jump start SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 244 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual [Carrier and hold-down]

The battery carrier and hold-down clamp should

be clean and free from corrosion before instal-

ling the battery. The carrier should be in good

condition so that it will support SUZUKI GRAND VITARA 1987 Service Repair Manual [Carrier and hold-down]

The battery carrier and hold-down clamp should

be clean and free from corrosion before instal-

ling the battery. The carrier should be in good

condition so that it will support](/img/20/57437/w960_57437-243.png)

[Carrier and hold-down]

The battery carrier and hold-down clamp should

be clean and free from corrosion before instal-

ling the battery. The carrier should be in good

condition so that it will support the battery

securely and keep it level.

Make certain there are no parts in carrier before

installing the battery.

To prevent the battery from shaking in its

carrier, the hold-down bolts should be tight but

not over tightened.

[Visual inspection]

Check for obvious damage, such as cracked or

broken case or cover, that could permit loss of

electrolyte. If obvious damage is noted, replace

the battery. Determine cause of damage and

correct as needed.

Check the battery terminal and cords for corro-

sion. If any, it should be cleaned.

[Built-in indicator]

This sealed battery has a built-in temperature

compensated indicator in the top of the battery.

This indicator is to be used with the following

diagnostic procedure. When observing the

indicator, make sure that the battery has a clean

top. A light may be needed in some poorly-lit

areas.

Under normal operation, two indications can

be seen

2

Clear

RedCHARGING

NECESSARY

Fig. lo-23

l Clear with Red Dot

This means the discharging battery. In this case,

charge the battery until the indicator will be

blue with red dot. The charging and electrical

systems should also be checked at this time. If

any defective is found, correct it. While charging

it, if the battery feels hot 52°C (125” F), or if

violent gassing or spewing of electrolyte through

the vent hole occurs, discontinue charging or

reduce charging rate.

[Jump starting in case of emergency with

auxiliary (booster) battery]

NOTE:

l Do not push or tow the vehicle to start.

Damage to the emission system and/or to

other parts of the vehicle may result.

8 Both booster and discharged battery should

be treated carefully when using jumper cables.

Follow the procedure outlined below, being

careful not to cause sparks:

CAUTION:

l Departure from these conditions or the

procedure below could result in: (1)

Serious personal injury (particularly to

eyes) or property damage from such

causes as battery explosion, battery acid,

or electrical burns; and/or (2) damage to

electronic components of either vehicle.

l Never expose battery to open flame or

electric spark-batteries generate a gas

which is flammable and explosive.

l Remove rings,watches,and other

jewelry. Wear approved eye protection.

l Do not allow battery fluid to contact

eyes, skin, fabrics, or painted surfaces -

fluid is a corrosive acid. Flush any con-

tacted area with water immediately and

thoroughly. Be careful that metal tools

or jumper cables do not contact the

positive battery terminal (or metal in

contact with it) and any other metal on

the car, because a short circuit could

occur. Batteries should always be kept

out of the reach of children.

1) Set parking brake and place transmission in

neutral. Turn off the ignition, turn off lights

and all other electrical loads.

2) Check electrolyte level. If level is below low

level line, replace battery.

NOTE:

When jump starting an engine with charging

equipment, be sure equipment used is 12volt

and negative ground. Do not use 24volt charging

equipment. Using each equipment can cause

serious damage to the electrical system or

electronic parts.

10-11

Page 245 of 962

3) Attach the end of one jumper cable to the

positive terminal of the booster battery and

the other end of the same cable to the positive

terminal of the discharged battery. Do not

permit vehicles to touch each other as this

could cause a ground connection and counte-

ract the benefits of this procedure. (Use

12-volt battery only to jump start the engine).

4) Attach one end of the remaining negative

cable to the negative terminal of the booster

battery, and the other end to a solid engine

ground (such as A/C compressor bracket or

generator mounting bracket) at least 18 inches

from the battery of the vehicle being started

(DO NOT CONNECT DIRECTLY TO THE

NEGATIVE TERMINAL OF THE DEAD

BATTERY).

5) Start the engine of the vehicle that is provid-

ing the jump start and turn off electrical

accessories. Then start the engine in the car

with the discharged battery.

6) Reverse these directions exactly when remov-

ing the jumper cables. The negative cable

must be disconnected from the engine that

was jump started first.

REMOVE AND REPLACE

When handling a battery, the following safety

precautions should be followed:

1) Hydrogen gas is produced by the battery.

A flame or spark near the battery may cause

the gas to ignite.

2) Battery fluid is highly acidic. Avoid spilling

on clothing or other fabric. Any spilled

electrolyte should be flushed with large

quantity of water and cleaned immediately.

To remove or replace a battery, always

disconnect the negative cable first, then the

positive cable.

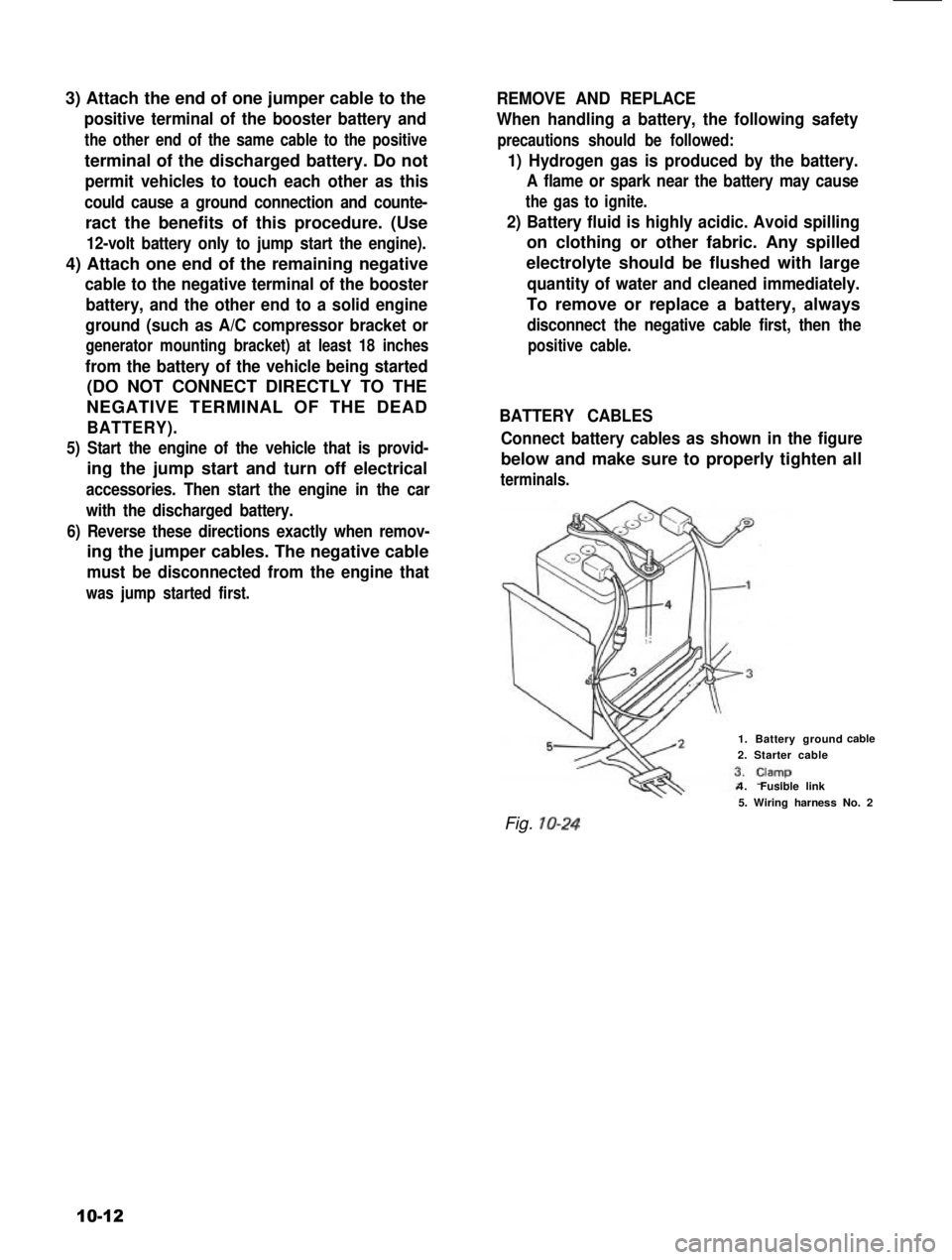

BATTERY CABLES

Connect battery cables as shown in the figure

below and make sure to properly tighten all

terminals.

1. Battery ground

2. Starter cable

4.Fusible link

cable

Fig. IO-24

5. Wiring harness No. 2

10-12

Page 271 of 962

10) Remove low gear bush, low speed synchro-

nizer hub, ring, spring, 2nd gear and 2nd

gear bearing by using hydraulic press.

Hydraulic press

Bush

Fig. 13-20

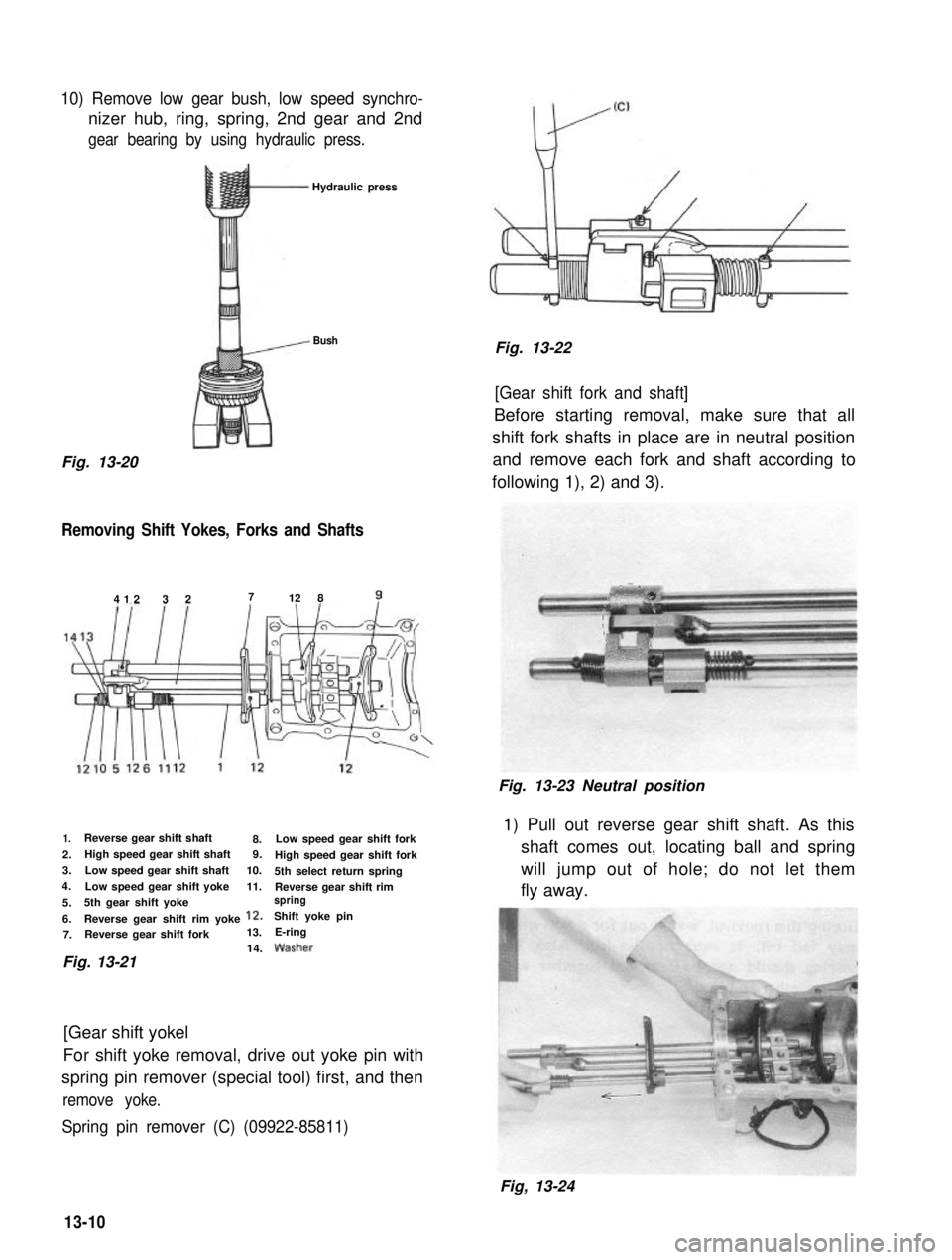

Removing Shift Yokes, Forks and Shafts

412 3 2712 8?

1.

2.

3.

4.

5.

6. 7. Reverse gear shift shaft

8.

Reverse gear shift rim yoke 12.

High speed gear shift shaft

9.

Reverse gear shift fork Low speed gear shift shaft

13.

10.

Low speed gear shift yoke 11.

5th gear shift yoke Low speed gear shift fork

Shift yoke pin High speed gear shift fork

5th select return spring Reverse gear shift rim

spring

E-ring

14.

Fig. 13-21

[Gear shift yokel

For shift yoke removal, drive out yoke pin with

spring pin remover (special tool) first, and then

remove yoke.

Spring pin remover (C) (09922-85811)

Fig. 13-22

[Gear shift fork and shaft]

Before starting removal, make sure that all

shift fork shafts in place are in neutral position and remove each fork and shaft according to

following 1), 2) and 3).

Fig. 13-23 Neutral position1) Pull out reverse gear shift shaft. As this shaft comes out, locating ball and spring

will jump out of hole; do not let them

fly away.

13-10

Fig, 13-24

Page 458 of 962

3) Automatic stop action test

Connect yellow terminal of motor to positive

@ battery terminal, and put a jumper

between Blue/White (Blue/Black) and Blue

terminals to see if motor output shaft comes

to a halt at a certain, not just any, angular

position. That position corresponds to start-

ing position of the blade. Using jumper,

stop motor a number of times to make sure

that motor stops at the same position each

time.

Fig. 21-14 Testing motor

1. Positive terminal

2. Negative terminal

3. Put a jumper between

Blue/White (Blue/Black) and Blue

4) Internal wiper relay test

1. Disconnect wiper & washer switch coupler.

2. Turn wiper switch to “I NT” position.

3. Connect positive battery terminal to

Yellow/White coupler terminal and nega-

tive battery terminal to Black terminal.

If an operating sound is heard, the relay is

at work properly.

Switch connector

14.Yellow/White

15.Blue16.Blue/Red17.Blue/Black

18.Black19.Blue/White

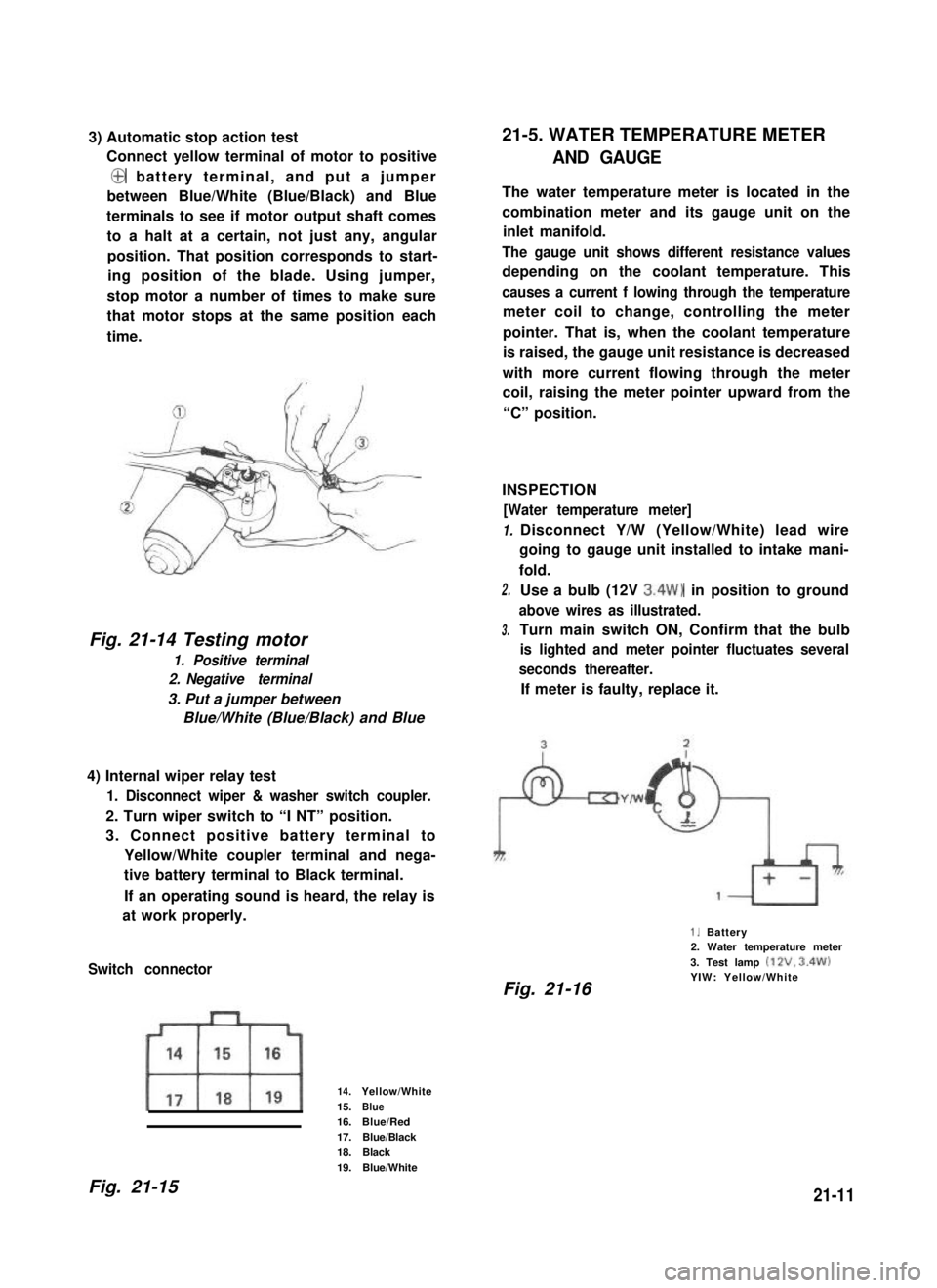

21-5. WATER TEMPERATURE METER

AND GAUGE

The water temperature meter is located in the

combination meter and its gauge unit on the

inlet manifold.

The gauge unit shows different resistance values

depending on the coolant temperature. This

causes a current f lowing through the temperature

meter coil to change, controlling the meter

pointer. That is, when the coolant temperature

is raised, the gauge unit resistance is decreased

with more current flowing through the meter

coil, raising the meter pointer upward from the

“C” position.

INSPECTION

[Water temperature meter]

1.

2.

3.

Disconnect Y/W (Yellow/White) lead wire

going to gauge unit installed to intake mani-

fold.

Use a bulb (12V 3.4W) in position to ground

above wires as illustrated.

Turn main switch ON, Confirm that the bulb

is lighted and meter pointer fluctuates several

seconds thereafter.

If meter is faulty, replace it.

1. Battery2. Water temperature meter

3. Test lamp (12V. 3.4W)YIW: Yellow/WhiteFig. 21-16

Fig. 21-1521-11