Main fuse SUZUKI GRAND VITARA 1999 2.G Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 582 of 656

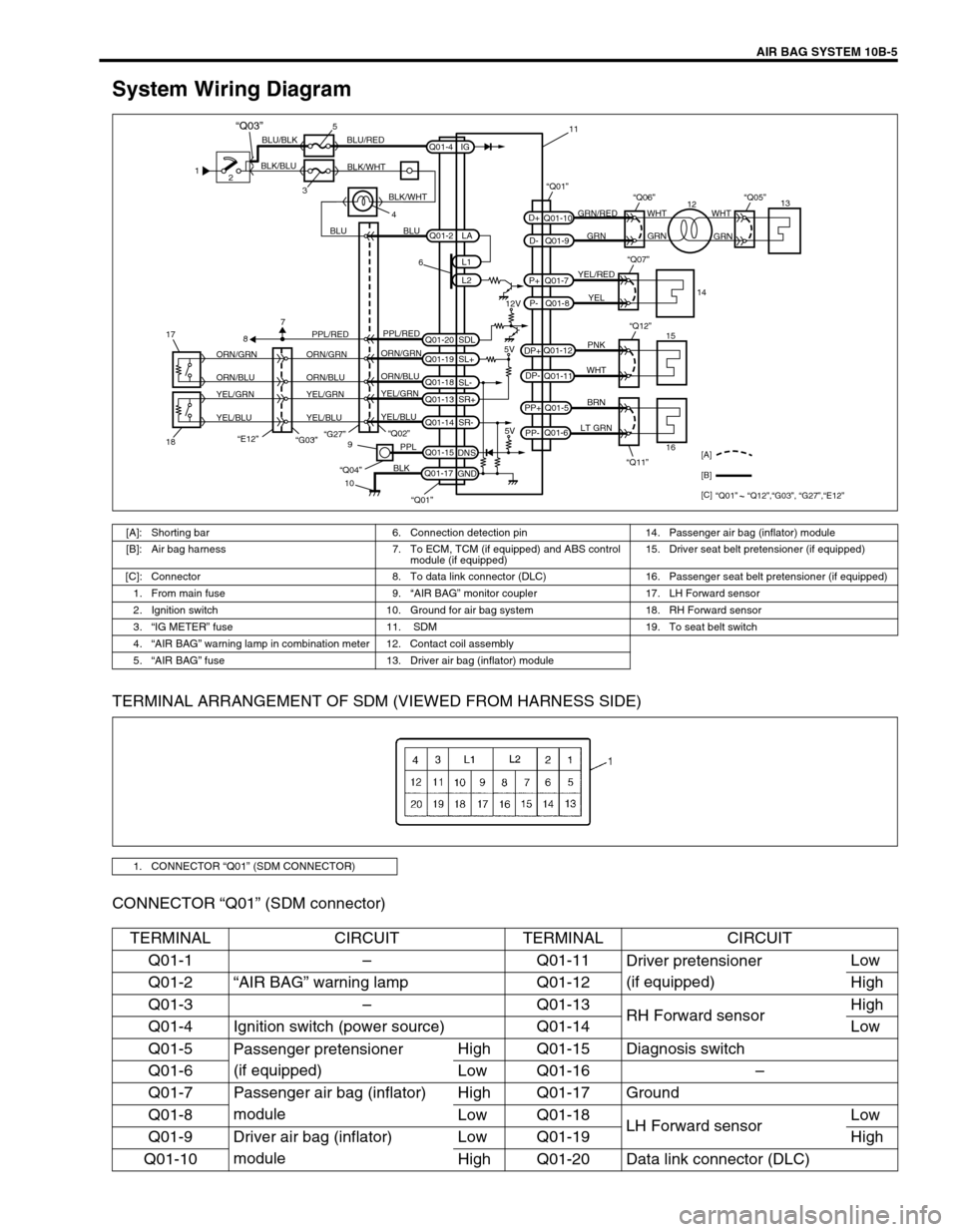

AIR BAG SYSTEM 10B-5

System Wiring Diagram

TERMINAL ARRANGEMENT OF SDM (VIEWED FROM HARNESS SIDE)

CONNECTOR “Q01” (SDM connector)

1

2

35

4 BLK/BLUBLU/BLK BLU/RED

BLK/WHT

BLU BLUGRN/RED

GRN GRNWHT WHT

GRN

YEL/RED

YEL

PNK

WHT

BRN

LT GRN

6

12V

5V 5V PPL/RED

ORN/GRN

ORN/BLU

YEL/GRN

YEL/BLUORN/GRN

ORN/BLU

YEL/GRN

YEL/BLUORN/GRN

ORN/BLU

YEL/GRN

YEL/BLUPPL/RED

87

“G27”

“E12”18 17“Q02”

“Q11” “Q12”9

10PPL

BLK

“Q04”

Q01-2

Q01-4

Q01-20Q01-7

Q01-8 Q01-10

Q01-9

Q01-12

Q01-11

Q01-5

Q01-6

Q01-15

Q01-17L1

L2 IG

SDL

Q01-19

SL+

Q01-18

SL-

Q01-13

SR+

Q01-14

SR-

DNS

GNDLA

PP- PP+DP- DP+P- P+D- D+

“Q07”

“Q06”“Q01”“Q05”

15

161413

12 11

[A]

[B]

[C]

“Q01” “Q12”,“G03”, “G27”,“E12”

“Q01”

BLK/WHT

“Q03”

“G03”

[A]: Shorting bar 6. Connection detection pin 14. Passenger air bag (inflator) module

[B]: Air bag harness 7. To ECM, TCM (if equipped) and ABS control

module (if equipped) 15. Driver seat belt pretensioner (if equipped)

[C]: Connector 8. To data link connector (DLC) 16. Passenger seat belt pretensioner (if equipped)

1. From main fuse 9.“AIR BAG” monitor coupler 17. LH Forward sensor

2. Ignition switch 10. Ground for air bag system 18. RH Forward sensor

3.“IG METER” fuse 11. SDM 19. To seat belt switch

4.“AIR BAG” warning lamp in combination meter 12. Contact coil assembly

5.“AIR BAG” fuse 13. Driver air bag (inflator) module

1. CONNECTOR “Q01” (SDM CONNECTOR)

TERMINAL CIRCUIT TERMINAL CIRCUIT

Q01-1–Q01-11

Driver pretensioner

(if equipped)Low

Q01-2“AIR BAG” warning lamp Q01-12 High

Q01-3–Q01-13

RH Forward sensorHigh

Q01-4 Ignition switch (power source) Q01-14 Low

Q01-5

Passenger pretensioner

(if equipped)High Q01-15 Diagnosis switch

Q01-6 Low Q01-16–

Q01-7 Passenger air bag (inflator)

moduleHigh Q01-17 Ground

Q01-8 Low Q01-18

LH Forward sensorLow

Q01-9 Driver air bag (inflator)

moduleLow Q01-19 High

Q01-10 High Q01-20 Data link connector (DLC)

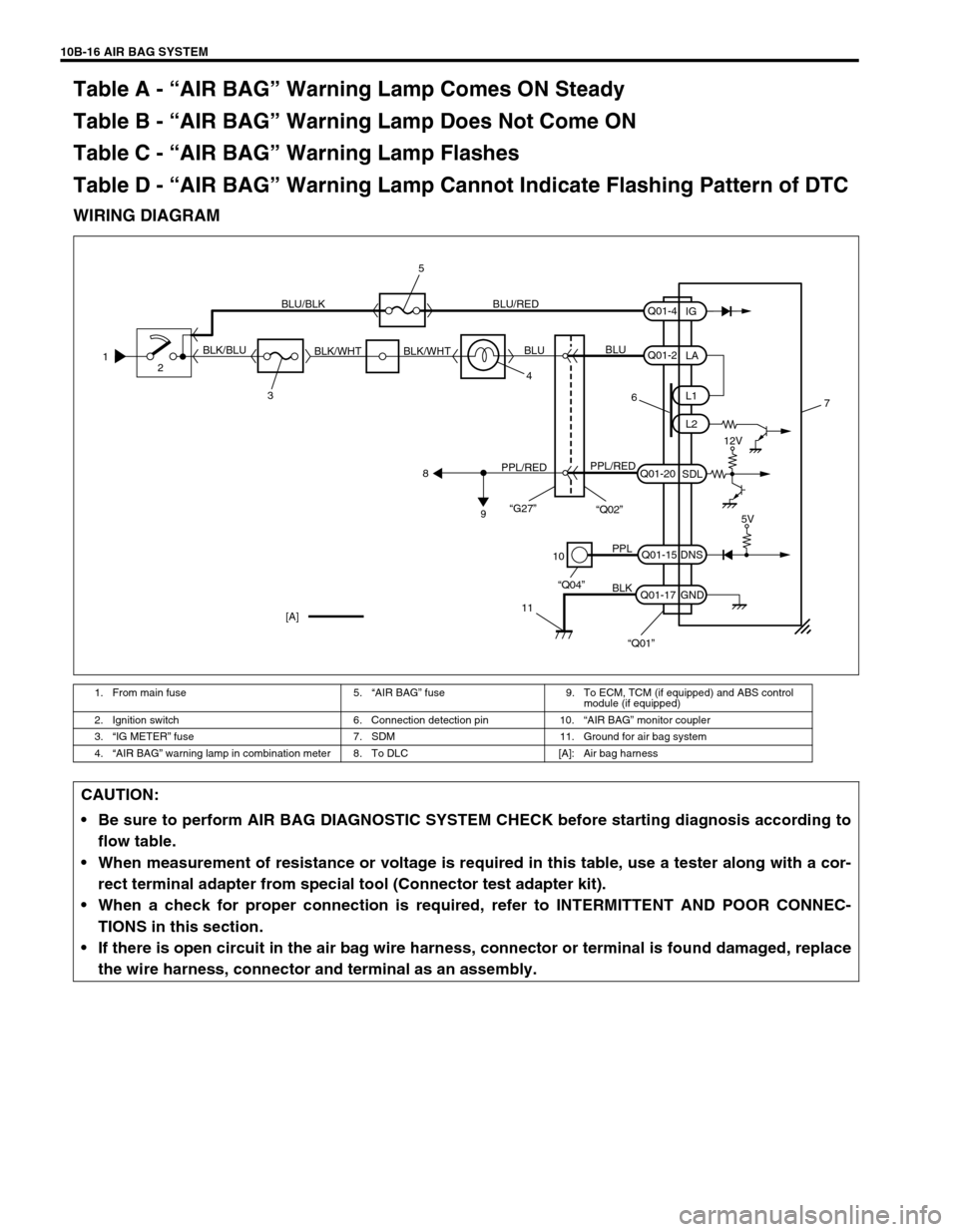

Page 593 of 656

10B-16 AIR BAG SYSTEM

Table A - “AIR BAG” Warning Lamp Comes ON Steady

Table B - “AIR BAG” Warning Lamp Does Not Come ON

Table C - “AIR BAG” Warning Lamp Flashes

Table D - “AIR BAG” Warning Lamp Cannot Indicate Flashing Pattern of DTC

WIRING DIAGRAM

1. From main fuse 5.“AIR BAG” fuse 9. To ECM, TCM (if equipped) and ABS control

module (if equipped)

2. Ignition switch 6. Connection detection pin 10.“AIR BAG” monitor coupler

3.“IG METER” fuse 7. SDM 11. Ground for air bag system

4.“AIR BAG” warning lamp in combination meter 8. To DLC [A]: Air bag harness

1

2

34 BLK/BLUBLU/BLK BLU/RED

BLK/WHT BLK/WHTBLUBLU

6

PPL/REDPPL/RED

8

9

10

11

PPL

BLK

“Q04”

“Q01”

Q01-2

Q01-20

Q01-15

Q01-17L1

L2

SDL

DNS

GNDLA

Q01-4

IG

7

[A]

12V

5V

“G27”“Q02”

5

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

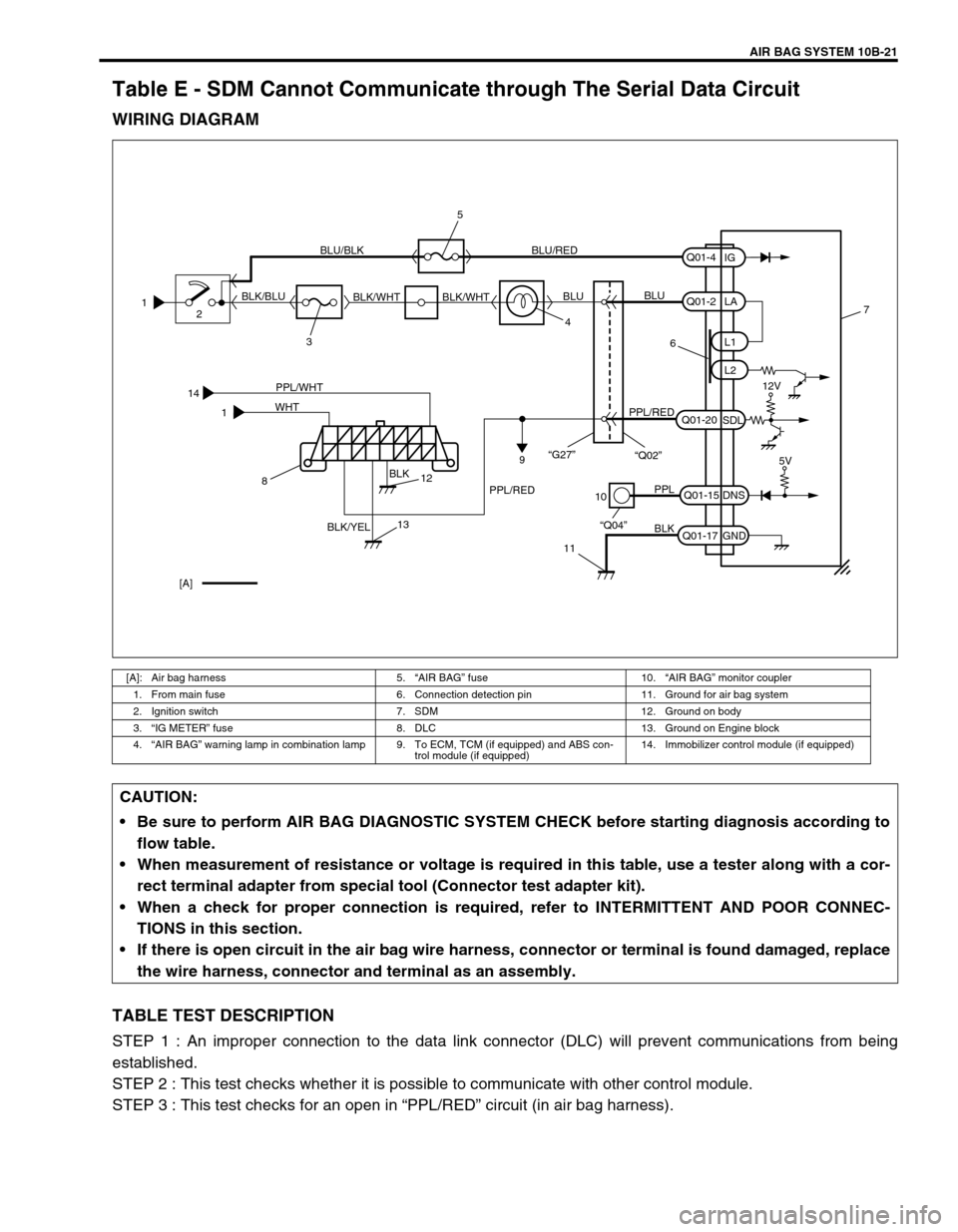

Page 598 of 656

AIR BAG SYSTEM 10B-21

Table E - SDM Cannot Communicate through The Serial Data Circuit

WIRING DIAGRAM

TABLE TEST DESCRIPTION

STEP 1 : An improper connection to the data link connector (DLC) will prevent communications from being

established.

STEP 2 : This test checks whether it is possible to communicate with other control module.

STEP 3 : This test checks for an open in “PPL/RED” circuit (in air bag harness).

[A]: Air bag harness 5.“AIR BAG” fuse 10.“AIR BAG” monitor coupler

1. From main fuse 6. Connection detection pin 11. Ground for air bag system

2. Ignition switch 7. SDM 12. Ground on body

3.“IG METER” fuse 8. DLC 13. Ground on Engine block

4.“AIR BAG” warning lamp in combination lamp 9. To ECM, TCM (if equipped) and ABS con-

trol module (if equipped)14. Immobilizer control module (if equipped)

14

1PPL/WHT

BLK

BLK/YEL WHT

10

11

PPL

BLK

“Q04”Q01-15

Q01-17DNS

GND7

[A]5V

812

13

1

2

34 BLK/BLUBLU/BLK BLU/RED

BLK/WHT BLK/WHTBLUBLU

6

PPL/REDPPL/RED

9

Q01-2

Q01-20L1

L2

SDLLA

Q01-4

IG

12V

“G27”

“Q02”

5

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

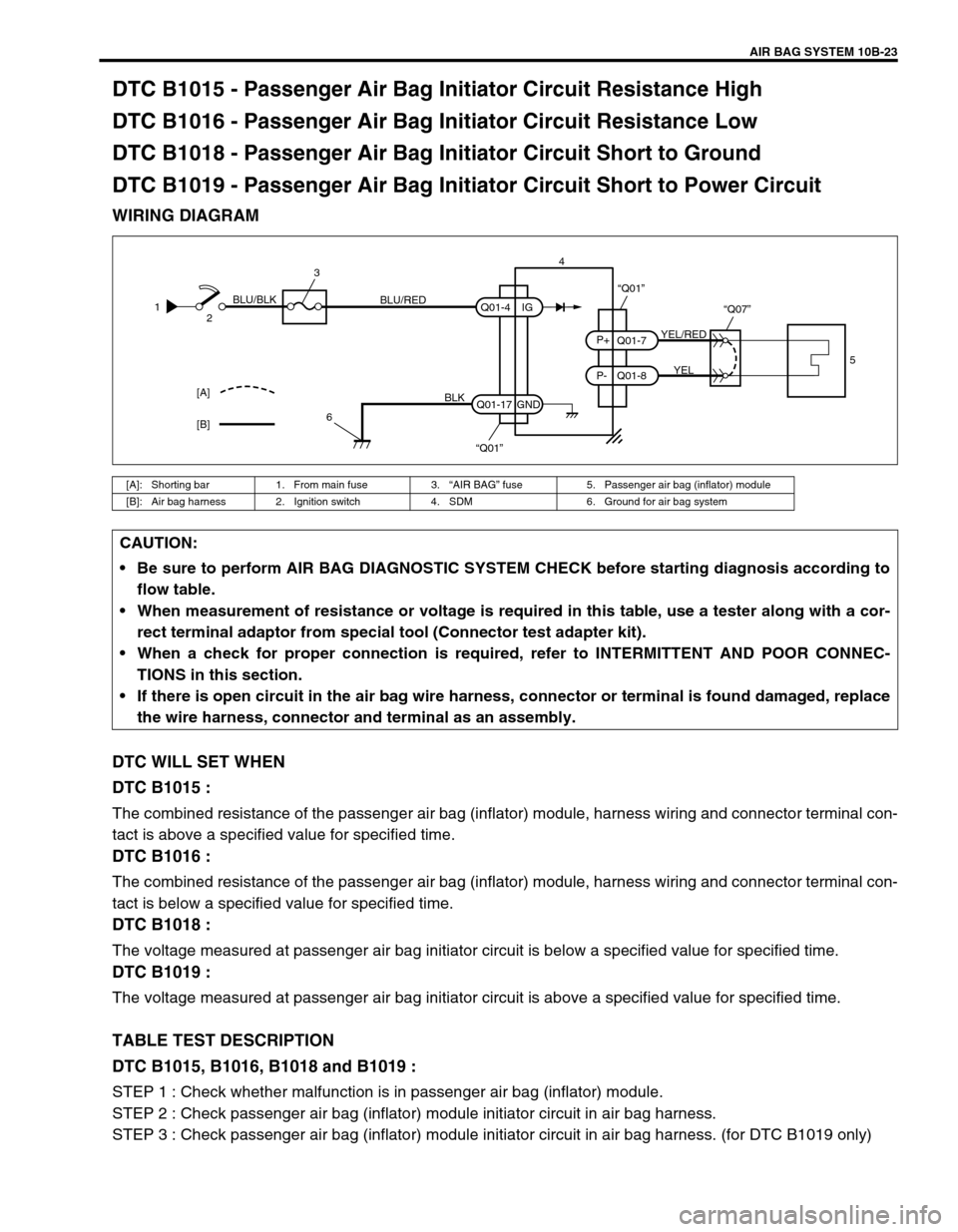

Page 600 of 656

AIR BAG SYSTEM 10B-23

DTC B1015 - Passenger Air Bag Initiator Circuit Resistance High

DTC B1016 - Passenger Air Bag Initiator Circuit Resistance Low

DTC B1018 - Passenger Air Bag Initiator Circuit Short to Ground

DTC B1019 - Passenger Air Bag Initiator Circuit Short to Power Circuit

WIRING DIAGRAM

DTC WILL SET WHEN

DTC B1015 :

The combined resistance of the passenger air bag (inflator) module, harness wiring and connector terminal con-

tact is above a specified value for specified time.

DTC B1016 :

The combined resistance of the passenger air bag (inflator) module, harness wiring and connector terminal con-

tact is below a specified value for specified time.

DTC B1018 :

The voltage measured at passenger air bag initiator circuit is below a specified value for specified time.

DTC B1019 :

The voltage measured at passenger air bag initiator circuit is above a specified value for specified time.

TABLE TEST DESCRIPTION

DTC B1015, B1016, B1018 and B1019 :

STEP 1 : Check whether malfunction is in passenger air bag (inflator) module.

STEP 2 : Check passenger air bag (inflator) module initiator circuit in air bag harness.

STEP 3 : Check passenger air bag (inflator) module initiator circuit in air bag harness. (for DTC B1019 only)

[A]: Shorting bar 1. From main fuse 3.“AIR BAG” fuse 5. Passenger air bag (inflator) module

[B]: Air bag harness 2. Ignition switch 4. SDM 6. Ground for air bag system

1

2BLU/BLK

BLU/RED

3

6

BLK

“Q01” Q01-4

Q01-17IG

GND4

YEL/RED

YEL Q01-7

Q01-8 P- P+“Q07”

“Q01”

5

[A]

[B]

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adaptor from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Page 605 of 656

10B-28 AIR BAG SYSTEM

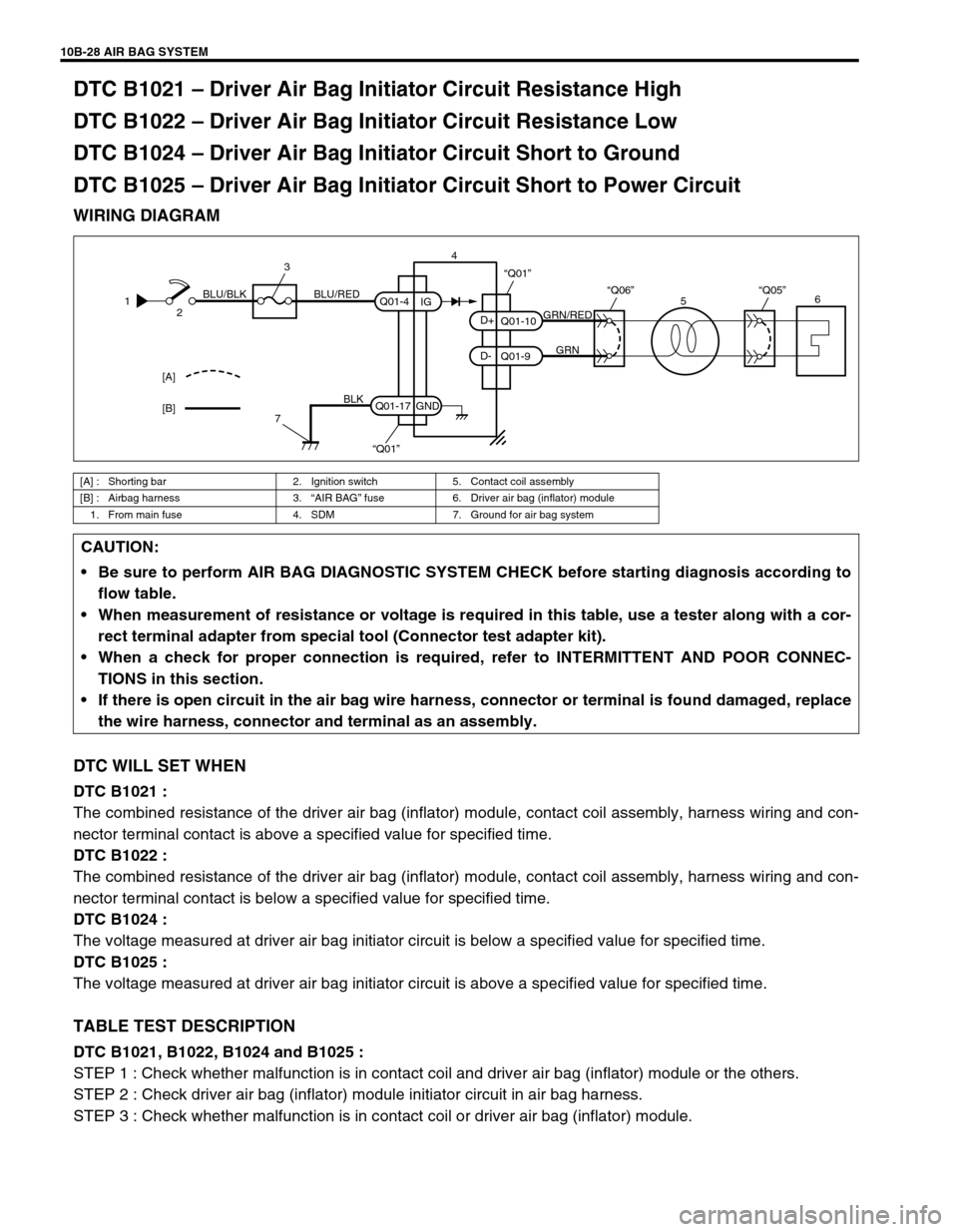

DTC B1021 – Driver Air Bag Initiator Circuit Resistance High

DTC B1022 – Driver Air Bag Initiator Circuit Resistance Low

DTC B1024 – Driver Air Bag Initiator Circuit Short to Ground

DTC B1025 – Driver Air Bag Initiator Circuit Short to Power Circuit

WIRING DIAGRAM

DTC WILL SET WHEN

DTC B1021 :

The combined resistance of the driver air bag (inflator) module, contact coil assembly, harness wiring and con-

nector terminal contact is above a specified value for specified time.

DTC B1022 :

The combined resistance of the driver air bag (inflator) module, contact coil assembly, harness wiring and con-

nector terminal contact is below a specified value for specified time.

DTC B1024 :

The voltage measured at driver air bag initiator circuit is below a specified value for specified time.

DTC B1025 :

The voltage measured at driver air bag initiator circuit is above a specified value for specified time.

TABLE TEST DESCRIPTION

DTC B1021, B1022, B1024 and B1025 :

STEP 1 : Check whether malfunction is in contact coil and driver air bag (inflator) module or the others.

STEP 2 : Check driver air bag (inflator) module initiator circuit in air bag harness.

STEP 3 : Check whether malfunction is in contact coil or driver air bag (inflator) module.

[A] : Shorting bar 2. Ignition switch 5. Contact coil assembly

[B] : Airbag harness 3.“AIR BAG” fuse 6. Driver air bag (inflator) module

1. From main fuse 4. SDM 7. Ground for air bag system

1

2BLU/RED BLU/BLK

3

7

BLK

“Q01” Q01-4

Q01-17IG

GND4

[A]

[B]

GRN/RED

GRN Q01-10

Q01-9 D- D+“Q06”

“Q01”

“Q05”6

5

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Page 610 of 656

AIR BAG SYSTEM 10B-33

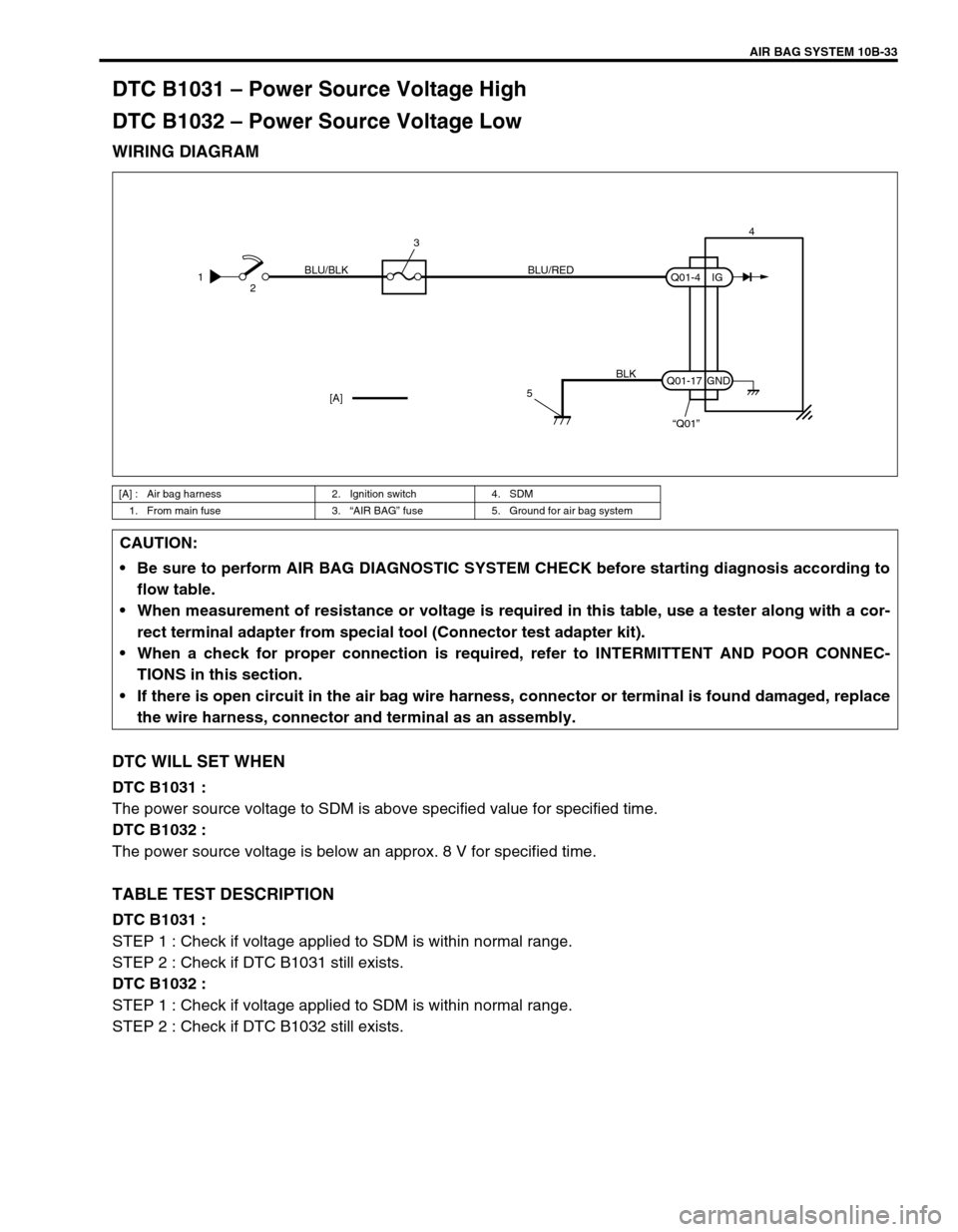

DTC B1031 – Power Source Voltage High

DTC B1032 – Power Source Voltage Low

WIRING DIAGRAM

DTC WILL SET WHEN

DTC B1031 :

The power source voltage to SDM is above specified value for specified time.

DTC B1032 :

The power source voltage is below an approx. 8 V for specified time.

TABLE TEST DESCRIPTION

DTC B1031 :

STEP 1 : Check if voltage applied to SDM is within normal range.

STEP 2 : Check if DTC B1031 still exists.

DTC B1032 :

STEP 1 : Check if voltage applied to SDM is within normal range.

STEP 2 : Check if DTC B1032 still exists.

[A] : Air bag harness 2. Ignition switch 4. SDM

1. From main fuse 3.“AIR BAG” fuse 5. Ground for air bag system

1

2BLU/RED BLU/BLK

3

5

BLK

“Q01” Q01-4

Q01-17IG

GND4

[A]

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Page 617 of 656

10B-40 AIR BAG SYSTEM

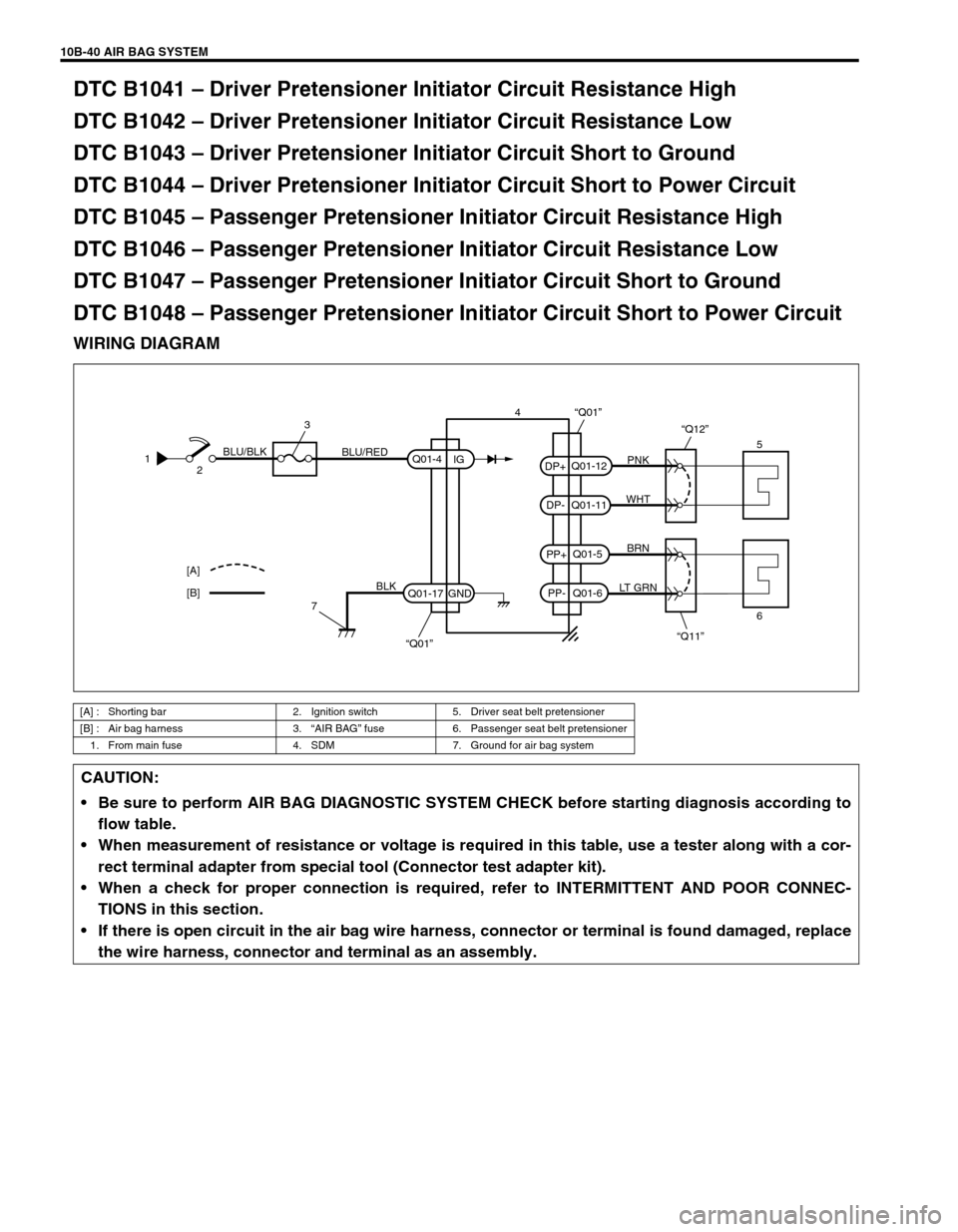

DTC B1041 – Driver Pretensioner Initiator Circuit Resistance High

DTC B1042 – Driver Pretensioner Initiator Circuit Resistance Low

DTC B1043 – Driver Pretensioner Initiator Circuit Short to Ground

DTC B1044 – Driver Pretensioner Initiator Circuit Short to Power Circuit

DTC B1045 – Passenger Pretensioner Initiator Circuit Resistance High

DTC B1046 – Passenger Pretensioner Initiator Circuit Resistance Low

DTC B1047 – Passenger Pretensioner Initiator Circuit Short to Ground

DTC B1048 – Passenger Pretensioner Initiator Circuit Short to Power Circuit

WIRING DIAGRAM

[A] : Shorting bar 2. Ignition switch 5. Driver seat belt pretensioner

[B] : Air bag harness 3.“AIR BAG” fuse 6. Passenger seat belt pretensioner

1. From main fuse 4. SDM 7. Ground for air bag system

PNK

WHT

BRN

LT GRN

“Q11” “Q12”

Q01-12

Q01-11

Q01-5

Q01-6 PP- PP+ DP- DP+

“Q01”

5

6 [A]

[B]1

2BLU/BLK

BLU/RED

3

7

BLK

“Q01” Q01-4

Q01-17IG

GND4

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Page 624 of 656

AIR BAG SYSTEM 10B-47

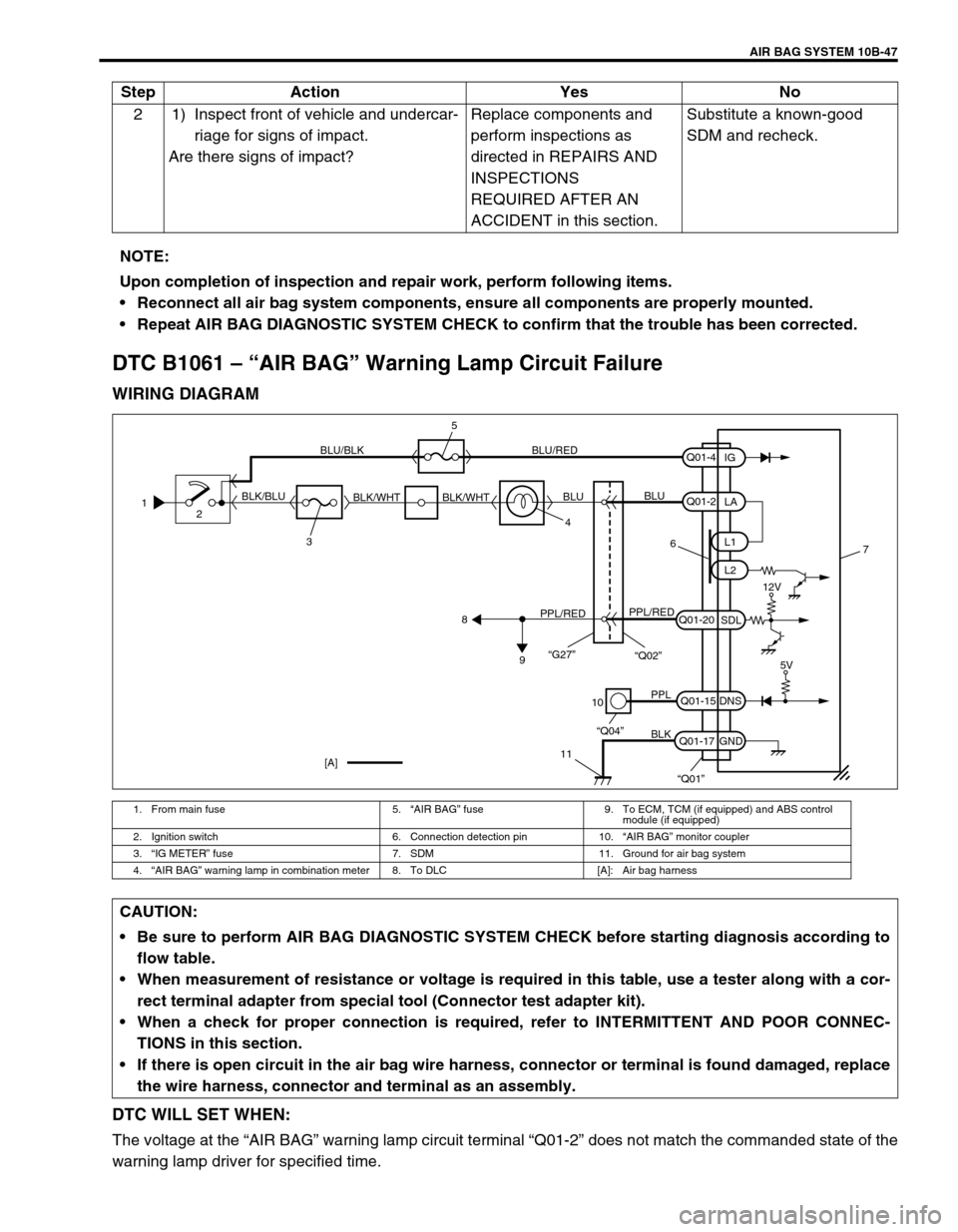

DTC B1061 – “AIR BAG” Warning Lamp Circuit Failure

WIRING DIAGRAM

DTC WILL SET WHEN:

The voltage at the “AIR BAG” warning lamp circuit terminal “Q01-2” does not match the commanded state of the

warning lamp driver for specified time.2 1) Inspect front of vehicle and undercar-

riage for signs of impact.

Are there signs of impact?Replace components and

perform inspections as

directed in REPAIRS AND

INSPECTIONS

REQUIRED AFTER AN

ACCIDENT in this section.Substitute a known-good

SDM and recheck. Step Action Yes No

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

1. From main fuse 5.“AIR BAG” fuse 9. To ECM, TCM (if equipped) and ABS control

module (if equipped)

2. Ignition switch 6. Connection detection pin 10.“AIR BAG” monitor coupler

3.“IG METER” fuse 7. SDM 11. Ground for air bag system

4.“AIR BAG” warning lamp in combination meter 8. To DLC [A]: Air bag harness

1

2

34 BLK/BLUBLU/BLK BLU/RED

BLK/WHT BLK/WHTBLUBLU

6

PPL/REDPPL/RED

8

9

10

11

PPL

BLK

“Q04”

“Q01”

Q01-2

Q01-20

Q01-15

Q01-17L1

L2

SDL

DNS

GNDLA

Q01-4

IG

7

[A]

12V

5V

“G27”“Q02”

5

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Page 642 of 656

AIR BAG SYSTEM 10B-65

Air Bag (Inflator) Module and Seat Belt Pretensioner Disposal

Do not dispose of the live (undeployed) air bag (inflator) modules and seat belt pretensioners.

The method employed depends upon the final disposition of the particular vehicle, as noted in “DEPLOYMENT/

ACTIVATION OUTSIDE VEHICLE” and “DEPLOYMENT/ACTIVATION INSIDE VEHICLE”.

Deployment/Activation Outside Vehicle :

Follow this procedure when disposing of the air bag (inflator) module(s) and seat belt pretensioner(s) only (i.e.,

the vehicle itself will be used again).

Deployment/Activation Inside Vehicle :

Follow this procedure when scrapping the entire vehicle including the air bag (inflator) modules and seat belt

pretensioners.WARNING:

Failure to follow proper air bag (inflator) module and seat belt pretensioner disposal procedures can

result in air bag deployment and pretensioner activation which may cause personal injury.

Undeployed air bag (inflator) module/inactivated seat belt pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and inactivated seat belt pretensioner contain substances

that can cause severe illness or personal injury if the sealed container is damaged during disposal.

WARNING:

Following precautions must be observed for this work. Failure to observe any of them may result in

personal injury.

The procedure should be followed strictly as described here.

Be sure to read “SERVICE PRECAUTIONS” beforehand.

To avoid an accidental deployment, this work should be performed by no more than one person.

Since the smoke is produced when air bag is deployed and pretensioner is activated, select a well-

ventilated area.

The air bag (inflator) module and seat belt pretensioner will immediately deploy/activate when a

power source is connected to it. Wear safety glasses throughout this entire deployment/activation

and disposal procedure.

Wear suitable ear protection when deploying air bag/activating pretensioner. Also, advise those

who are in the area close to deployment/activation site to wear suitable ear protection.

Do not deploy/activate two or more air bag system components (air bag (inflator) modules and seat

belt pretensioners) at the same time.

Never connect deployment harness to any power source before connecting deployment harness to

the air bag (inflator) module and seat belt pretensioner. Deployment harness shall remain shorted

and not be connected to a power source until the air bag is to be deployed and the pretensioner is

to be activated.

Page 648 of 656

AIR BAG SYSTEM 10B-71

18) Dispose of the deployed air bag (inflator) module and the

activated seat belt pretensioner through normal refuse chan-

nels after it has cooled for at least 10 minutes and tightly seal

the air bag (inflator) module and the seat belt pretensioner in

a strong vinyl bag. (Refer to “DEPLOYED AIR BAG (INFLA-

TOR) MODULE AND ACTIVATED SEAT BELT PRETEN-

SIONER DISPOSAL” in detail.)

19) Wash your hands with mild soap and water afterward.

20) Ensure that the deployment harness has been disconnected

from the power source and that its two banana plugs have

been shorted together by fully seating one banana plug into

the other.

21) Disconnect the deployment harness from the air bag (infla-

tor) module and the seat belt pretensioner.

22) Temporarily store air bag (inflator) module or seat belt pre-

tensioner.

[For driver air bag (inflator) module]

Temporarily store the air bag (inflator) module with its vinyl

trim cover facing up, away from the surface upon which it

rests. Refer to “SERVICE PRECAUTIONS” for details.

[For seat belt pretensioner]

When temporarily strong the seat belt pretensioner, be sure

NOT to face its exhaust hole provided side down. It must

face up. Refer to “SERVICE PRECAUTIONS” for details.

23) Contact your local distributor for further assistance.

NOTE:

The remaining steps are to be followed in the unlikely

event that the air bag (inflator) module did not deploy or

the seat belt pretensioner did not activate after following

these procedures.