torque SUZUKI GRAND VITARA 2001 2.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 77 of 656

3C1-2 AIR BAG STEERING WHEEL AND COLUMN

General Description

This double tube type steering column has the following three important features in addition to the steering func-

tion:

The column is energy absorbing, designed to compress in a front-end collision.

The ignition switch and lock are mounted conveniently on this column.

With the column mounted lock, the ignition and steering operations can be locked to inhibit theft of the vehi-

cle.

To insure the energy absorbing action, it is important that only the specified screws, bolts, and nuts be used as

designated and that they are tightened to the specified torque. When the column assembly is removed from the

vehicle, special care must be taken in handling it. Use of a steering wheel puller other than the one recom-

mended in this manual or a sharp blow on the end of the steering shaft, leaning on the assembly, or dropping

the assembly could shear the plastic shear pins which maintain column length and position.

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is

mounted to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the

restraint of the driver’s and passenger’s seat belts by deploying the air bags. The air bag (inflator) module

should be handled with care to prevent accidental deployment. When servicing, be sure to observe all WARN-

INGS in this section. Refer to “SERVICE PRECAUTIONS” in Section 10B.

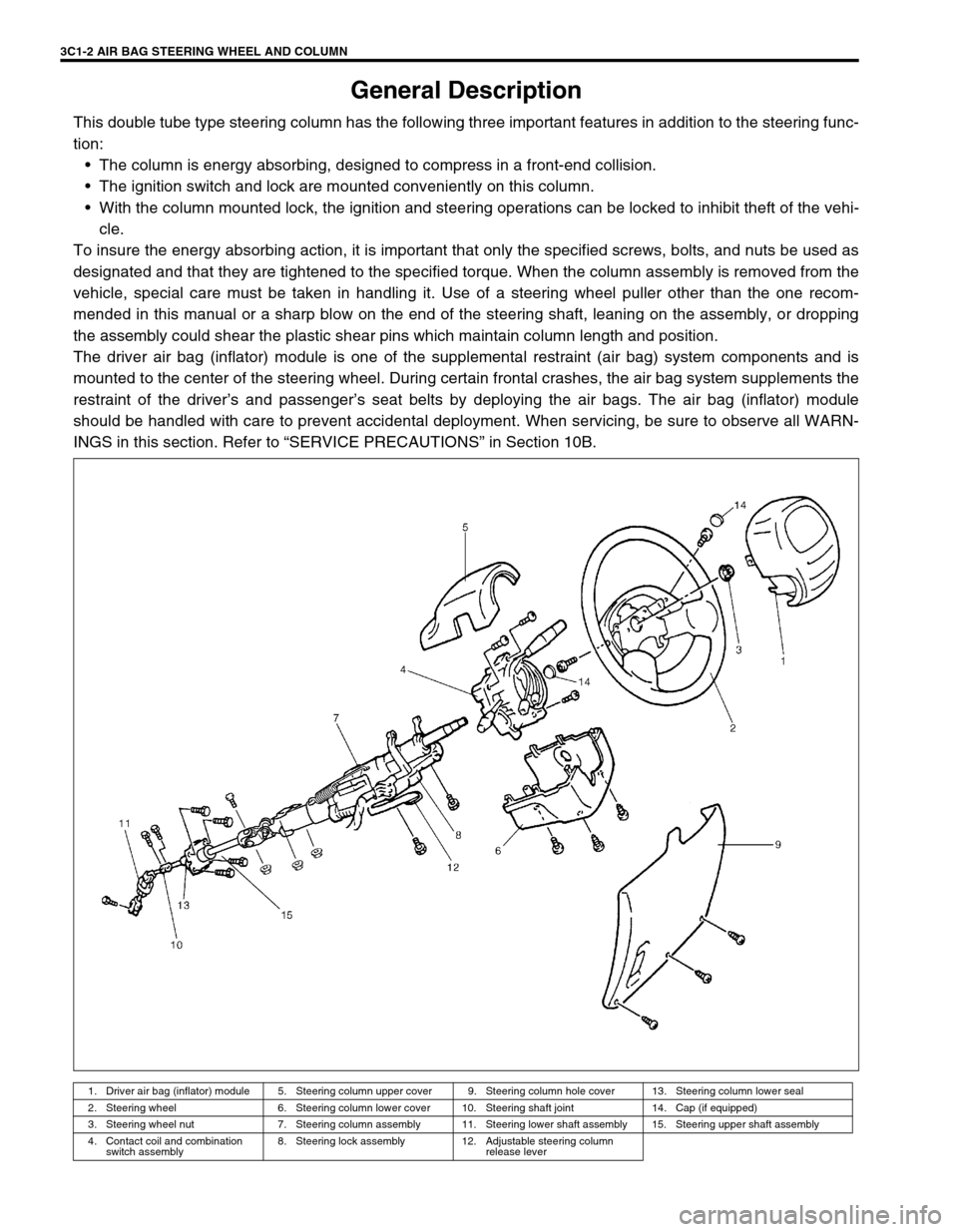

1. Driver air bag (inflator) module 5. Steering column upper cover 9. Steering column hole cover 13. Steering column lower seal

2. Steering wheel 6. Steering column lower cover 10. Steering shaft joint 14. Cap (if equipped)

3. Steering wheel nut 7. Steering column assembly 11. Steering lower shaft assembly 15. Steering upper shaft assembly

4. Contact coil and combination

switch assembly8. Steering lock assembly 12. Adjustable steering column

release lever

Page 80 of 656

AIR BAG STEERING WHEEL AND COLUMN 3C1-5

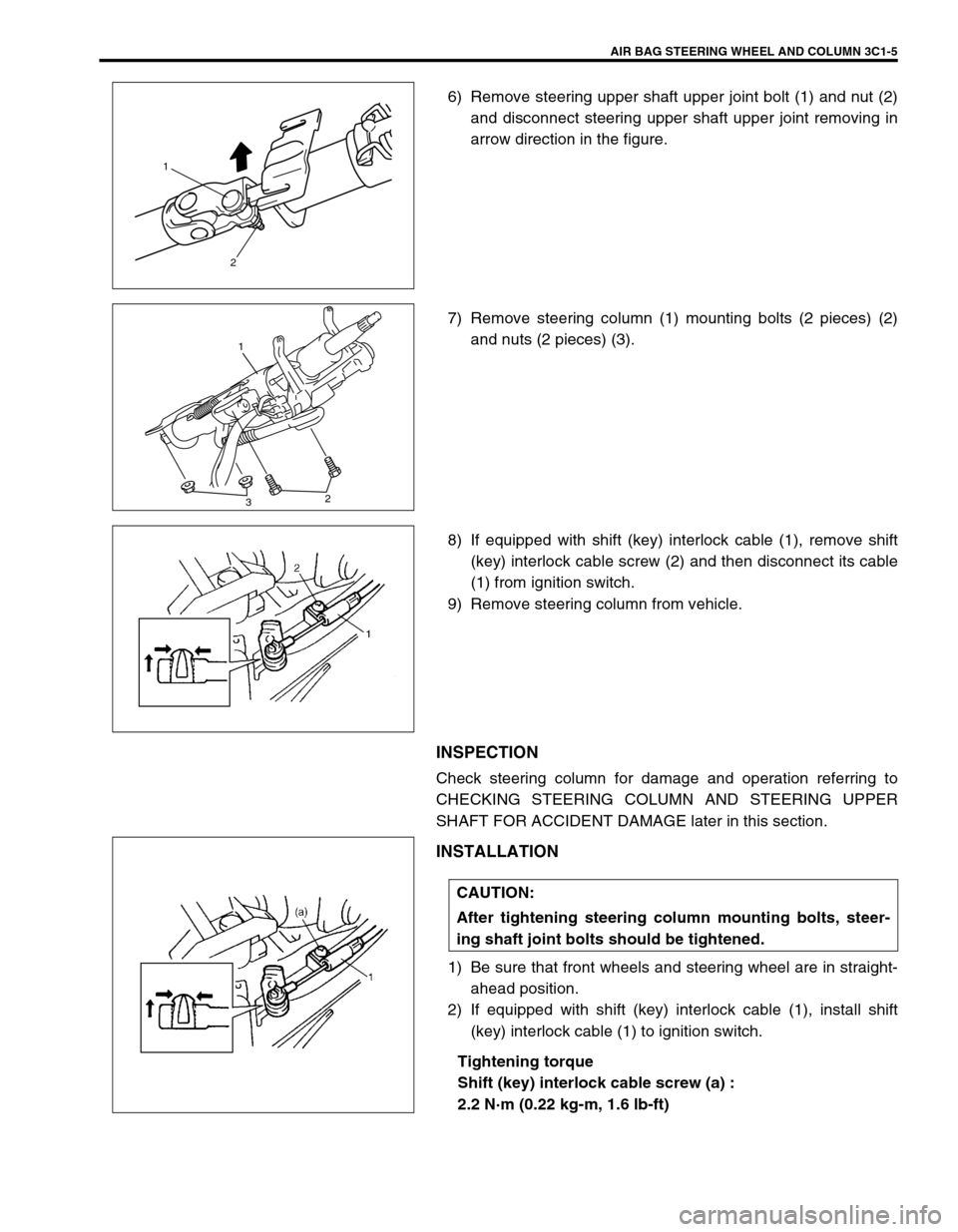

6) Remove steering upper shaft upper joint bolt (1) and nut (2)

and disconnect steering upper shaft upper joint removing in

arrow direction in the figure.

7) Remove steering column (1) mounting bolts (2 pieces) (2)

and nuts (2 pieces) (3).

8) If equipped with shift (key) interlock cable (1), remove shift

(key) interlock cable screw (2) and then disconnect its cable

(1) from ignition switch.

9) Remove steering column from vehicle.

INSPECTION

Check steering column for damage and operation referring to

CHECKING STEERING COLUMN AND STEERING UPPER

SHAFT FOR ACCIDENT DAMAGE later in this section.

INSTALLATION

1) Be sure that front wheels and steering wheel are in straight-

ahead position.

2) If equipped with shift (key) interlock cable (1), install shift

(key) interlock cable (1) to ignition switch.

Tightening torque

Shift (key) interlock cable screw (a) :

2.2 N·m (0.22 kg-m, 1.6 lb-ft)

1

2

1

32

CAUTION:

After tightening steering column mounting bolts, steer-

ing shaft joint bolts should be tightened.

Page 81 of 656

3C1-6 AIR BAG STEERING WHEEL AND COLUMN

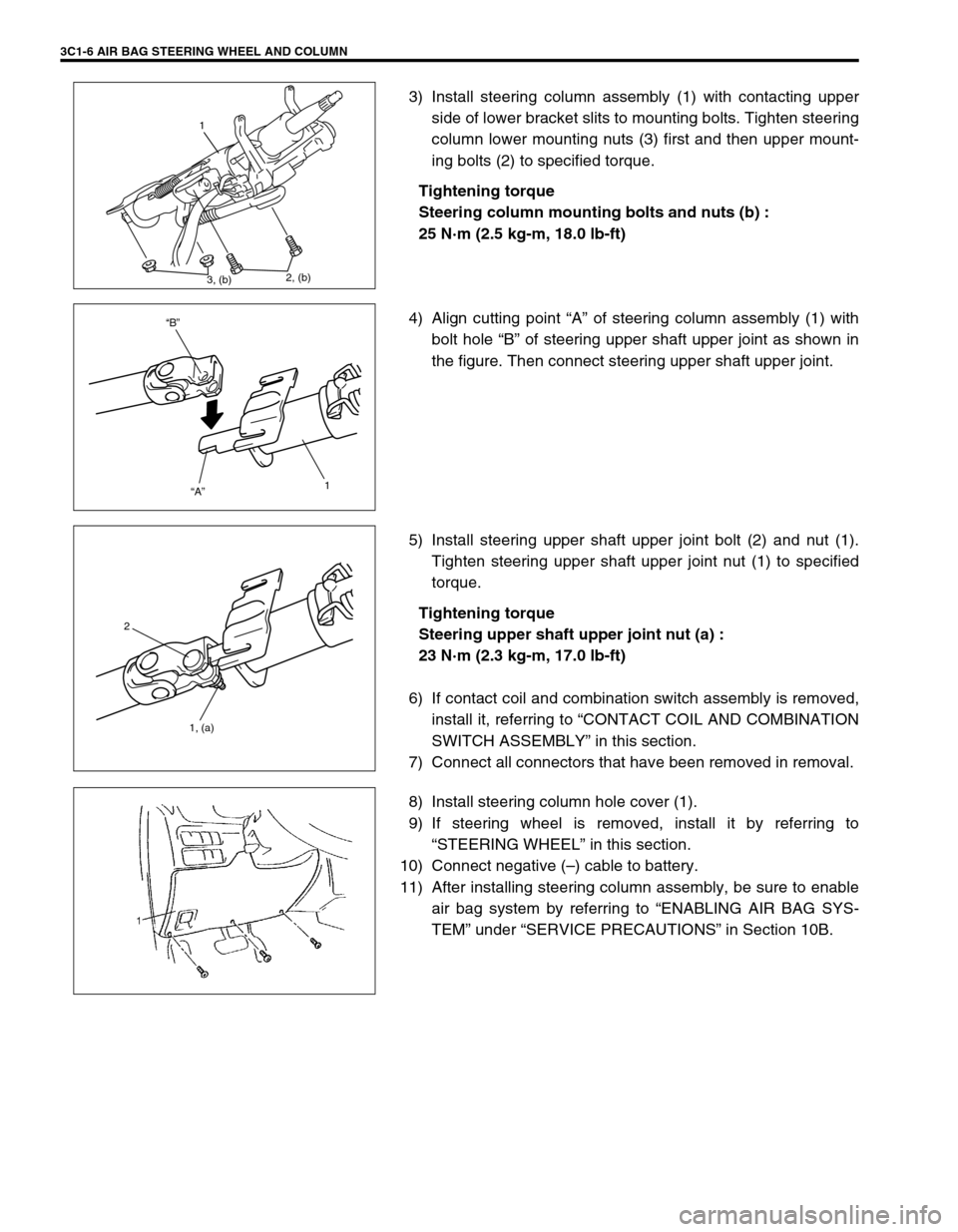

3) Install steering column assembly (1) with contacting upper

side of lower bracket slits to mounting bolts. Tighten steering

column lower mounting nuts (3) first and then upper mount-

ing bolts (2) to specified torque.

Tightening torque

Steering column mounting bolts and nuts (b) :

25 N·m (2.5 kg-m, 18.0 lb-ft)

4) Align cutting point “A” of steering column assembly (1) with

bolt hole “B” of steering upper shaft upper joint as shown in

the figure. Then connect steering upper shaft upper joint.

5) Install steering upper shaft upper joint bolt (2) and nut (1).

Tighten steering upper shaft upper joint nut (1) to specified

torque.

Tightening torque

Steering upper shaft upper joint nut (a) :

23 N·m (2.3 kg-m, 17.0 lb-ft)

6) If contact coil and combination switch assembly is removed,

install it, referring to “CONTACT COIL AND COMBINATION

SWITCH ASSEMBLY” in this section.

7) Connect all connectors that have been removed in removal.

8) Install steering column hole cover (1).

9) If steering wheel is removed, install it by referring to

“STEERING WHEEL” in this section.

10) Connect negative (–) cable to battery.

11) After installing steering column assembly, be sure to enable

air bag system by referring to “ENABLING AIR BAG SYS-

TEM” under “SERVICE PRECAUTIONS” in Section 10B.

1

3, (b)2, (b)

“B”

“A”

1

2

1, (a)

Page 83 of 656

3C1-8 AIR BAG STEERING WHEEL AND COLUMN

INSPECTION

Check steering shaft damage and operation referring to CHECK

STEERING COLUMN AND STEERING UPPER SHAFT FOR

ACCIDENT DAMAGE later in this section.

INSTALLATION

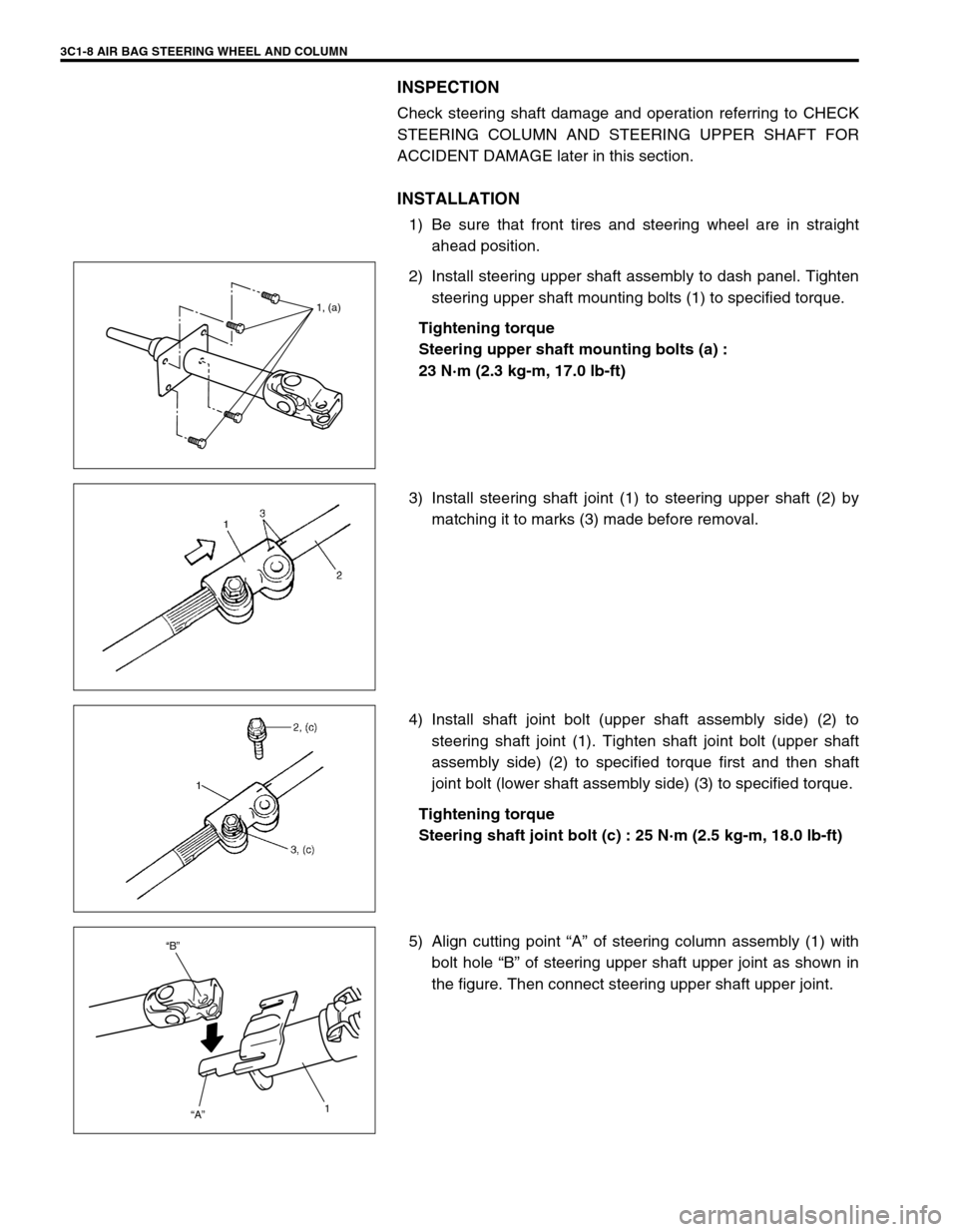

1) Be sure that front tires and steering wheel are in straight

ahead position.

2) Install steering upper shaft assembly to dash panel. Tighten

steering upper shaft mounting bolts (1) to specified torque.

Tightening torque

Steering upper shaft mounting bolts (a) :

23 N·m (2.3 kg-m, 17.0 lb-ft)

3) Install steering shaft joint (1) to steering upper shaft (2) by

matching it to marks (3) made before removal.

4) Install shaft joint bolt (upper shaft assembly side) (2) to

steering shaft joint (1). Tighten shaft joint bolt (upper shaft

assembly side) (2) to specified torque first and then shaft

joint bolt (lower shaft assembly side) (3) to specified torque.

Tightening torque

Steering shaft joint bolt (c) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

5) Align cutting point “A” of steering column assembly (1) with

bolt hole “B” of steering upper shaft upper joint as shown in

the figure. Then connect steering upper shaft upper joint.

1, (a)

“B”

“A”

1

Page 84 of 656

AIR BAG STEERING WHEEL AND COLUMN 3C1-9

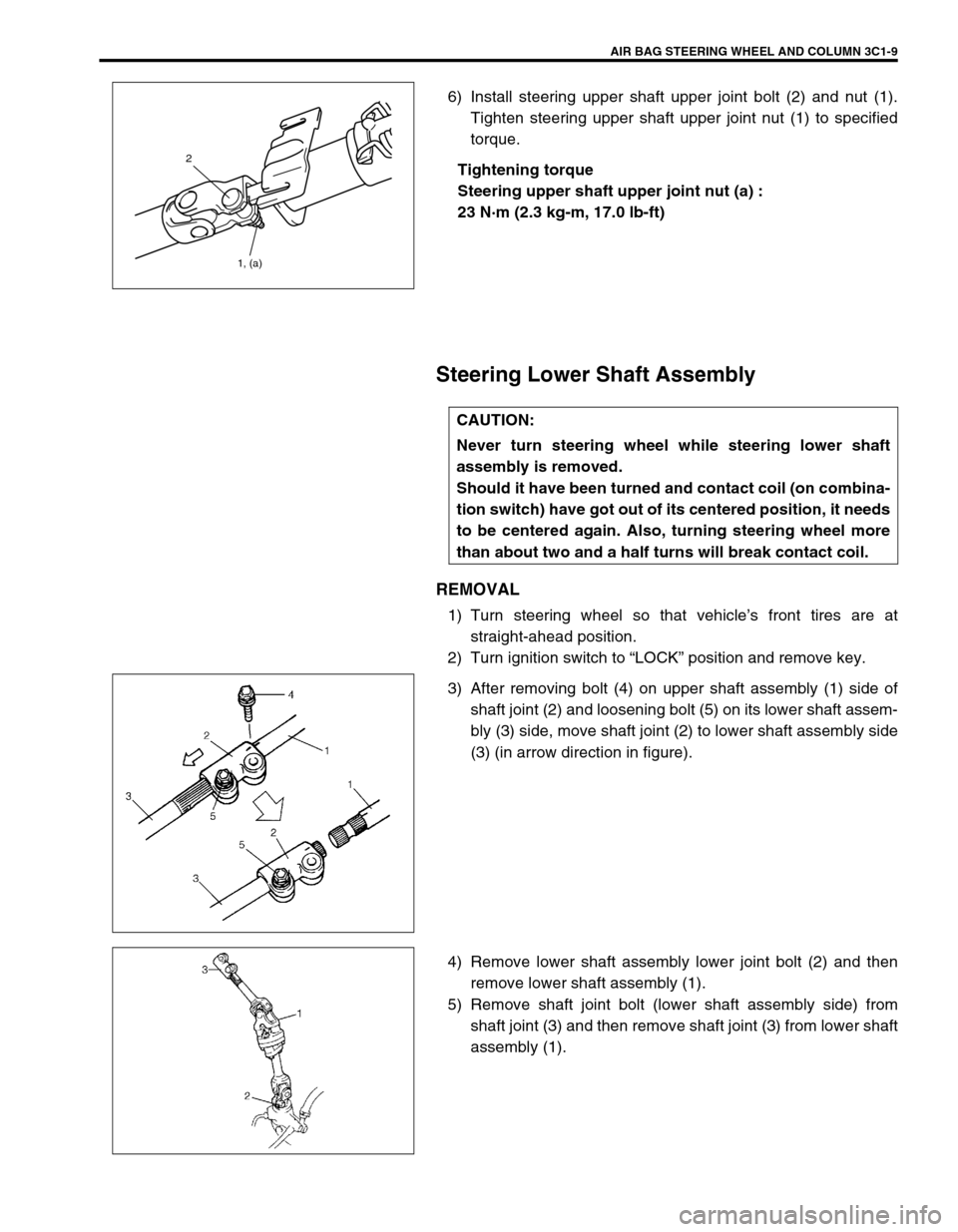

6) Install steering upper shaft upper joint bolt (2) and nut (1).

Tighten steering upper shaft upper joint nut (1) to specified

torque.

Tightening torque

Steering upper shaft upper joint nut (a) :

23 N·m (2.3 kg-m, 17.0 lb-ft)

Steering Lower Shaft Assembly

REMOVAL

1) Turn steering wheel so that vehicle’s front tires are at

straight-ahead position.

2) Turn ignition switch to “LOCK” position and remove key.

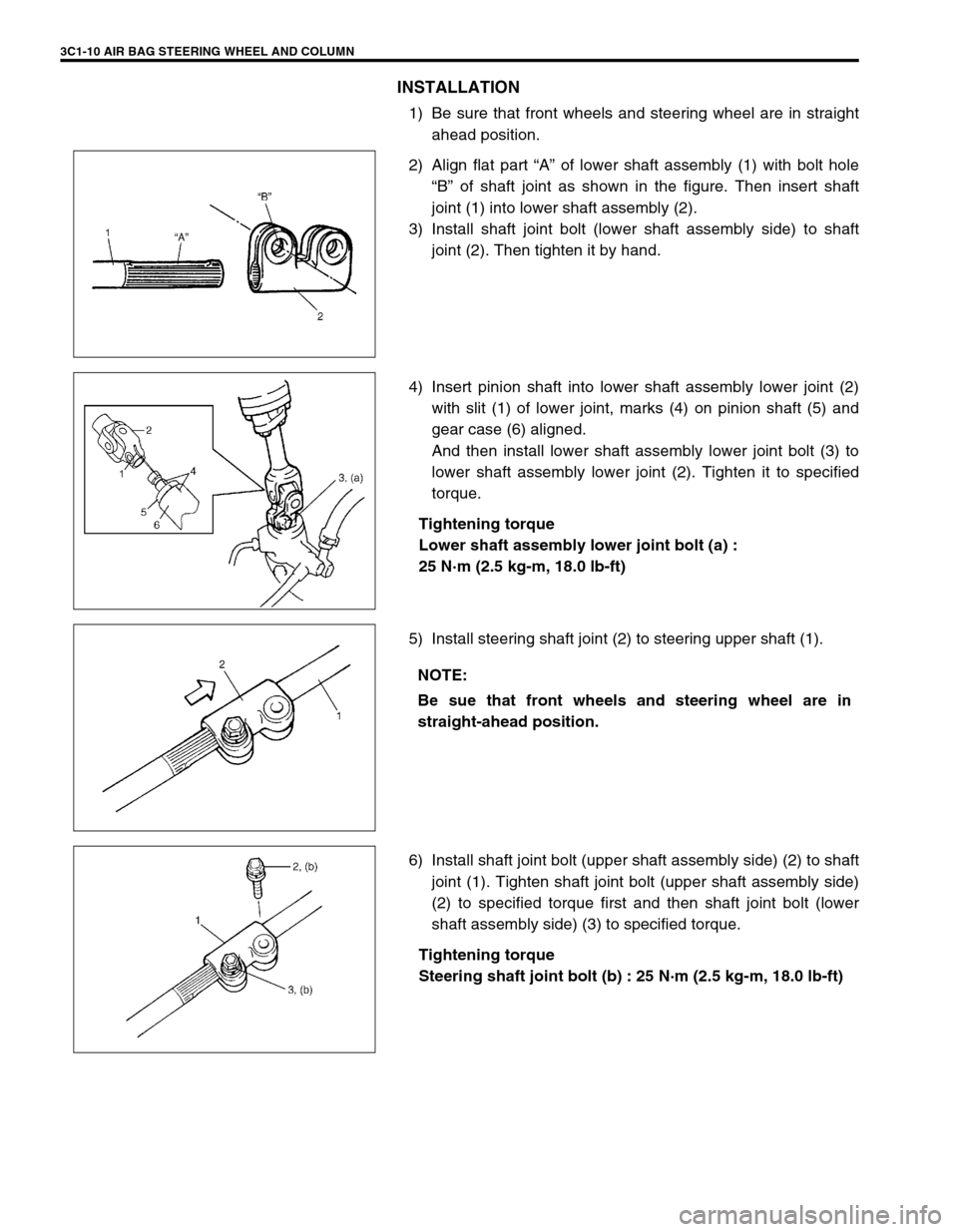

3) After removing bolt (4) on upper shaft assembly (1) side of

shaft joint (2) and loosening bolt (5) on its lower shaft assem-

bly (3) side, move shaft joint (2) to lower shaft assembly side

(3) (in arrow direction in figure).

4) Remove lower shaft assembly lower joint bolt (2) and then

remove lower shaft assembly (1).

5) Remove shaft joint bolt (lower shaft assembly side) from

shaft joint (3) and then remove shaft joint (3) from lower shaft

assembly (1).

1, (a) 2

CAUTION:

Never turn steering wheel while steering lower shaft

assembly is removed.

Should it have been turned and contact coil (on combina-

tion switch) have got out of its centered position, it needs

to be centered again. Also, turning steering wheel more

than about two and a half turns will break contact coil.

Page 85 of 656

3C1-10 AIR BAG STEERING WHEEL AND COLUMN

INSTALLATION

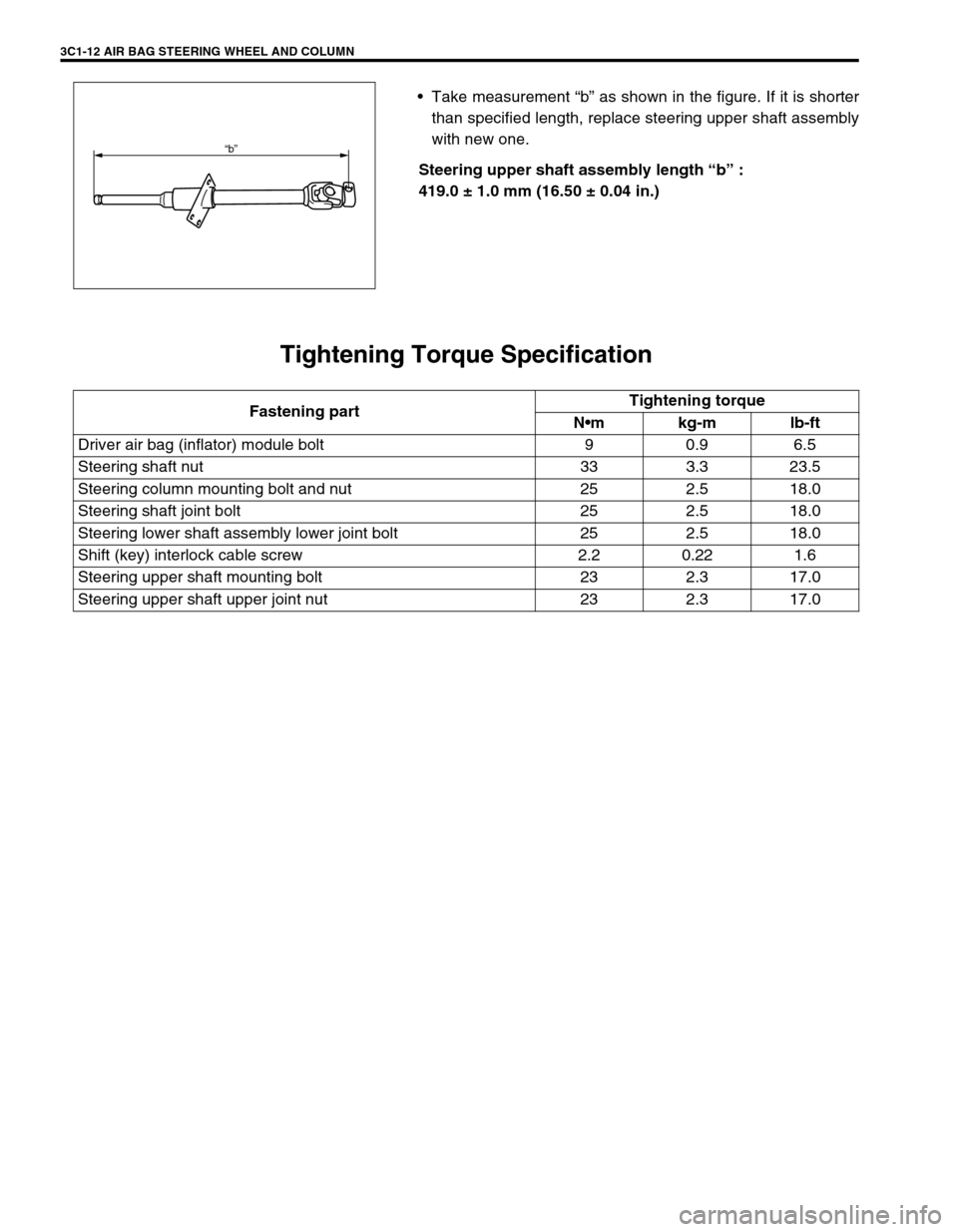

1) Be sure that front wheels and steering wheel are in straight

ahead position.

2) Align flat part “A” of lower shaft assembly (1) with bolt hole

“B” of shaft joint as shown in the figure. Then insert shaft

joint (1) into lower shaft assembly (2).

3) Install shaft joint bolt (lower shaft assembly side) to shaft

joint (2). Then tighten it by hand.

4) Insert pinion shaft into lower shaft assembly lower joint (2)

with slit (1) of lower joint, marks (4) on pinion shaft (5) and

gear case (6) aligned.

And then install lower shaft assembly lower joint bolt (3) to

lower shaft assembly lower joint (2). Tighten it to specified

torque.

Tightening torque

Lower shaft assembly lower joint bolt (a) :

25 N·m (2.5 kg-m, 18.0 lb-ft)

5) Install steering shaft joint (2) to steering upper shaft (1).

6) Install shaft joint bolt (upper shaft assembly side) (2) to shaft

joint (1). Tighten shaft joint bolt (upper shaft assembly side)

(2) to specified torque first and then shaft joint bolt (lower

shaft assembly side) (3) to specified torque.

Tightening torque

Steering shaft joint bolt (b) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

NOTE:

Be sue that front wheels and steering wheel are in

straight-ahead position.

Page 87 of 656

3C1-12 AIR BAG STEERING WHEEL AND COLUMN

Take measurement “b” as shown in the figure. If it is shorter

than specified length, replace steering upper shaft assembly

with new one.

Steering upper shaft assembly length “b” :

419.0 ± 1.0 mm (16.50 ± 0.04 in.)

Tightening Torque Specification

“b”

Fastening partTightening torque

Nm kg-m lb-ft

Driver air bag (inflator) module bolt 9 0.9 6.5

Steering shaft nut 33 3.3 23.5

Steering column mounting bolt and nut 25 2.5 18.0

Steering shaft joint bolt 25 2.5 18.0

Steering lower shaft assembly lower joint bolt 25 2.5 18.0

Shift (key) interlock cable screw 2.2 0.22 1.6

Steering upper shaft mounting bolt 23 2.3 17.0

Steering upper shaft upper joint nut 23 2.3 17.0

Page 88 of 656

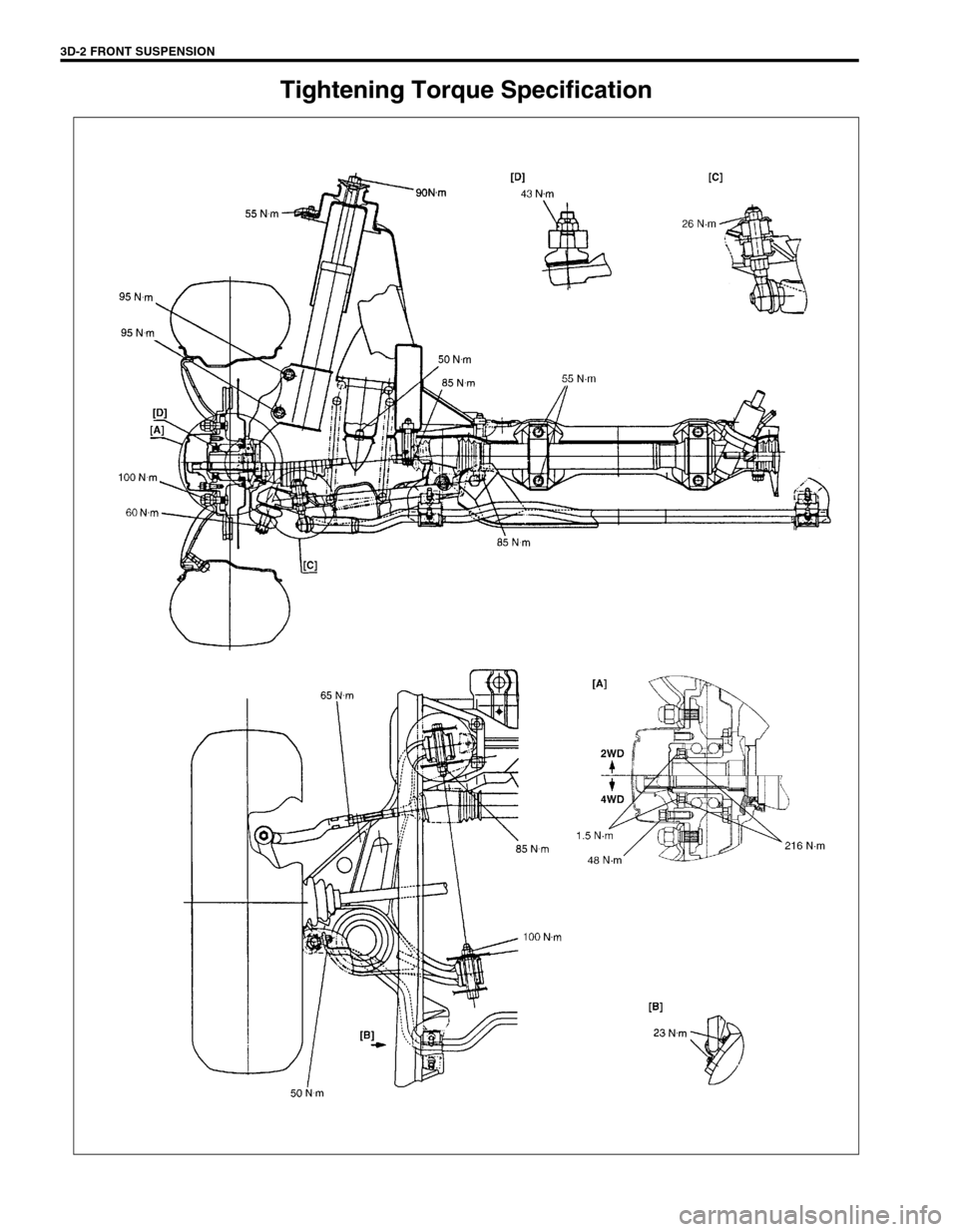

FRONT SUSPENSION 3D-1

3D

SECTION 3D

FRONT SUSPENSION

CONTENTS

On-Vehicle Service......................................... 3D-1

Suspension Control Arm/Bushings .............. 3D-1Tightening Torque Specification .................. 3D-2

On-Vehicle Service

Suspension Control Arm/Bushings

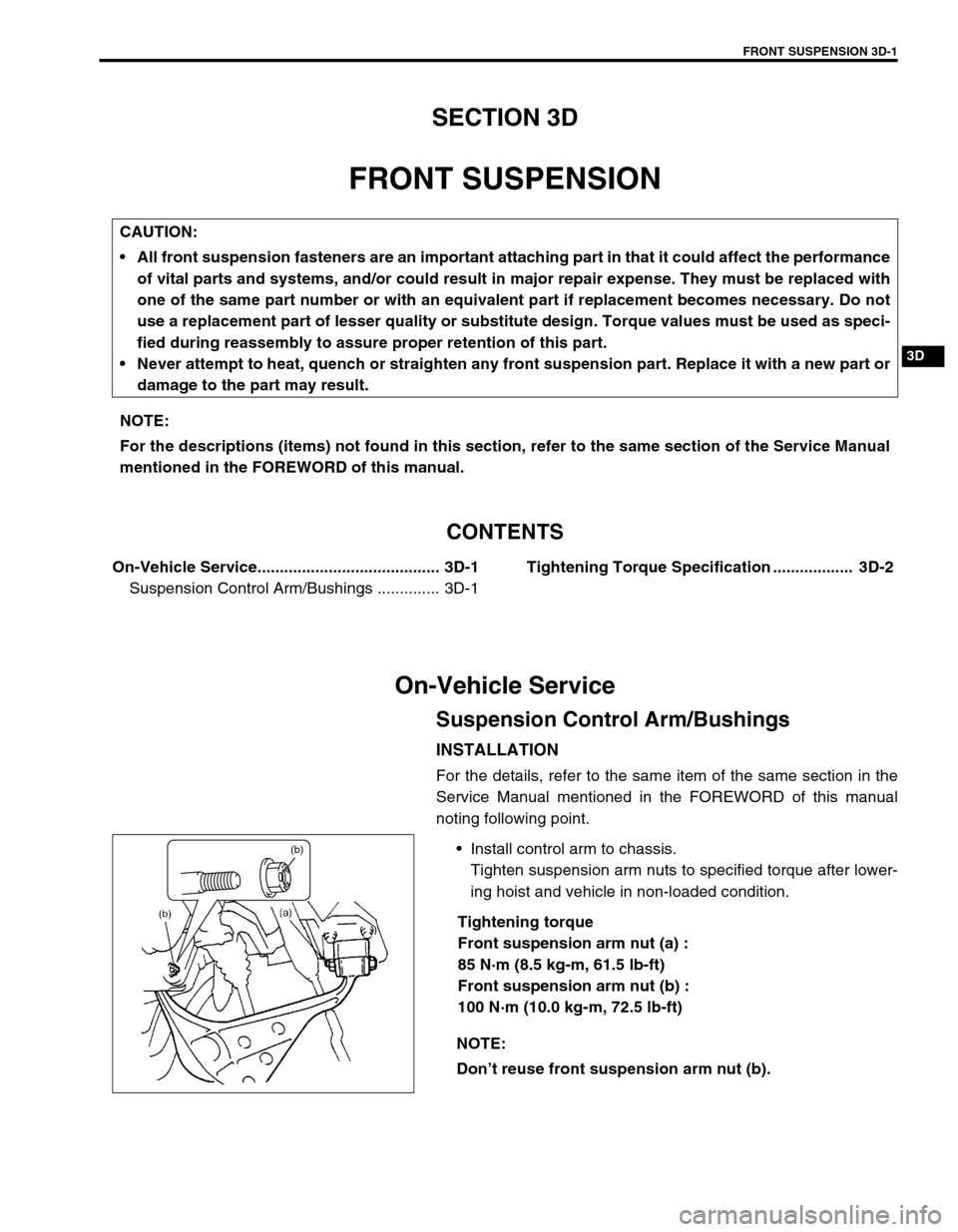

INSTALLATION

For the details, refer to the same item of the same section in the

Service Manual mentioned in the FOREWORD of this manual

noting following point.

Install control arm to chassis.

Tighten suspension arm nuts to specified torque after lower-

ing hoist and vehicle in non-loaded condition.

Tightening torque

Front suspension arm nut (a) :

85 N·m (8.5 kg-m, 61.5 lb-ft)

Front suspension arm nut (b) :

100 N·m (10.0 kg-m, 72.5 lb-ft) CAUTION:

All front suspension fasteners are an important attaching part in that it could affect the performance

of vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not

use a replacement part of lesser quality or substitute design. Torque values must be used as speci-

fied during reassembly to assure proper retention of this part.

Never attempt to heat, quench or straighten any front suspension part. Replace it with a new part or

damage to the part may result.

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Manual

mentioned in the FOREWORD of this manual.

NOTE:

Don’t reuse front suspension arm nut (b).

(b)

Page 89 of 656

3D-2 FRONT SUSPENSION

Tightening Torque Specification

Page 90 of 656

REAR SUSPENSION 3E-1

3E

SECTION 3E

REAR SUSPENSION

CONTENTS

On-Vehicle Service......................................... 3E-1

Rear Axle Shaft and Wheel Bearing ............ 3E-1

Rear Axle Shaft Inner Oil Seal ..................... 3E-5

Rear Axle Housing ....................................... 3E-5Tightening Torque Specification .................. 3E-6

Required Service Material ............................. 3E-6

Special Tool .................................................... 3E-7

On-Vehicle Service

Rear Axle Shaft and Wheel Bearing

REMOVAL

1) Remove axle shaft from axle housing according to Step1) to

6) in the same section in the service manual mentioned in

the FOREWORD of this manual noting following points. NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Man-

ual mentioned in the FOREWORD of this manual.

All suspension fasteners are an important attaching part in that it could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not

use a replacement part of lesser quality or substitute design. Torque values must be used as speci-

fied during reassembly to assure proper retention of this part.

Never attempt to heat, quench or straighten any suspension part. Replace it with a new part, or

damage to the part may result.