Normal Operation SUZUKI GRAND VITARA 2012 User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2012, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2012Pages: 337, PDF Size: 6.21 MB

Page 239 of 337

6-2

VEHICLE LOADING AND TOWING

79K21-03E

Trailer TowingYou can use your SUZUKI to tow a trailer,

but you should always observe the require-

ments and recommendations in this sec-

tion. If you intend to tow a trailer, it is

essential to select a trailer and trailer tow-

ing equipment which are compatible. A

reputable trailer dealer can help you.

For Automatic transmission vehicles, shift

into “3” (Low 2) or “L” (Low 1) (if necessary)

and frequently monitor the coolant temper-

ature gauge when towing up a steep hill. If

the gauge indicates overheating, park the

vehicle in a safe place and let the enginecool down. Refer to “If the Engine Over-

heats” section for details on how to deal

with overheating.

HitchesUse only a trailer hitch bracket that is

designed to bolt to the frame of your vehi-

cle, and a hitch that is designed to bolt to

this bracket. We recommend that you use

a genuine SUZUKI trailer hitch bracket and

trailer hitch (available as options), or equiv-

alent.Safety ChainsAlways attach safety chains between your

vehicle and trailer. Cross safety chains

under the tongue of the trailer so that the

tongue will not drop to the road if the trailer

becomes separated from the hitch. Follow

the manufacturer’s recommendation for

attaching safety chains. Always leave just

enough slack to permit full turning. Never

allow safety chains to drag on the road.

Trailer LightsMake sure your trailer is equipped with

lights which meet federal, state and local

requirements. Always check for the proper

operation of all trailer lights before you

start to tow.Brakes CAUTION

Trailer towing puts additional stress

on the engine, drive train and brakes

of your vehicle. Never tow a trailer

during the first 960 km (600 miles) of

vehicle operation.

CAUTION

Because towing a trailer puts addi-

tional stress on your vehicle, more

frequent maintenance will be

required than under normal driving

conditions. Follow the schedule for

Maintenance Recommended Under

Severe Driving Conditions or perform

more frequent maintenance as nec-

essary.

CAUTION

Towing in “D” range up a steep hill

can cause coolant overheating which

may result in engine/automatic trans-

mission damage.

WARNING

Never use a bumper hitch or a hitch

which attaches to the axle of your

vehicle.

WARNING

Never attach safety chains to the

bumper of your vehicle. Secure con-

nections so that they can’t come

loose.

WARNING

Never splice trailer lights directly into

your vehicle’s electrical system, or

electrical system damage may occur.

WARNING

If trailer brakes are used, you should

follow all instructions provided by the

manufacturer. Never tap into the

brake system of your vehicle.

Trailer Towing: 5, 11, 13

Page 274 of 337

7-25INSPECTION AND MAINTENANCE

79K21-03E

TiresFor safe operation of your vehicle, it is

important that the tires be the correct

type and size, in good condition, and

properly inflated. Be sure to follow the

requirements and recommendations in

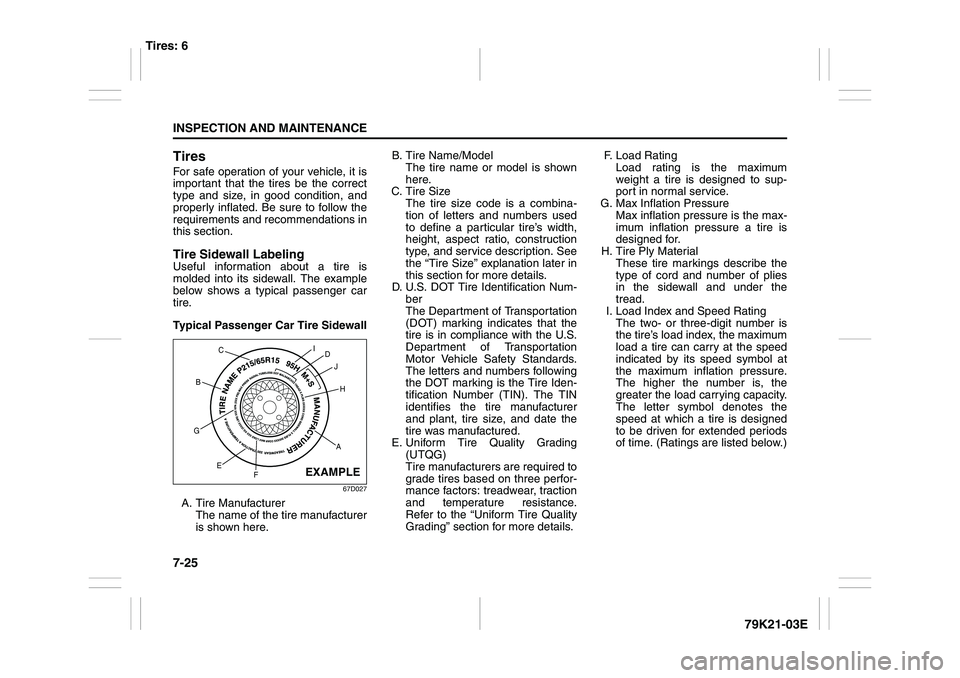

this section.Tire Sidewall LabelingUseful information about a tire is

molded into its sidewall. The example

below shows a typical passenger car

tire.

Typical Passenger Car Tire Sidewall

67D027

A. Tire Manufacturer

The name of the tire manufacturer

is shown here.B. Tire Name/Model

The tire name or model is shown

here.

C. Tire Size

The tire size code is a combina-

tion of letters and numbers used

to define a particular tire’s width,

height, aspect ratio, construction

type, and service description. See

the “Tire Size” explanation later in

this section for more details.

D. U.S. DOT Tire Identification Num-

ber

The Department of Transportation

(DOT) marking indicates that the

tire is in compliance with the U.S.

Department of Transportation

Motor Vehicle Safety Standards.

The letters and numbers following

the DOT marking is the Tire Iden-

tification Number (TIN). The TIN

identifies the tire manufacturer

and plant, tire size, and date the

tire was manufactured.

E. Uniform Tire Quality Grading

(UTQG)

Tire manufacturers are required to

grade tires based on three perfor-

mance factors: treadwear, traction

and temperature resistance.

Refer to the “Uniform Tire Quality

Grading” section for more details.F. Load Rating

Load rating is the maximum

weight a tire is designed to sup-

port in normal service.

G. Max Inflation Pressure

Max inflation pressure is the max-

imum inflation pressure a tire is

designed for.

H. Tire Ply Material

These tire markings describe the

type of cord and number of plies

in the sidewall and under the

tread.

I. Load Index and Speed Rating

The two- or three-digit number is

the tire’s load index, the maximum

load a tire can carry at the speed

indicated by its speed symbol at

the maximum inflation pressure.

The higher the number is, the

greater the load carrying capacity.

The letter symbol denotes the

speed at which a tire is designed

to be driven for extended periods

of time. (Ratings are listed below.)

AH B

G

E

FD

J I

C

EXAMPLE

Tires: 6

Page 320 of 337

10-3GENERAL INFORMATION

79K21-03E

On-Board Vehicle Computers

and Event Data RecordersYour vehicle is equipped with on-board

computer systems which monitor and

control several aspects of vehicle per-

formance, including the following:

Emission-related components and

engine parameters such as engine

speed and throttle position are moni-

tored to provide emissions control

and to provide optimum fuel econ-

omy. Your vehicle also has an on-

board diagnostic system which mon-

itors and records information about

emission-related malfunctions.

Signals from various sensors are

monitored to provide air bag deploy-

ment.

If your vehicle is equipped with

antilock brakes, conditions such as

vehicle speed and brake perfor-

mance are monitored, so that the

ABS system can provide effective

antilock braking. If your vehicle has

an Electronic Stability Program

(ESP

®) system, conditions such as

yaw rate, lateral acceleration, and

brake fluid pressure are monitored,

so that the ESP

® system can help

the driver control the vehicle in diffi-

cult driving situations.

Some information may be stored by

the on-board computers during normaloperation of the vehicle. This stored

information can assist technicians in

repairing the vehicle when malfunc-

tions occur. Other information is stored

only in the event of crash, by computer

systems that are commonly called

Event Data Recorders (EDRs).

In a crash event, EDRs such as the

Airbag Sensing and Diagnostic Mod-

ule (SDM) in your vehicle may record

information about the condition of the

vehicle and how it was operated, such

as data related to airbag readiness,

airbag performance, safety belt usage,

and the severity of the collision. These

data can help provide a better under-

standing of the circumstances in which

crashes and injuries occur and lead to

the designing of safer vehicles. The

SDM in your vehicle does not collect

or store personal information.

To read the stored information, special

equipment is needed and access to

the vehicle or storage device is

required. SUZUKI will not access infor-

mation about a crash event or share it

with others other than with the consent

of the vehicle owner or lessee, in

response to an official request from

the police or similar government office,

as part of SUZUKI’s defense of litiga-

tion through the discovery process, or

as required by law.In addition, once SUZUKI collects or

receives data, SUZUKI may use the

data for research conducted by

SUZUKI, make the data available for

outside research if need is shown and

confidentiality is assured, or make

summary data which does not identify

specific vehicles available for outside

research.

Others, such as law enforcement per-

sonnel, may have access to the spe-

cial equipment that can read the

information if they have access to the

vehicle or storage device.

Reporting Safety Defects: NO