engine SUZUKI GRAND VITARA 2001 2.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 21 of 656

0B-8 MAINTENANCE AND LUBRICATION

6) Replenish oil until oil level is brought to FULL level mark on

dipstick. (oil pan and oil filter capacity). The filler inlet is at

the top of the cylinder head cover.

It is recommended to use engine oil of SE, SF, SG, SH or SJ

grade.

NOTE:

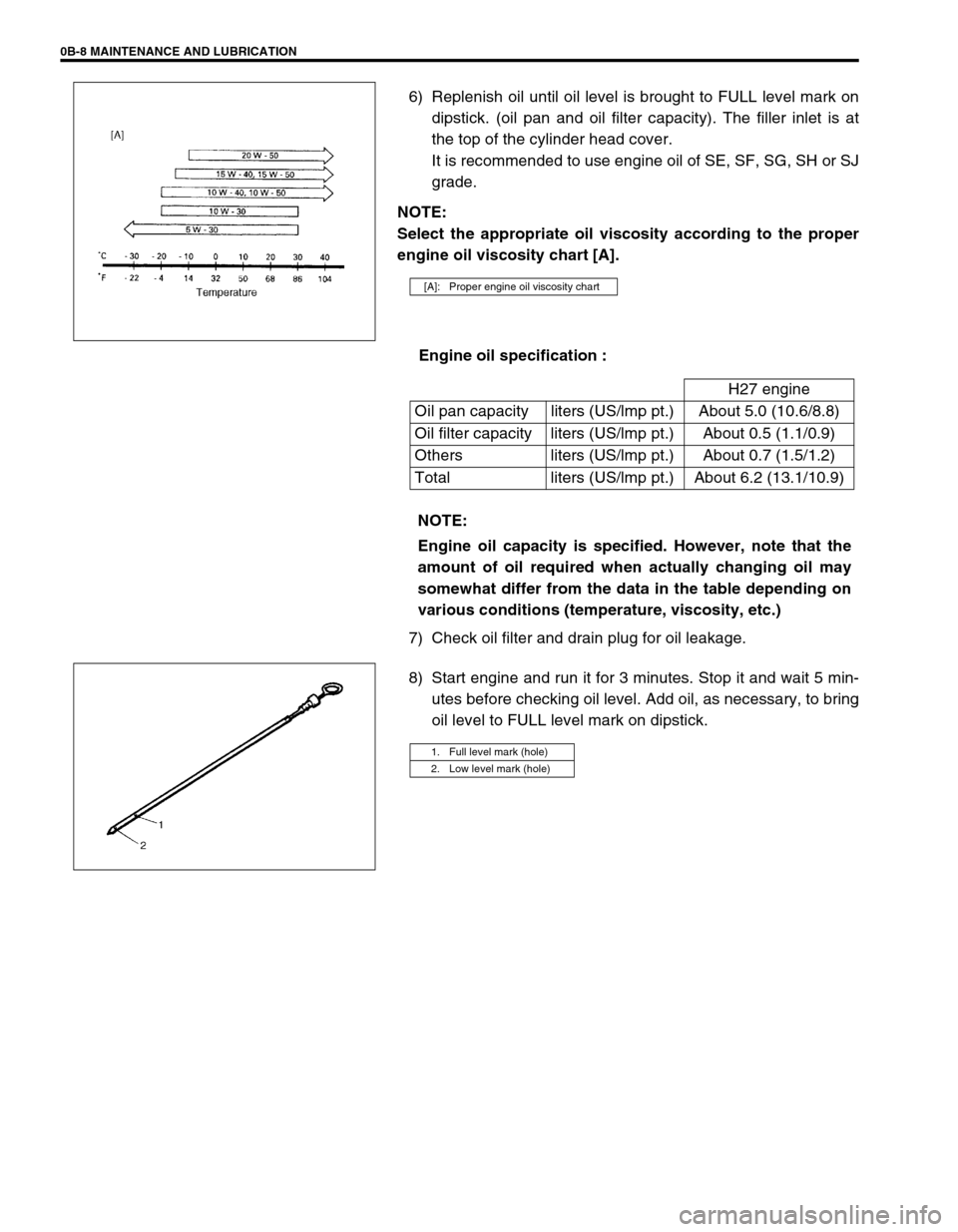

Select the appropriate oil viscosity according to the proper

engine oil viscosity chart [A].

Engine oil specification :

7) Check oil filter and drain plug for oil leakage.

8) Start engine and run it for 3 minutes. Stop it and wait 5 min-

utes before checking oil level. Add oil, as necessary, to bring

oil level to FULL level mark on dipstick.

[A]: Proper engine oil viscosity chart

H27 engine

Oil pan capacity liters (US/lmp pt.) About 5.0 (10.6/8.8)

Oil filter capacity liters (US/lmp pt.) About 0.5 (1.1/0.9)

Others liters (US/lmp pt.) About 0.7 (1.5/1.2)

Total liters (US/lmp pt.) About 6.2 (13.1/10.9)

NOTE:

Engine oil capacity is specified. However, note that the

amount of oil required when actually changing oil may

somewhat differ from the data in the table depending on

various conditions (temperature, viscosity, etc.)

1. Full level mark (hole)

2. Low level mark (hole)

Page 34 of 656

AIR CONDITIONING (OPTIONAL) 1B-9

Quickly Checking of Refrigerant Charge (If

Equipped with Sight Glass)

The following procedure can be used for quickly checking whether

the A/C system has a proper charge of refrigerant or not.

1) Run engine at fast idle.

2) Operate A/C at the following conditions for a few minutes.

Main (front) A/C switch at ON position.

Rear A/C main switch at ON position (if equipped).

Front blower motor switch at max position.

Rear blower motor switch at max position (if equipped).

Air outlet control button at face position.

Temperature control lever at max cool position.

Vehicle door at all open.

Air inlet door at recirculation position.

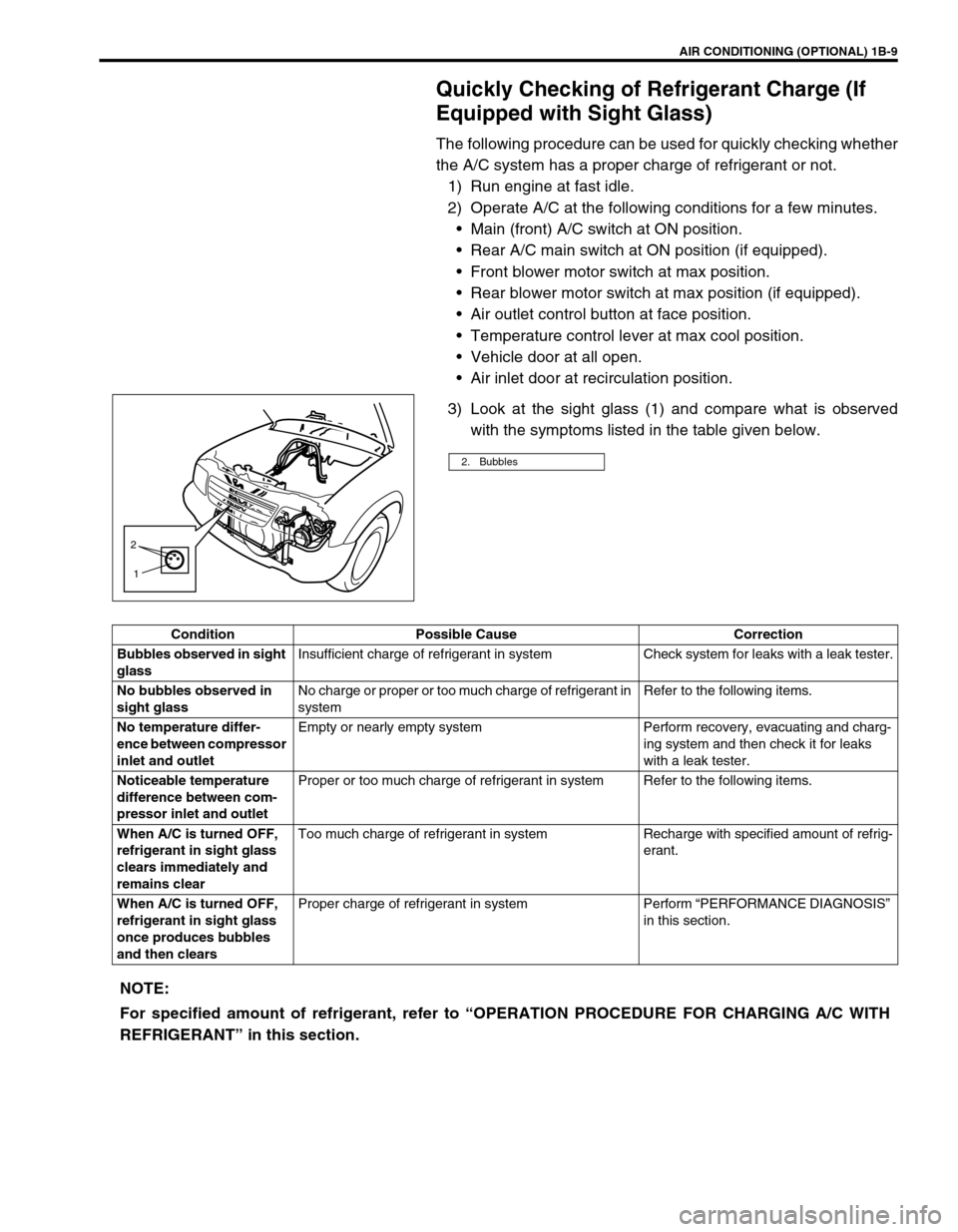

3) Look at the sight glass (1) and compare what is observed

with the symptoms listed in the table given below.

2. Bubbles

2

1

Condition Possible Cause Correction

Bubbles observed in sight

glassInsufficient charge of refrigerant in system Check system for leaks with a leak tester.

No bubbles observed in

sight glassNo charge or proper or too much charge of refrigerant in

systemRefer to the following items.

No temperature differ-

ence between compressor

inlet and outletEmpty or nearly empty system Perform recovery, evacuating and charg-

ing system and then check it for leaks

with a leak tester.

Noticeable temperature

difference between com-

pressor inlet and outletProper or too much charge of refrigerant in system Refer to the following items.

When A/C is turned OFF,

refrigerant in sight glass

clears immediately and

remains clearToo much charge of refrigerant in system Recharge with specified amount of refrig-

erant.

When A/C is turned OFF,

refrigerant in sight glass

once produces bubbles

and then clearsProper charge of refrigerant in system Perform “PERFORMANCE DIAGNOSIS”

in this section.

NOTE:

For specified amount of refrigerant, refer to “OPERATION PROCEDURE FOR CHARGING A/C WITH

REFRIGERANT” in this section.

Page 35 of 656

1B-10 AIR CONDITIONING (OPTIONAL)

Performance Diagnosis

1) Confirm that vehicle and environmental conditions are as fol-

lows.

Vehicle is not exposed to direct sun.

Ambient temperature is within 15 - 35 °C (59 - 95 °F).

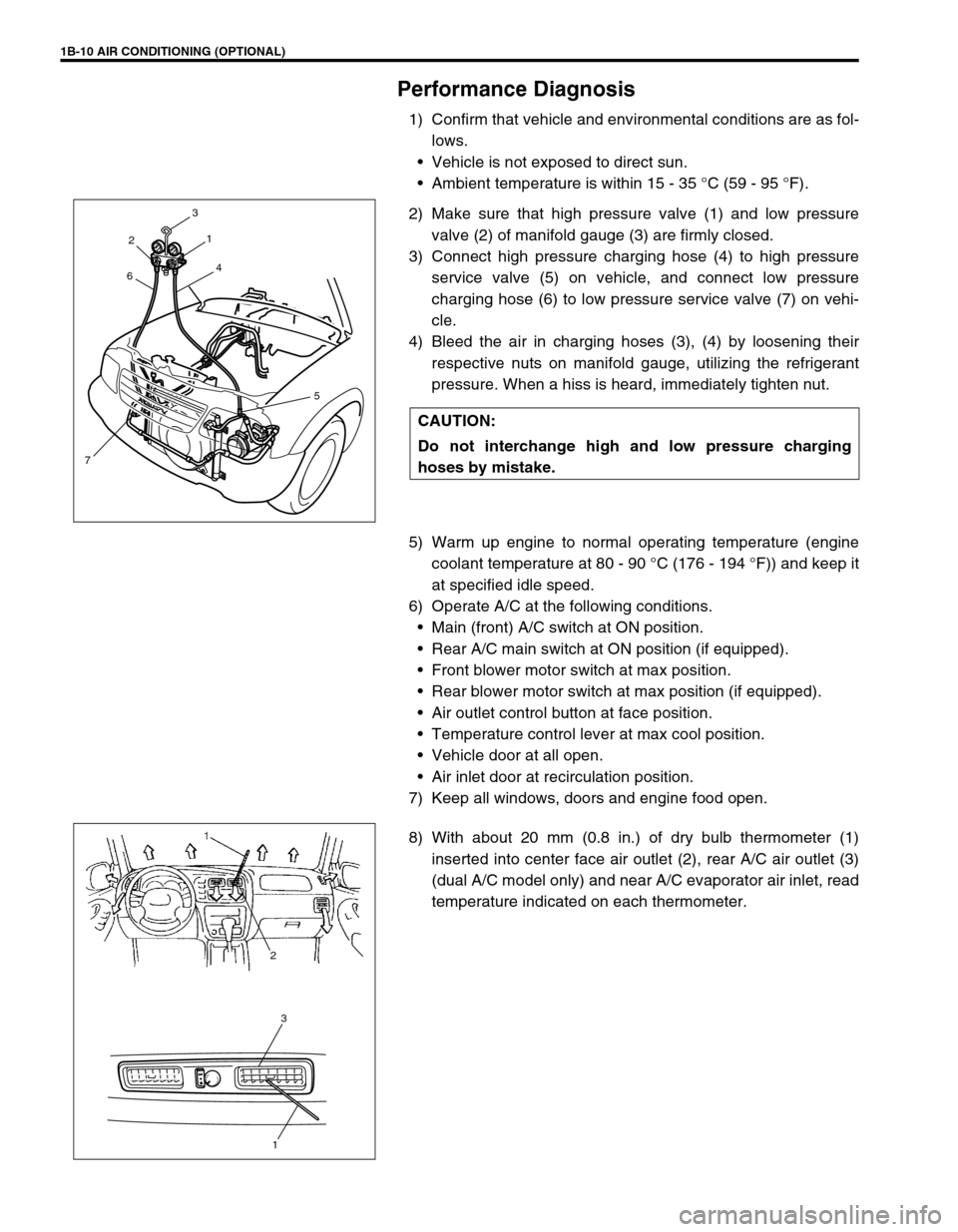

2) Make sure that high pressure valve (1) and low pressure

valve (2) of manifold gauge (3) are firmly closed.

3) Connect high pressure charging hose (4) to high pressure

service valve (5) on vehicle, and connect low pressure

charging hose (6) to low pressure service valve (7) on vehi-

cle.

4) Bleed the air in charging hoses (3), (4) by loosening their

respective nuts on manifold gauge, utilizing the refrigerant

pressure. When a hiss is heard, immediately tighten nut.

5) Warm up engine to normal operating temperature (engine

coolant temperature at 80 - 90 °C (176 - 194 °F)) and keep it

at specified idle speed.

6) Operate A/C at the following conditions.

Main (front) A/C switch at ON position.

Rear A/C main switch at ON position (if equipped).

Front blower motor switch at max position.

Rear blower motor switch at max position (if equipped).

Air outlet control button at face position.

Temperature control lever at max cool position.

Vehicle door at all open.

Air inlet door at recirculation position.

7) Keep all windows, doors and engine food open.

8) With about 20 mm (0.8 in.) of dry bulb thermometer (1)

inserted into center face air outlet (2), rear A/C air outlet (3)

(dual A/C model only) and near A/C evaporator air inlet, read

temperature indicated on each thermometer. CAUTION:

Do not interchange high and low pressure charging

hoses by mistake.

2

64

3

75 1

3

1

2

Page 37 of 656

1B-12 AIR CONDITIONING (OPTIONAL)

Performance diagnosis table

HIGH PRESSURE GAUGE

LOW PRESSURE GAUGE

THERMOMETER AT CENTER DUCT

Condition Possible Cause Correction

Pressure high

(“A” area of high side

graph)Refrigerant overcharged Recharge.

Expansion valve frozen or clogged Check expansion valve.

Clogged refrigerant passage of high side Clean or replace.

Condenser cooling fan malfunction (Insufficient cooling

of condenser)Check condenser cooling fan.

Dirty or bent condenser fins (Insufficient cooling of con-

denser)Clean or repair.

Compressor malfunction (Insufficient oil etc.) Check compressor.

Engine overheat Check engine cooling system.

Pressure low

(“B” area of high side

graph)Insufficient refrigerant (Insufficient charge or leakage) Check for leakage, repair if necessary

and recharge.

Expansion valve malfunction (valve opens too wide) Check expansion valve.

Compressor malfunction (Insufficient compression) Check compressor.

Condition Possible Cause Correction

Pressure high

(“C” area of low side

graph)Expansion valve malfunction (valve opens too wide) Check expansion valve.

Compressor malfunction (Insufficient compression) Check compressor.

Pressure low

(“D” area of low side

graph)Insufficient refrigerant (Insufficient charge or leakage) Check for leakage, repair if necessary

and recharge.

Expansion valve malfunction (valve opens too narrow) Check expansion valve.

Clogged refrigerant passage (crashed pipe) Repair or replace.

Condition Possible Cause Correction

Outlet air temperature at

center duct is high

(Crossing point is in area

“E”)Insufficient or excessive charge of refrigerant Check refrigerant pressure.

Dirty or bent A/C evaporator fins Clean or repair.

Air leakage from cooling (heater) unit or air duct Repair or replace.

Malfunctioning, switch over function of damper in cool-

ing (heater) unitRepair or replace.

Compressor malfunction Check compressor.

Outlet air temperature at

center duct is low

(Crossing point is in area

“F”)Insufficient air volume from center duct (Heater blower

malfunction)Check blower motor and fan.

Compressor malfunction Check compressor.

NOTE:

If ambient temperature is within 30 - 35 °C (85 - 95 °F), it is possible to do using “DETAIL DIAGNOSIS

TABLE” in this section for detail diagnosis.

Page 38 of 656

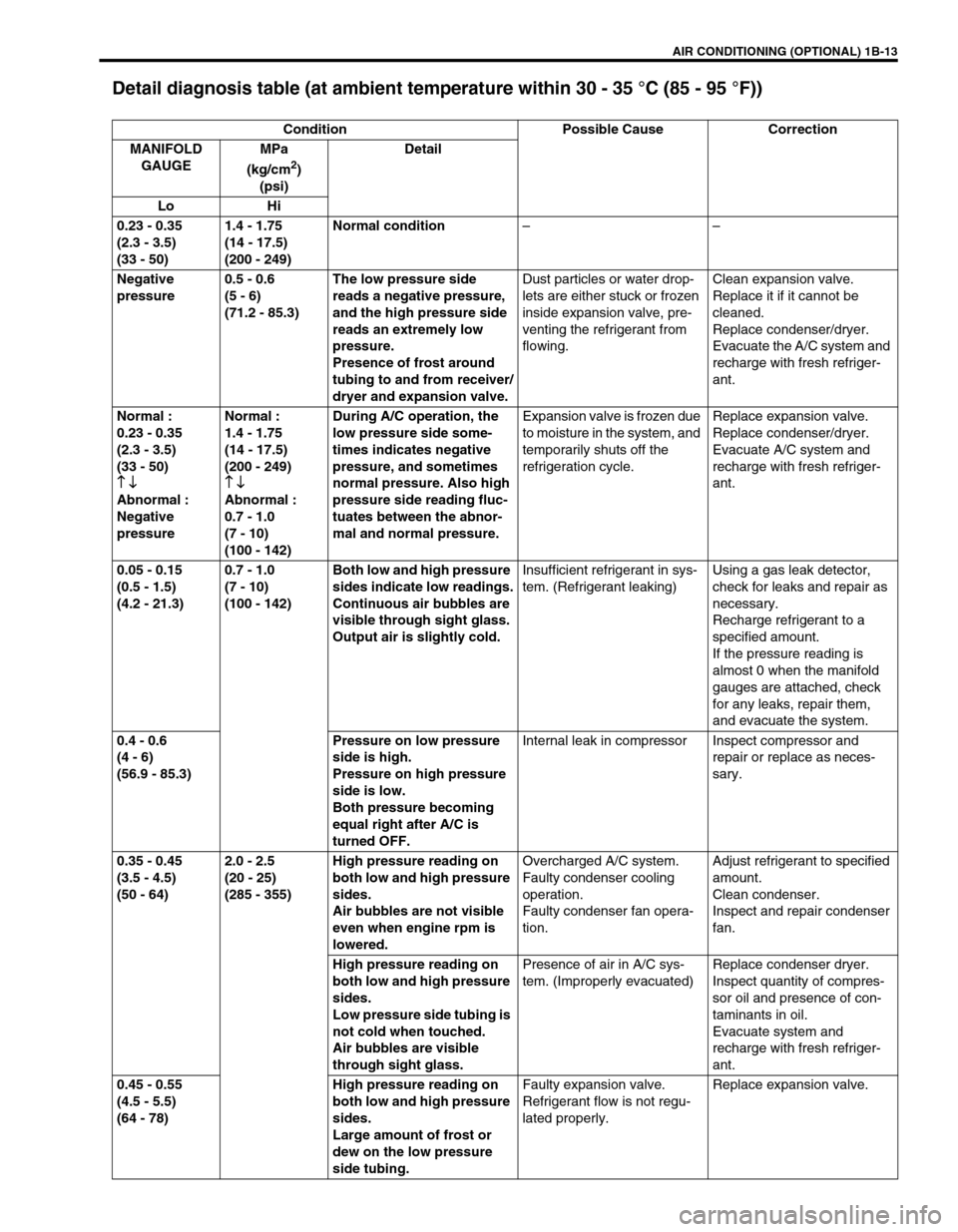

AIR CONDITIONING (OPTIONAL) 1B-13

Detail diagnosis table (at ambient temperature within 30 - 35 °C (85 - 95 °F))

Condition Possible Cause Correction

MANIFOLD

GAUGEMPa

(kg/cm

2)

(psi)Detail

Lo Hi

0.23 - 0.35

(2.3 - 3.5)

(33 - 50)1.4 - 1.75

(14 - 17.5)

(200 - 249)Normal condition––

Negative

pressure0.5 - 0.6

(5 - 6)

(71.2 - 85.3)The low pressure side

reads a negative pressure,

and the high pressure side

reads an extremely low

pressure.

Presence of frost around

tubing to and from receiver/

dryer and expansion valve.Dust particles or water drop-

lets are either stuck or frozen

inside expansion valve, pre-

venting the refrigerant from

flowing.Clean expansion valve.

Replace it if it cannot be

cleaned.

Replace condenser/dryer.

Evacuate the A/C system and

recharge with fresh refriger-

ant.

Normal :

0.23 - 0.35

(2.3 - 3.5)

(33 - 50)

↑ ↓

↑ ↓↑ ↓ ↑ ↓

Abnormal :

Negative

pressureNormal :

1.4 - 1.75

(14 - 17.5)

(200 - 249)

↑ ↓

↑ ↓↑ ↓ ↑ ↓

Abnormal :

0.7 - 1.0

(7 - 10)

(100 - 142)During A/C operation, the

low pressure side some-

times indicates negative

pressure, and sometimes

normal pressure. Also high

pressure side reading fluc-

tuates between the abnor-

mal and normal pressure.Expansion valve is frozen due

to moisture in the system, and

temporarily shuts off the

refrigeration cycle.Replace expansion valve.

Replace condenser/dryer.

Evacuate A/C system and

recharge with fresh refriger-

ant.

0.05 - 0.15

(0.5 - 1.5)

(4.2 - 21.3)0.7 - 1.0

(7 - 10)

(100 - 142)Both low and high pressure

sides indicate low readings.

Continuous air bubbles are

visible through sight glass.

Output air is slightly cold.Insufficient refrigerant in sys-

tem. (Refrigerant leaking)Using a gas leak detector,

check for leaks and repair as

necessary.

Recharge refrigerant to a

specified amount.

If the pressure reading is

almost 0 when the manifold

gauges are attached, check

for any leaks, repair them,

and evacuate the system.

0.4 - 0.6

(4 - 6)

(56.9 - 85.3)Pressure on low pressure

side is high.

Pressure on high pressure

side is low.

Both pressure becoming

equal right after A/C is

turned OFF.Internal leak in compressor Inspect compressor and

repair or replace as neces-

sary.

0.35 - 0.45

(3.5 - 4.5)

(50 - 64)2.0 - 2.5

(20 - 25)

(285 - 355)High pressure reading on

both low and high pressure

sides.

Air bubbles are not visible

even when engine rpm is

lowered.Overcharged A/C system.

Faulty condenser cooling

operation.

Faulty condenser fan opera-

tion.Adjust refrigerant to specified

amount.

Clean condenser.

Inspect and repair condenser

fan.

High pressure reading on

both low and high pressure

sides.

Low pressure side tubing is

not cold when touched.

Air bubbles are visible

through sight glass.Presence of air in A/C sys-

tem. (Improperly evacuated)Replace condenser dryer.

Inspect quantity of compres-

sor oil and presence of con-

taminants in oil.

Evacuate system and

recharge with fresh refriger-

ant.

0.45 - 0.55

(4.5 - 5.5)

(64 - 78)High pressure reading on

both low and high pressure

sides.

Large amount of frost or

dew on the low pressure

side tubing.Faulty expansion valve.

Refrigerant flow is not regu-

lated properly.Replace expansion valve.

Page 42 of 656

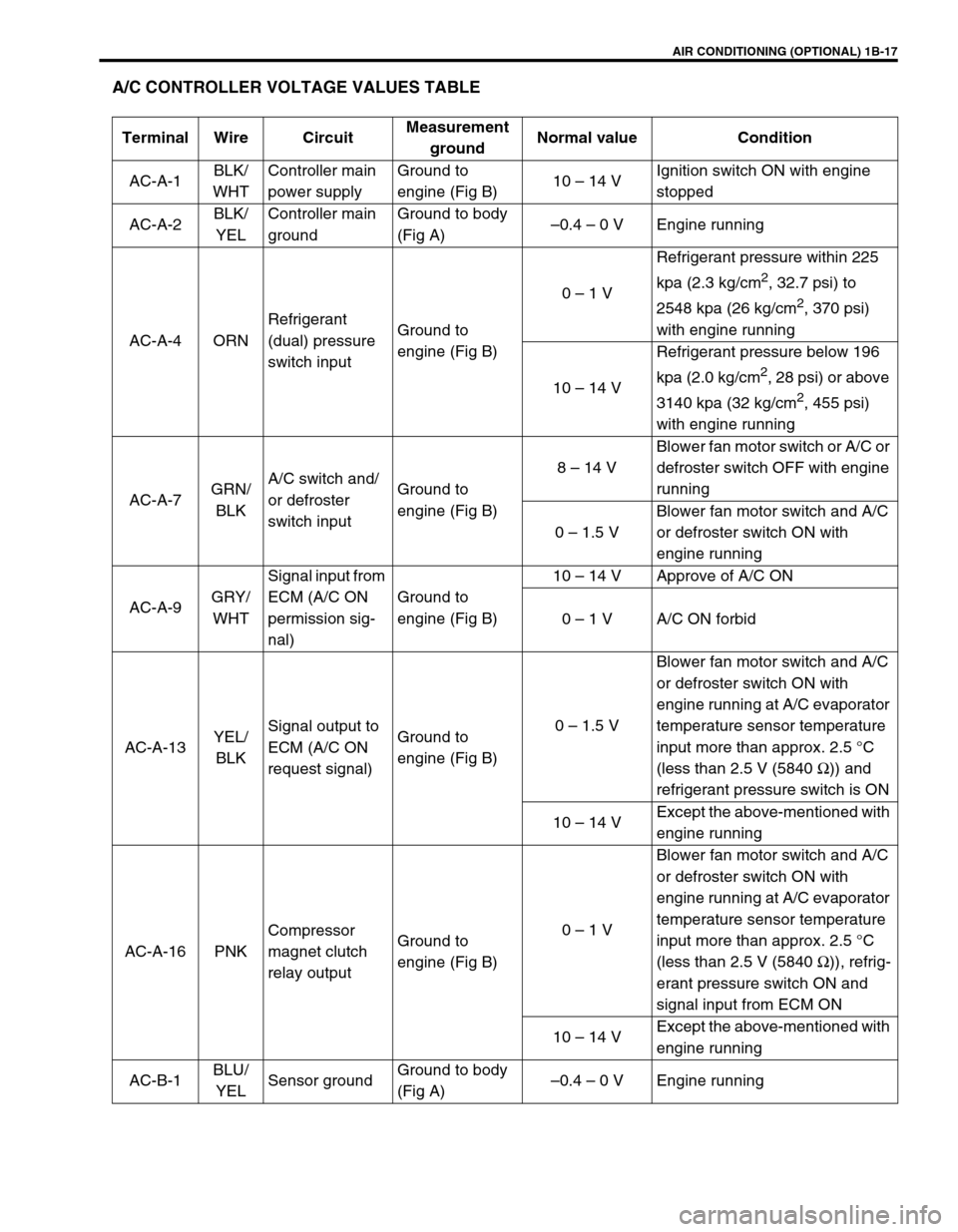

AIR CONDITIONING (OPTIONAL) 1B-17

A/C CONTROLLER VOLTAGE VALUES TABLE

Terminal Wire CircuitMeasurement

groundNormal value Condition

AC-A-1BLK/

WHTController main

power supplyGround to

engine (Fig B)10 – 14 VIgnition switch ON with engine

stopped

AC-A-2BLK/

YELController main

groundGround to body

(Fig A)–0.4 – 0 V Engine running

AC-A-4 ORNRefrigerant

(dual) pressure

switch inputGround to

engine (Fig B)0 – 1 VRefrigerant pressure within 225

kpa (2.3 kg/cm

2, 32.7 psi) to

2548 kpa (26 kg/cm

2, 370 psi)

with engine running

10 – 14 VRefrigerant pressure below 196

kpa (2.0 kg/cm

2, 28 psi) or above

3140 kpa (32 kg/cm

2, 455 psi)

with engine running

AC-A-7GRN/

BLKA/C switch and/

or defroster

switch inputGround to

engine (Fig B)8 – 14 VBlower fan motor switch or A/C or

defroster switch OFF with engine

running

0 – 1.5 VBlower fan motor switch and A/C

or defroster switch ON with

engine running

AC-A-9GRY/

WHTSignal input from

ECM (A/C ON

permission sig-

nal)Ground to

engine (Fig B)10 – 14 V Approve of A/C ON

0 – 1 V A/C ON forbid

AC-A-13YEL/

BLKSignal output to

ECM (A/C ON

request signal)Ground to

engine (Fig B)0 – 1.5 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)) and

refrigerant pressure switch is ON

10 – 14 VExcept the above-mentioned with

engine running

AC-A-16 PNKCompressor

magnet clutch

relay outputGround to

engine (Fig B)0 – 1 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)), refrig-

erant pressure switch ON and

signal input from ECM ON

10 – 14 VExcept the above-mentioned with

engine running

AC-B-1BLU/

YELSensor groundGround to body

(Fig A)–0.4 – 0 V Engine running

Page 43 of 656

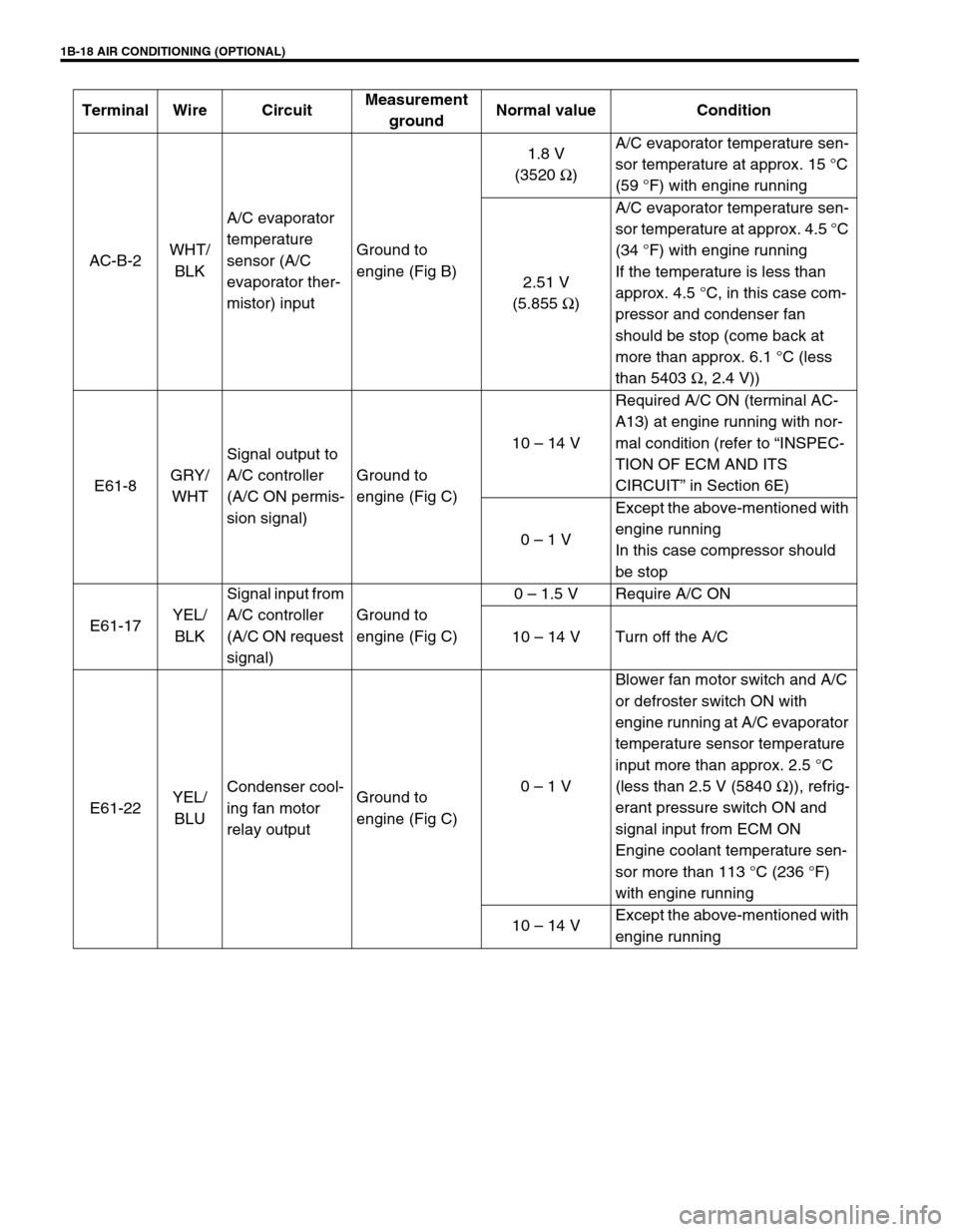

1B-18 AIR CONDITIONING (OPTIONAL)

Terminal Wire CircuitMeasurement

groundNormal value Condition

AC-B-2WHT/

BLKA/C evaporator

temperature

sensor (A/C

evaporator ther-

mistor) inputGround to

engine (Fig B)1.8 V

(3520 Ω)A/C evaporator temperature sen-

sor temperature at approx. 15 °C

(59 °F) with engine running

2.51 V

(5.855 Ω)A/C evaporator temperature sen-

sor temperature at approx. 4.5 °C

(34 °F) with engine running

If the temperature is less than

approx. 4.5 °C, in this case com-

pressor and condenser fan

should be stop (come back at

more than approx. 6.1 °C (less

than 5403 Ω, 2.4 V))

E61-8GRY/

WHTSignal output to

A/C controller

(A/C ON permis-

sion signal)Ground to

engine (Fig C)10 – 14 VRequired A/C ON (terminal AC-

A13) at engine running with nor-

mal condition (refer to “INSPEC-

TION OF ECM AND ITS

CIRCUIT” in Section 6E)

0 – 1 VExcept the above-mentioned with

engine running

In this case compressor should

be stop

E61-17YEL/

BLKSignal input from

A/C controller

(A/C ON request

signal)Ground to

engine (Fig C)0 – 1.5 V Require A/C ON

10 – 14 V Turn off the A/C

E61-22YEL/

BLUCondenser cool-

ing fan motor

relay outputGround to

engine (Fig C)0 – 1 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)), refrig-

erant pressure switch ON and

signal input from ECM ON

Engine coolant temperature sen-

sor more than 113 °C (236 °F)

with engine running

10 – 14 VExcept the above-mentioned with

engine running

Page 47 of 656

1B-22 AIR CONDITIONING (OPTIONAL)

Checking system for pressure leaks

After completing the evacuation, close manifold gauge high pres-

sure valve (HI) and low-pressure valve (LO) and wait 10 minutes.

Verify that low-pressure gauge reading has not changed.

Charging

CAUTION:

If the gauge reading moves closer to “0”, there is a leak

somewhere. Inspect the tubing connections, make nec-

essary corrections, and evacuate system once again,

making sure that there are no leaks.

CAUTION:

ALWAYS CHARGE THROUGH LOW PRESSURE-SIDE of A/C system at after the initial charging is

performed from the high-pressure side with the engine stopped.

NEVER CHARGE TO HIGH PRESSURE-SIDE of A/C system with engine running.

Do not charge while compressor is hot.

When installing tap valve to refrigerant container to make a hole there through, carefully follow

directions given by manufacturer.

A pressure gauge should always be used before and during charging.

The refrigerant container should be emptied of refrigerant when discarding it.

The refrigerant container should not be heated up to 40 °C (104 °F) or over.

Refrigerant container should not be reversed in direction during charging. Reversing in direction

causes liquid refrigerant to enter compressor, causing troubles, such as compression of liquid

refrigerant and the like.

NOTE:

The air conditioning system contains HFC-134a (R-134a).

Described here is a method to charge the air conditioning system with refrigerant from the refrigerant

service container.

When charging refrigerant recovered by using the refrigerant and recycling equipment (when recy-

cling refrigerant), follow the procedure described in the equipment manufacturer’s instruction manual.

Page 48 of 656

AIR CONDITIONING (OPTIONAL) 1B-23

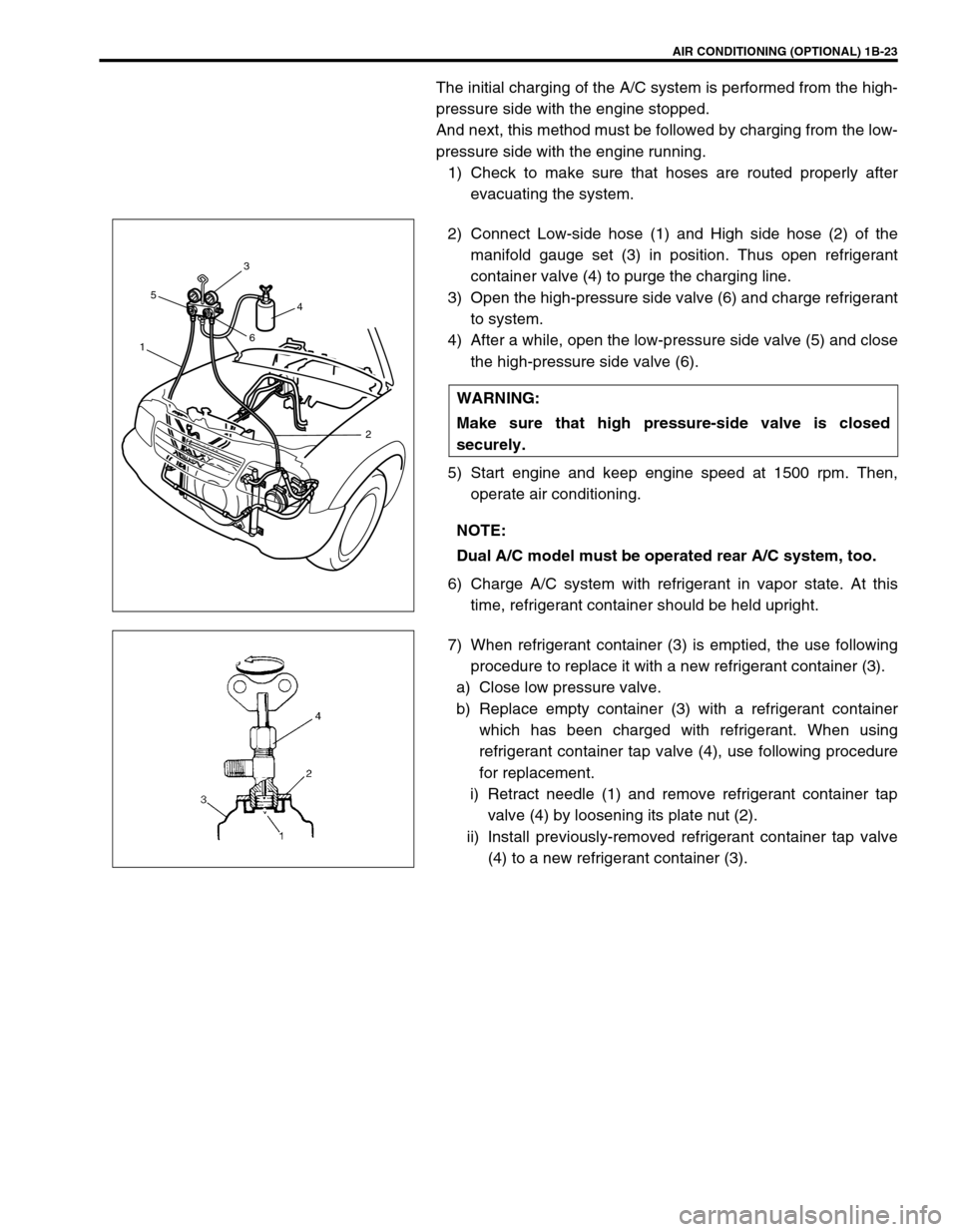

The initial charging of the A/C system is performed from the high-

pressure side with the engine stopped.

And next, this method must be followed by charging from the low-

pressure side with the engine running.

1) Check to make sure that hoses are routed properly after

evacuating the system.

2) Connect Low-side hose (1) and High side hose (2) of the

manifold gauge set (3) in position. Thus open refrigerant

container valve (4) to purge the charging line.

3) Open the high-pressure side valve (6) and charge refrigerant

to system.

4) After a while, open the low-pressure side valve (5) and close

the high-pressure side valve (6).

5) Start engine and keep engine speed at 1500 rpm. Then,

operate air conditioning.

6) Charge A/C system with refrigerant in vapor state. At this

time, refrigerant container should be held upright.

7) When refrigerant container (3) is emptied, the use following

procedure to replace it with a new refrigerant container (3).

a) Close low pressure valve.

b) Replace empty container (3) with a refrigerant container

which has been charged with refrigerant. When using

refrigerant container tap valve (4), use following procedure

for replacement.

i) Retract needle (1) and remove refrigerant container tap

valve (4) by loosening its plate nut (2).

ii) Install previously-removed refrigerant container tap valve

(4) to a new refrigerant container (3). WARNING:

Make sure that high pressure-side valve is closed

securely.

NOTE:

Dual A/C model must be operated rear A/C system, too.

153

64

2

Page 50 of 656

AIR CONDITIONING (OPTIONAL) 1B-25

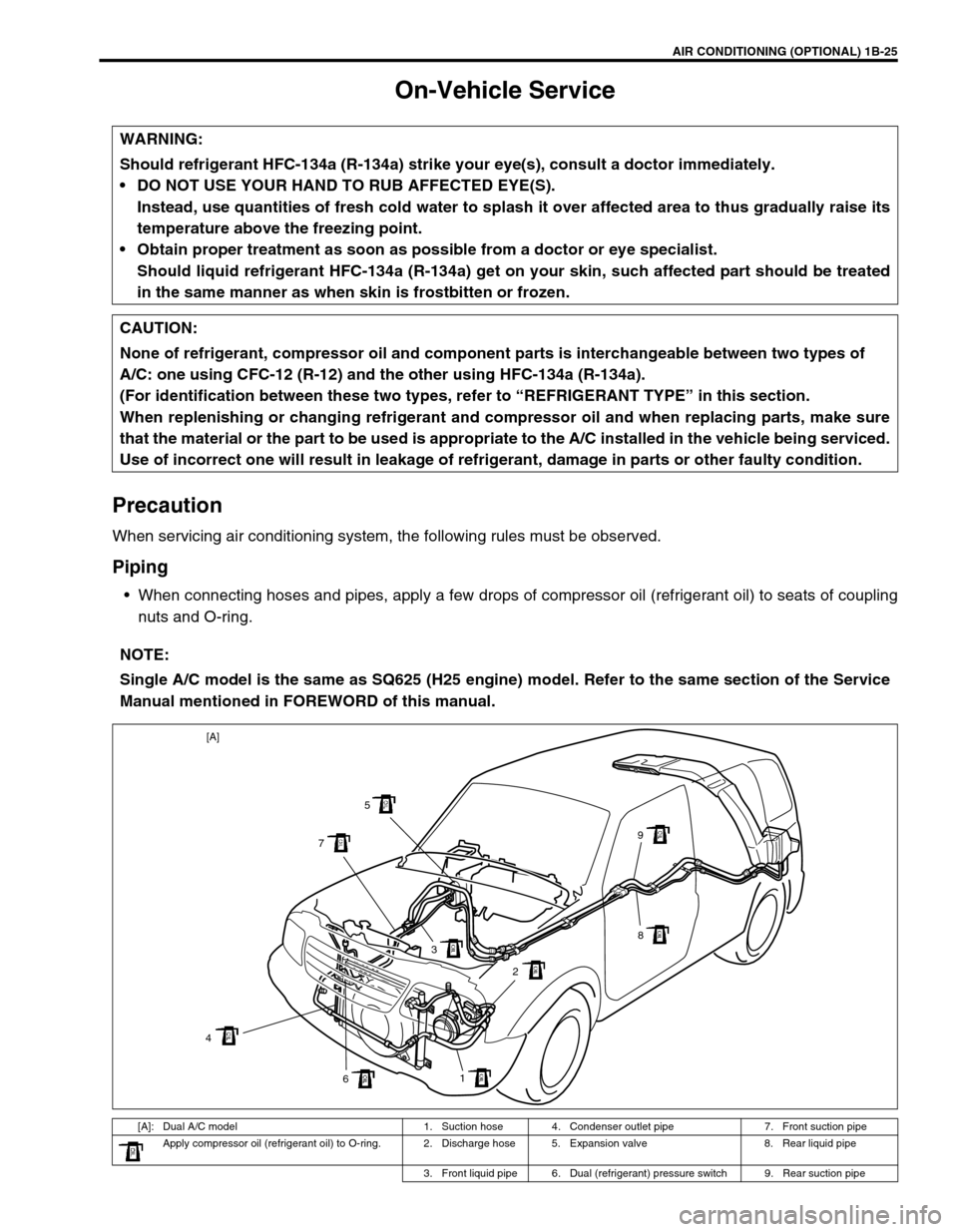

On-Vehicle Service

Precaution

When servicing air conditioning system, the following rules must be observed.

Piping

When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to seats of coupling

nuts and O-ring. WARNING:

Should refrigerant HFC-134a (R-134a) strike your eye(s), consult a doctor immediately.

DO NOT USE YOUR HAND TO RUB AFFECTED EYE(S).

Instead, use quantities of fresh cold water to splash it over affected area to thus gradually raise its

temperature above the freezing point.

Obtain proper treatment as soon as possible from a doctor or eye specialist.

Should liquid refrigerant HFC-134a (R-134a) get on your skin, such affected part should be treated

in the same manner as when skin is frostbitten or frozen.

CAUTION:

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using CFC-12 (R-12) and the other using HFC-134a (R-134a).

(For identification between these two types, refer to “REFRIGERANT TYPE” in this section.

When replenishing or changing refrigerant and compressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

NOTE:

Single A/C model is the same as SQ625 (H25 engine) model. Refer to the same section of the Service

Manual mentioned in FOREWORD of this manual.

[A]: Dual A/C model 1. Suction hose 4. Condenser outlet pipe 7. Front suction pipe

Apply compressor oil (refrigerant oil) to O-ring. 2. Discharge hose 5. Expansion valve 8. Rear liquid pipe

3. Front liquid pipe 6. Dual (refrigerant) pressure switch 9. Rear suction pipe

1

6 43 75

9

8

2 [A]