jump start terminals SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 245 of 962

3) Attach the end of one jumper cable to the

positive terminal of the booster battery and

the other end of the same cable to the positive

terminal of the discharged battery. Do not

permit vehicles to touch each other as this

could cause a ground connection and counte-

ract the benefits of this procedure. (Use

12-volt battery only to jump start the engine).

4) Attach one end of the remaining negative

cable to the negative terminal of the booster

battery, and the other end to a solid engine

ground (such as A/C compressor bracket or

generator mounting bracket) at least 18 inches

from the battery of the vehicle being started

(DO NOT CONNECT DIRECTLY TO THE

NEGATIVE TERMINAL OF THE DEAD

BATTERY).

5) Start the engine of the vehicle that is provid-

ing the jump start and turn off electrical

accessories. Then start the engine in the car

with the discharged battery.

6) Reverse these directions exactly when remov-

ing the jumper cables. The negative cable

must be disconnected from the engine that

was jump started first.

REMOVE AND REPLACE

When handling a battery, the following safety

precautions should be followed:

1) Hydrogen gas is produced by the battery.

A flame or spark near the battery may cause

the gas to ignite.

2) Battery fluid is highly acidic. Avoid spilling

on clothing or other fabric. Any spilled

electrolyte should be flushed with large

quantity of water and cleaned immediately.

To remove or replace a battery, always

disconnect the negative cable first, then the

positive cable.

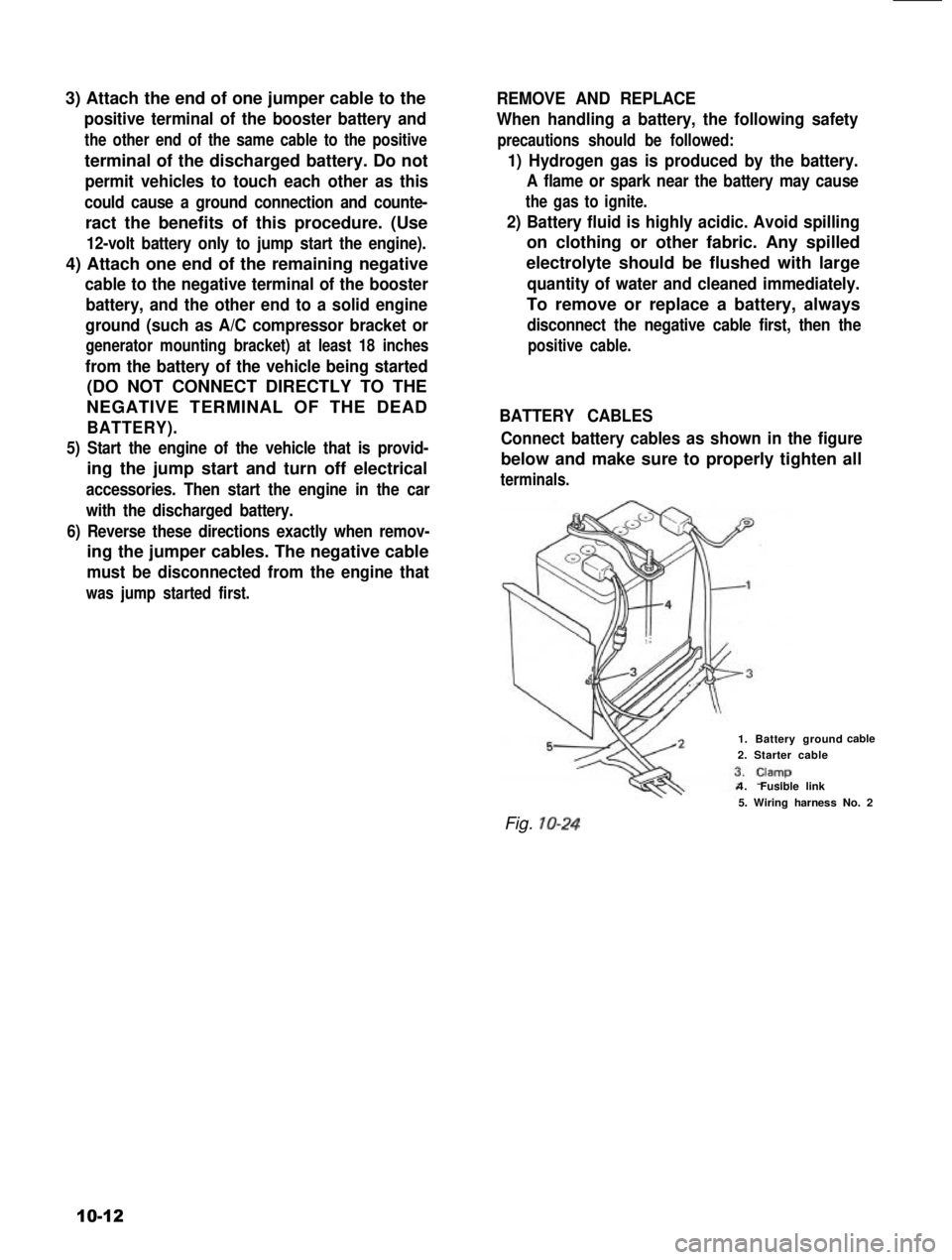

BATTERY CABLES

Connect battery cables as shown in the figure

below and make sure to properly tighten all

terminals.

1. Battery ground

2. Starter cable

4.Fusible link

cable

Fig. IO-24

5. Wiring harness No. 2

10-12

Page 458 of 962

3) Automatic stop action test

Connect yellow terminal of motor to positive

@ battery terminal, and put a jumper

between Blue/White (Blue/Black) and Blue

terminals to see if motor output shaft comes

to a halt at a certain, not just any, angular

position. That position corresponds to start-

ing position of the blade. Using jumper,

stop motor a number of times to make sure

that motor stops at the same position each

time.

Fig. 21-14 Testing motor

1. Positive terminal

2. Negative terminal

3. Put a jumper between

Blue/White (Blue/Black) and Blue

4) Internal wiper relay test

1. Disconnect wiper & washer switch coupler.

2. Turn wiper switch to “I NT” position.

3. Connect positive battery terminal to

Yellow/White coupler terminal and nega-

tive battery terminal to Black terminal.

If an operating sound is heard, the relay is

at work properly.

Switch connector

14.Yellow/White

15.Blue16.Blue/Red17.Blue/Black

18.Black19.Blue/White

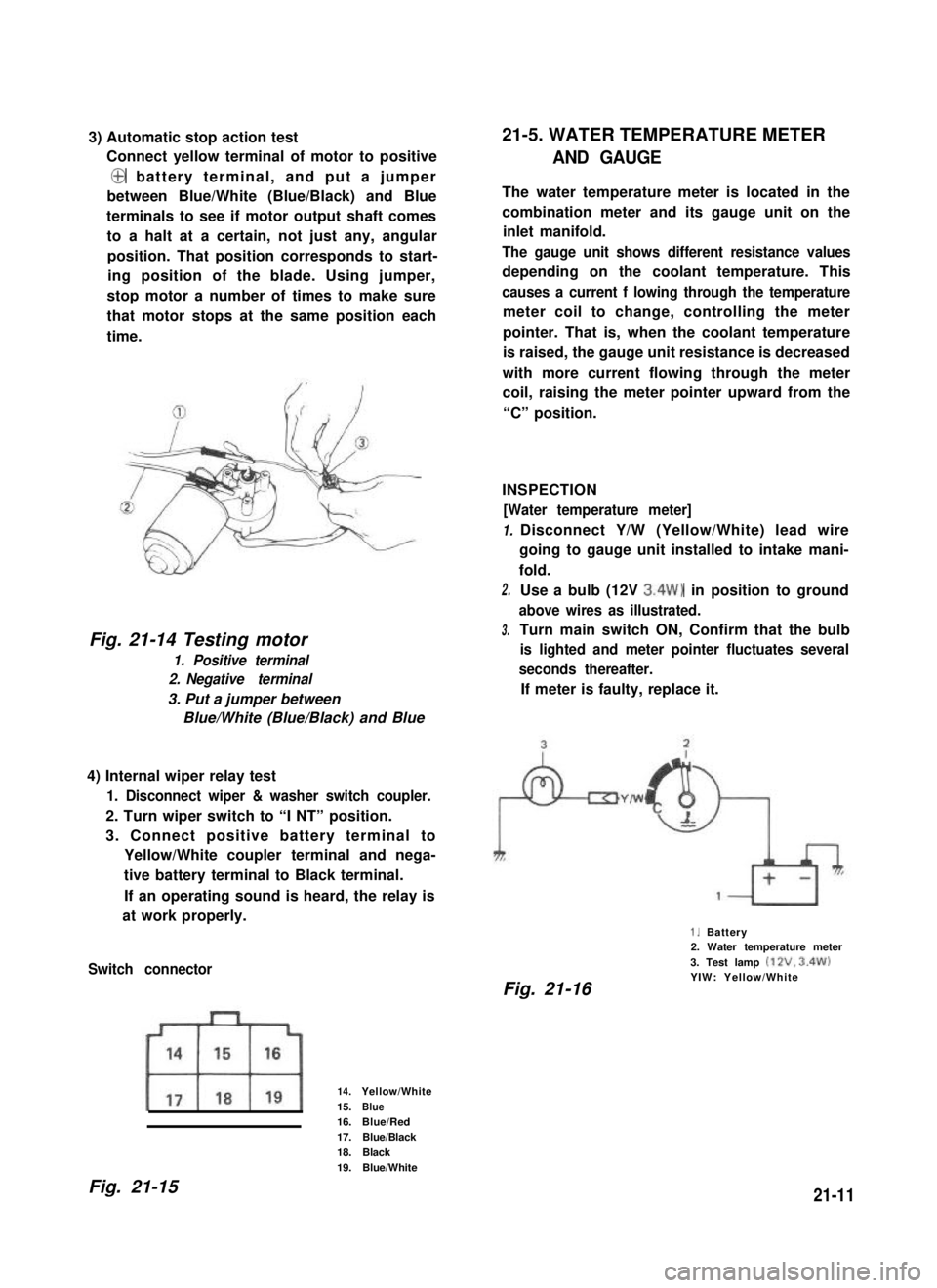

21-5. WATER TEMPERATURE METER

AND GAUGE

The water temperature meter is located in the

combination meter and its gauge unit on the

inlet manifold.

The gauge unit shows different resistance values

depending on the coolant temperature. This

causes a current f lowing through the temperature

meter coil to change, controlling the meter

pointer. That is, when the coolant temperature

is raised, the gauge unit resistance is decreased

with more current flowing through the meter

coil, raising the meter pointer upward from the

“C” position.

INSPECTION

[Water temperature meter]

1.

2.

3.

Disconnect Y/W (Yellow/White) lead wire

going to gauge unit installed to intake mani-

fold.

Use a bulb (12V 3.4W) in position to ground

above wires as illustrated.

Turn main switch ON, Confirm that the bulb

is lighted and meter pointer fluctuates several

seconds thereafter.

If meter is faulty, replace it.

1. Battery2. Water temperature meter

3. Test lamp (12V. 3.4W)YIW: Yellow/WhiteFig. 21-16

Fig. 21-1521-11