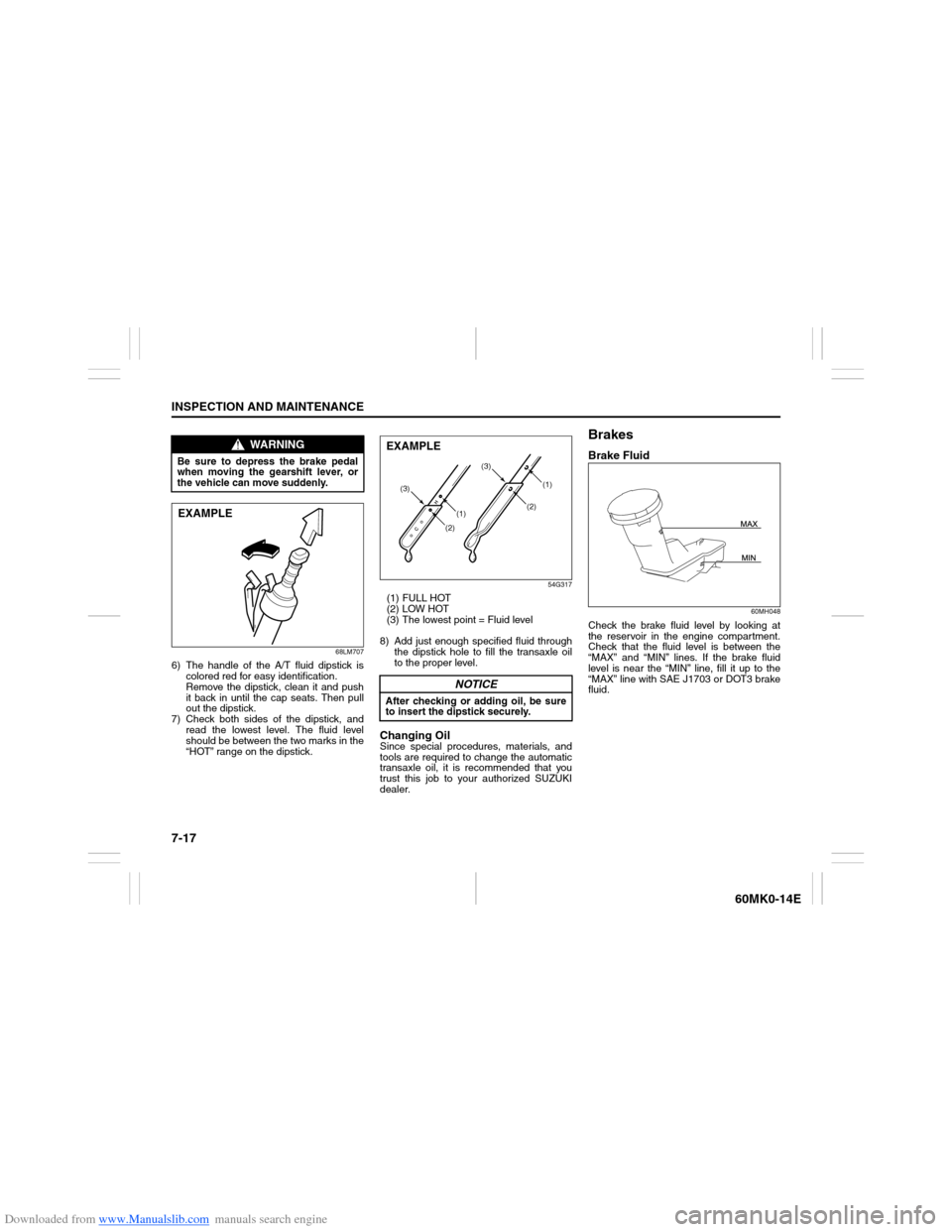

6) The handle of the A/T fluid dipstick is

colored red for easy identification.

Remove the dipstick, clean it and push

it back in until the cap seats. Then pull

out the dipstick.

7) Check both sides of the dipstick, and

read the lowest level. The fluid level

should be between the two marks in the

“HOT” range on the dipstick.

54G317

(1) FULL HOT

(2) LOW HOT

(3) The lowest point = Fluid level

8) Add just enough specified fluid through

the dipstick hole to fill the transaxle oil

to the proper level.Changing OilSince special procedures, materials, and

tools are required to change the automatic

transaxle oil, it is recommended that you

trust this job to your authorized SUZUKI

dealer.

BrakesBrake Fluid

60MH048

Check the brake fluid level by looking at

the reservoir in the engine compartment.

Check that the fluid level is between the

“MAX” and “MIN” lines. If the brake fluid

level is near the “MIN” line, fill it up to the

“MAX” line with SAE J1703 or DOT3 brake

fluid.

WARNING

Be sure to depress the brake pedal

when moving the gearshift lever, or

the vehicle can move suddenly.EXAMPLE

NOTICE

After checking or adding oil, be sure

to insert the dipstick securely.

(1)(2) (3)(1)

(2)(3)

EXAMPLE

Page 164 of 207

Downloaded from www.Manualslib.com manuals search engine 7-19INSPECTION AND MAINTENANCE

60MK0-14E

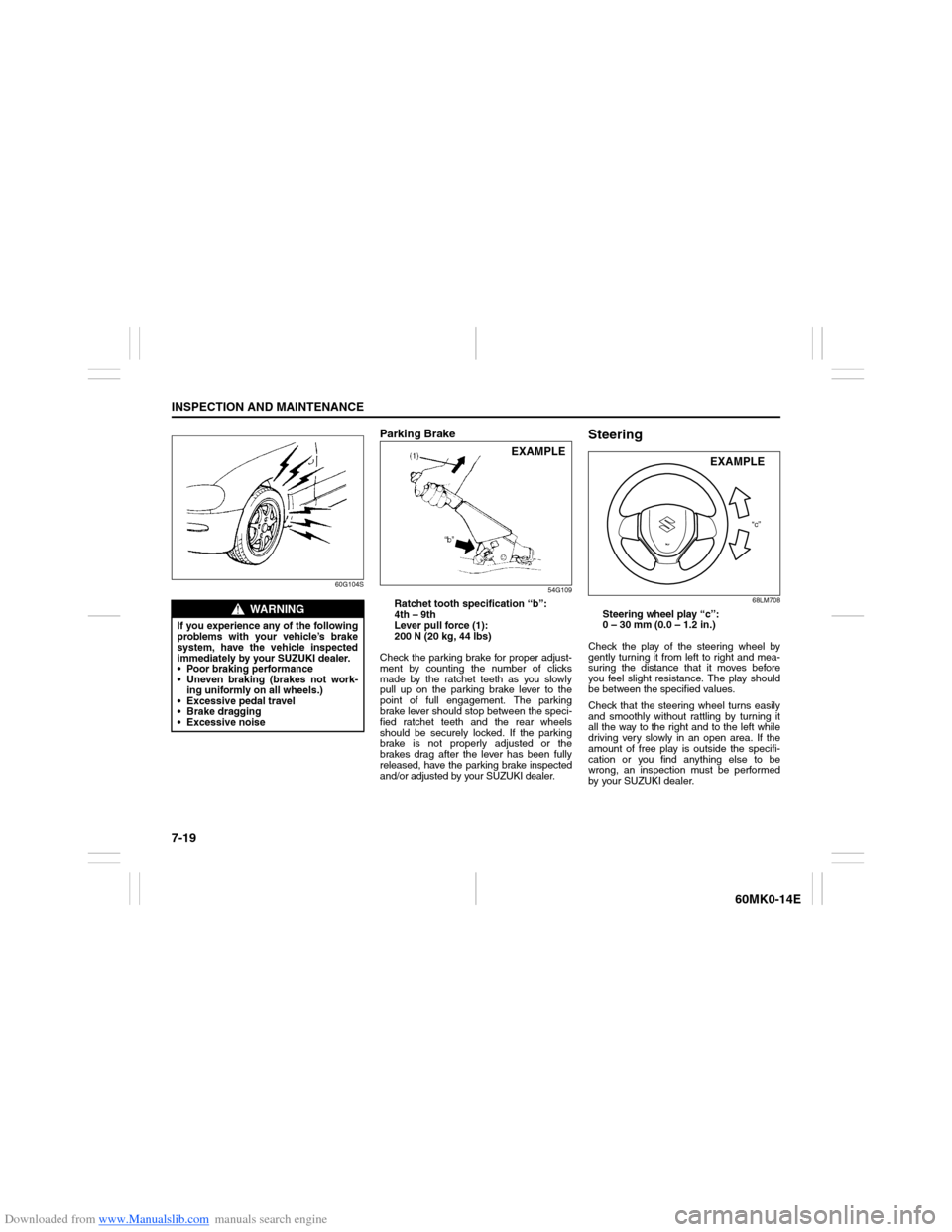

60G104S

Parking Brake

54G109

Ratchet tooth specification “b”:

4th – 9th

Lever pull force (1):

200 N (20 kg, 44 lbs)

Check the parking brake for proper adjust-

ment by counting the number of clicks

made by the ratchet teeth as you slowly

pull up on the parking brake lever to the

point of full engagement. The parking

brake lever should stop between the speci-

fied ratchet teeth and the rear wheels

should be securely locked. If the parking

brake is not properly adjusted or the

brakes drag after the lever has been fully

released, have the parking brake inspected

and/or adjusted by your SUZUKI dealer.

Steering

68LM708

Steering wheel play “c”:

0 – 30 mm (0.0 – 1.2 in.)

Check the play of the steering wheel by

gently turning it from left to right and mea-

suring the distance that it moves before

you feel slight resistance. The play should

be between the specified values.

Check that the steering wheel turns easily

and smoothly without rattling by turning it

all the way to the right and to the left while

driving very slowly in an open area. If the

amount of free play is outside the specifi-

cation or you find anything else to be

wrong, an inspection must be performed

by your SUZUKI dealer.

WARNING

If you experience any of the following

problems with your vehicle’s brake

system, have the vehicle inspected

immediately by your SUZUKI dealer.

Poor braking performance

Uneven braking (brakes not work-

ing uniformly on all wheels.)

Excessive pedal travel

Brake dragging

Excessive noise

EXAMPLE

“c”

EXAMPLE

Page 172 of 207

Downloaded from www.Manualslib.com manuals search engine 7-27INSPECTION AND MAINTENANCE

60MK0-14E

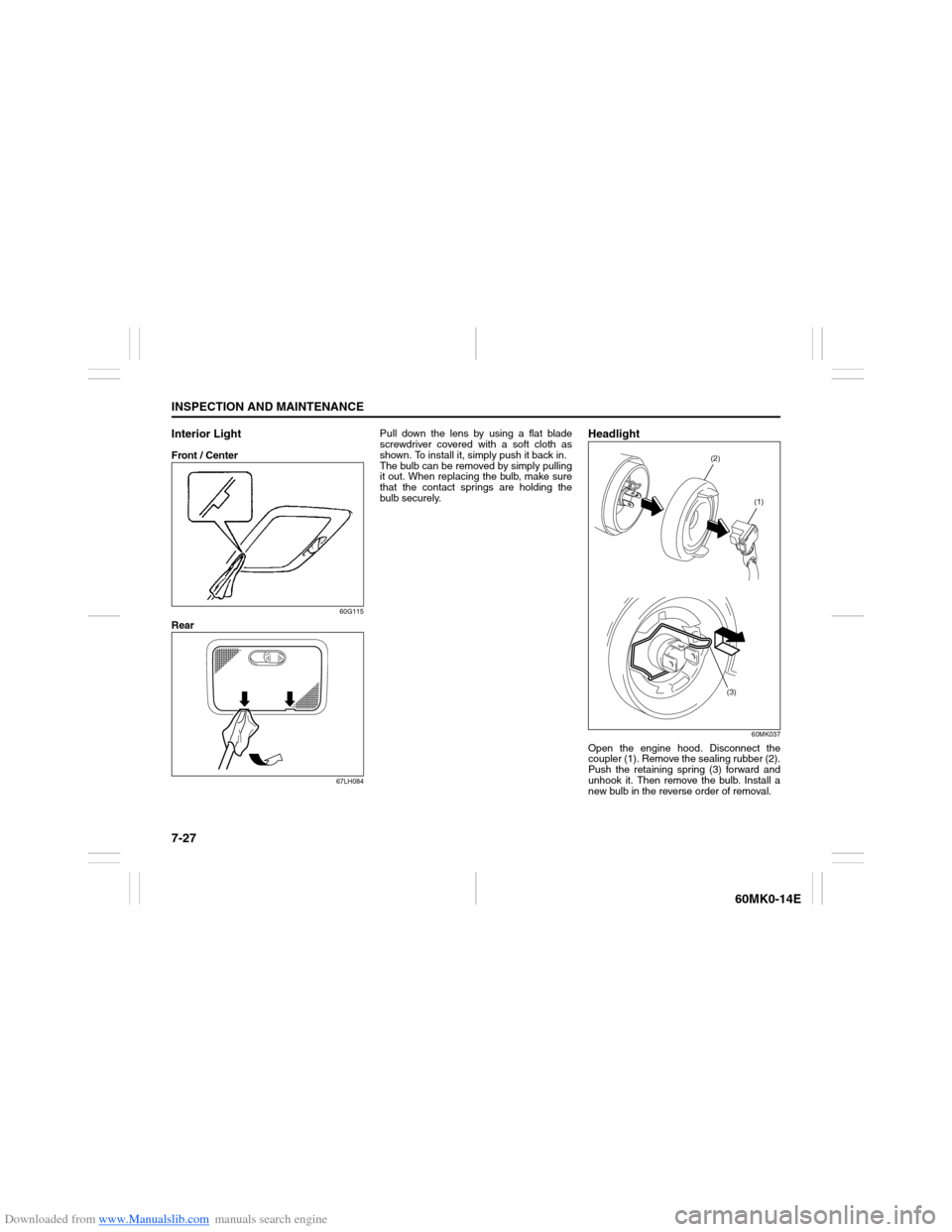

Interior Light Front / Center

60G115

Rear

67LH084

Pull down the lens by using a flat blade

screwdriver covered with a soft cloth as

shown. To install it, simply push it back in.

The bulb can be removed by simply pulling

it out. When replacing the bulb, make sure

that the contact springs are holding the

bulb securely.

Headlight

60MK037

Open the engine hood. Disconnect the

coupler (1). Remove the sealing rubber (2).

Push the retaining spring (3) forward and

unhook it. Then remove the bulb. Install a

new bulb in the reverse order of removal.

(2)

(1)

(3)

Page 178 of 207

Downloaded from www.Manualslib.com manuals search engine 7-33INSPECTION AND MAINTENANCE

60MK0-14E

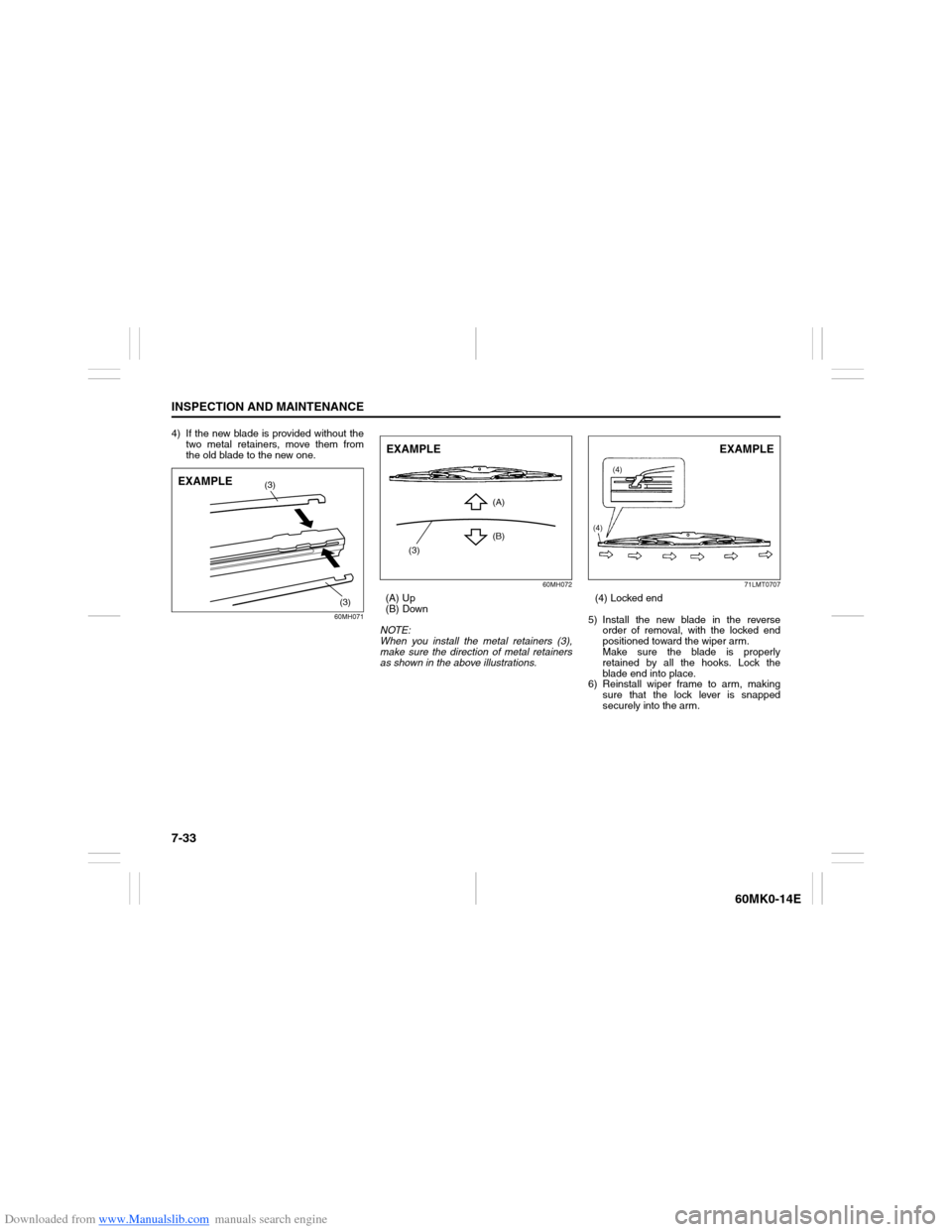

4) If the new blade is provided without the

two metal retainers, move them from

the old blade to the new one.

60MH07160MH072

(A) Up

(B) Down

NOTE:

When you install the metal retainers (3),

make sure the direction of metal retainers

as shown in the above illustrations.

71LMT0707

(4) Locked end

5) Install the new blade in the reverse

order of removal, with the locked end

positioned toward the wiper arm.

Make sure the blade is properly

retained by all the hooks. Lock the

blade end into place.

6) Reinstall wiper frame to arm, making

sure that the lock lever is snapped

securely into the arm.

(3)

(3)

EXAMPLE

(3)(A)

(B)

EXAMPLE

(4)(4)

EXAMPLE

Page 182 of 207

Downloaded from www.Manualslib.com manuals search engine 8-1EMERGENCY SERVICE

60MK0-14E

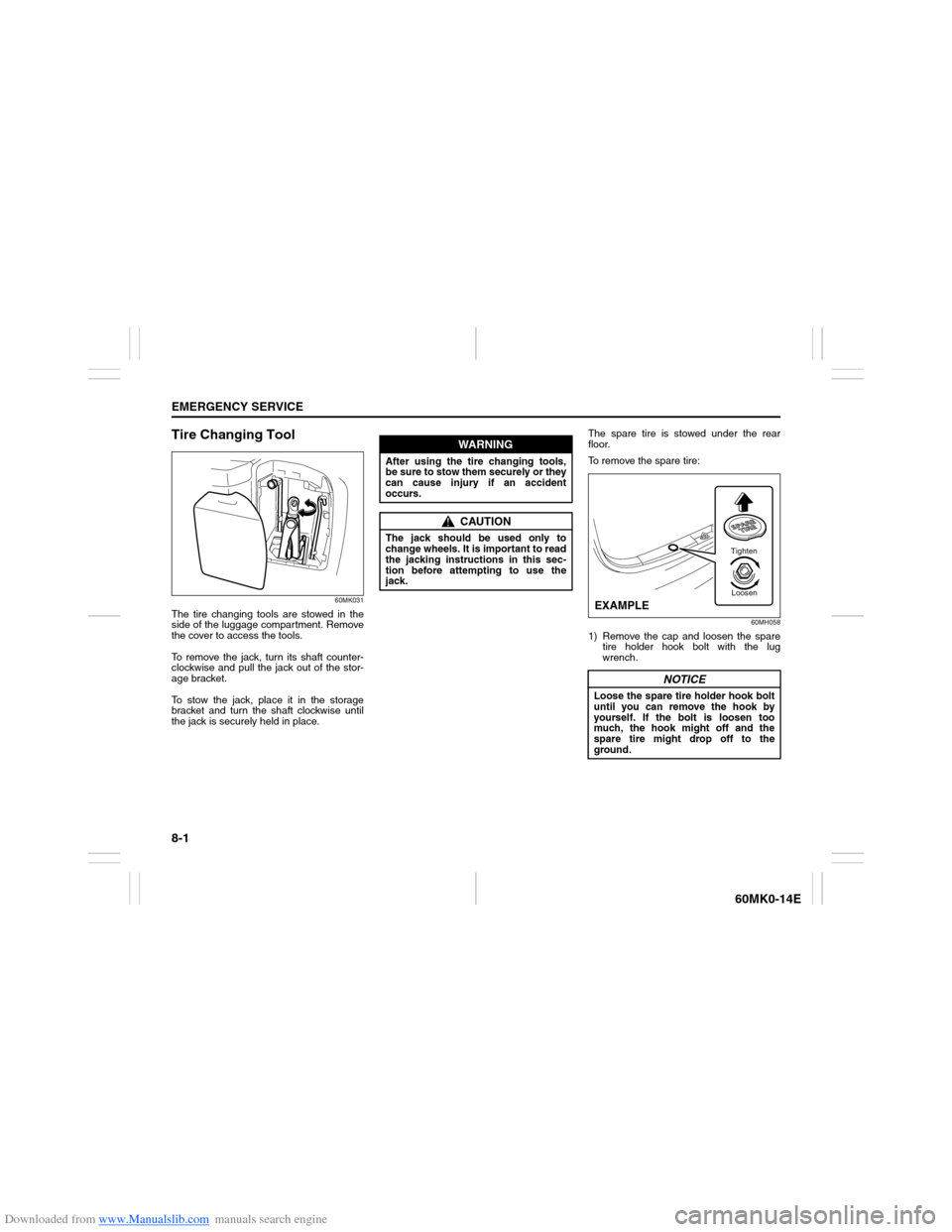

Tire Changing Tool

60MK031

The tire changing tools are stowed in the

side of the luggage compartment. Remove

the cover to access the tools.

To remove the jack, turn its shaft counter-

clockwise and pull the jack out of the stor-

age bracket.

To stow the jack, place it in the storage

bracket and turn the shaft clockwise until

the jack is securely held in place.The spare tire is stowed under the rear

floor.

To remove the spare tire:

60MH058

1) Remove the cap and loosen the spare

tire holder hook bolt with the lug

wrench.

WARNING

After using the tire changing tools,

be sure to stow them securely or they

can cause injury if an accident

occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

NOTICE

Loose the spare tire holder hook bolt

until you can remove the hook by

yourself. If the bolt is loosen too

much, the hook might off and the

spare tire might drop off to the

ground.

Tighten

Loosen

EXAMPLE

Page 183 of 207

Downloaded from www.Manualslib.com manuals search engine 8-2

EMERGENCY SERVICE

60MK0-14E

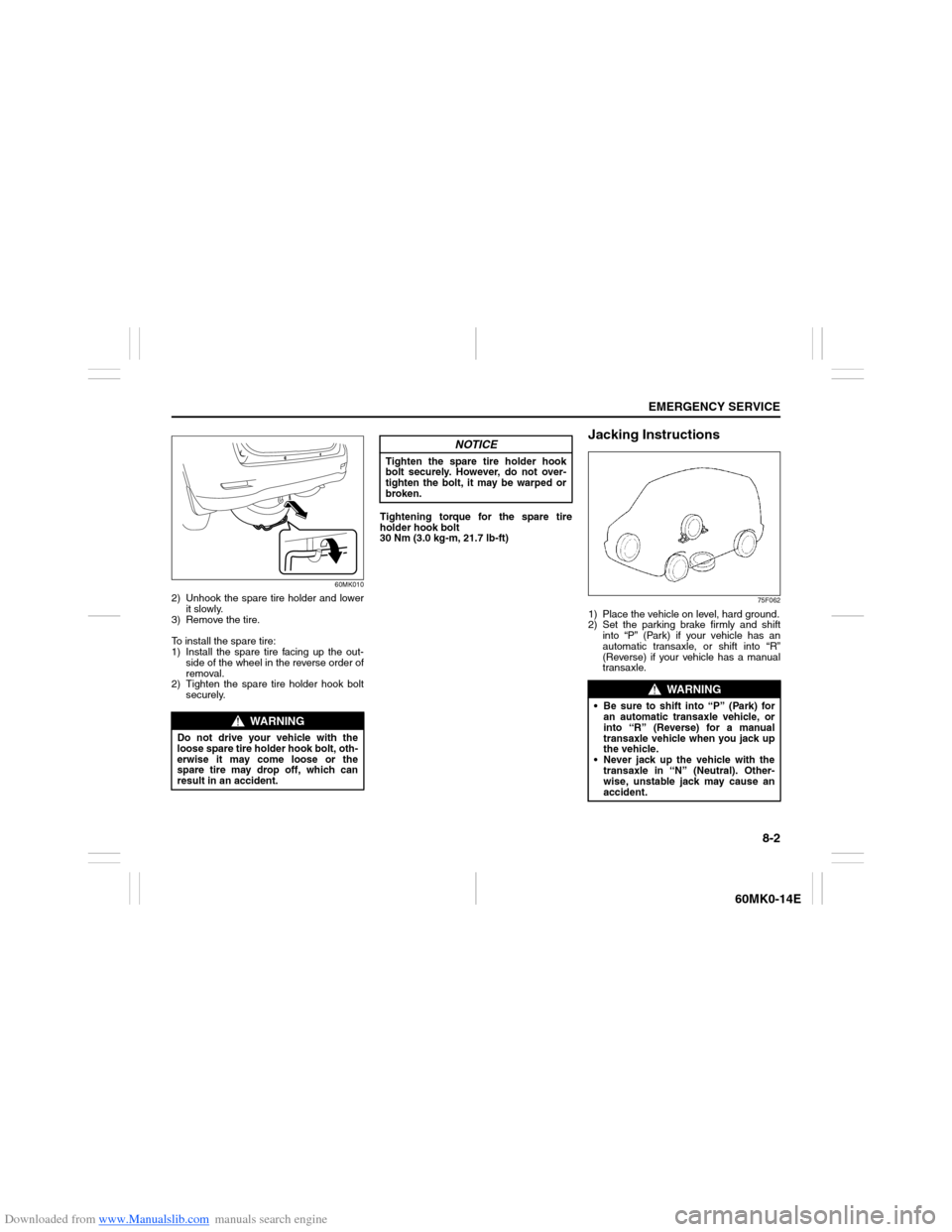

60MK010

2) Unhook the spare tire holder and lower

it slowly.

3) Remove the tire.

To install the spare tire:

1) Install the spare tire facing up the out-

side of the wheel in the reverse order of

removal.

2) Tighten the spare tire holder hook bolt

securely.Tightening torque for the spare tire

holder hook bolt

30 Nm (3.0 kg-m, 21.7 lb-ft)

Jacking Instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “P” (Park) if your vehicle has an

automatic transaxle, or shift into “R”

(Reverse) if your vehicle has a manual

transaxle.

WARNING

Do not drive your vehicle with the

loose spare tire holder hook bolt, oth-

erwise it may come loose or the

spare tire may drop off, which can

result in an accident.

NOTICE

Tighten the spare tire holder hook

bolt securely. However, do not over-

tighten the bolt, it may be warped or

broken.

WARNING

Be sure to shift into “P” (Park) for

an automatic transaxle vehicle, or

into “R” (Reverse) for a manual

transaxle vehicle when you jack up

the vehicle.

Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

Page 186 of 207

Downloaded from www.Manualslib.com manuals search engine 8-5EMERGENCY SERVICE

60MK0-14E

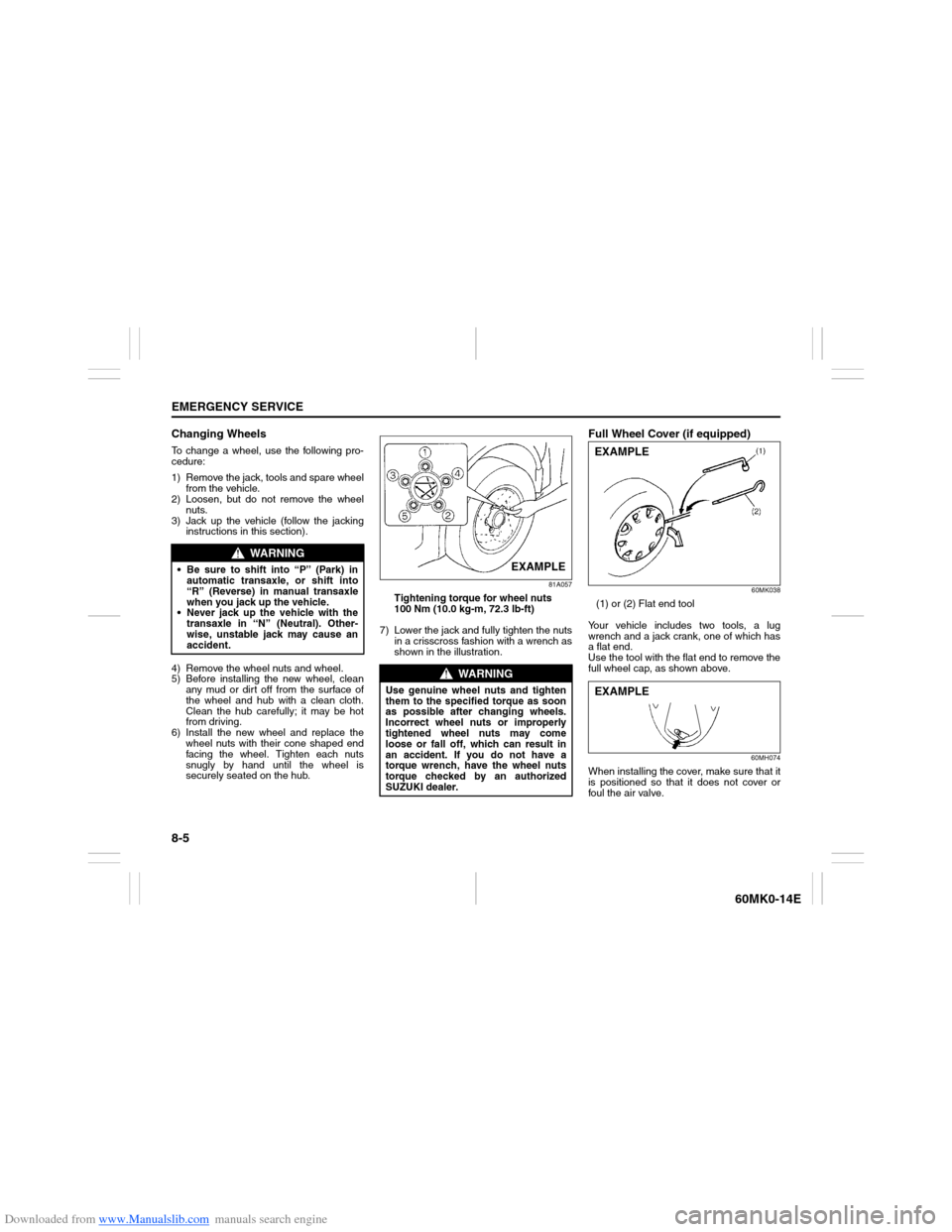

Changing WheelsTo change a wheel, use the following pro-

cedure:

1) Remove the jack, tools and spare wheel

from the vehicle.

2) Loosen, but do not remove the wheel

nuts.

3) Jack up the vehicle (follow the jacking

instructions in this section).

4) Remove the wheel nuts and wheel.

5) Before installing the new wheel, clean

any mud or dirt off from the surface of

the wheel and hub with a clean cloth.

Clean the hub carefully; it may be hot

from driving.

6) Install the new wheel and replace the

wheel nuts with their cone shaped end

facing the wheel. Tighten each nuts

snugly by hand until the wheel is

securely seated on the hub.

81A057

Tightening torque for wheel nuts

100 Nm (10.0 kg-m, 72.3 lb-ft)

7) Lower the jack and fully tighten the nuts

in a crisscross fashion with a wrench as

shown in the illustration.

Full Wheel Cover (if equipped)

60MK038

(1) or (2) Flat end tool

Your vehicle includes two tools, a lug

wrench and a jack crank, one of which has

a flat end.

Use the tool with the flat end to remove the

full wheel cap, as shown above.

60MH074

When installing the cover, make sure that it

is positioned so that it does not cover or

foul the air valve.

WARNING

Be sure to shift into “P” (Park) in

automatic transaxle, or shift into

“R” (Reverse) in manual transaxle

when you jack up the vehicle.

Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

WARNING

Use genuine wheel nuts and tighten

them to the specified torque as soon

as possible after changing wheels.

Incorrect wheel nuts or improperly

tightened wheel nuts may come

loose or fall off, which can result in

an accident. If you do not have a

torque wrench, have the wheel nuts

torque checked by an authorized

SUZUKI dealer.

EXAMPLE

EXAMPLEEXAMPLE

Page 189 of 207

Downloaded from www.Manualslib.com manuals search engine 8-8

EMERGENCY SERVICE

60MK0-14E

2-Wheel Drive (2WD) Manual Tran-

saxleManual transaxle vehicles may be towed

using either of the following methods.

1) From the front, with the front wheels

lifted and the rear wheels on the

ground. Before towing, make sure that

the parking brake is released.

2) From the rear, with the rear wheels

lifted and the front wheels on the

ground, provided the steering and driv-

etrain are in operational condition.

Before towing, make sure that transaxle

is in neutral, the steering wheel is

unlocked (the ignition key should be in

the “ACC” position), and the steering

wheel is secured with a clamping

device designed for towing service.

If the Starter Does Not

Operate1) Try turning the ignition switch to the

“START” position with the headlights

turned on to determine the battery con-

dition. If the headlights go excessively

dim or go off, it usually means that

either the battery is flat or the battery

terminal contact is poor. Recharge the

battery or correct battery terminal con-

tact as necessary.

2) If the headlights remain bright, check

the fuses. If the reason for failure of the

starter is not obvious, there may be a

major electrical problem. Have the vehi-

cle inspected by your authorized

SUZUKI dealer.

If the Engine is FloodedIf the engine is flooded with gasoline, it

may be hard to start. If this happens, press

the accelerator pedal all the way to the

floor and hold it there while cranking the

engine. (Do not operate the starter motor

for more than 15 seconds).

NOTICE

The steering column is not strong

enough to withstand shocks trans-

mitted from the front wheels during

towing. Always unlock the steering

wheel before towing.