Fun fuse SUZUKI GRAND VITARA 2001 2.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 269 of 656

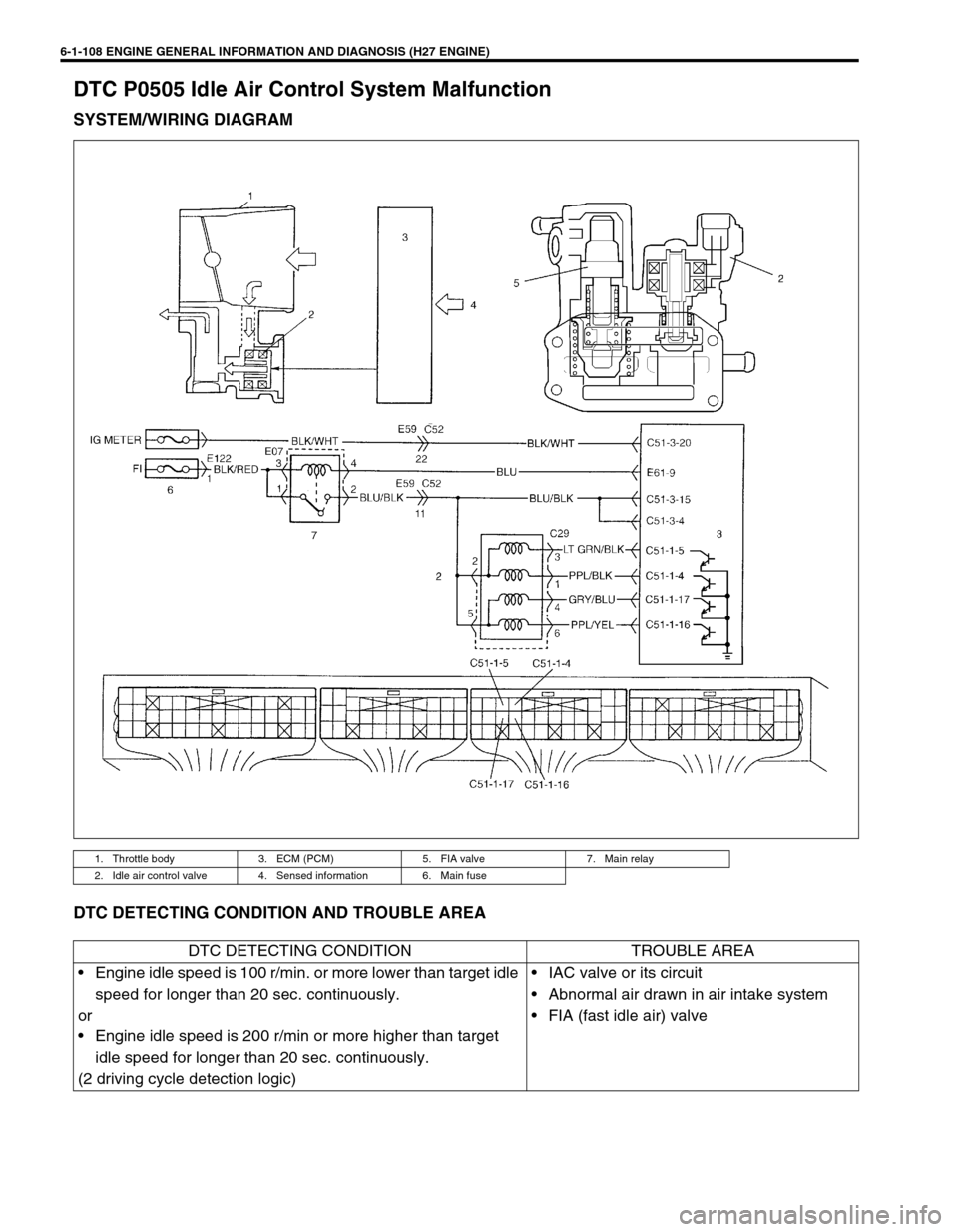

6-1-108 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

DTC P0505 Idle Air Control System Malfunction

SYSTEM/WIRING DIAGRAM

DTC DETECTING CONDITION AND TROUBLE AREA

1. Throttle body 3. ECM (PCM) 5. FIA valve 7. Main relay

2. Idle air control valve 4. Sensed information 6. Main fuse

DTC DETECTING CONDITION TROUBLE AREA

•Engine idle speed is 100 r/min. or more lower than target idle

speed for longer than 20 sec. continuously.

or

•Engine idle speed is 200 r/min or more higher than target

idle speed for longer than 20 sec. continuously.

(2 driving cycle detection logic)•IAC valve or its circuit

•Abnormal air drawn in air intake system

•FIA (fast idle air) valve

Page 276 of 656

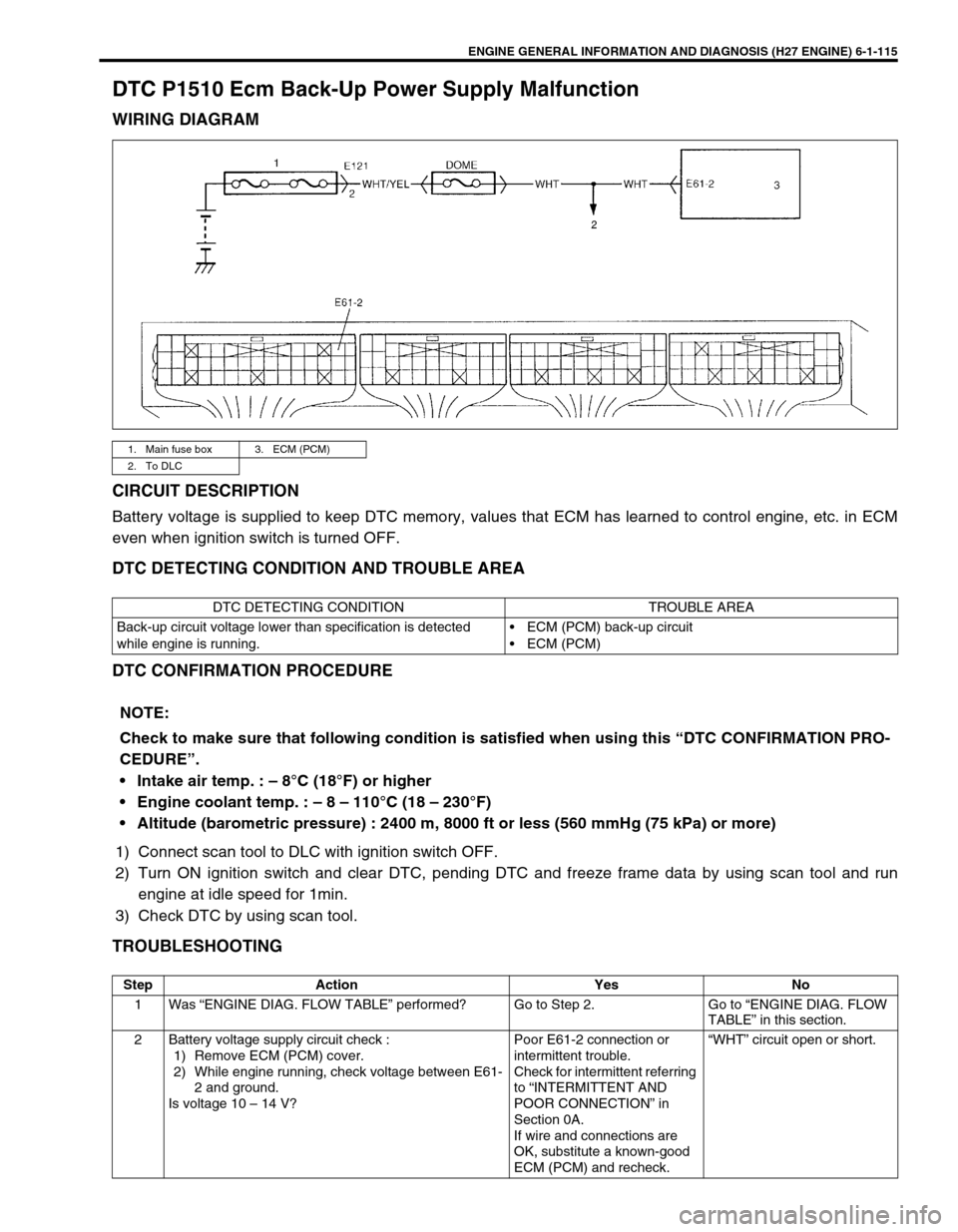

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-115

DTC P1510 Ecm Back-Up Power Supply Malfunction

WIRING DIAGRAM

CIRCUIT DESCRIPTION

Battery voltage is supplied to keep DTC memory, values that ECM has learned to control engine, etc. in ECM

even when ignition switch is turned OFF.

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and run

engine at idle speed for 1min.

3) Check DTC by using scan tool.

TROUBLESHOOTING

1. Main fuse box 3. ECM (PCM)

2. To DLC

DTC DETECTING CONDITION TROUBLE AREA

Back-up circuit voltage lower than specification is detected

while engine is running.•ECM (PCM) back-up circuit

•ECM (PCM)

NOTE:

Check to make sure that following condition is satisfied when using this “DTC CONFIRMATION PRO-

CEDURE”.

Intake air temp. : – 8°C (18°F) or higher

Engine coolant temp. : – 8 – 110°C (18 – 230°F)

Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg (75 kPa) or more)

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE DIAG. FLOW

TABLE” in this section.

2 Battery voltage supply circuit check :

1) Remove ECM (PCM) cover.

2) While engine running, check voltage between E61-

2 and ground.

Is voltage 10 – 14 V?Poor E61-2 connection or

intermittent trouble.

Check for intermittent referring

to “INTERMITTENT AND

POOR CONNECTION” in

Section 0A.

If wire and connections are

OK, substitute a known-good

ECM (PCM) and recheck.“WHT” circuit open or short.

Page 277 of 656

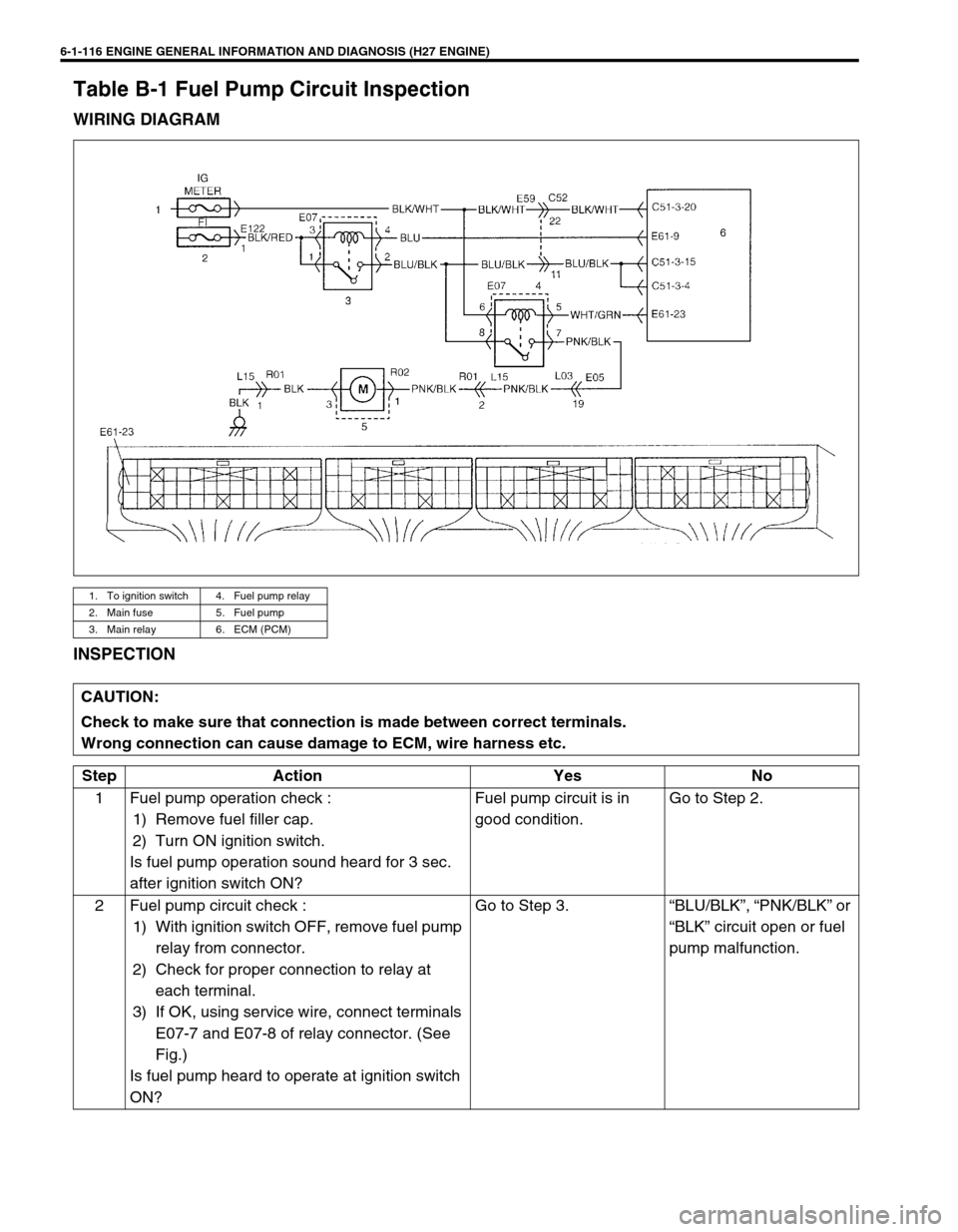

6-1-116 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

Table B-1 Fuel Pump Circuit Inspection

WIRING DIAGRAM

INSPECTION

1. To ignition switch 4. Fuel pump relay

2. Main fuse 5. Fuel pump

3. Main relay 6. ECM (PCM)

CAUTION:

Check to make sure that connection is made between correct terminals.

Wrong connection can cause damage to ECM, wire harness etc.

Step Action Yes No

1 Fuel pump operation check :

1) Remove fuel filler cap.

2) Turn ON ignition switch.

Is fuel pump operation sound heard for 3 sec.

after ignition switch ON?Fuel pump circuit is in

good condition.Go to Step 2.

2 Fuel pump circuit check :

1) With ignition switch OFF, remove fuel pump

relay from connector.

2) Check for proper connection to relay at

each terminal.

3) If OK, using service wire, connect terminals

E07-7 and E07-8 of relay connector. (See

Fig.)

Is fuel pump heard to operate at ignition switch

ON?Go to Step 3.“BLU/BLK”, “PNK/BLK” or

“BLK” circuit open or fuel

pump malfunction.

Page 285 of 656

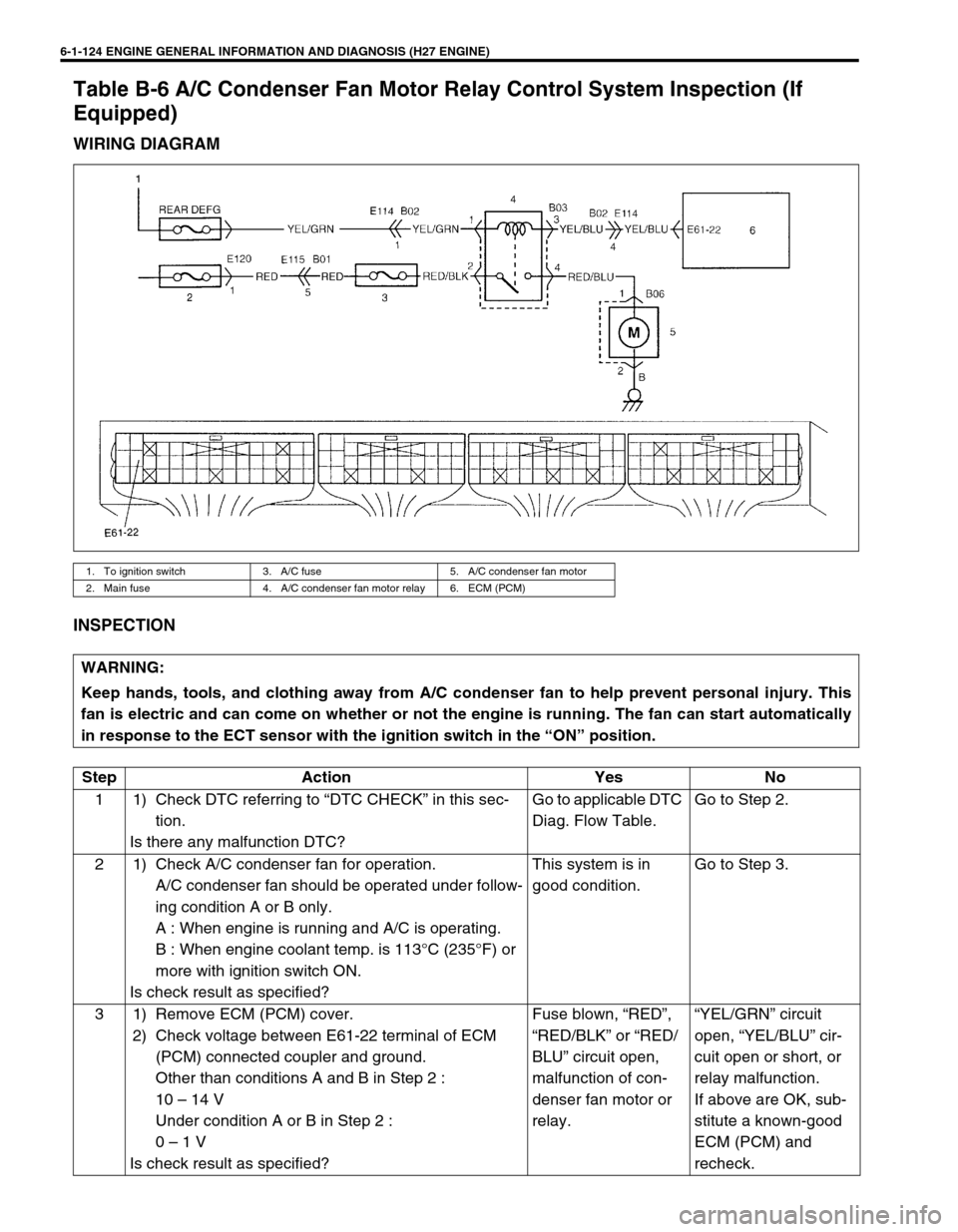

6-1-124 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

Table B-6 A/C Condenser Fan Motor Relay Control System Inspection (If

Equipped)

WIRING DIAGRAM

INSPECTION

1. To ignition switch 3. A/C fuse 5. A/C condenser fan motor

2. Main fuse 4. A/C condenser fan motor relay 6. ECM (PCM)

WARNING:

Keep hands, tools, and clothing away from A/C condenser fan to help prevent personal injury. This

fan is electric and can come on whether or not the engine is running. The fan can start automatically

in response to the ECT sensor with the ignition switch in the “ON” position.

Step Action Yes No

1 1) Check DTC referring to “DTC CHECK” in this sec-

tion.

Is there any malfunction DTC?Go to applicable DTC

Diag. Flow Table.Go to Step 2.

2 1) Check A/C condenser fan for operation.

A/C condenser fan should be operated under follow-

ing condition A or B only.

A : When engine is running and A/C is operating.

B : When engine coolant temp. is 113°C (235°F) or

more with ignition switch ON.

Is check result as specified?This system is in

good condition.Go to Step 3.

3 1) Remove ECM (PCM) cover.

2) Check voltage between E61-22 terminal of ECM

(PCM) connected coupler and ground.

Other than conditions A and B in Step 2 :

10 – 14 V

Under condition A or B in Step 2 :

0 – 1 V

Is check result as specified?Fuse blown, “RED”,

“RED/BLK” or “RED/

BLU” circuit open,

malfunction of con-

denser fan motor or

relay.“YEL/GRN” circuit

open, “YEL/BLU” cir-

cuit open or short, or

relay malfunction.

If above are OK, sub-

stitute a known-good

ECM (PCM) and

recheck.

Page 341 of 656

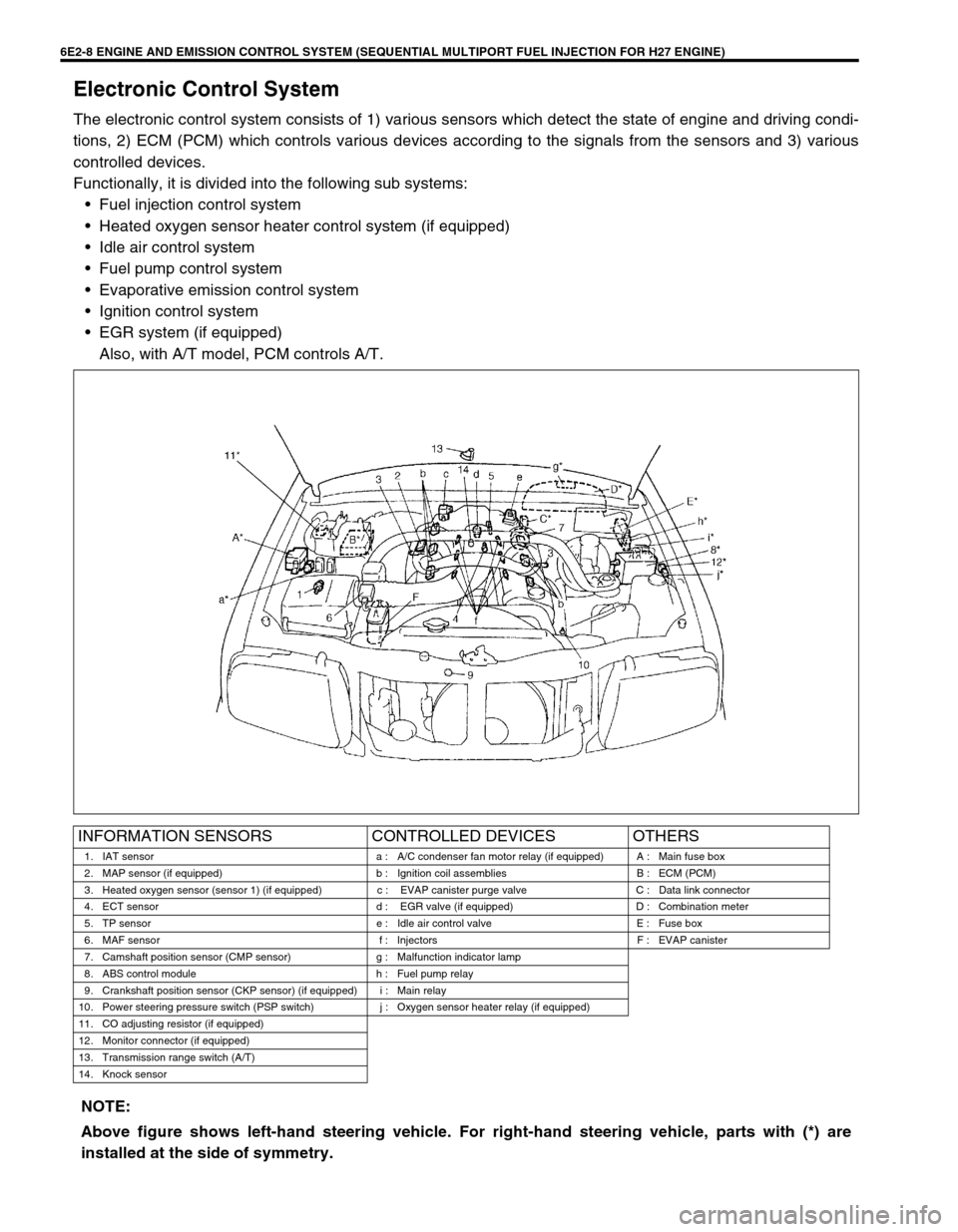

6E2-8 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

Electronic Control System

The electronic control system consists of 1) various sensors which detect the state of engine and driving condi-

tions, 2) ECM (PCM) which controls various devices according to the signals from the sensors and 3) various

controlled devices.

Functionally, it is divided into the following sub systems:

•Fuel injection control system

•Heated oxygen sensor heater control system (if equipped)

•Idle air control system

•Fuel pump control system

•Evaporative emission control system

•Ignition control system

•EGR system (if equipped)

Also, with A/T model, PCM controls A/T.

INFORMATION SENSORS CONTROLLED DEVICES OTHERS

1. IAT sensor a : A/C condenser fan motor relay (if equipped) A : Main fuse box

2. MAP sensor (if equipped) b : Ignition coil assemblies B : ECM (PCM)

3. Heated oxygen sensor (sensor 1) (if equipped) c : EVAP canister purge valve C : Data link connector

4. ECT sensor d : EGR valve (if equipped) D : Combination meter

5. TP sensor e : Idle air control valve E : Fuse box

6. MAF sensor f : Injectors F : EVAP canister

7. Camshaft position sensor (CMP sensor) g : Malfunction indicator lamp

8. ABS control module h : Fuel pump relay

9. Crankshaft position sensor (CKP sensor) (if equipped) i : Main relay

10. Power steering pressure switch (PSP switch) j : Oxygen sensor heater relay (if equipped)

11. CO adjusting resistor (if equipped)

12. Monitor connector (if equipped)

13. Transmission range switch (A/T)

14. Knock sensor

NOTE:

Above figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are

installed at the side of symmetry.

Page 375 of 656

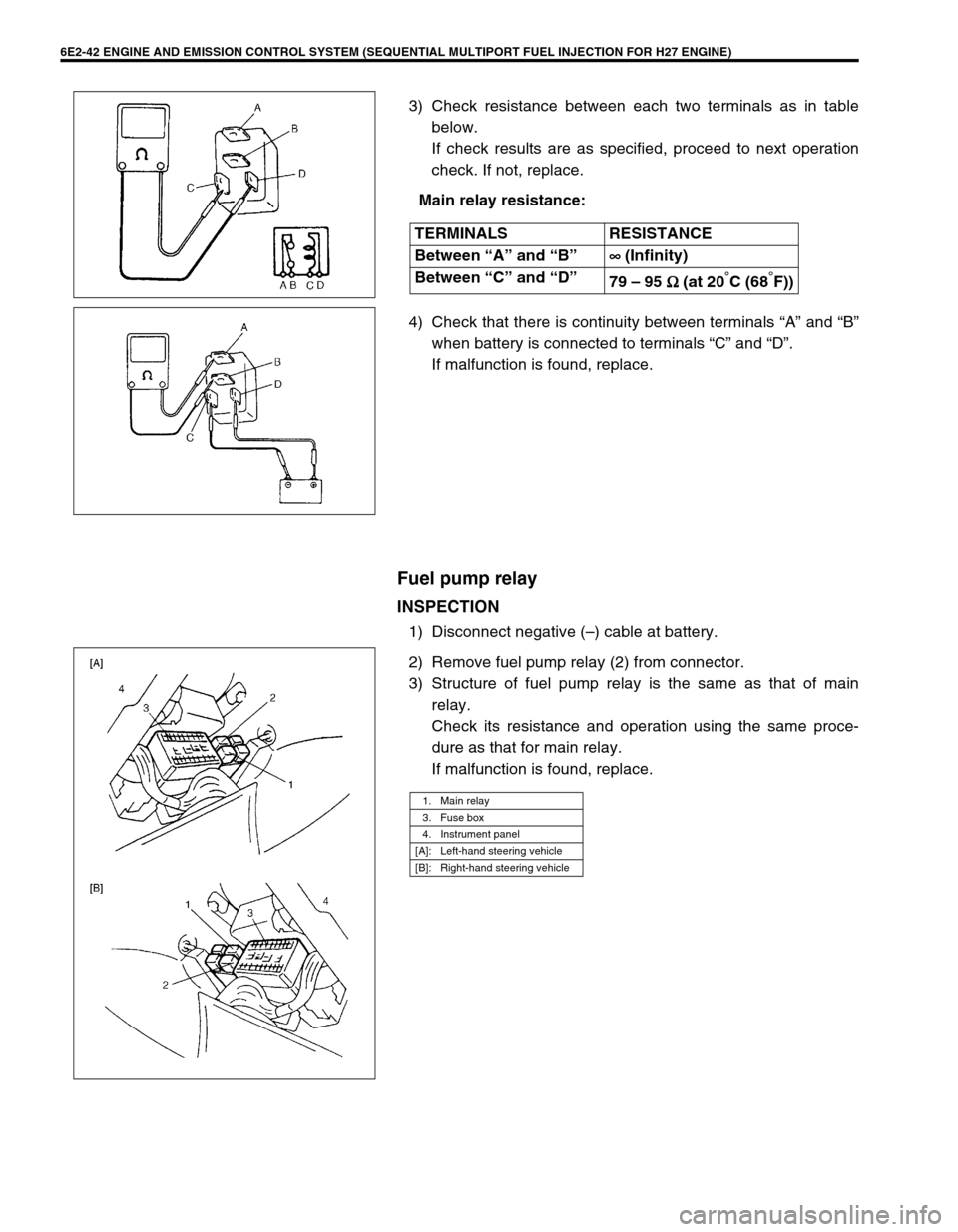

6E2-42 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

3) Check resistance between each two terminals as in table

below.

If check results are as specified, proceed to next operation

check. If not, replace.

Main relay resistance:

4) Check that there is continuity between terminals “A” and “B”

when battery is connected to terminals “C” and “D”.

If malfunction is found, replace.

Fuel pump relay

INSPECTION

1) Disconnect negative (–) cable at battery.

2) Remove fuel pump relay (2) from connector.

3) Structure of fuel pump relay is the same as that of main

relay.

Check its resistance and operation using the same proce-

dure as that for main relay.

If malfunction is found, replace. TERMINALS RESISTANCE

Between “A” and “B”∞

∞∞ ∞ (Infinity)

Between “C” and “D”

79 – 95 Ω

ΩΩ Ω (at 20

°C (68°F))

1. Main relay

3. Fuse box

4. Instrument panel

[A]: Left-hand steering vehicle

[B]: Right-hand steering vehicle

Page 387 of 656

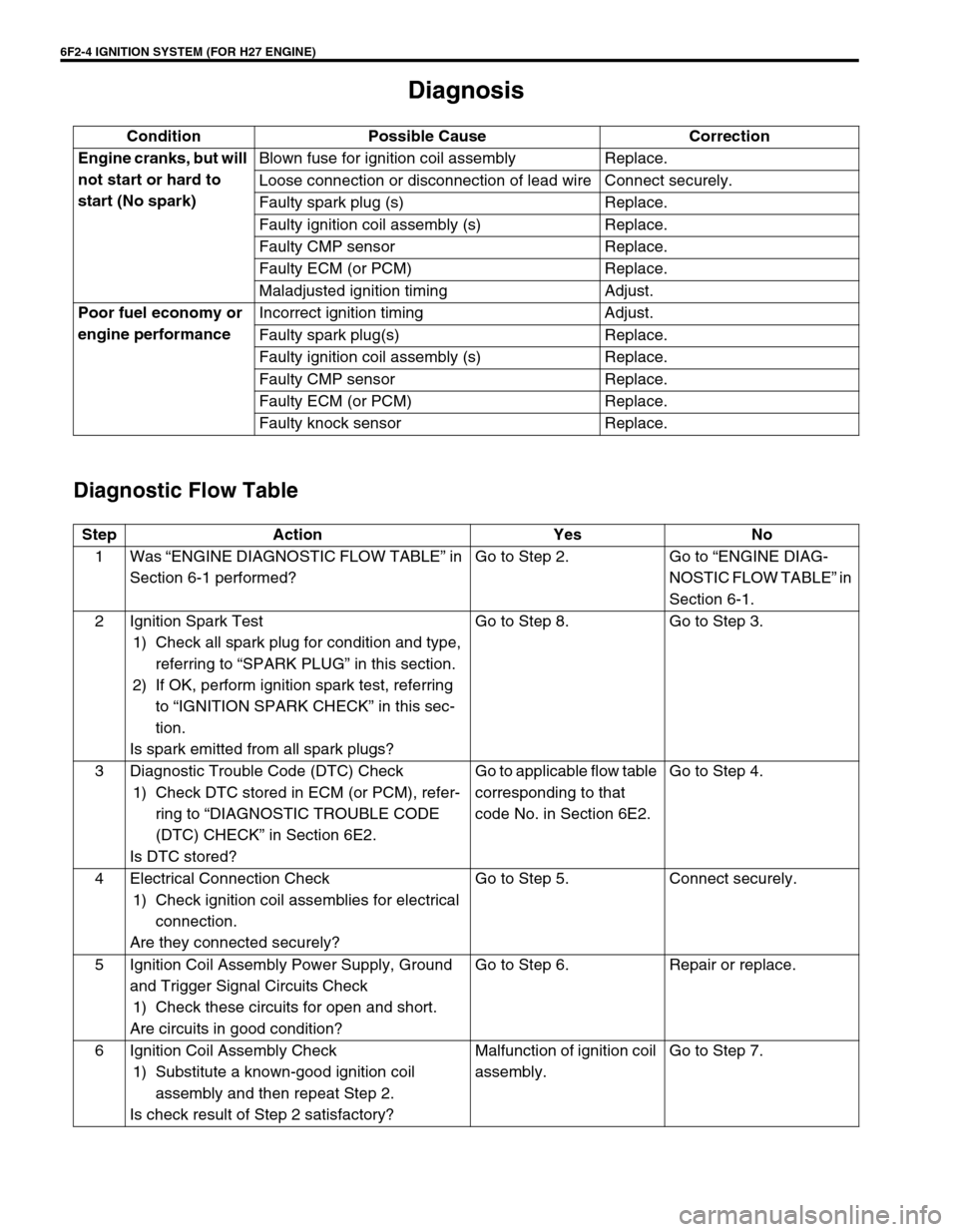

6F2-4 IGNITION SYSTEM (FOR H27 ENGINE)

Diagnosis

Diagnostic Flow Table

Condition Possible Cause Correction

Engine cranks, but will

not start or hard to

start (No spark)Blown fuse for ignition coil assembly Replace.

Loose connection or disconnection of lead wire Connect securely.

Faulty spark plug (s) Replace.

Faulty ignition coil assembly (s) Replace.

Faulty CMP sensor Replace.

Faulty ECM (or PCM) Replace.

Maladjusted ignition timing Adjust.

Poor fuel economy or

engine performanceIncorrect ignition timing Adjust.

Faulty spark plug(s) Replace.

Faulty ignition coil assembly (s) Replace.

Faulty CMP sensor Replace.

Faulty ECM (or PCM) Replace.

Faulty knock sensor Replace.

Step Action Yes No

1Was “ENGINE DIAGNOSTIC FLOW TABLE” in

Section 6-1 performed?Go to Step 2. Go to “ENGINE DIAG-

NOSTIC FLOW TABLE” in

Section 6-1.

2 Ignition Spark Test

1) Check all spark plug for condition and type,

referring to “SPARK PLUG” in this section.

2) If OK, perform ignition spark test, referring

to “IGNITION SPARK CHECK” in this sec-

tion.

Is spark emitted from all spark plugs?Go to Step 8. Go to Step 3.

3 Diagnostic Trouble Code (DTC) Check

1) Check DTC stored in ECM (or PCM), refer-

ring to “DIAGNOSTIC TROUBLE CODE

(DTC) CHECK” in Section 6E2.

Is DTC stored?Go to applicable flow table

corresponding to that

code No. in Section 6E2.Go to Step 4.

4 Electrical Connection Check

1) Check ignition coil assemblies for electrical

connection.

Are they connected securely?Go to Step 5. Connect securely.

5 Ignition Coil Assembly Power Supply, Ground

and Trigger Signal Circuits Check

1) Check these circuits for open and short.

Are circuits in good condition?Go to Step 6. Repair or replace.

6 Ignition Coil Assembly Check

1) Substitute a known-good ignition coil

assembly and then repeat Step 2.

Is check result of Step 2 satisfactory?Malfunction of ignition coil

assembly.Go to Step 7.

Page 418 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-9

Precaution in Diagnosing Trouble

•Don’t disconnect couplers from PCM (ECM), battery cable

from battery, PCM ground wire harness from engine or main

fuse before checking the diagnosis information (DTC, freeze

frame data, etc.) stored in PCM memory. Such disconnec-

tion will clear memorized information in PCM memory.

•Using SUZUKI scan tool or also generic scan tool for vehicle

without monitor connector, the diagnostic information stored

in PCM memory can be checked and cleared as well. Before

its use, be sure to read Operator’s (Instruction) Manual sup-

plied with it carefully to have good understanding of its func-

tions and usage.

•Priorities for diagnosing troubles

If two or more diagnostic trouble codes (DTCs) are stored,

proceed to the flow table of the DTC which was detected

earliest in the order and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble

codes according to the following priorities.

–Diagnostic trouble codes (DTCs) other than DTC P0171/

P0172/P0174/P0175 (Fuel system too lean/too rich), DTC

P0300/P0301/P0302/P0303/P0304/P0305/P0306 (Misfire

detected) and DTC P0400 (EGR flow malfunction)

–DTC P0171/P0172/P0174/P0175 (Fuel system too lean/too

rich) and DTC P0400 (EGR flow malfunction)

–DTC P0300/P0301/P0302/P0303/P0304/P0305/P0306

(Misfire detected)

•Be sure to read “PRECAUTIONS FOR ELECTRICAL CIR-

CUIT SERVICE” in Section 0A before inspection and

observe what is written there.

•PCM replacement

When substituting a known-good PCM, check for following

conditions.

Neglecting this check may result in damage to a good PCM.

–All relays and actuators have resistance of specified value.

–MAF sensor, MDP sensor, TP sensor and fuel tank pres-

sure sensor are in good condition. Also, the power circuit of

these sensors is not shorted to the ground.

Page 423 of 656

7B1-14 AUTOMATIC TRANSMISSION (4 A/T)

Diagnostic Trouble Code Table

Refer to the same item in Section 6-1.

Fail Safe Table

Refer to the same item in Section 6-1.

Visual Inspection

Visually check following parts and systems.

A/T Basic Check

This inspection is important for troubleshooting when PCM (ECM) has detected no DTC and no abnormality has

been noted in visual inspection. Follow flow table carefully.INSPECTION ITEM REFERRING SECTION

•A/T fluid - - - - - level, leakage, color SECTION 0B

•A/T fluid hoses - - - - - disconnection, looseness, deterioration SECTION 7B1

•Throttle (accelerator) cable - - - - - play, installation SECTION 6E2

•A/T throttle cable - - - - - play, installation SECTION 7B1

•A/T select cable - - - - - installation, operation SECTION 7B1

•Engine oil - - - - - level, leakage SECTION 0B

•Engine coolant - - - - - level, leakage SECTION 0B

•Battery - - - - - fluid level, corrosion of terminal

•Connectors of electric wire harness - - - - - disconnection, friction Section 6-1 or 7B1

•Fuses - - - - - burning SECTION 8

•Parts - - - - - installation, damage

•bolt - - - - - looseness

•Other parts that can be checked visually

•Also check following items at engine start, if possible.

–“O/D OFF” lamp - - - - - Operation SECTION 7B1

–“POWER” lamp - - - - - Operation SECTION 7B1

–Malfunction indicator lamp (“SERVICE ENGINE SOON” lamp) - -

- - - OperationSection 6-1

–Charge warning lamp - - - - - Operation SECTION 6H

–Engine oil pressure warning lamp - - - - - Operation SECTION 8C (SECTION 6A2 for pres-

sure check)

–Engine coolant temp. meter - - - - - Operation

–Other parts that can be checked visually

Step Action Yes No

1Was “AUTOMATIC TRANSMISSION DIAGNOSTIC

FLOW TABLE” performed?Go to Step 2. Go to “AUTOMATIC

TRANSMISSION DIAG-

NOSTIC FLOW TABLE”.

2Perform “MANUAL ROAD TEST” in this section.

Is it OK?Go to Step 3. Go to Step 4.

3Proceed to “TROUBLE DIAGNOSIS TABLE 1” in this

section.

Is trouble identified?Repair or replace

defective parts.Go to Step 5.

Page 435 of 656

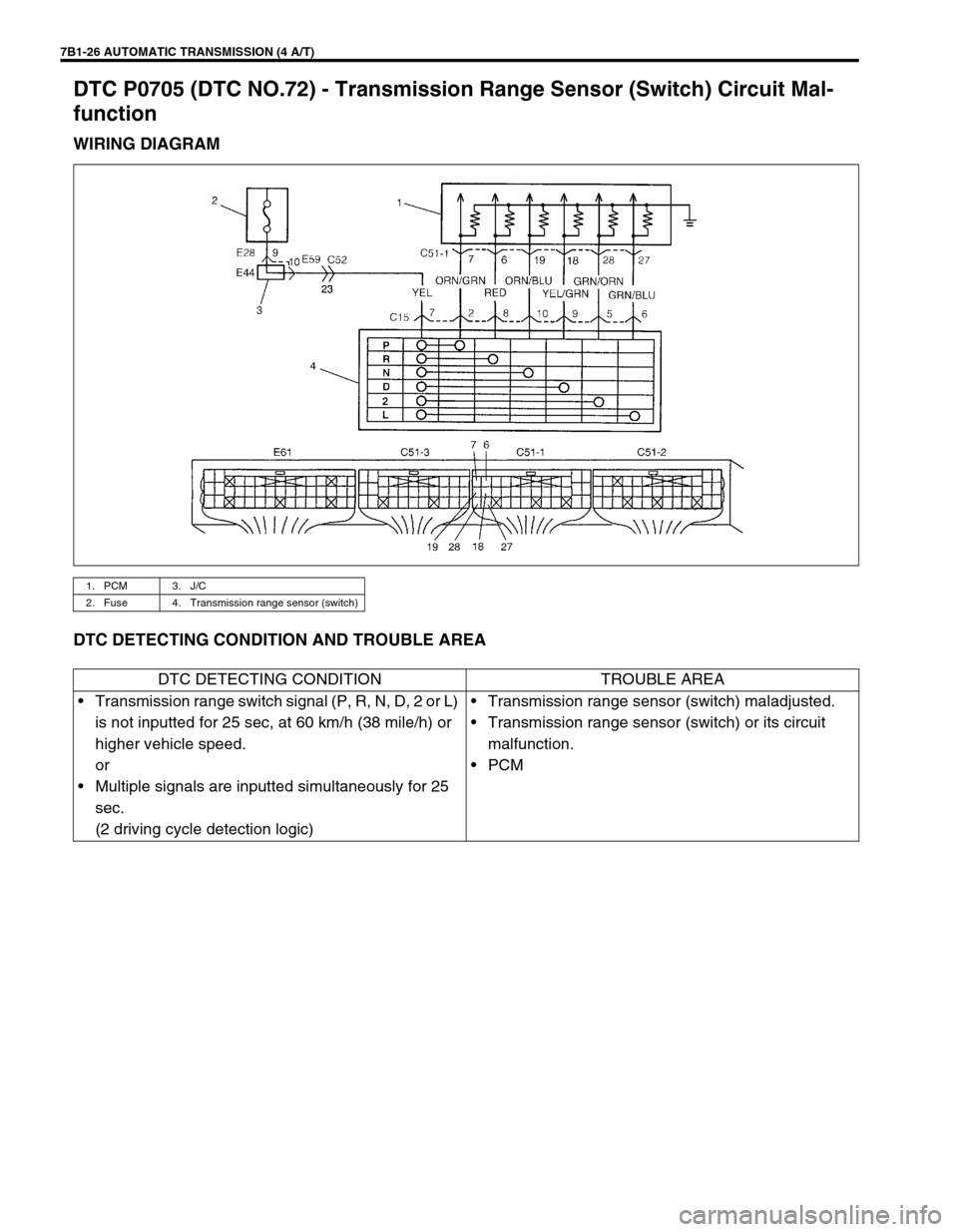

7B1-26 AUTOMATIC TRANSMISSION (4 A/T)

DTC P0705 (DTC NO.72) - Transmission Range Sensor (Switch) Circuit Mal-

function

WIRING DIAGRAM

DTC DETECTING CONDITION AND TROUBLE AREA

1. PCM 3. J/C

2. Fuse 4. Transmission range sensor (switch)

DTC DETECTING CONDITION TROUBLE AREA

•Transmission range switch signal (P, R, N, D, 2 or L)

is not inputted for 25 sec, at 60 km/h (38 mile/h) or

higher vehicle speed.

or

•Multiple signals are inputted simultaneously for 25

sec.

(2 driving cycle detection logic)•Transmission range sensor (switch) maladjusted.

•Transmission range sensor (switch) or its circuit

malfunction.

•PCM