Transfer SUZUKI GRAND VITARA 1999 2.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 200 of 656

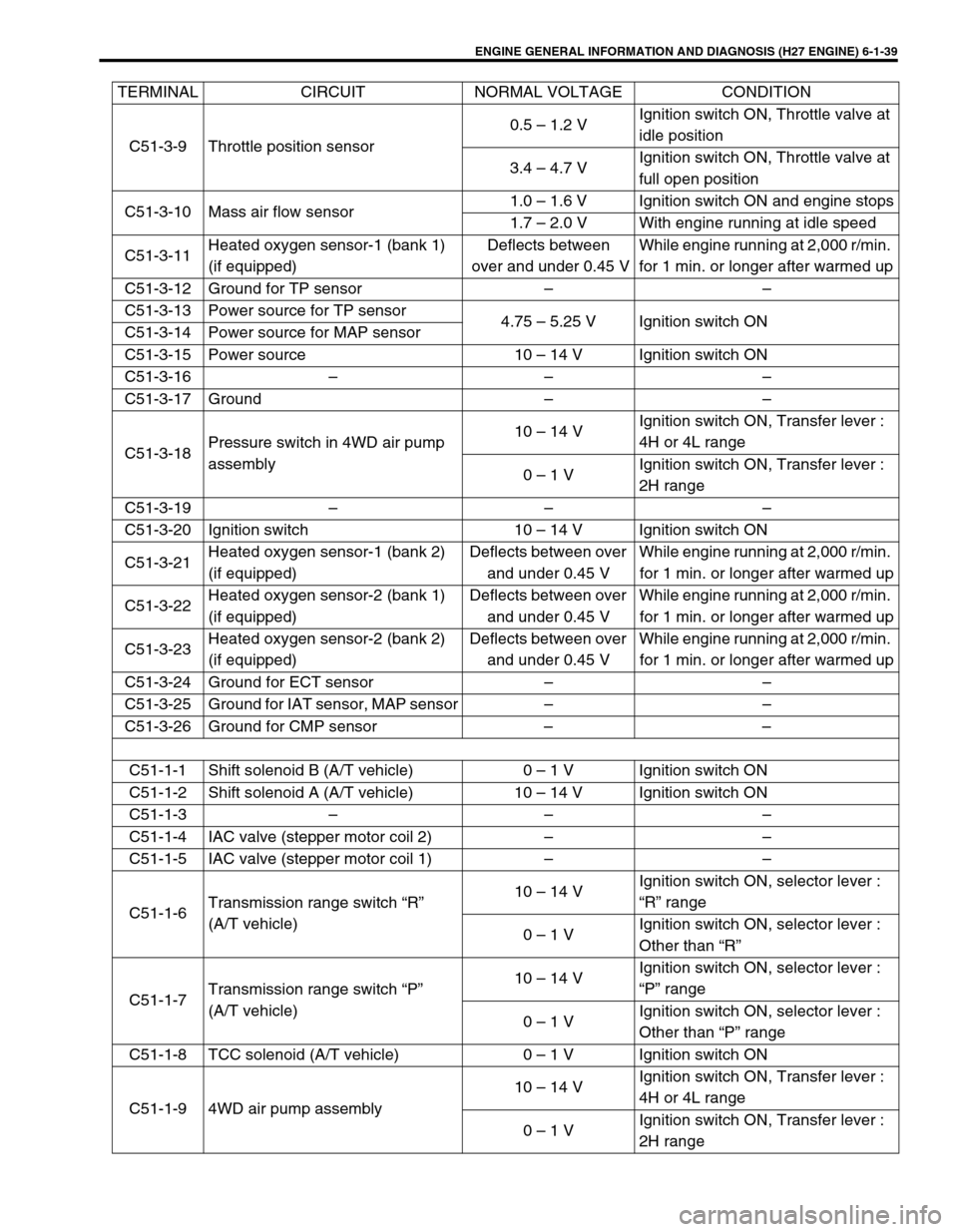

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-39

C51-3-9 Throttle position sensor0.5 – 1.2 VIgnition switch ON, Throttle valve at

idle position

3.4 – 4.7 VIgnition switch ON, Throttle valve at

full open position

C51-3-10 Mass air flow sensor1.0 – 1.6 V Ignition switch ON and engine stops

1.7 – 2.0 V With engine running at idle speed

C51-3-11Heated oxygen sensor-1 (bank 1)

(if equipped)Deflects between

over and under 0.45 VWhile engine running at 2,000 r/min.

for 1 min. or longer after warmed up

C51-3-12 Ground for TP sensor – –

C51-3-13 Power source for TP sensor

4.75 – 5.25 V Ignition switch ON

C51-3-14 Power source for MAP sensor

C51-3-15 Power source 10 – 14 V Ignition switch ON

C51-3-16 – – –

C51-3-17 Ground – –

C51-3-18Pressure switch in 4WD air pump

assembly10 – 14 VIgnition switch ON, Transfer lever :

4H or 4L range

0 – 1 VIgnition switch ON, Transfer lever :

2H range

C51-3-19 – – –

C51-3-20 Ignition switch 10 – 14 V Ignition switch ON

C51-3-21Heated oxygen sensor-1 (bank 2)

(if equipped)Deflects between over

and under 0.45 VWhile engine running at 2,000 r/min.

for 1 min. or longer after warmed up

C51-3-22Heated oxygen sensor-2 (bank 1)

(if equipped)Deflects between over

and under 0.45 VWhile engine running at 2,000 r/min.

for 1 min. or longer after warmed up

C51-3-23Heated oxygen sensor-2 (bank 2)

(if equipped)Deflects between over

and under 0.45 VWhile engine running at 2,000 r/min.

for 1 min. or longer after warmed up

C51-3-24 Ground for ECT sensor – –

C51-3-25 Ground for IAT sensor, MAP sensor – –

C51-3-26 Ground for CMP sensor – –

C51-1-1 Shift solenoid B (A/T vehicle) 0 – 1 V Ignition switch ON

C51-1-2 Shift solenoid A (A/T vehicle) 10 – 14 V Ignition switch ON

C51-1-3 – – –

C51-1-4 IAC valve (stepper motor coil 2) – –

C51-1-5 IAC valve (stepper motor coil 1) – –

C51-1-6Transmission range switch “R”

(A/T vehicle)10 – 14 VIgnition switch ON, selector lever :

“R” range

0 – 1 VIgnition switch ON, selector lever :

Other than “R”

C51-1-7Transmission range switch “P”

(A/T vehicle)10 – 14 VIgnition switch ON, selector lever :

“P” range

0 – 1 VIgnition switch ON, selector lever :

Other than “P” range

C51-1-8 TCC solenoid (A/T vehicle) 0 – 1 V Ignition switch ON

C51-1-9 4WD air pump assembly10 – 14 VIgnition switch ON, Transfer lever :

4H or 4L range

0 – 1 VIgnition switch ON, Transfer lever :

2H range TERMINAL CIRCUIT NORMAL VOLTAGE CONDITION

Page 201 of 656

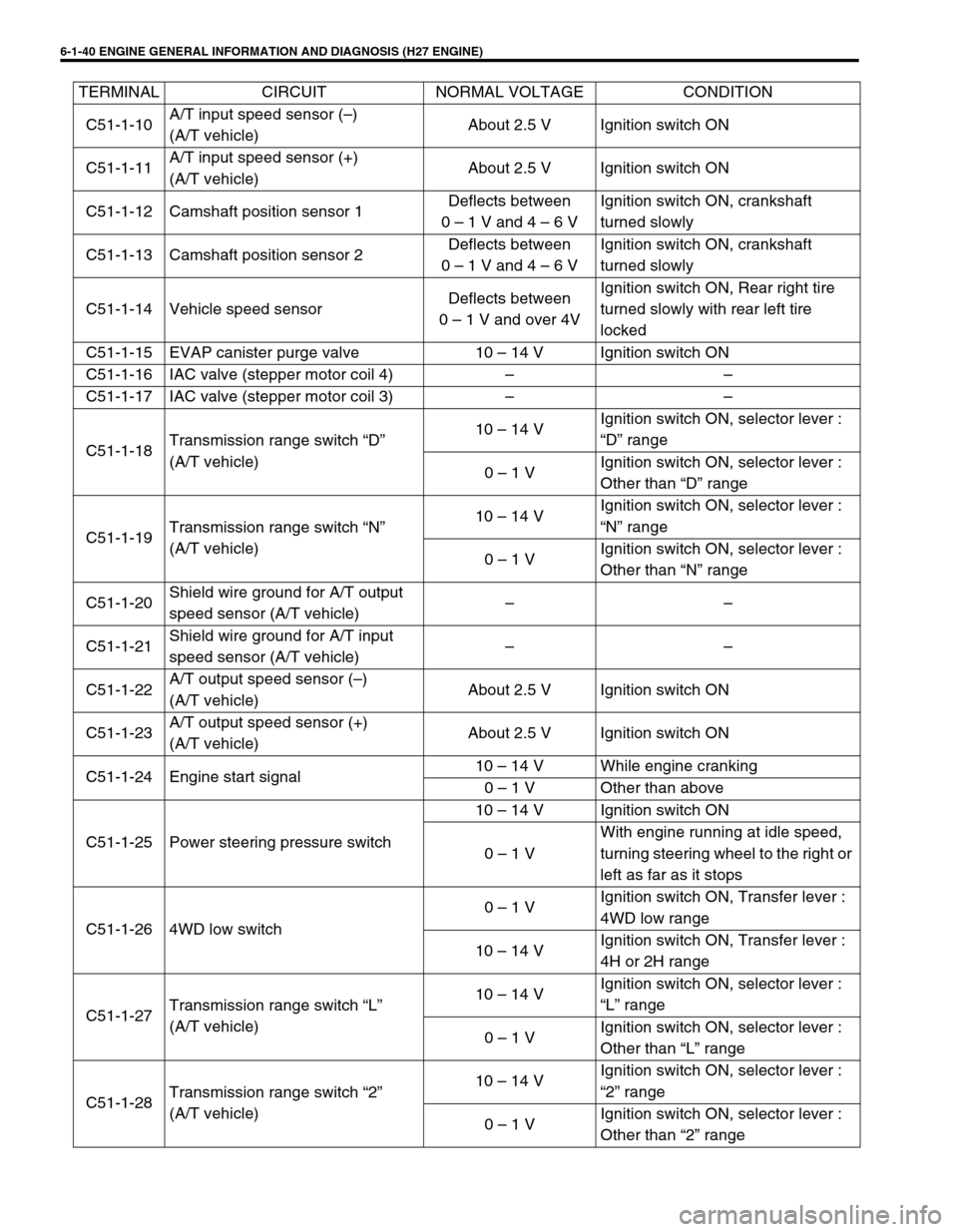

6-1-40 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

C51-1-10A/T input speed sensor (–)

(A/T vehicle)About 2.5 V Ignition switch ON

C51-1-11A/T input speed sensor (+)

(A/T vehicle)About 2.5 V Ignition switch ON

C51-1-12 Camshaft position sensor 1Deflects between

0 – 1 V and 4 – 6 VIgnition switch ON, crankshaft

turned slowly

C51-1-13 Camshaft position sensor 2Deflects between

0 – 1 V and 4 – 6 VIgnition switch ON, crankshaft

turned slowly

C51-1-14 Vehicle speed sensorDeflects between

0 – 1 V and over 4VIgnition switch ON, Rear right tire

turned slowly with rear left tire

locked

C51-1-15 EVAP canister purge valve 10 – 14 V Ignition switch ON

C51-1-16 IAC valve (stepper motor coil 4) – –

C51-1-17 IAC valve (stepper motor coil 3) – –

C51-1-18Transmission range switch “D”

(A/T vehicle)10 – 14 VIgnition switch ON, selector lever :

“D” range

0 – 1 VIgnition switch ON, selector lever :

Other than “D” range

C51-1-19Transmission range switch “N”

(A/T vehicle)10 – 14 VIgnition switch ON, selector lever :

“N” range

0 – 1 VIgnition switch ON, selector lever :

Other than “N” range

C51-1-20Shield wire ground for A/T output

speed sensor (A/T vehicle)––

C51-1-21Shield wire ground for A/T input

speed sensor (A/T vehicle)––

C51-1-22A/T output speed sensor (–)

(A/T vehicle)About 2.5 V Ignition switch ON

C51-1-23A/T output speed sensor (+)

(A/T vehicle)About 2.5 V Ignition switch ON

C51-1-24 Engine start signal10 – 14 V While engine cranking

0 – 1 V Other than above

C51-1-25 Power steering pressure switch10 – 14 V Ignition switch ON

0 – 1 VWith engine running at idle speed,

turning steering wheel to the right or

left as far as it stops

C51-1-26 4WD low switch0 – 1 VIgnition switch ON, Transfer lever :

4WD low range

10 – 14 VIgnition switch ON, Transfer lever :

4H or 2H range

C51-1-27Transmission range switch “L”

(A/T vehicle)10 – 14 VIgnition switch ON, selector lever :

“L” range

0 – 1 VIgnition switch ON, selector lever :

Other than “L” range

C51-1-28Transmission range switch “2”

(A/T vehicle)10 – 14 VIgnition switch ON, selector lever :

“2” range

0 – 1 VIgnition switch ON, selector lever :

Other than “2” range TERMINAL CIRCUIT NORMAL VOLTAGE CONDITION

Page 261 of 656

6-1-100 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

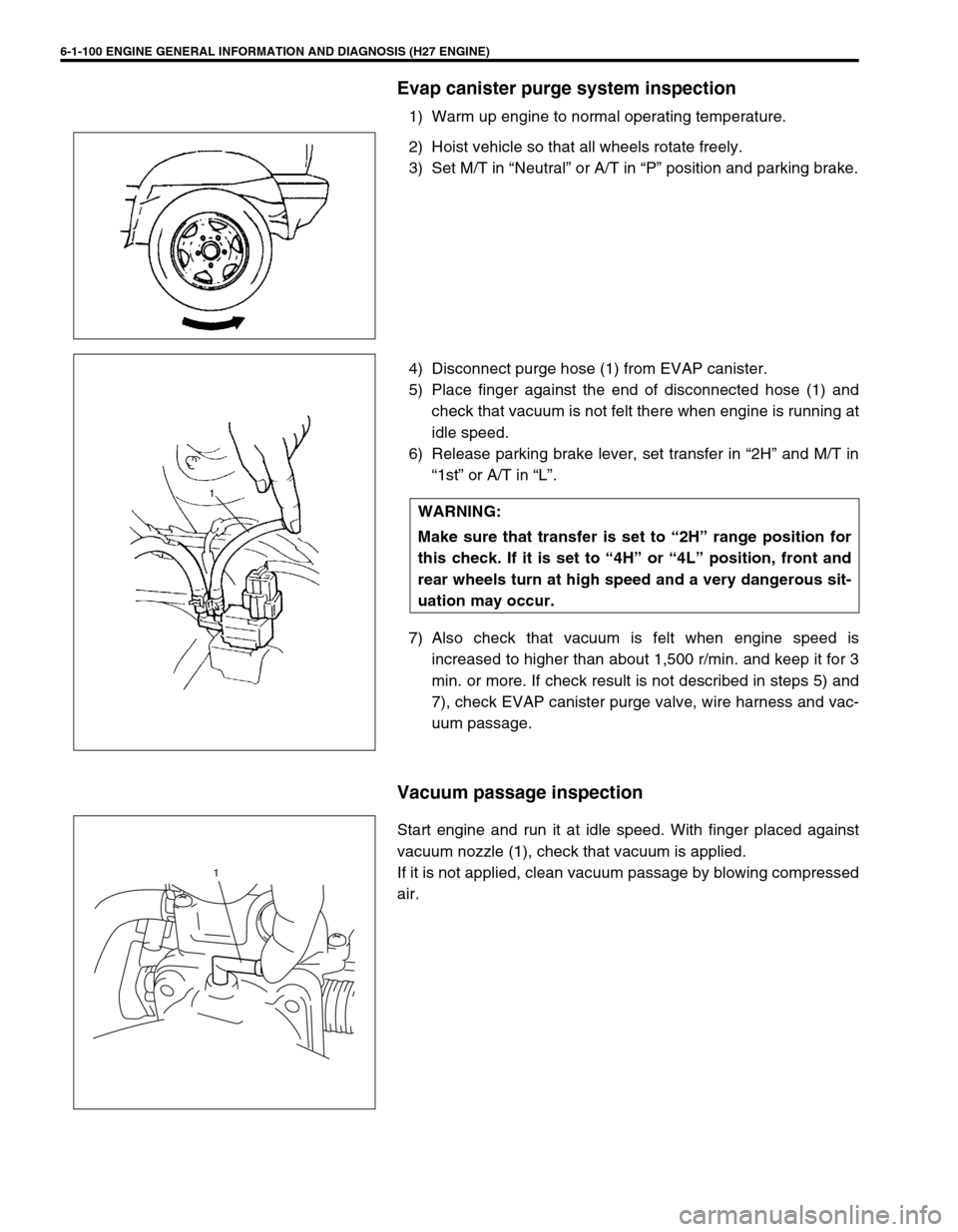

Evap canister purge system inspection

1) Warm up engine to normal operating temperature.

2) Hoist vehicle so that all wheels rotate freely.

3) Set M/T in “Neutral” or A/T in “P” position and parking brake.

4) Disconnect purge hose (1) from EVAP canister.

5) Place finger against the end of disconnected hose (1) and

check that vacuum is not felt there when engine is running at

idle speed.

6) Release parking brake lever, set transfer in “2H” and M/T in

“1st” or A/T in “L”.

7) Also check that vacuum is felt when engine speed is

increased to higher than about 1,500 r/min. and keep it for 3

min. or more. If check result is not described in steps 5) and

7), check EVAP canister purge valve, wire harness and vac-

uum passage.

Vacuum passage inspection

Start engine and run it at idle speed. With finger placed against

vacuum nozzle (1), check that vacuum is applied.

If it is not applied, clean vacuum passage by blowing compressed

air.

WARNING:

Make sure that transfer is set to “2H” range position for

this check. If it is set to “4H” or “4L” position, front and

rear wheels turn at high speed and a very dangerous sit-

uation may occur.

1

Page 268 of 656

![SUZUKI GRAND VITARA 1999 2.G User Guide ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-107

[A] Fig. for Step 3 / [B] Fig. for Step 4, 6, 7

Fig. for Step 55 VSS visual inspection:

1) Remove VSS referring to “TRANSFER”

section SUZUKI GRAND VITARA 1999 2.G User Guide ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-107

[A] Fig. for Step 3 / [B] Fig. for Step 4, 6, 7

Fig. for Step 55 VSS visual inspection:

1) Remove VSS referring to “TRANSFER”

section](/img/20/7583/w960_7583-267.png)

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-107

[A] Fig. for Step 3 / [B] Fig. for Step 4, 6, 7

Fig. for Step 55 VSS visual inspection:

1) Remove VSS referring to “TRANSFER”

section.

2) Check VSS drive and driven gears for

damage and excessive wear.

Are they in good condition?Poor VSS connection or VSS

malfunction.

If connection is OK, substi-

tute a known-good VSS and

recheck.Replace VSS.

6 Speedometer circuit check:

1) With ignition switch OFF, disconnect

G11 coupler from combination meter.

2) With ignition switch ON leaving engine

OFF, check voltage between C20-1 and

C20-2 terminal of VSS coupler.

Is voltage 4 V or more?Substitute a known-good

combination meter and

recheck.Go to Step 7.

7 Cruise control module circuit check (if

equipped):

1) With ignition switch OFF, disconnect

E132 coupler from cruise control mod-

ule.

2) With ignition switch ON leaving engine

OFF, check voltage between C20-1 and

C20-2 terminal of VSS coupler.

Is voltage 4 V or more?Substitute a known-good

cruise control module and

recheck.“BLU/YEL” wire open/

short or faulty ECM

(PCM).

If wire and connection are

OK, substitute a known-

good ECM (PCM) and

recheck.

1. VSS coupler

2.“BLU/YEL” (C20-1) terminal

3.“BLK/YEL” (C20-2) terminal

4.“BLU/BLK” (C20-3) terminal

Step Action Yes No

1. VSS coupler

2. VSS driven gear

3. VSS drive gear

Page 372 of 656

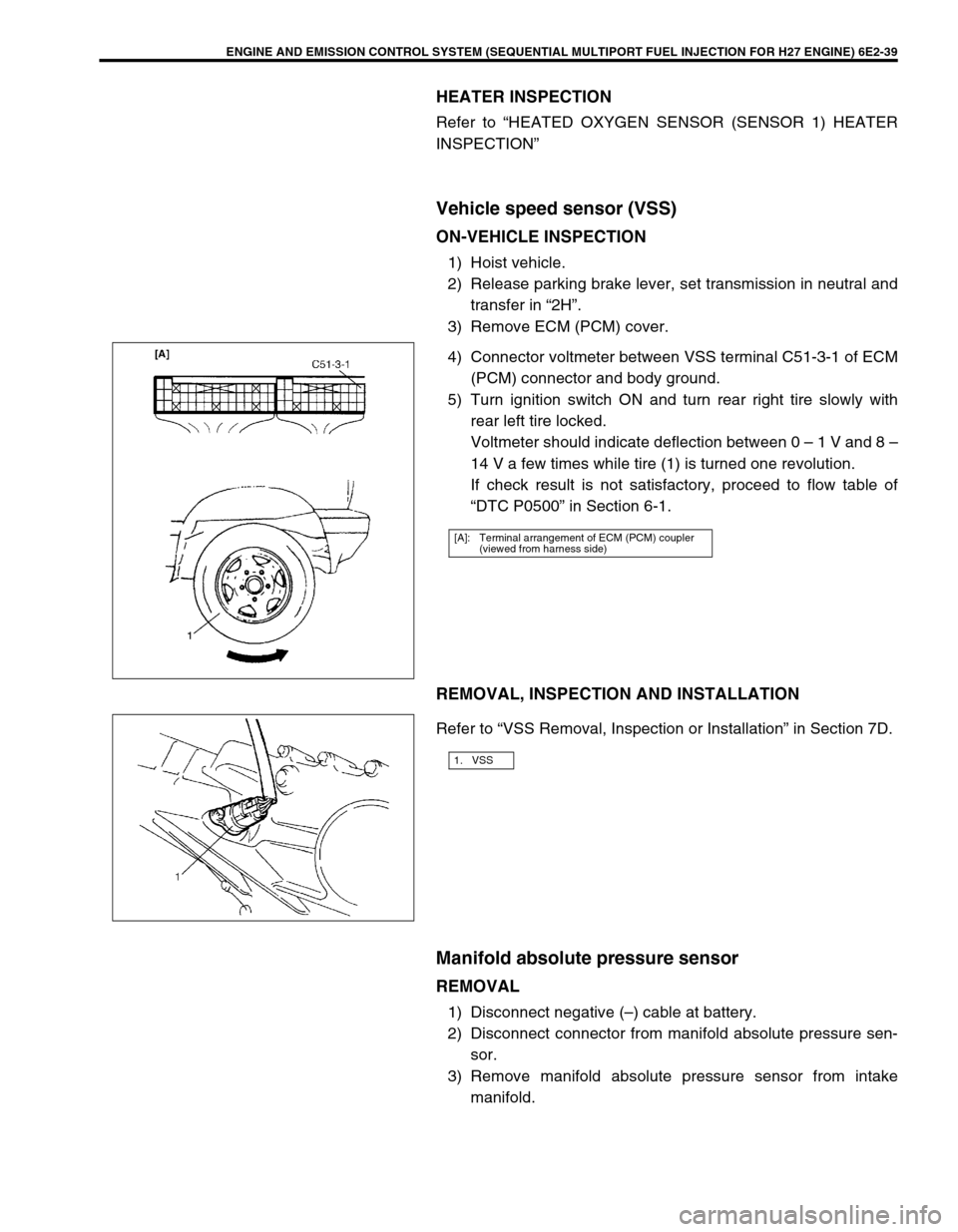

ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE) 6E2-39

HEATER INSPECTION

Refer to “HEATED OXYGEN SENSOR (SENSOR 1) HEATER

INSPECTION”

Vehicle speed sensor (VSS)

ON-VEHICLE INSPECTION

1) Hoist vehicle.

2) Release parking brake lever, set transmission in neutral and

transfer in “2H”.

3) Remove ECM (PCM) cover.

4) Connector voltmeter between VSS terminal C51-3-1 of ECM

(PCM) connector and body ground.

5) Turn ignition switch ON and turn rear right tire slowly with

rear left tire locked.

Voltmeter should indicate deflection between 0 – 1 V and 8 –

14 V a few times while tire (1) is turned one revolution.

If check result is not satisfactory, proceed to flow table of

“DTC P0500” in Section 6-1.

REMOVAL, INSPECTION AND INSTALLATION

Refer to “VSS Removal, Inspection or Installation” in Section 7D.

Manifold absolute pressure sensor

REMOVAL

1) Disconnect negative (–) cable at battery.

2) Disconnect connector from manifold absolute pressure sen-

sor.

3) Remove manifold absolute pressure sensor from intake

manifold.

[A]: Terminal arrangement of ECM (PCM) coupler

(viewed from harness side)

1. VSS

Page 412 of 656

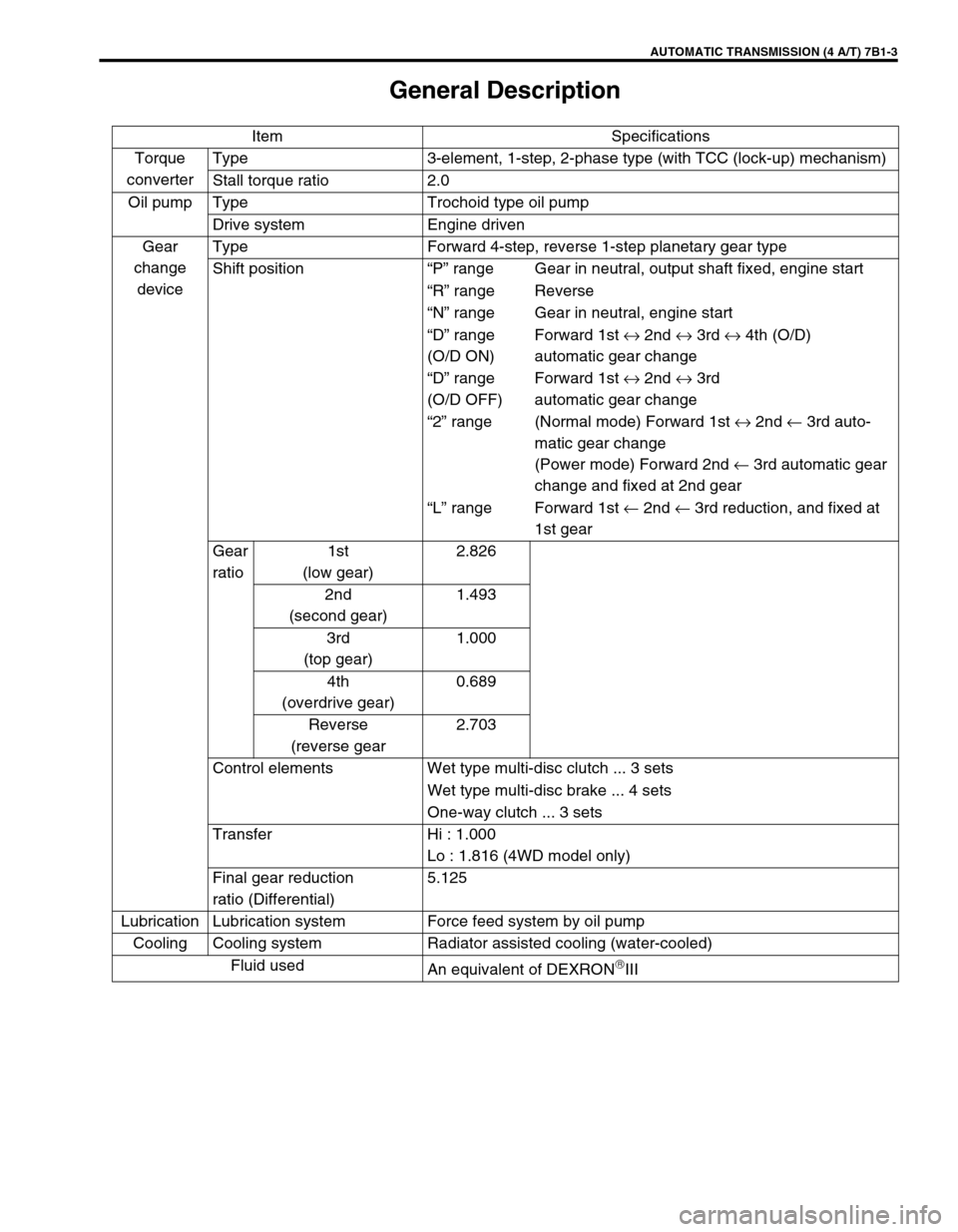

AUTOMATIC TRANSMISSION (4 A/T) 7B1-3

General Description

Item Specifications

Torque

converterType 3-element, 1-step, 2-phase type (with TCC (lock-up) mechanism)

Stall torque ratio 2.0

Oil pump Type Trochoid type oil pump

Drive system Engine driven

Gear

change

deviceType Forward 4-step, reverse 1-step planetary gear type

Shift position“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

(O/D ON)Forward 1st ↔ 2nd ↔ 3rd ↔ 4th (O/D)

automatic gear change

“D” range

(O/D OFF)Forward 1st ↔ 2nd ↔ 3rd

automatic gear change

“2” range (Normal mode) Forward 1st ↔ 2nd ← 3rd auto-

matic gear change

(Power mode) Forward 2nd ← 3rd automatic gear

change and fixed at 2nd gear

“L” range Forward 1st ← 2nd ← 3rd reduction, and fixed at

1st gear

Gear

ratio1st

(low gear)2.826

2nd

(second gear)1.493

3rd

(top gear)1.000

4th

(overdrive gear)0.689

Reverse

(reverse gear2.703

Control elements Wet type multi-disc clutch ... 3 sets

Wet type multi-disc brake ... 4 sets

One-way clutch ... 3 sets

Transfer Hi : 1.000

Lo : 1.816 (4WD model only)

Final gear reduction

ratio (Differential)5.125

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Radiator assisted cooling (water-cooled)

Fluid used

An equivalent of DEXRON

III

Page 427 of 656

7B1-18 AUTOMATIC TRANSMISSION (4 A/T)

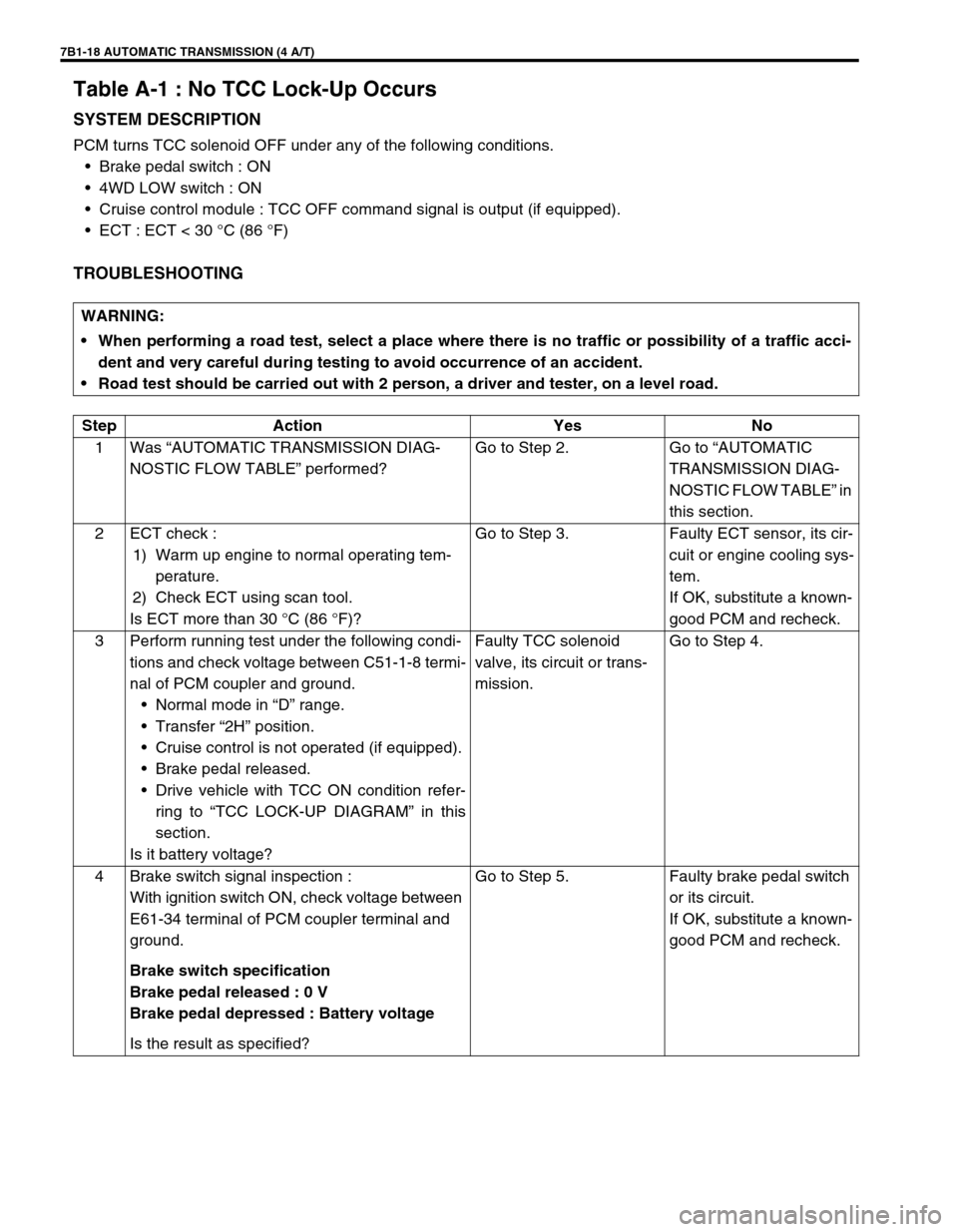

Table A-1 : No TCC Lock-Up Occurs

SYSTEM DESCRIPTION

PCM turns TCC solenoid OFF under any of the following conditions.

•Brake pedal switch : ON

•4WD LOW switch : ON

•Cruise control module : TCC OFF command signal is output (if equipped).

•ECT : ECT < 30 °C (86 °F)

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 person, a driver and tester, on a level road.

Step Action Yes No

1Was “AUTOMATIC TRANSMISSION DIAG-

NOSTIC FLOW TABLE” performed?Go to Step 2. Go to “AUTOMATIC

TRANSMISSION DIAG-

NOSTIC FLOW TABLE” in

this section.

2 ECT check :

1) Warm up engine to normal operating tem-

perature.

2) Check ECT using scan tool.

Is ECT more than 30 °C (86 °F)?Go to Step 3. Faulty ECT sensor, its cir-

cuit or engine cooling sys-

tem.

If OK, substitute a known-

good PCM and recheck.

3 Perform running test under the following condi-

tions and check voltage between C51-1-8 termi-

nal of PCM coupler and ground.

•Normal mode in “D” range.

•Transfer “2H” position.

•Cruise control is not operated (if equipped).

•Brake pedal released.

•Drive vehicle with TCC ON condition refer-

ring to “TCC LOCK-UP DIAGRAM” in this

section.

Is it battery voltage?Faulty TCC solenoid

valve, its circuit or trans-

mission.Go to Step 4.

4 Brake switch signal inspection :

With ignition switch ON, check voltage between

E61-34 terminal of PCM coupler terminal and

ground.

Brake switch specification

Brake pedal released : 0 V

Brake pedal depressed : Battery voltage

Is the result as specified?Go to Step 5. Faulty brake pedal switch

or its circuit.

If OK, substitute a known-

good PCM and recheck.

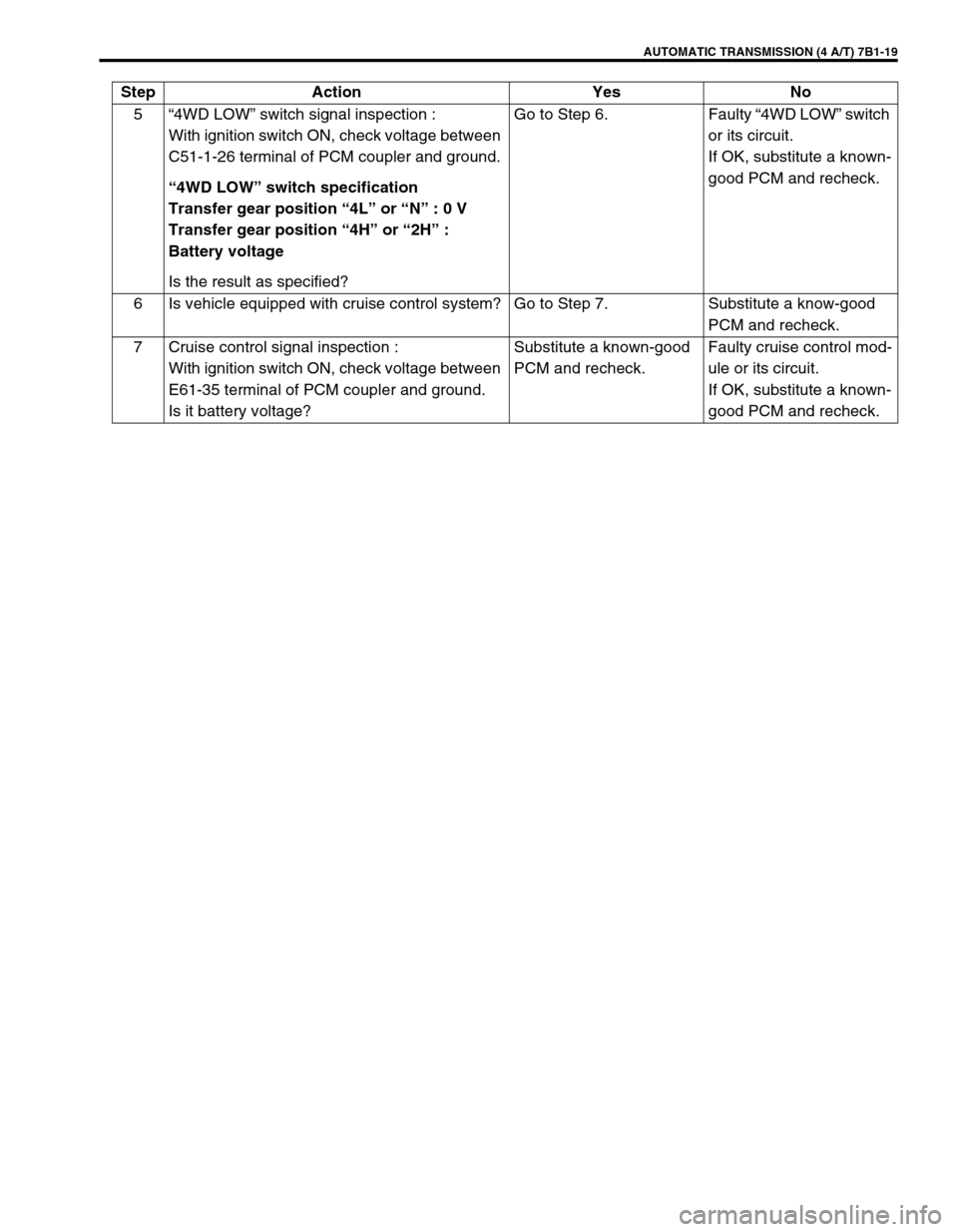

Page 428 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-19

5“4WD LOW” switch signal inspection :

With ignition switch ON, check voltage between

C51-1-26 terminal of PCM coupler and ground.

“4WD LOW” switch specification

Transfer gear position “4L” or “N” : 0 V

Transfer gear position “4H” or “2H” :

Battery voltage

Is the result as specified?Go to Step 6. Faulty “4WD LOW” switch

or its circuit.

If OK, substitute a known-

good PCM and recheck.

6 Is vehicle equipped with cruise control system? Go to Step 7. Substitute a know-good

PCM and recheck.

7 Cruise control signal inspection :

With ignition switch ON, check voltage between

E61-35 terminal of PCM coupler and ground.

Is it battery voltage?Substitute a known-good

PCM and recheck.Faulty cruise control mod-

ule or its circuit.

If OK, substitute a known-

good PCM and recheck. Step Action Yes No

Page 429 of 656

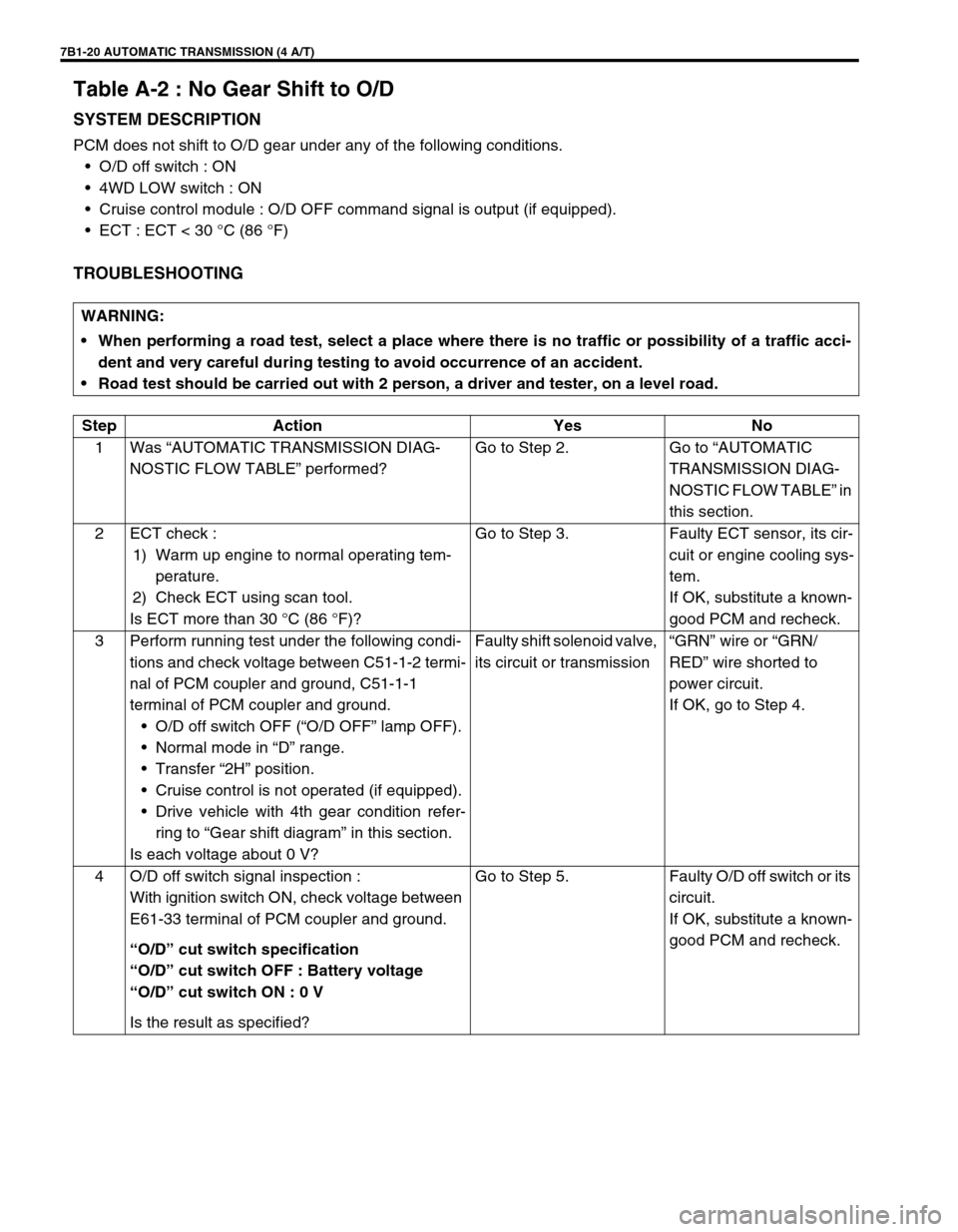

7B1-20 AUTOMATIC TRANSMISSION (4 A/T)

Table A-2 : No Gear Shift to O/D

SYSTEM DESCRIPTION

PCM does not shift to O/D gear under any of the following conditions.

•O/D off switch : ON

•4WD LOW switch : ON

•Cruise control module : O/D OFF command signal is output (if equipped).

•ECT : ECT < 30 °C (86 °F)

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 person, a driver and tester, on a level road.

Step Action Yes No

1Was “AUTOMATIC TRANSMISSION DIAG-

NOSTIC FLOW TABLE” performed?Go to Step 2. Go to “AUTOMATIC

TRANSMISSION DIAG-

NOSTIC FLOW TABLE” in

this section.

2 ECT check :

1) Warm up engine to normal operating tem-

perature.

2) Check ECT using scan tool.

Is ECT more than 30 °C (86 °F)?Go to Step 3. Faulty ECT sensor, its cir-

cuit or engine cooling sys-

tem.

If OK, substitute a known-

good PCM and recheck.

3 Perform running test under the following condi-

tions and check voltage between C51-1-2 termi-

nal of PCM coupler and ground, C51-1-1

terminal of PCM coupler and ground.

•O/D off switch OFF (“O/D OFF” lamp OFF).

•Normal mode in “D” range.

•Transfer “2H” position.

•Cruise control is not operated (if equipped).

•Drive vehicle with 4th gear condition refer-

ring to “Gear shift diagram” in this section.

Is each voltage about 0 V?Faulty shift solenoid valve,

its circuit or transmission“GRN” wire or “GRN/

RED” wire shorted to

power circuit.

If OK, go to Step 4.

4 O/D off switch signal inspection :

With ignition switch ON, check voltage between

E61-33 terminal of PCM coupler and ground.

“O/D” cut switch specification

“O/D” cut switch OFF : Battery voltage

“O/D” cut switch ON : 0 V

Is the result as specified?Go to Step 5. Faulty O/D off switch or its

circuit.

If OK, substitute a known-

good PCM and recheck.

Page 430 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-21

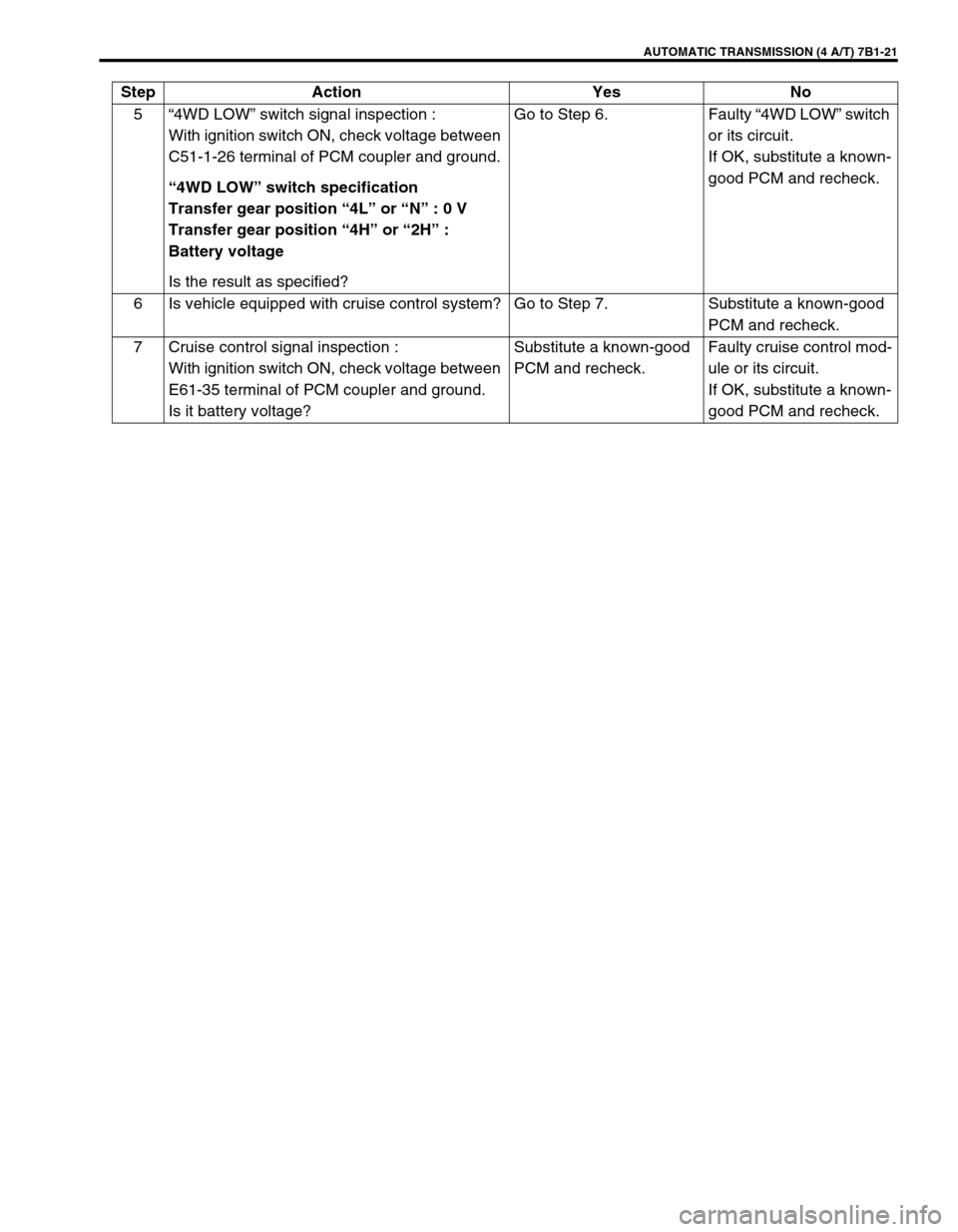

5“4WD LOW” switch signal inspection :

With ignition switch ON, check voltage between

C51-1-26 terminal of PCM coupler and ground.

“4WD LOW” switch specification

Transfer gear position “4L” or “N” : 0 V

Transfer gear position “4H” or “2H” :

Battery voltage

Is the result as specified?Go to Step 6. Faulty “4WD LOW” switch

or its circuit.

If OK, substitute a known-

good PCM and recheck.

6 Is vehicle equipped with cruise control system? Go to Step 7. Substitute a known-good

PCM and recheck.

7 Cruise control signal inspection :

With ignition switch ON, check voltage between

E61-35 terminal of PCM coupler and ground.

Is it battery voltage?Substitute a known-good

PCM and recheck.Faulty cruise control mod-

ule or its circuit.

If OK, substitute a known-

good PCM and recheck. Step Action Yes No