engine SUZUKI GRAND VITARA 2008 3.G Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2008 3.GPages: 290, PDF Size: 4.99 MB

Page 222 of 290

9-15INSPECTION AND MAINTENANCE

66J22-03E

Gear Oil ReplacementTo change the gear oil in the manual trans-

mission, transfer case, extension case or

differential(s), use the following procedure:

1) Remove the oil filler plug (1).

2) Remove the drain plug (2), drain the oil

and reinstall the drain plug.

3) Pour new gear oil of the specified type

through the filler hole until the oil level

reaches the bottom of the filler hole.

4) Reinstall the filler plug.Tightening torque

Automatic Transmission

FluidSpecified FluidUse an automatic transmission fluid

SUZUKI ATF 3317 or Mobil ATF 3309.Fluid Level CheckYou must check the fluid level with the

automatic transmission fluid at normal

operating temperature.

To check the fluid level:

1) To warm up the transmission fluid, drive

the vehicle or idle the engine until the

temperature gauge indicates normal

operating temperature.

2) Then drive for ten more minutes.

WARNING

After driving the vehicle, gear oil tem-

perature may be high enough to burn

you. Wait until the oil filler plug is

cool enough to touch with your bare

hands before inspecting or replacing

gear oil.

CAUTION

When tightening these plugs, apply

sealing compound “SUZUKI Bond

No. 1215” or equivalent to the plug

threads to prevent oil leakage and

tighten them to the specified torque

shown below.

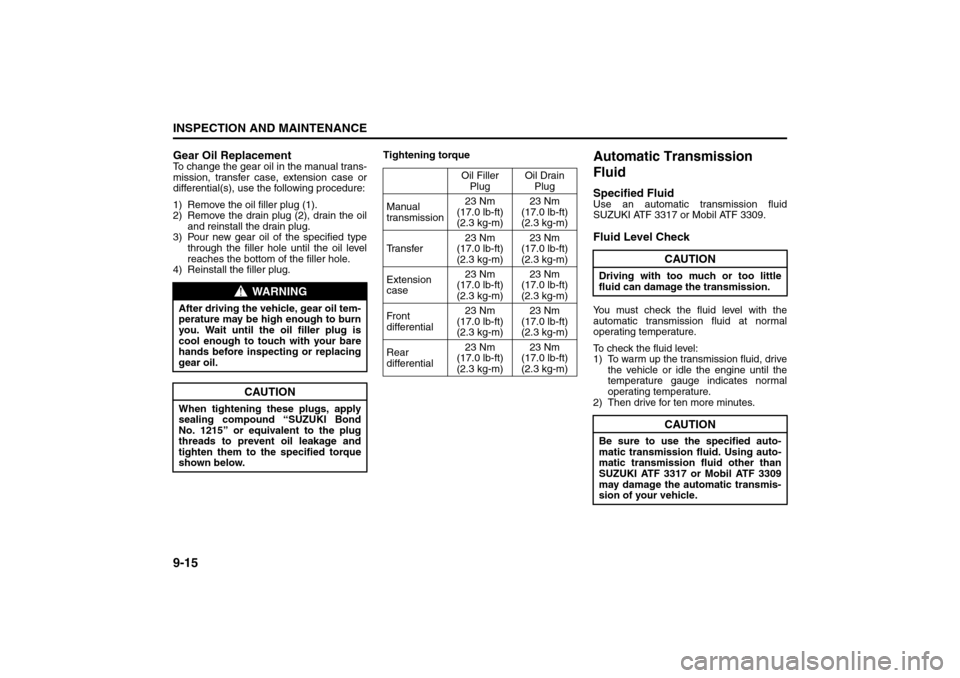

Oil Filler

PlugOil Drain

Plug

Manual

transmission23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

Tr a n s f e r23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

Extension

case23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

Front

differential23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

Rear

differential23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

CAUTION

Driving with too much or too little

fluid can damage the transmission.

CAUTION

Be sure to use the specified auto-

matic transmission fluid. Using auto-

matic transmission fluid other than

SUZUKI ATF 3317 or Mobil ATF 3309

may damage the automatic transmis-

sion of your vehicle.

Automatic Transmission Fluid: 10

Engine Coolant: 1, 2

Page 223 of 290

9-16

INSPECTION AND MAINTENANCE

66J22-03E

NOTE:

Do not check the fluid level if you have just

driven the vehicle for a long time at high

speed, if you have driven in city traffic in

hot weather, or if the vehicle has been pull-

ing a trailer. Wait until the fluid cools down

(about 30 minutes), or the fluid level indica-

tion will not be correct.

3) Park your vehicle on level ground.

4) Apply the parking brake and then start

the engine in “P” (Park). Let it idle for

two minutes and keep it running during

the fluid level check.

5) With your foot on the brake pedal, move

the gearshift lever through each gear,

pausing for about three seconds in

each range. Then move it back to the

“P” (Park) position.

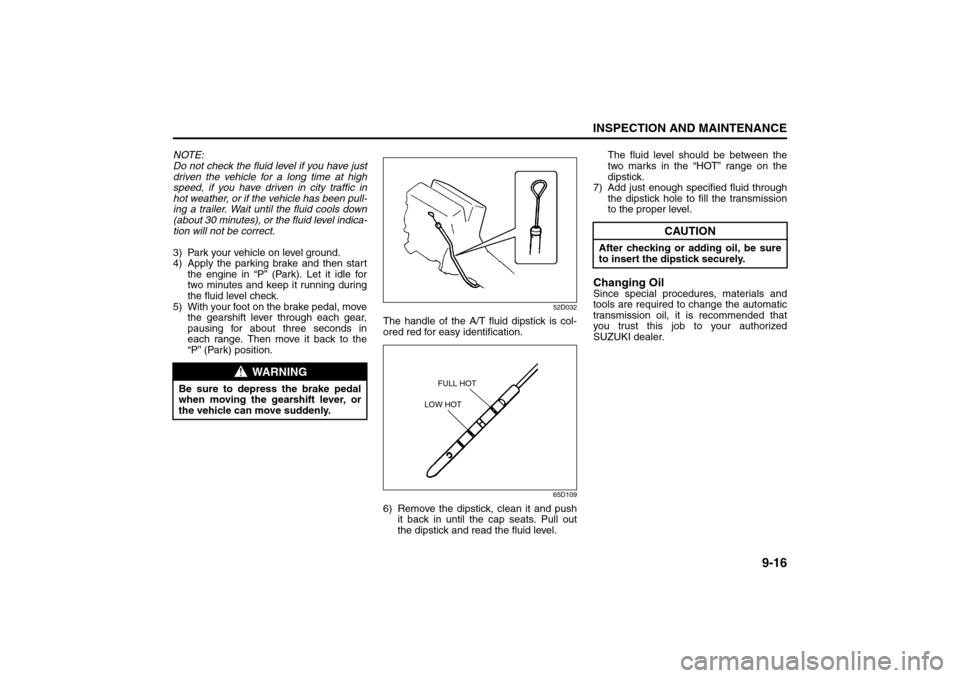

52D032

The handle of the A/T fluid dipstick is col-

ored red for easy identification.

65D109

6) Remove the dipstick, clean it and push

it back in until the cap seats. Pull out

the dipstick and read the fluid level. The fluid level should be between the

two marks in the “HOT” range on the

dipstick.

7) Add just enough specified fluid through

the dipstick hole to fill the transmission

to the proper level.

Changing OilSince special procedures, materials and

tools are required to change the automatic

transmission oil, it is recommended that

you trust this job to your authorized

SUZUKI dealer.

WARNING

Be sure to depress the brake pedal

when moving the gearshift lever, or

the vehicle can move suddenly.

FULL HOT

LOW HOT

CAUTION

After checking or adding oil, be sure

to insert the dipstick securely.

Engine Coolant: 1, 2

Page 224 of 290

9-17INSPECTION AND MAINTENANCE

66J22-03E

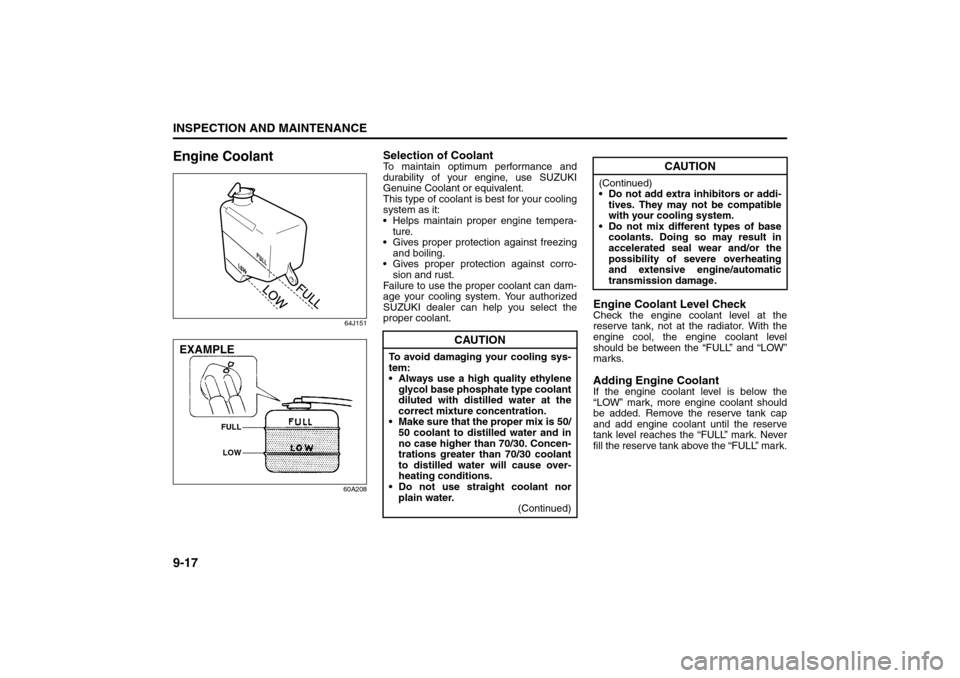

Engine Coolant

64J151

60A208

Selection of CoolantTo maintain optimum performance and

durability of your engine, use SUZUKI

Genuine Coolant or equivalent.

This type of coolant is best for your cooling

system as it:

Helps maintain proper engine tempera-

ture.

Gives proper protection against freezing

and boiling.

Gives proper protection against corro-

sion and rust.

Failure to use the proper coolant can dam-

age your cooling system. Your authorized

SUZUKI dealer can help you select the

proper coolant.

Engine Coolant Level CheckCheck the engine coolant level at the

reserve tank, not at the radiator. With the

engine cool, the engine coolant level

should be between the “FULL” and “LOW”

marks.Adding Engine CoolantIf the engine coolant level is below the

“LOW” mark, more engine coolant should

be added. Remove the reserve tank cap

and add engine coolant until the reserve

tank level reaches the “FULL” mark. Never

fill the reserve tank above the “FULL” mark.

EXAMPLE

FULL

LOW

CAUTION

To avoid damaging your cooling sys-

tem:

Always use a high quality ethylene

glycol base phosphate type coolant

diluted with distilled water at the

correct mixture concentration.

Make sure that the proper mix is 50/

50 coolant to distilled water and in

no case higher than 70/30. Concen-

trations greater than 70/30 coolant

to distilled water will cause over-

heating conditions.

Do not use straight coolant nor

plain water.

(Continued)

CAUTION

(Continued)

Do not add extra inhibitors or addi-

tives. They may not be compatible

with your cooling system.

Do not mix different types of base

coolants. Doing so may result in

accelerated seal wear and/or the

possibility of severe overheating

and extensive engine/automatic

transmission damage.

Engine Coolant: 1, 2

Windshield Washer Fluid: 3

Page 225 of 290

9-18

INSPECTION AND MAINTENANCE

66J22-03E

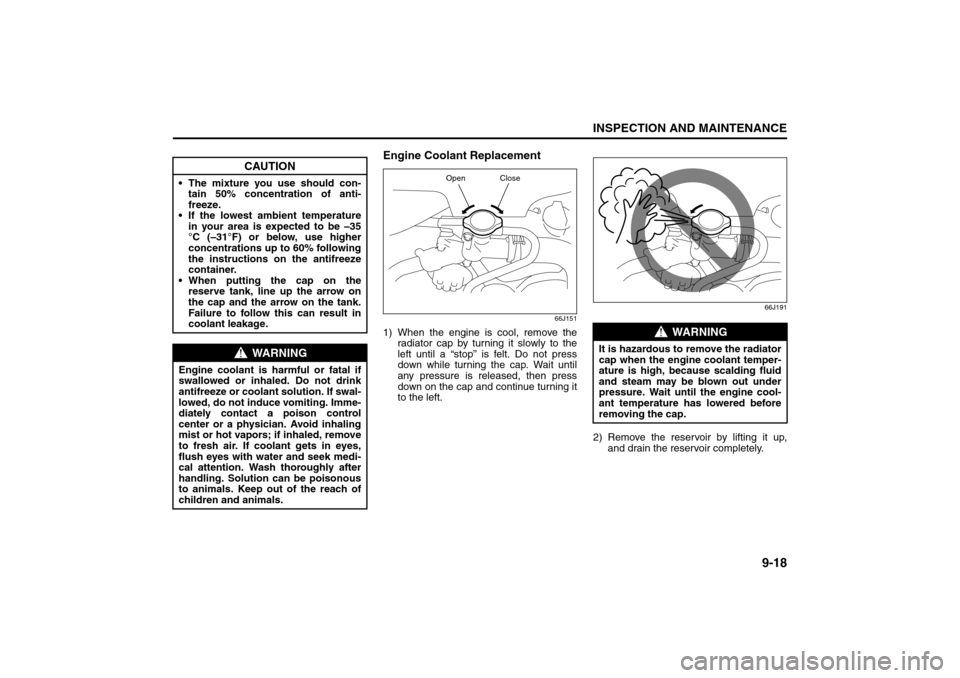

Engine Coolant Replacement

66J151

1) When the engine is cool, remove the

radiator cap by turning it slowly to the

left until a “stop” is felt. Do not press

down while turning the cap. Wait until

any pressure is released, then press

down on the cap and continue turning it

to the left.

66J191

2) Remove the reservoir by lifting it up,

and drain the reservoir completely.

CAUTION

The mixture you use should con-

tain 50% concentration of anti-

freeze.

If the lowest ambient temperature

in your area is expected to be –35

°C (–31°F) or below, use higher

concentrations up to 60% following

the instructions on the antifreeze

container.

When putting the cap on the

reserve tank, line up the arrow on

the cap and the arrow on the tank.

Failure to follow this can result in

coolant leakage.

WARNING

Engine coolant is harmful or fatal if

swallowed or inhaled. Do not drink

antifreeze or coolant solution. If swal-

lowed, do not induce vomiting. Imme-

diately contact a poison control

center or a physician. Avoid inhaling

mist or hot vapors; if inhaled, remove

to fresh air. If coolant gets in eyes,

flush eyes with water and seek medi-

cal attention. Wash thoroughly after

handling. Solution can be poisonous

to animals. Keep out of the reach of

children and animals.

OpenClose

WARNING

It is hazardous to remove the radiator

cap when the engine coolant temper-

ature is high, because scalding fluid

and steam may be blown out under

pressure. Wait until the engine cool-

ant temperature has lowered before

removing the cap.

Windshield Washer Fluid: 3

Air Cleaner: 1, 2

Page 226 of 290

9-19INSPECTION AND MAINTENANCE

66J22-03E

64J191

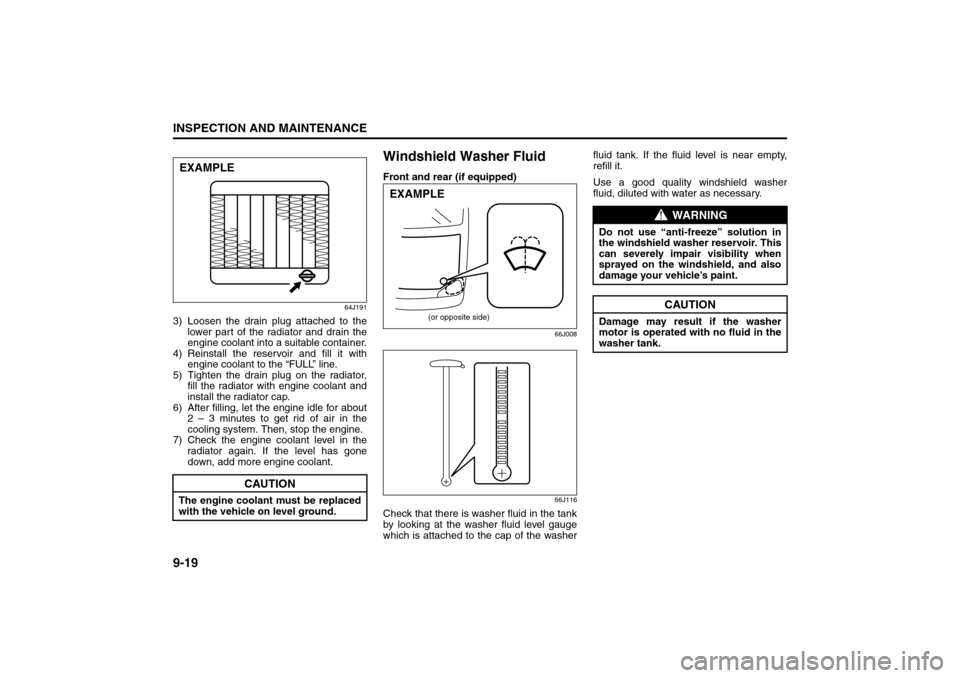

3) Loosen the drain plug attached to the

lower part of the radiator and drain the

engine coolant into a suitable container.

4) Reinstall the reservoir and fill it with

engine coolant to the “FULL” line.

5) Tighten the drain plug on the radiator,

fill the radiator with engine coolant and

install the radiator cap.

6) After filling, let the engine idle for about

2 – 3 minutes to get rid of air in the

cooling system. Then, stop the engine.

7) Check the engine coolant level in the

radiator again. If the level has gone

down, add more engine coolant.

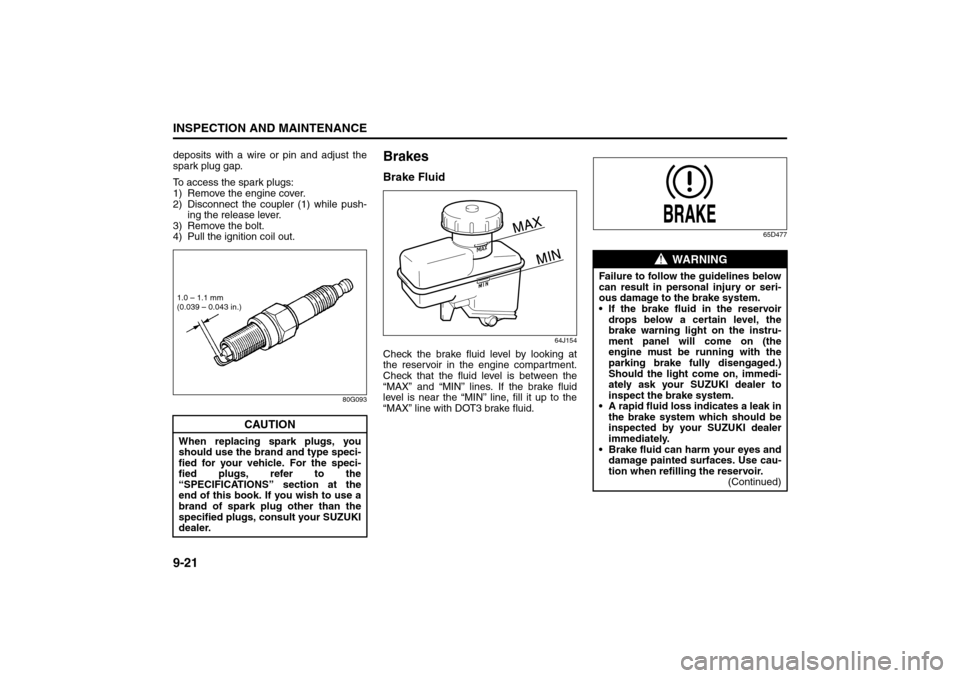

Windshield Washer FluidFront and rear (if equipped)

66J008

66J116

Check that there is washer fluid in the tank

by looking at the washer fluid level gauge

which is attached to the cap of the washerfluid tank. If the fluid level is near empty,

refill it.

Use a good quality windshield washer

fluid, diluted with water as necessary.

CAUTION

The engine coolant must be replaced

with the vehicle on level ground.EXAMPLE

(or opposite side)

EXAMPLE

WARNING

Do not use “anti-freeze” solution in

the windshield washer reservoir. This

can severely impair visibility when

sprayed on the windshield, and also

damage your vehicle’s paint.

CAUTION

Damage may result if the washer

motor is operated with no fluid in the

washer tank.

Spark Plugs: 1, 2

Brakes: 6

Page 228 of 290

9-21INSPECTION AND MAINTENANCE

66J22-03E

deposits with a wire or pin and adjust the

spark plug gap.

To access the spark plugs:

1) Remove the engine cover.

2) Disconnect the coupler (1) while push-

ing the release lever.

3) Remove the bolt.

4) Pull the ignition coil out.

80G093

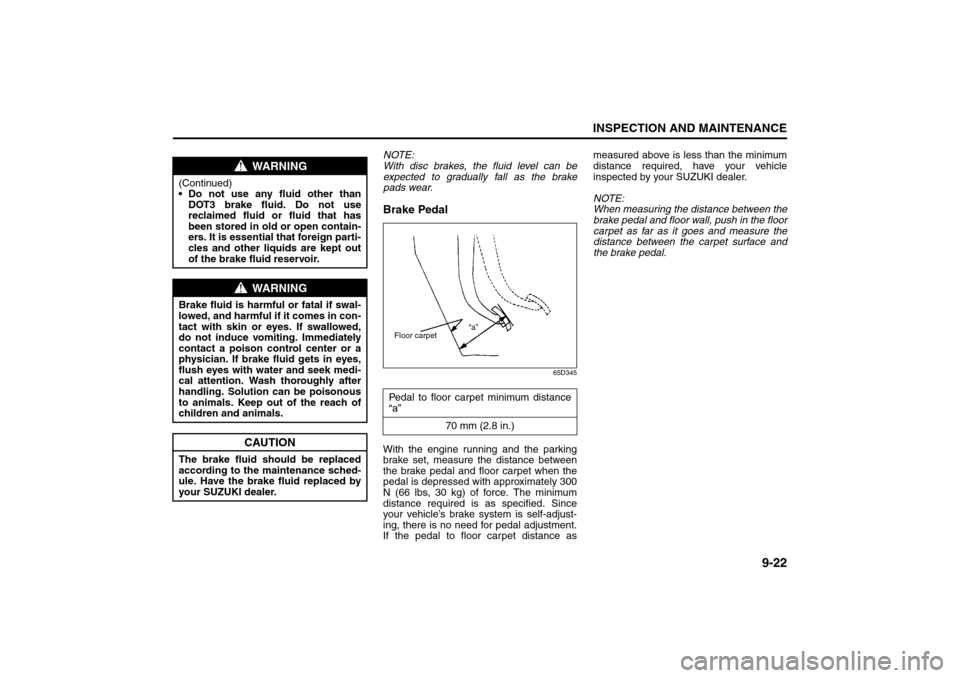

BrakesBrake Fluid

64J154

Check the brake fluid level by looking at

the reservoir in the engine compartment.

Check that the fluid level is between the

“MAX” and “MIN” lines. If the brake fluid

level is near the “MIN” line, fill it up to the

“MAX” line with DOT3 brake fluid.

65D477

CAUTION

When replacing spark plugs, you

should use the brand and type speci-

fied for your vehicle. For the speci-

fied plugs, refer to the

“SPECIFICATIONS” section at the

end of this book. If you wish to use a

brand of spark plug other than the

specified plugs, consult your SUZUKI

dealer.1.0 – 1.1 mm

(0.039 – 0.043 in.)

WARNING

Failure to follow the guidelines below

can result in personal injury or seri-

ous damage to the brake system.

If the brake fluid in the reservoir

drops below a certain level, the

brake warning light on the instru-

ment panel will come on (the

engine must be running with the

parking brake fully disengaged.)

Should the light come on, immedi-

ately ask your SUZUKI dealer to

inspect the brake system.

A rapid fluid loss indicates a leak in

the brake system which should be

inspected by your SUZUKI dealer

immediately.

Brake fluid can harm your eyes and

damage painted surfaces. Use cau-

tion when refilling the reservoir.

(Continued)

Brakes: 6

Page 229 of 290

9-22

INSPECTION AND MAINTENANCE

66J22-03E

NOTE:

With disc brakes, the fluid level can be

expected to gradually fall as the brake

pads wear.Brake Pedal

65D345

With the engine running and the parking

brake set, measure the distance between

the brake pedal and floor carpet when the

pedal is depressed with approximately 300

N (66 lbs, 30 kg) of force. The minimum

distance required is as specified. Since

your vehicle’s brake system is self-adjust-

ing, there is no need for pedal adjustment.

If the pedal to floor carpet distance asmeasured above is less than the minimum

distance required, have your vehicle

inspected by your SUZUKI dealer.

NOTE:

When measuring the distance between the

brake pedal and floor wall, push in the floor

carpet as far as it goes and measure the

distance between the carpet surface and

the brake pedal.

WARNING

(Continued)

Do not use any fluid other than

DOT3 brake fluid. Do not use

reclaimed fluid or fluid that has

been stored in old or open contain-

ers. It is essential that foreign parti-

cles and other liquids are kept out

of the brake fluid reservoir.

WARNING

Brake fluid is harmful or fatal if swal-

lowed, and harmful if it comes in con-

tact with skin or eyes. If swallowed,

do not induce vomiting. Immediately

contact a poison control center or a

physician. If brake fluid gets in eyes,

flush eyes with water and seek medi-

cal attention. Wash thoroughly after

handling. Solution can be poisonous

to animals. Keep out of the reach of

children and animals.

CAUTION

The brake fluid should be replaced

according to the maintenance sched-

ule. Have the brake fluid replaced by

your SUZUKI dealer.

Pedal to floor carpet minimum distance

“a”

70 mm (2.8 in.)

“a”

Floor carpet

Steering Wheel: 6

Clutch Pedal: 6

Page 231 of 290

9-24

INSPECTION AND MAINTENANCE

66J22-03E

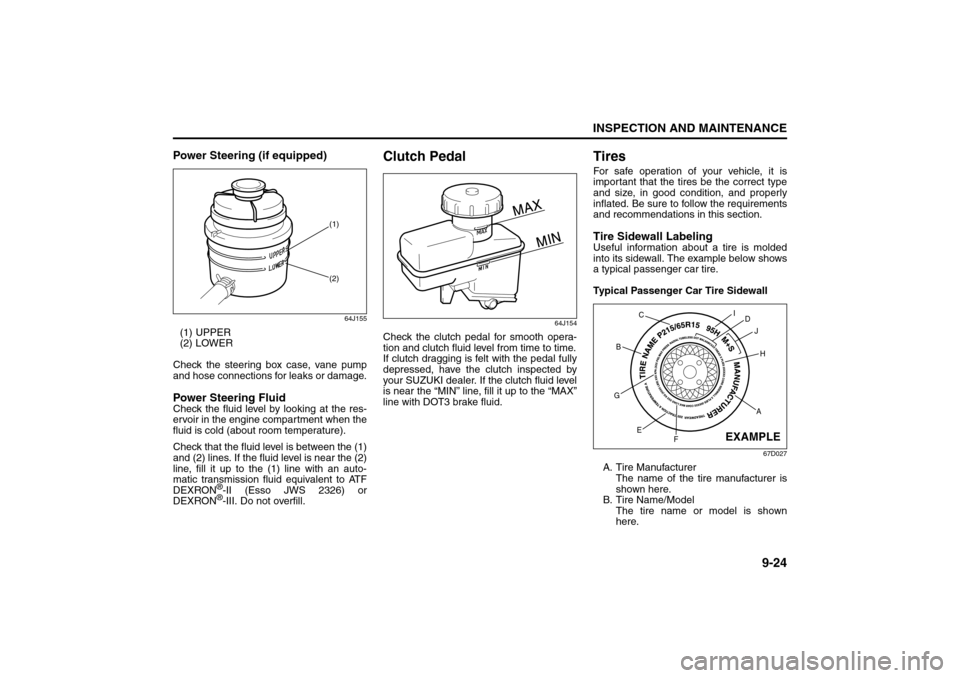

Power Steering (if equipped)

64J155

(1) UPPER

(2) LOWER

Check the steering box case, vane pump

and hose connections for leaks or damage.Power Steering FluidCheck the fluid level by looking at the res-

ervoir in the engine compartment when the

fluid is cold (about room temperature).

Check that the fluid level is between the (1)

and (2) lines. If the fluid level is near the (2)

line, fill it up to the (1) line with an auto-

matic transmission fluid equivalent to ATF

DEXRON

®-II (Esso JWS 2326) or

DEXRON®-III. Do not overfill.

Clutch Pedal

64J154

Check the clutch pedal for smooth opera-

tion and clutch fluid level from time to time.

If clutch dragging is felt with the pedal fully

depressed, have the clutch inspected by

your SUZUKI dealer. If the clutch fluid level

is near the “MIN” line, fill it up to the “MAX”

line with DOT3 brake fluid.

TiresFor safe operation of your vehicle, it is

important that the tires be the correct type

and size, in good condition, and properly

inflated. Be sure to follow the requirements

and recommendations in this section.Tire Sidewall LabelingUseful information about a tire is molded

into its sidewall. The example below shows

a typical passenger car tire.

Typical Passenger Car Tire Sidewall

67D027

A. Tire Manufacturer

The name of the tire manufacturer is

shown here.

B. Tire Name/Model

The tire name or model is shown

here.

(1)

(2)

AH B

G

E

FD

J I

C

EXAMPLE

Tires: 6

Page 239 of 290

9-32

INSPECTION AND MAINTENANCE

66J22-03E

Snow TiresYour vehicle is equipped with all-season

tires which are designed for use in summer

and most winter conditions. For improved

traction in severe winter conditions,

SUZUKI recommends mounting radial

snow tires on all four wheels. Snow tires

must be the same size as the standard

tires. Also be sure to use the tires of the

same type and brand on all four wheels of

your vehicle.

GLOSSARY OF TIRE TERMINOL-

OGYAccessory Weight – the combined weight

(in excess of those standard items which

may be replaced) of automatic transmis-

sion, power steering, power brakes, power

windows, power seats, radio, and heater,

to the extent that these items are available

as factory-installed equipment (whether

installed or not).

Cold Tire Inflation Pressure – the pressure

in a tire that has been driven less than 1

mile or has been standing for three hours

or more.

Curb Weight – the weight of a motor vehi-

cle with standard equipment including the

maximum capacity of fuel, oil, and coolant,

and, if so equipped, air conditioning and

additional weight optional engine.

Intended Outboard Sidewall – (1) the side-

wall that contains a whitewall, bears white

lettering or bears manufacturer, brand,

and/or model name molding that is higher

or deeper than the same molding on the

other sidewall of the tire, or (2) the outward

facing sidewall of an asymmetrical tire that

has a particular side that must always face

outward when mounted on a vehicle.

Maximum Inflation Pressure – the maxi-

mum cold inflation pressure a tire is

designed to support in normal service.

Maximum Loaded Vehicle Weight – the

sum of curb weight, accessory weight,vehicle capacity weight (total load capac-

ity), and production options weight.

Normal Occupant Weight – 68 kilograms

times the number of occupants specified in

the second column of Table 1 (shown

below).

Occupant distribution – distribution of

occupants in a vehicle as specified in the

third column of Table 1 (shown below).

Production Options Weight – the combined

weight of those installed regular production

options weighing over 2.3 kilograms in

excess of those standard items which they

replace, not previously considered in curb

weight or accessory weight, including

heavy duty brakes, ride levelers, roof rack,

heavy duty battery, and special trim.

Recommended Inflation Pressure – the

cold tire inflation pressure recommended

by a manufacturer.

Rim – metal support for a tire or tire and

tube assembly upon which the tire beads

are seated.

Vehicle Capacity Weight – the rated cargo

and luggage load plus 68 kilograms (150

lbs) times the vehicle’s designated seating

capacity.

Vehicle Maximum Load on the Tire – the

load on an individual tire that is determined

by distributing to each axle its share of the

maximum loaded vehicle weight and divid-

ing by two.

WARNING

(Continued)

Replace the spare tire with a new

one as soon as the tread wear indi-

cator appears.

When replacing the spare tire, use

a replacement tire with the exact

same size and construction.

Battery: 9

Fuses: 7

Page 243 of 290

9-36

INSPECTION AND MAINTENANCE

66J22-03E

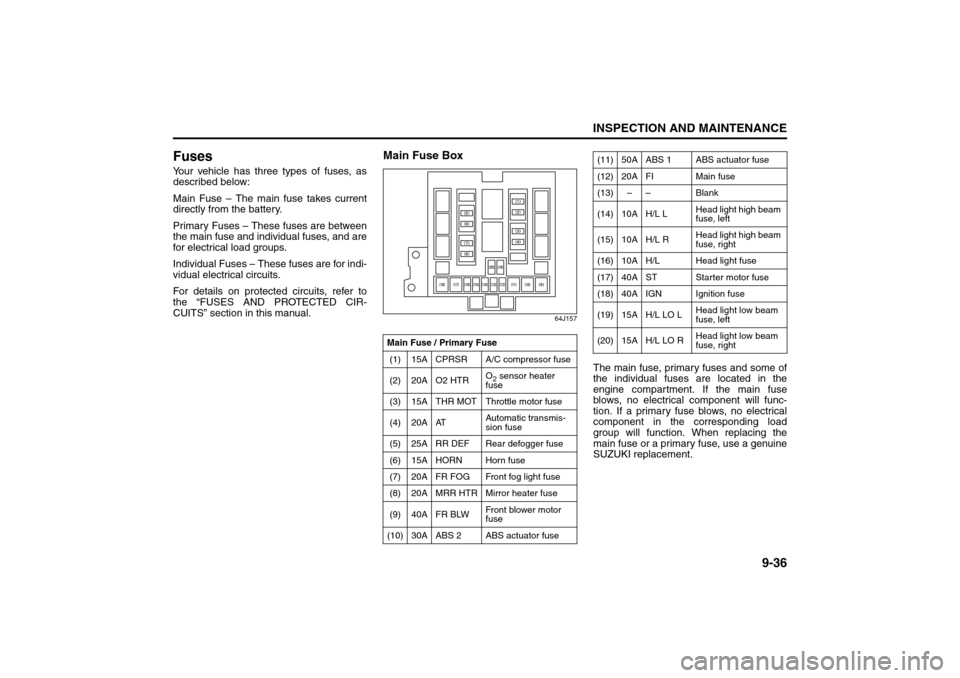

FusesYour vehicle has three types of fuses, as

described below:

Main Fuse – The main fuse takes current

directly from the battery.

Primary Fuses – These fuses are between

the main fuse and individual fuses, and are

for electrical load groups.

Individual Fuses – These fuses are for indi-

vidual electrical circuits.

For details on protected circuits, refer to

the “FUSES AND PROTECTED CIR-

CUITS” section in this manual.

Main Fuse Box

64J157

The main fuse, primary fuses and some of

the individual fuses are located in the

engine compartment. If the main fuse

blows, no electrical component will func-

tion. If a primary fuse blows, no electrical

component in the corresponding load

group will function. When replacing the

main fuse or a primary fuse, use a genuine

SUZUKI replacement.

Main Fuse / Primary Fuse

(1) 15A CPRSR A/C compressor fuse

(2) 20A O2 HTRO

2 sensor heater

fuse

(3) 15A THR MOT Throttle motor fuse

(4) 20A ATAutomatic transmis-

sion fuse

(5) 25A RR DEF Rear defogger fuse

(6) 15A HORN Horn fuse

(7) 20A FR FOG Front fog light fuse

(8) 20A MRR HTR Mirror heater fuse

(9) 40A FR BLWFront blower motor

fuse

(10) 30A ABS 2 ABS actuator fuse

(11) 50A ABS 1 ABS actuator fuse

(12) 20A FI Main fuse

(13) – – Blank

(14) 10A H/L LHead light high beam

fuse, left

(15) 10A H/L RHead light high beam

fuse, right

(16) 10A H/L Head light fuse

(17) 40A ST Starter motor fuse

(18) 40A IGN Ignition fuse

(19) 15A H/L LO LHead light low beam

fuse, left

(20) 15A H/L LO RHead light low beam

fuse, right

Bulb Replacement: 7