service SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 1 of 962

FOREWORD

This manual contains procedures for diagnosis, maintenance adjustments, \

service operations,

replacement of components (Service) and for disassembly and assembly o\

f major compo-

nents.

The contents are classified into sections each of which is given a secti\

on number as indicated

in the Table of Contents on next page. And on the first page of each ind\

ividual section is an

index of that section.

This manual should be kept in a handy place for ready reference of the s\

ervice work. Strict

observance of the so specified items will enable one to obtain the full \

performance of the

vehicle.

When replacing parts or servicing by disassembling, it is recommended to\

use SUZUKI

genuine parts, tools and service materials (lubricants, sealants, etc.)\

as specified in each

description.

All information, illustrations and specifications contained in this lite\

rature are based on the

latest product information available at the time of publication approval\

. The right is reserved

to make changes at any time without notice. And used as the main subject\

of description is

the vehicle of standard specifications among others. Therefore, note tha\

t illustrations and

photos may differ from the vehicle being actually serviced.

IMPORTANT:

It is important to note that, during any vehicle maintenance procedures,\

replacement

fasteners must have the same measurements as those removed.

Mismatched or incorrect fasteners can result in vehicle damage or malfun\

ction, or possible

personal injury.

Therefore, fasteners removed from the vehicle should be saved for re-use\

whenever possible.

Where the fasteners are not satisfactory for reuse, care should be taken\

to select a replace-

ment that matches the original.

Additional information concerning this subject will be found in the sect\

ion 0 (METRIC

INFORMATION).

This service manual is applicable to vehicles of and after the following\

body number.

Effective body No.:

J4235001

SUZUKI MOTOR

TECHNICAL DEPARTMENT

AUTOMOBILE SERVICE DIVISION

0 COPYRIGHT SUZUKI MOTOR CO., LTD. 1987

CO LTD

JS3JC51C J4235001

JS3JC51V J4150001

JS4JC51C J4235001

JS4JC51V 54150001

Page 2 of 962

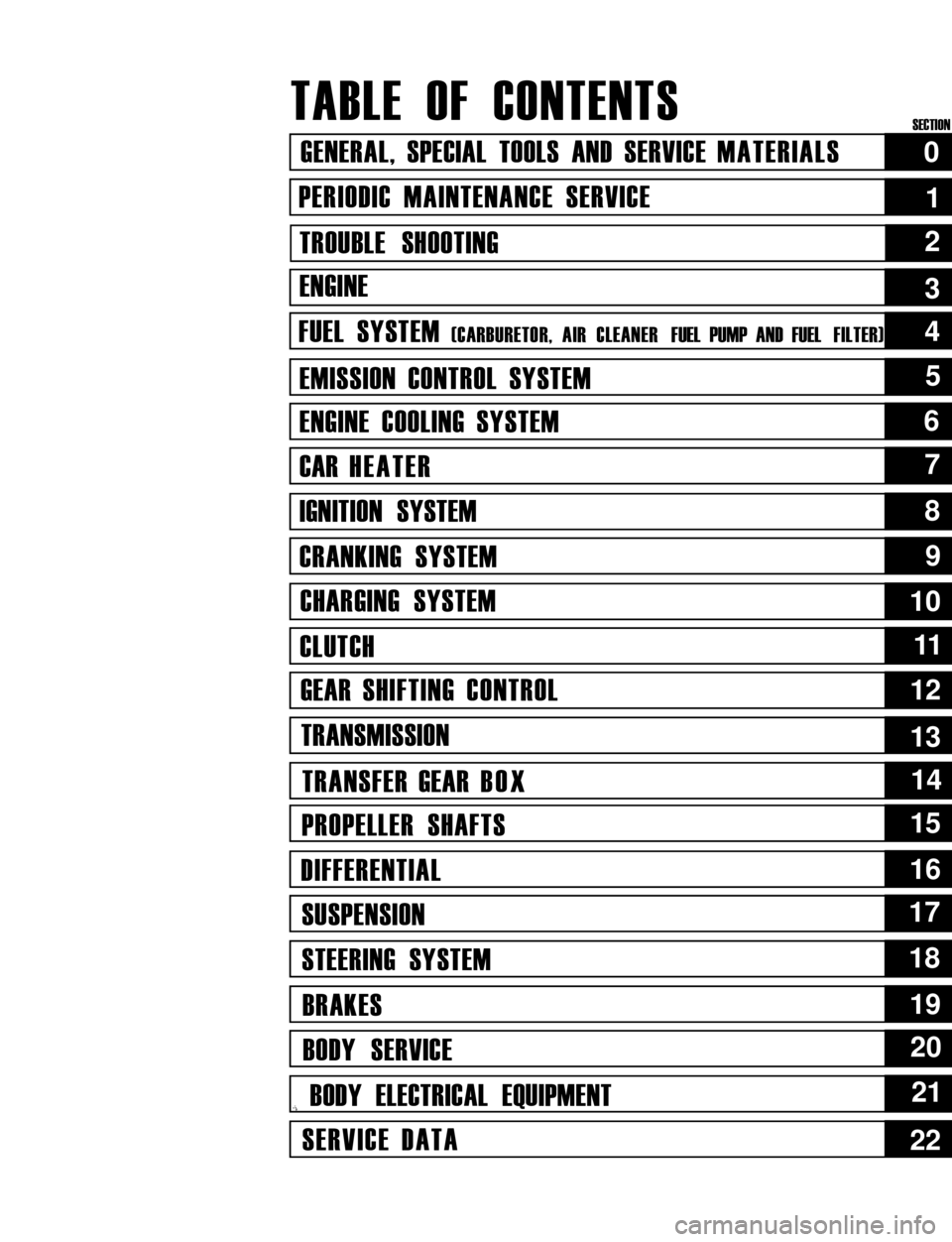

TABLE OF CONTENTS

GENERAL, SPECIAL TOOLS AND SERVICE MATERIALS

PERIODIC MAINTENANCE SERVICE

TROUBLE SHOOTING

ENGINE

FUEL SYSTEM (CARBURETOR, AIR CLEANER FUEL PUMP AND FUEL FILTER)

EMISSION CONTROL SYSTEM

ENGINE COOLING SYSTEM

CAR HEATER

IGNITION SYSTEM

CRANKING SYSTEM

CHARGING SYSTEM

CLUTCH

GEAR SHIFTING CONTROL

TRANSMISSION

TRANSFER GEAR BOX

PROPELLER SHAFTS

DIFFERENTIAL

SUSPENSION

STEERING SYSTEM

BRAKES

BODY SERVICE

,i BODY ELECTRICAL EQUIPMENT

SERVICE DATA

0

1

2

5

6

7

8

9

10

1111

12

13

14

15

16

17

18

19

20

21

22

4

3

SECTION

Page 3 of 962

SECTION 0

GENERAL, SPECIAL TOOLS AND

SERVICE MATERIALS

CONTENTS

0-1. IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . O-1

0-2. STANDARD SHOP PRACTICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . O-2

0-3.SPECIAL TOOLS.. . . . . . . . . . . . 1.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0-4.REQUIRED SERVICE MATERIALS . . . . . . . . . . . . . . . . . . . . . s . . . . . O-9

METRIC INFORMATION . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . O-12

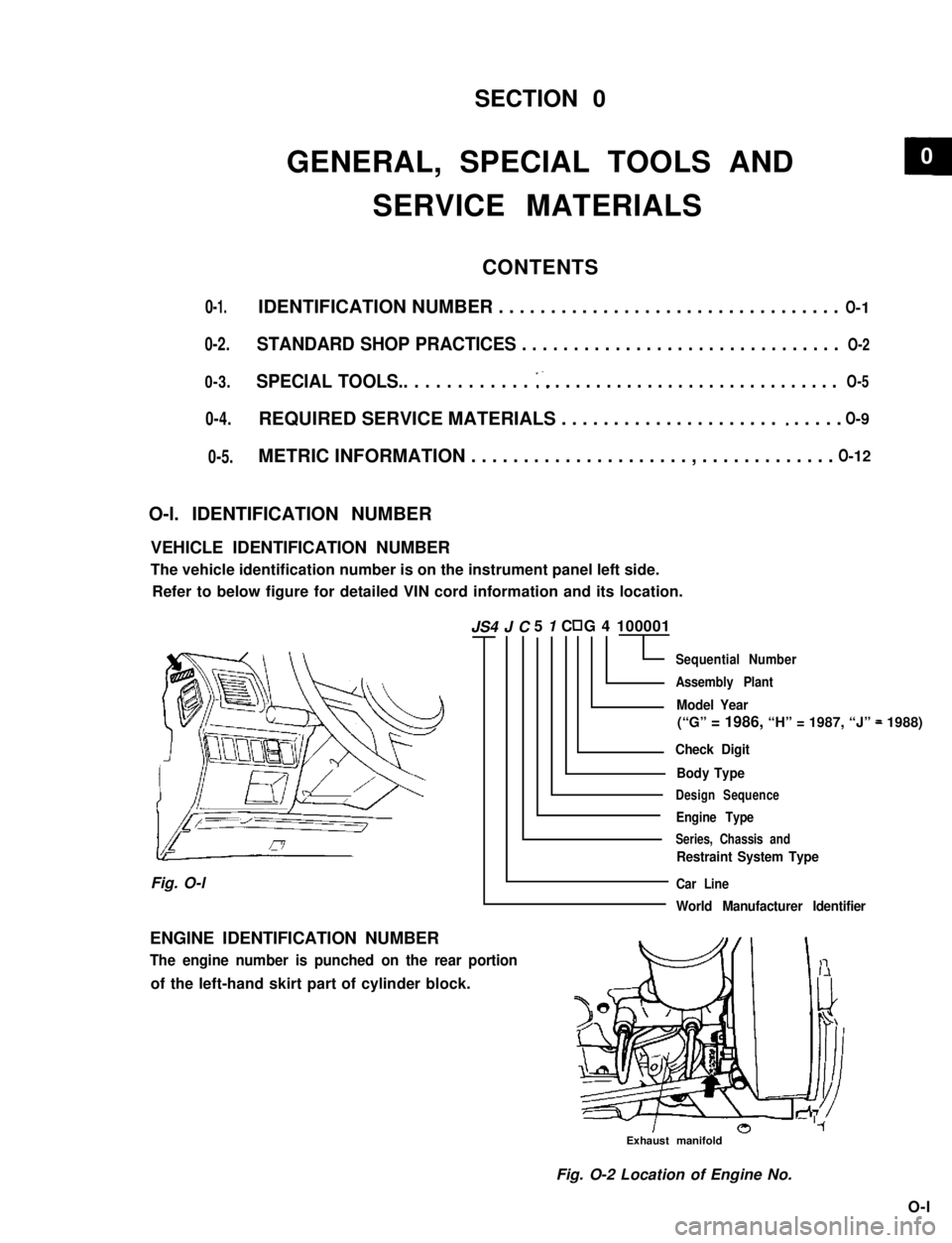

O-l. IDENTIFICATION NUMBER

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number is on the instrument panel left side.

Refer to below figure for detailed VIN cord information and its location.

5 1 C G 4 100001

Sequential Number

Assembly Plant

Model Year

(“G” = 1986, “H” = 1987, “J” = 1988)

Check Digit

Body Type

Design Sequence

Engine Type

Series, Chassis and

Restraint System Type

Car Line

World Manufacturer Identifier

Fig. O-l

ENGINE IDENTIFICATION NUMBER

The engine number is punched on the rear portion

of the left-hand skirt part of cylinder block.

Exhaust manifold

Fig. O-2 Location of Engine No.

O-l

JS4 J C

0-5.

O- 5

0

Page 4 of 962

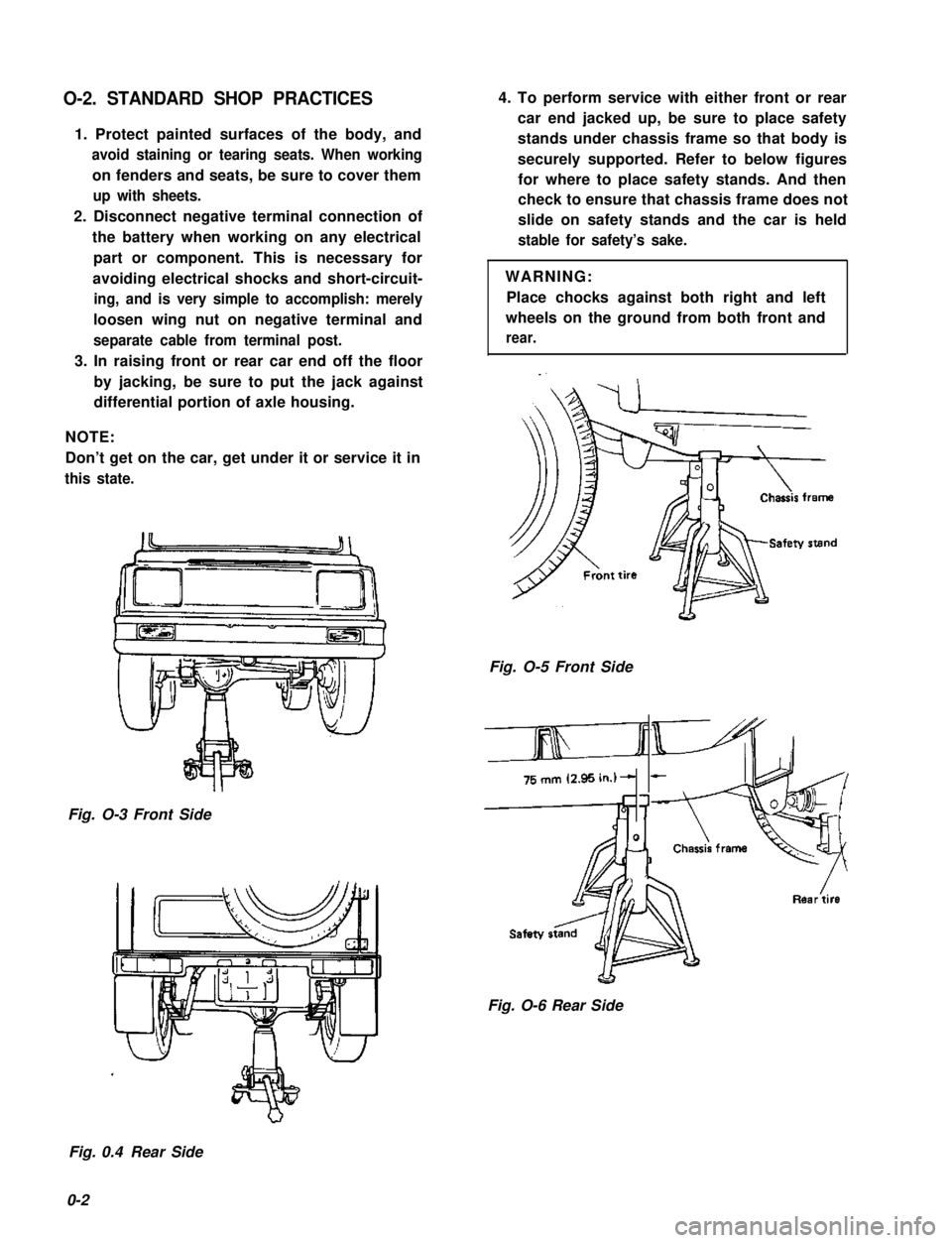

O-2. STANDARD SHOP PRACTICES

1. Protect painted surfaces of the body, and

avoid staining or tearing seats. When working

on fenders and seats, be sure to cover them

up with sheets.

2. Disconnect negative terminal connection of

the battery when working on any electrical

part or component. This is necessary for

avoiding electrical shocks and short-circuit-

ing, and is very simple to accomplish: merely

loosen wing nut on negative terminal and

separate cable from terminal post.

3. In raising front or rear car end off the floor

by jacking, be sure to put the jack against

differential portion of axle housing.

NOTE:

Don’t get on the car, get under it or service it in

this state.

Fig. O-3 Front Side

4. To perform service with either front or rear

car end jacked up, be sure to place safety

stands under chassis frame so that body is

securely supported. Refer to below figures

for where to place safety stands. And then

check to ensure that chassis frame does not

slide on safety stands and the car is held

stable for safety’s sake.

WARNING:

Place chocks against both right and left

wheels on the ground from both front and

rear.

Fig. O-5 Front Side

&

Fig. O-6 Rear Side

Fig. 0.4 Rear Side

0-2

Page 17 of 962

SECTION 1

PERIODIC MAINTENANCE SERVICE

CONTENTS

1-1. MAINTENANCE SCHEDULE..................................

1-2.ENGINE AND EMISSION CONTROL...........................1-5

1-3.CHASSIS AND BODY......................................1-17

1

1-2

1-1

Page 25 of 962

CAUTION:

When changing engine coolant, use mixture

of 56% water and 50% GOLDEN CRUISER

1200for the market where ambient tem-

perature falls lower than -16°C (3°F) in

winter and mixture of 70% water and

30% GOLDEN CRUISER 1200for the

market where ambient temperature doesn’t

fall lower than -16°C (3” F).

Even in a market where no freezing tempe-

rature is anticipated, mixture of 70% water

and 30% GOLDEN CRUISER 1200

should be used for the purpose of corro-

sion protection and lubrication.

7. EXHAUST PIPES AND MOUNTINGS

INSPECTION

1.Drain plug

1. Reservoir tank cap2. Reservoir tank

3. Arrow marks

5) Fill radiator with specified amount of coolant,

and run engine for 2 or 3 minutes at idle.

This drives out any air which may still be

trappedwithincoolingsystem.STOP

ENGINE. Add coolant as necessary until

coolant level reaches the filler throat of

radiator. Reinstall radiator cap.

6) Add coolant to reservoir tank so that the level

aligns with Full mark. Then, reinstall cap

aligning the arrow marks on the tank and cap.

r.

COOLANT CAPACITY

Engine, radiator and4.2 liters

heater(8.9/7.4 US/Imp pt.)

Reservoir tank0.6 liters

(1.3/1.1 US/Imp pt.)

ITotal4.8 liters

(10.1/8.4US/lmp pt.)

WARNING:

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Any service on exhaust system should be

performed when system is cool.

When carrying out periodic maintenance, or the

car is raised for other service, check exhaust

system as follows:

l Check rubber mountings for damage, deterio-

ration, and out of position.

l Check exhaust system for leakage, loose

connections, dents, and damages.

If bolts or nuts are loose, tighten them to

specification. Refer to below chart for torque

specification.

l Check nearby body areas for damaged, miss-

ing, or mispositioned parts, open seams,

holes, loose connections or’ other defects

which could permit exhaust fumes to seep

into the car.

l Make sure that exhaust system components

have enough clearance from the underbody to

avoid overheating and possible damage to the

floor carpet.

l Any defects should be fixed at once.

IBolts and nutTightening torqueI

40-80 N-m

Exhaustpipebolts4.0-6.0 kg-m

29.0-43.0 lb-ft

Muffler nuts

18 - 28 N-m

1.8 - 2.8 kg-m

13.5 - 20.0 lb-ft

Replace center pipe rubber mounting and muffler

rubber mountings with new ones periodically.

l-9

Page 26 of 962

8. PCV VALVE REPLACEMENT

1) Disconnect crankcase ventilation hose from

PCV valve.

2) Remove PCV valve from intake manifold.

3) Wind sealing tape on thread of the new valve

and install it securely.

Tightenlng torque

for PCV valve

15-25 N.m

1.5-2.5 kg-m,

11 .O-18.0 lb-ft

4) Install hose and clamp it securely.

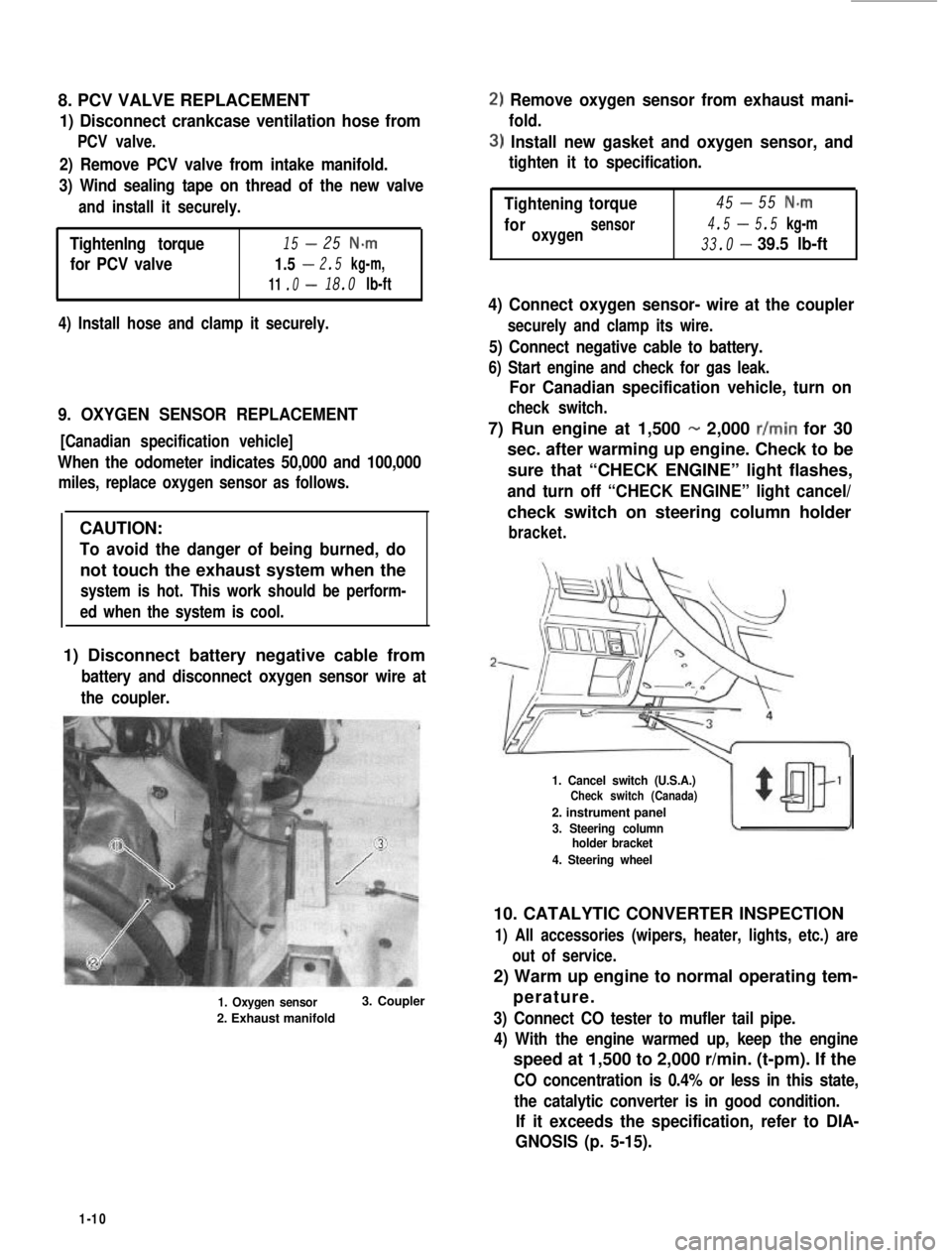

9. OXYGEN SENSOR REPLACEMENT

[Canadian specification vehicle]

When the odometer indicates 50,000 and 100,000

miles, replace oxygen sensor as follows.

CAUTION:

To avoid the danger of being burned, do

not touch the exhaust system when the

system is hot. This work should be perform-

ed when the system is cool.

1) Disconnect battery negative cable from

battery and disconnect oxygen sensor wire at

the coupler.

1. Oxygen sensor

2. Exhaust manifold

3. Coupler

2) Remove oxygen sensor from exhaust mani-

fold.

3) Install new gasket and oxygen sensor, and

tighten it to specification.

-Tightening45torque55 N-m

4.5-foroxygensensor5.5 kg-m

33.0-39.5 lb-ft

4) Connect oxygen sensor- wire at the coupler

securely and clamp its wire.

5) Connect negative cable to battery.

6) Start engine and check for gas leak.

For Canadian specification vehicle, turn on

check switch.

7) Run engine at 1,500 - 2,000 r/min for 30

sec. after warming up engine. Check to be

sure that “CHECK ENGINE” light flashes,

and turn off “CHECK ENGINE” light cancel/

check switch on steering column holder

bracket.

1. Cancel switch (U.S.A.)Check switch (Canada)

2. instrument panel

3. Steering columnholder bracket

4. Steering wheel

10. CATALYTIC CONVERTER INSPECTION

1) All accessories (wipers, heater, lights, etc.) are

out of service.

2) Warm up engine to normal operating tem-

perature.

3) Connect CO tester to mufler tail pipe.

4) With the engine warmed up, keep the engine

speed at 1,500 to 2,000 r/min. (t-pm). If the

CO concentration is 0.4% or less in this state,

the catalytic converter is in good condition.

If it exceeds the specification, refer to DIA-

GNOSIS (p. 5-15).

1-10

Page 31 of 962

1) Replace fuel hoses (pipe to fuel pump, pipe to

fuel filter and breather hose) in fuel feed and

return lines with new ones.

2) Remove fuel tank.

3) Replace return hose (tank to return pipe)

with new one.

4) Clamp hoses securely.

5) Install fuel tank referring to p. 4-35.

6) After installation, start engine and check it

for leaks.

27. IDLE SPEED INSPECTION

NOTE:

Before starting engine, place transmission gear

shift lever in “Neutral”, and set parking brake

and block drive wheels.

1) Warm up engine to normal operating tempe-

rature.

2) Check to ensure that idle speed is within

750 - 850 r/min (rpm).

3) If idle speed is not within specified range,

adjust idle speed. Refer to MAINTENANCE

SERVICE (p. 4-26) for procedures to check

and adjust idle speed.

28. IDLE MIXTURE INSPECTION

1) Warm up engine to normal operating tem-

perature.

2) Remove seal rubber of duty check coupler

and connect positive terminal of duty meter

to “Blue/Red” wire and negative terminal to

“Black/Green” wire.

1

1. Duty check coupler

2. Air intake case

3) Set tachometer.

4) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

5) Check duty at specified idle speed. If it is out

of specification,adjust it to specification

according to following adjustment procedure.

Specified Duty10-50

at 750 - 850 r/min.I

After inspection, install seal rubber to duty

check coupler.

Idle mixture adjustment procedure is as follows:

1) Remove carburetor from intake manifold

following normal service procedure to gain

access to mixture adjusting screw pin covering

mixture adjusting screw.

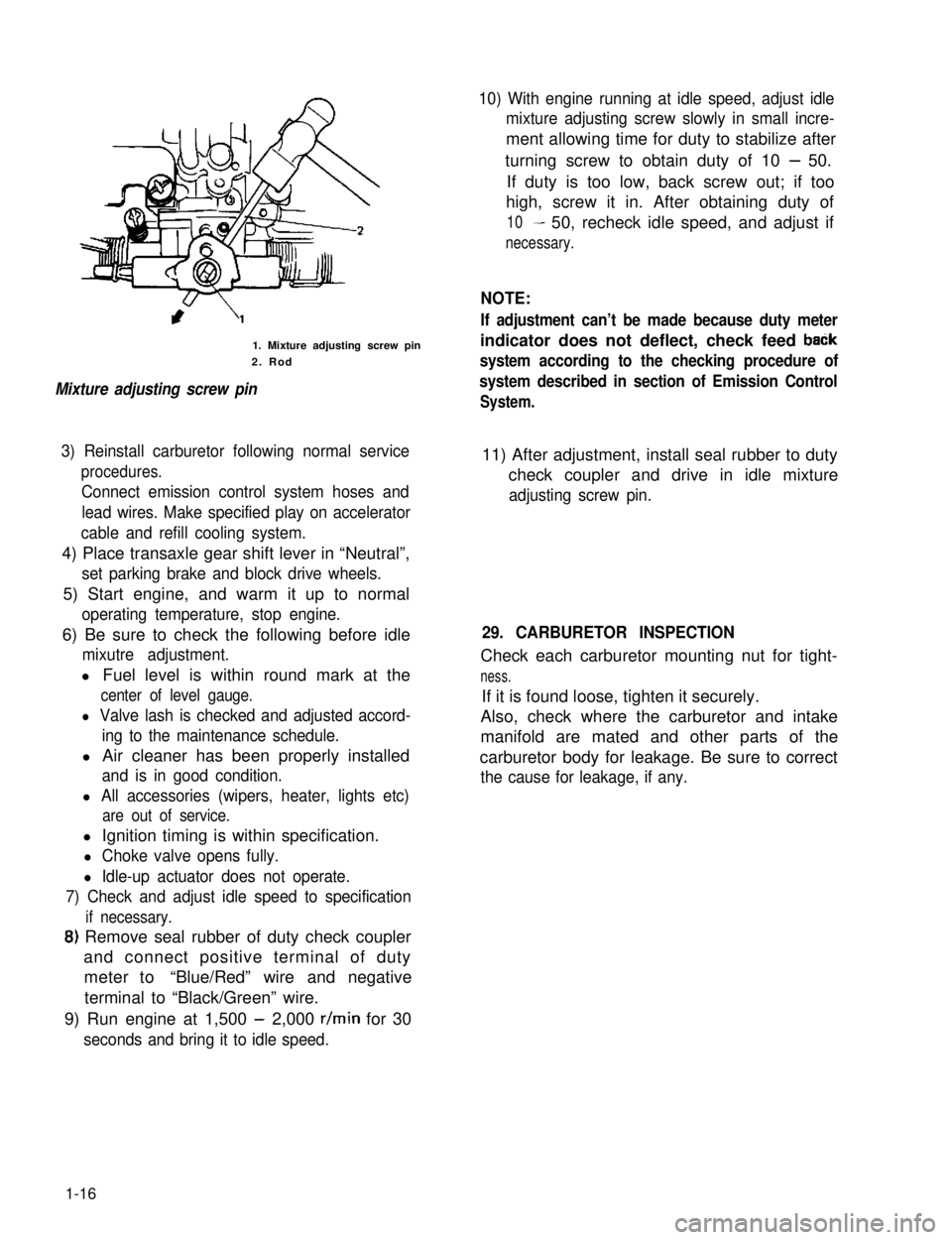

2) Drive out mixture adjusting screw pin using

about 4.5 mm (0.18 in) thick iron rod as

shown below.

1-15

Page 32 of 962

1. Mixture adjusting screw pin

2. Rod

Mixture adjusting screw pin

10) With engine running at idle speed, adjust idle

mixture adjusting screw slowly in small incre-

ment allowing time for duty to stabilize after

turning screw to obtain duty of 10 - 50.

If duty is too low, back screw out; if too

high, screw it in. After obtaining duty of

10- 50, recheck idle speed, and adjust if

necessary.

NOTE:

If adjustment can’t be made because duty meter

indicator does not deflect, check feed baCk

system according to the checking procedure of

system described in section of Emission Control

System.

3) Reinstall carburetor following normal service

procedures.

Connect emission control system hoses and

lead wires. Make specified play on accelerator

cable and refill cooling system.

11) After adjustment, install seal rubber to duty

check coupler and drive in idle mixture

adjusting screw pin.

4) Place transaxle gear shift lever in “Neutral”,

set parking brake and block drive wheels.

5) Start engine, and warm it up to normal

operating temperature, stop engine.

6) Be sure to check the following before idle

mixutre adjustment.

l Fuel level is within round mark at the

center of level gauge.

l Valve lash is checked and adjusted accord-

ing to the maintenance schedule.

l Air cleaner has been properly installed

and is in good condition.

l All accessories (wipers, heater, lights etc)

are out of service.

29. CARBURETOR INSPECTION

Check each carburetor mounting nut for tight-

ness.

If it is found loose, tighten it securely.

Also, check where the carburetor and intake

manifold are mated and other parts of the

carburetor body for leakage. Be sure to correct

the cause for leakage, if any.

l Ignition timing is within specification.

l Choke valve opens fully.

l Idle-up actuator does not operate.

7) Check and adjust idle speed to specification

if necessary.

8) Remove seal rubber of duty check coupler

and connect positive terminal of duty

meter to“Blue/Red” wire and negative

terminal to “Black/Green” wire.

9) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

1-16

Page 33 of 962

1-3. CHASSIS AND BODY

30. CLUTCH PEDAL INSPECTION

1) Check clutch pedal height. It should be the

same as brake pedal height.

2) Check clutch pedal free travel.

Clutch pedal free travel20 - 30 mm

(0.8 - 1.1 in.)

For the details of the above steps 1) and 2),

refer to MAINTENANCE SERVICE (p. 11-8) of

SECTION 11.

31. BRAKE DISCS, PADS, BRAKE DRUMS

AND SHOES INSPECTION

Brake Discs and Pads

I) Remove wheel and caliper but don’t discon-

nect brake hose from caliper.

2) Check front disc brake pads and discs for

excessivewear,damageand deflection.

Replace parts as necessary. For the details,

refer to p. 19-I 6 and 19-I 7 of SECT ION 19.

Be sure to torque caliper guide pins to specifi-

cation for reinstallation.

Brake Drums and Shoes

I) Remove wheel and brake drum.

2) Check rear brake drums and brake linings for

excessive wear and damage, while wheels and

drums are removed. Also check wheel cylin-

ders for leaks, at the same time. Replace

these parts as necessary.

For the details, refer to p. 19-21 and p. 19-

22 of SECTION 19.

32. BRAKE HOSES AND PIPES INSPECTION

Check brake hoses and pipes for proper hook-

up, leaks, cracks, chafing and other damage.

Replace any of these parts as necessary.

CAUTION:

After replacing any brake pipe or hose, be

sure to carry out air purge operation.

33. BRAKE FLUID INSPECTION AND

CHANGE

[INSPECTION]

1) Check around master cylinder and reservoir

for fluid leakage.

If found leaky, correct.

2) Check fluid level

If fluid level is lower than the minimum level

of reservoir, refilling is necessary. Fill reservoir

with specified brake fluids.

Brake fluid Speifi;t3ons

For the details, refer to MAINTENANCE

SERVICE (p. 19-42) of SECTION 19.

CAUTION:

Since the brake system of this car is factory-

filled with glycol-base brake fluid, do not

use or mix different type of fluid when

refilling the system; otherwise serious

damage will occur. Do not use old or used

brake fluid, or one taken from unsealed

container.

[CHANGE]

1) Change brake fluid. As fluid change procedure,

drain existing fluid from brake system com-

pletely, fill the system with above recom-

mended fluid and carry out air purge opera-

tion.

For description of air purge, refer to p. 19-46

and 19-47 of SECTION 19.

34. BRAKE PEDAL INSPECTION

Check brake pedal travel.

For -checking procedure, refer to PEDAL TRA-

VEL CHECK (p. 19-43) of SECTION 19.

35. BRAKE LEVER AND CABLE

INSPECTION

Parking Brake Lever

I) Check tooth tip of each notch for damage or

wear. If any damage or wear is found, replace

parking lever.

2) Check parking brake lever for proper opera-

tion and stroke, and adjust it if necessary.

For checking and adjusting procedures,

refer to PARKING BRAKE INSPECTION

AND ADJUSTMENT (p. 19-44) of SECTION

19.

1-17