load capacity SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 243 of 962

3) Make sure to assemble stator terminal

insulator properly.

10-2. BATTERY

1. Stator terminal insulator

Fig. lo-20

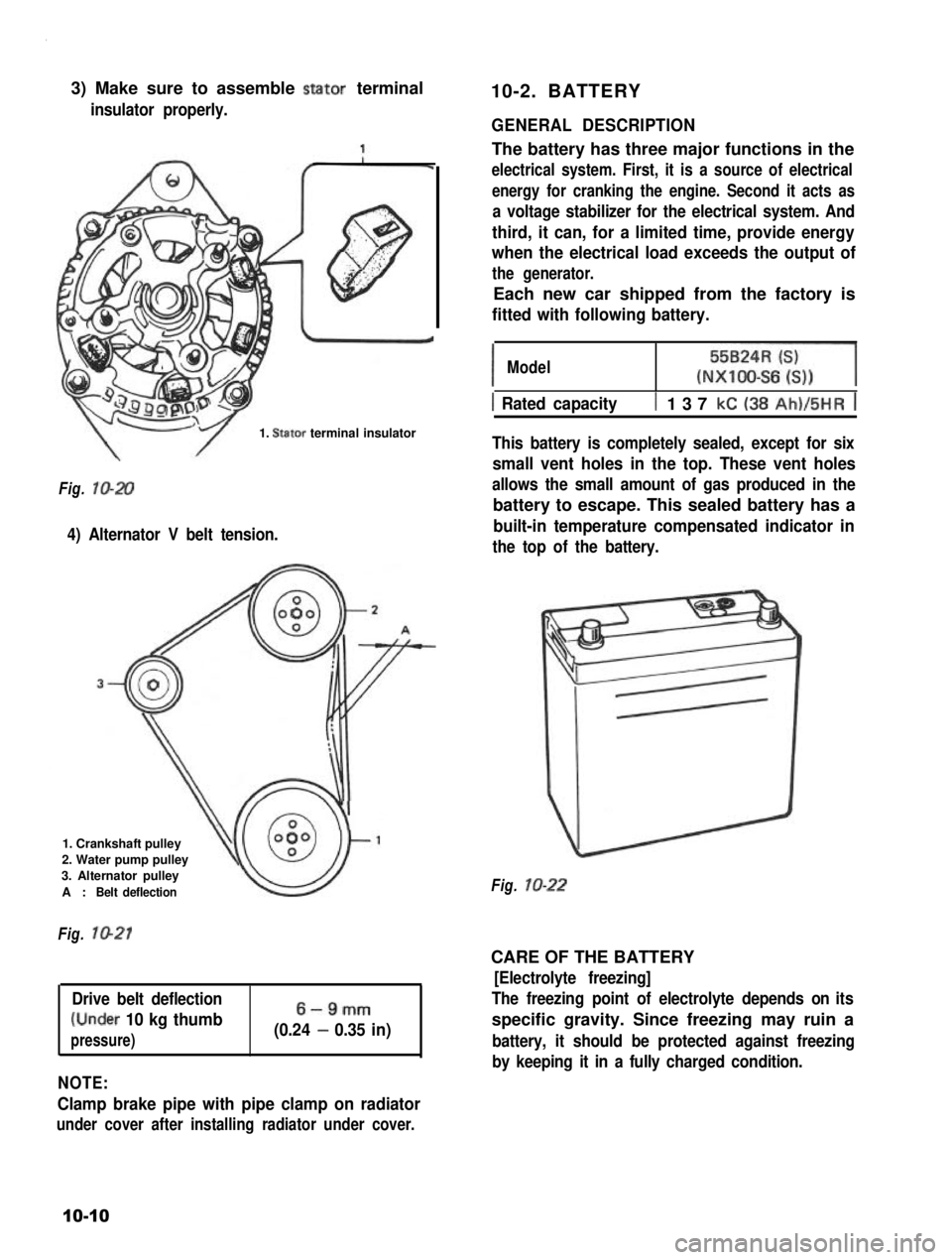

4) Alternator V belt tension.

1. Crankshaft pulley

2. Water pump pulley

3. Alternator pulley

A :Belt deflection

Fig. 1021

Drive belt deflection

(Under 10 kg thumb

pressure)

6-9mm

(0.24 - 0.35 in)

NOTE:

Clamp brake pipe with pipe clamp on radiator

under cover after installing radiator under cover.

GENERAL DESCRIPTION

The battery has three major functions in the

electrical system. First, it is a source of electrical

energy for cranking the engine. Second it acts as

a voltage stabilizer for the electrical system. And

third, it can, for a limited time, provide energy

when the electrical load exceeds the output of

the generator.

Each new car shipped from the factory is

fitted with following battery.

IModel55BzR=l(NXIOO-S6 6))

1 Rated capacityt 137 kC (38 Ah)/5HR j

This battery is completely sealed, except for six

small vent holes in the top. These vent holes

allows the small amount of gas produced in the

battery to escape. This sealed battery has a

built-in temperature compensated indicator in

the top of the battery.

Fig. lo-22

CARE OF THE BATTERY

[Electrolyte freezing]

The freezing point of electrolyte depends on its

specific gravity. Since freezing may ruin a

battery, it should be protected against freezing

by keeping it in a fully charged condition.

10-10

Page 383 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflati SUZUKI GRAND VITARA 1987 Service Repair Manual Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflati](/img/20/57437/w960_57437-382.png)

Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflation pressures should be checked

(including spare tire) at least monthly and

when significantly changing the load in the

car.

l Always check tire inflation pressures when

tires are “cold”.

l Always use tire pressure gauge when checking

inflation pressure.

l Be sure to reinstall tire inflation valve caps to

prevent dirt and moisture from getting into

valve core, as they may cause air leakage.

l If air loss occurs while driving, do not drive

on the deflated tire more than is needed to

stop safety. Driving even a short distance on a

deflated tire can damage a tire and wheel

beyond repair.

NOTE:

Before installing wheels, remove any build-up of

corrosion on the wheel mounting surface and

brake drum or disc mounting surface by scraping

and wire brushing. Installing wheels without

good metal-to-metal contact at the mounting

surfaces can cause wheel nuts to loosen, which

can later allow a wheel to come off while the

car is moving.

RADIAL TIRES

.i II

9T

\

I

4-wheels

Fig. 18-44

fT

u

[I

5-wheels

[Wheels]

Wheels must be replaced if they are bent, dented,

have excessive lateral or radial runout, leak air

through welds, have elongated bolt holes, if

lug nuts won’t stay tight, or if they are heavily

rusted. Wheels with greater runout than shown

in below figure may cause objectional vibrations.

Replacement wheels must be equivalent to the

original equipment wheels in load capacity,

diameter,rim width, offset and mounting

configuration. A wheel of improper size or type

may affect wheel and bearing life, brake cooling,

speedometer/odometer calibration, car ground

clearance and tire clearance to the body and

chassis.

[Tire rotation]

“Rotate” tires at the regular intervals in order to

equalize tire wear and thereby make full use of

each tire. Refer to below figure for the scheme

of rotation. Adherence to this scheme prolongs

tire life.

18-20